Nissan Rogue (T33) 2021-Present Service Manual: Transaxle Assembly

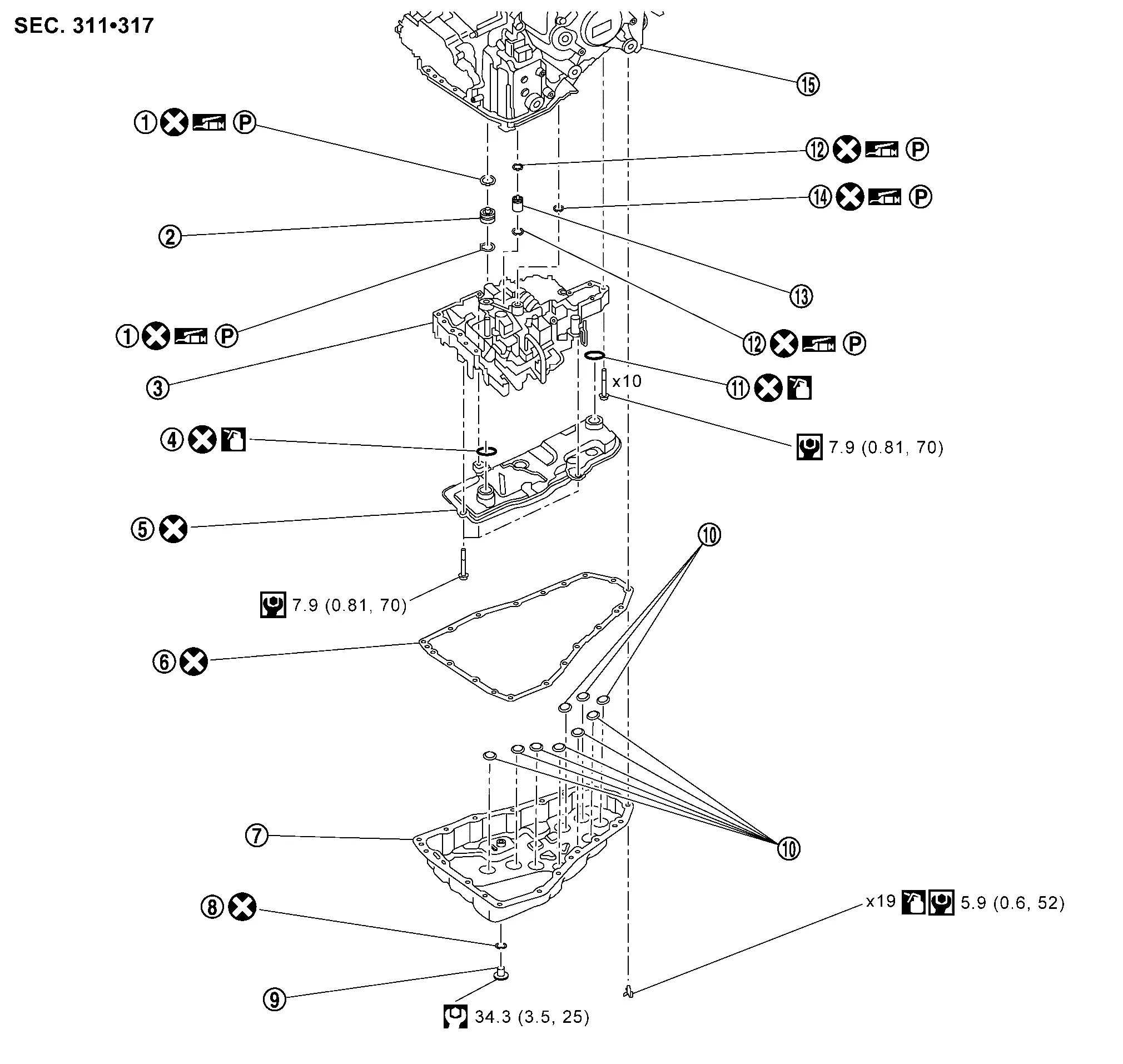

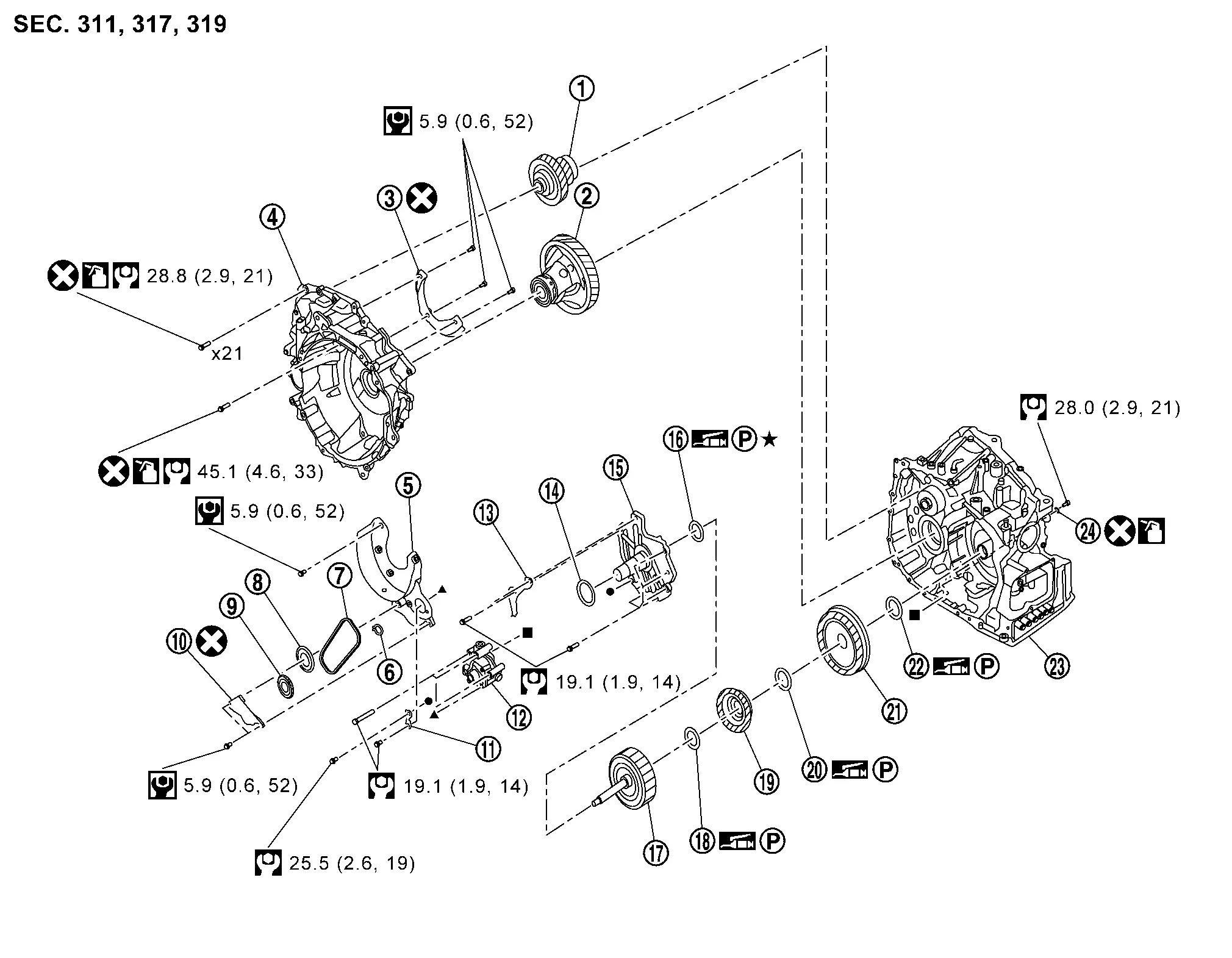

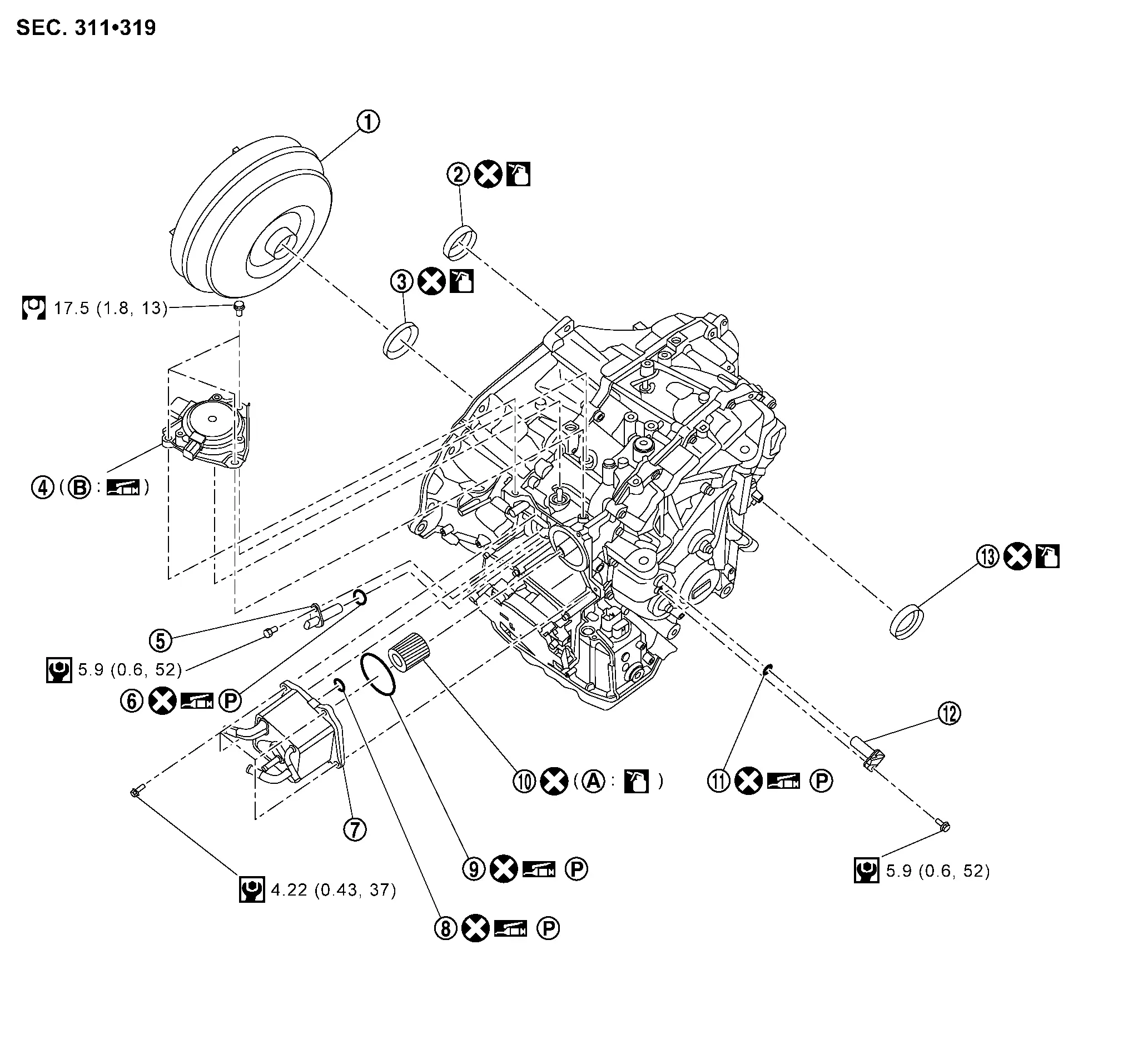

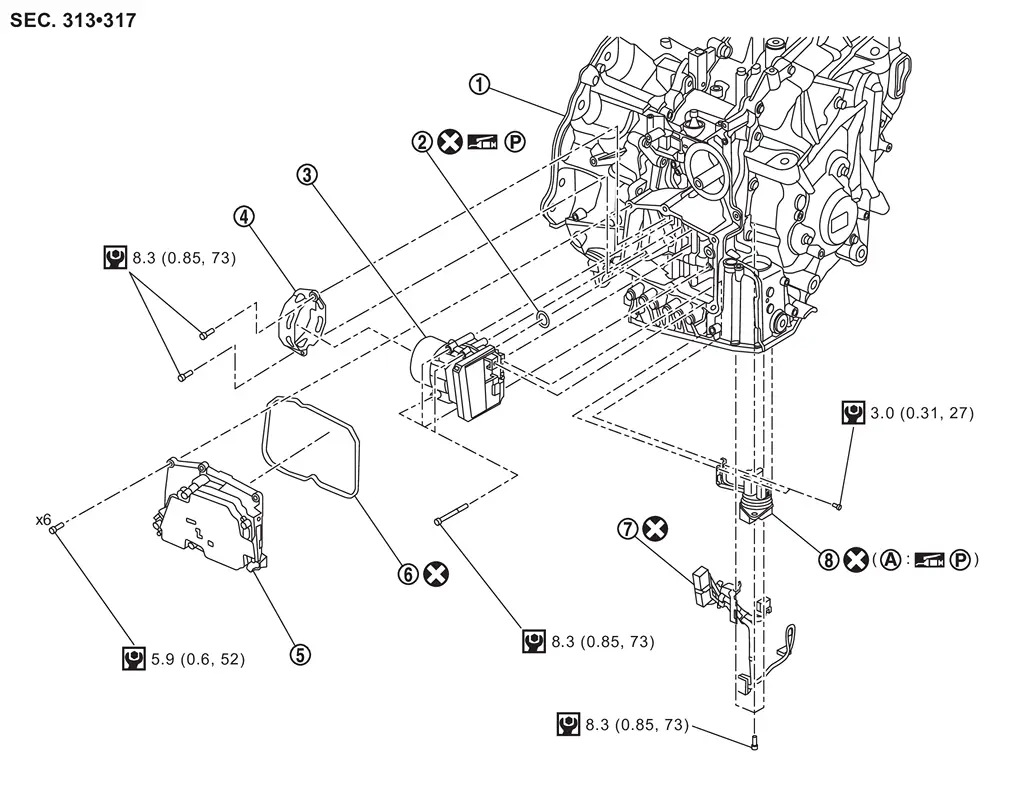

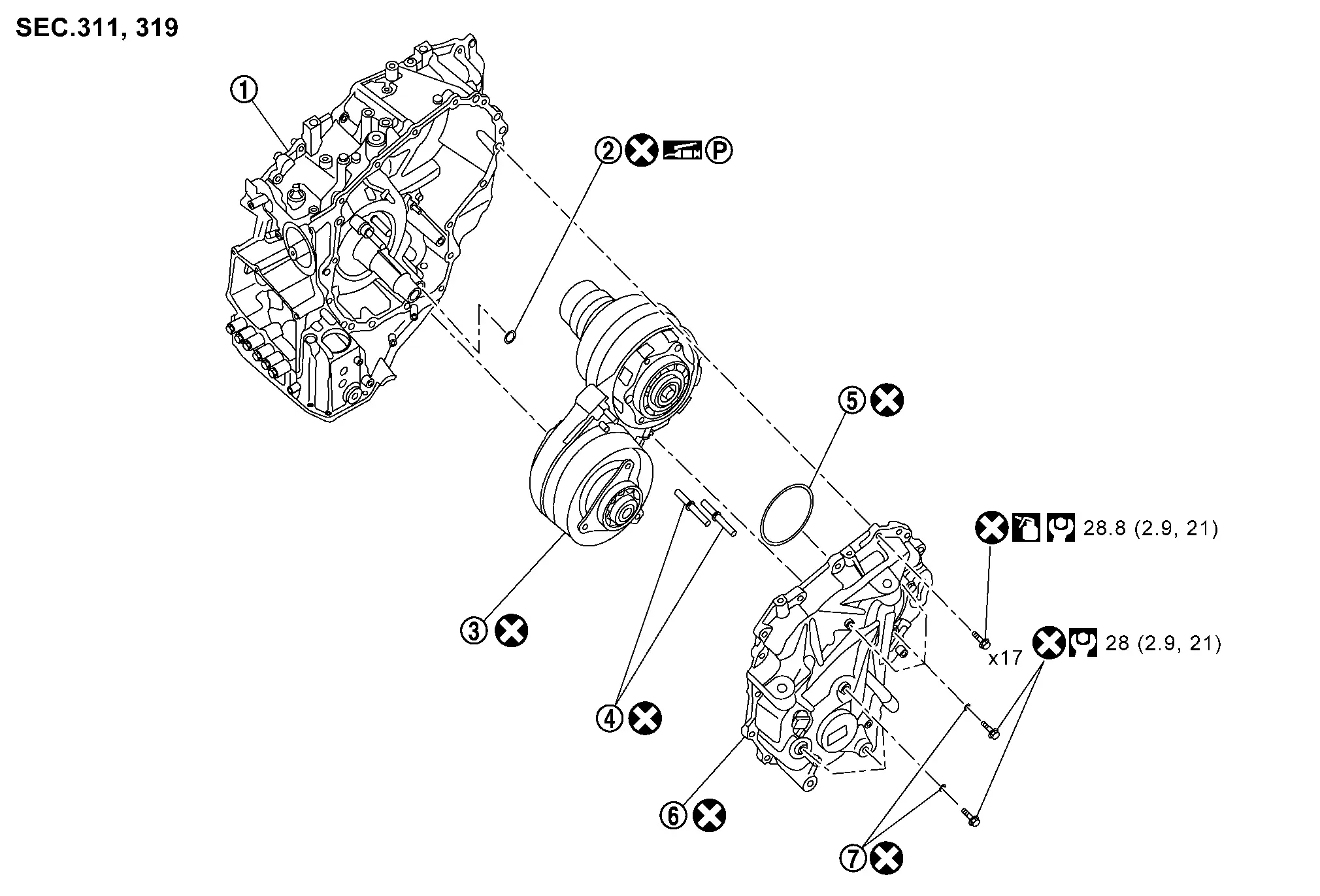

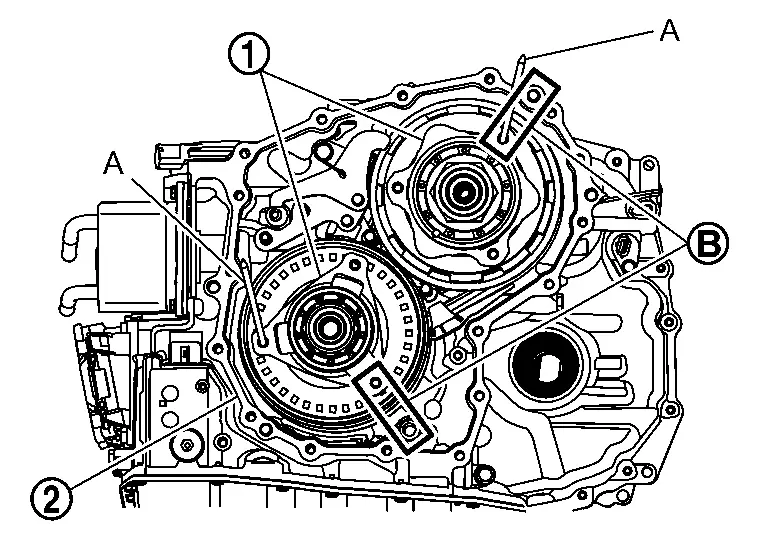

Exploded View

|

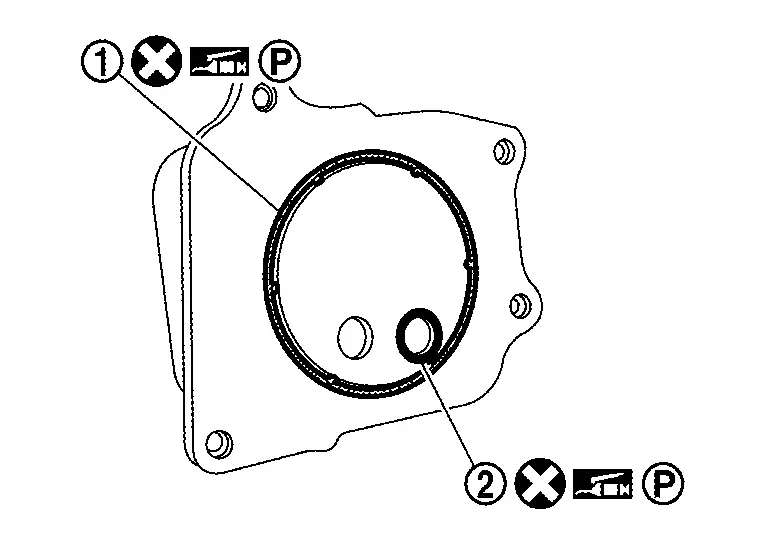

O-ring |  |

Tube A |  |

Control valve |

|

O-ring |  |

Oil strainer |  |

Oil pan gasket |

|

Oil pan |  |

Drain plug gasket |  |

Drain plug |

|

Magnet |  |

O-ring |  |

O-ring |

|

Tube B |  |

Lip seal |  |

Transaxle assembly |

|

: Always replace after every disassembly | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Apply CVT fluid | ||||

|

: Apply petroleum jelly |

|

Reduction gear assembly |  |

Differential assembly |  |

Baffle plate C |

|

Converter housing |  |

Baffle plate B |  |

Snap ring |

|

Chain |  |

Drive sprocket |  |

Driven sprocket |

|

Baffle plate A |  |

Oil pump bracket |  |

Oil pump |

|

Baffle plate D |  |

Thrust washer |  |

Dummy cover |

|

Thrust bearing |  |

Forward clutch |  |

Thrust bearing |

|

Sun gear |  |

Thrust bearing |  |

Planetary carrier assembly |

|

Thrust bearing |  |

Transaxle assembly |  |

O-ring |

|

: N·m (kg-m, in-lb) | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Apply CVT fluid | ||||

|

: Apply petroleum jelly | ||||

|

: Always replace after every disassembly. | ||||

|

: Indicates that the part is connected at points with same symbol | ||||

|

: Select with proper thickness | ||||

|

Torque converter |  |

Differential side oil seal (2WD only) |  |

Converter housing oil seal |

|

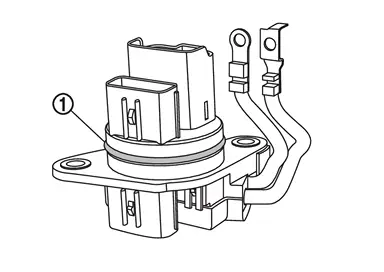

Shift actuator |  |

Input speed sensor |  |

O-ring |

|

CVT oil warmer |  |

O-ring* |  |

O-ring |

|

Oil filter |  |

O-ring |  |

Primary speed sensor |

|

Differential side oil seal | ||||

|

Grommet |  |

Spline part | ||

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Apply CVT fluid | ||||

|

: Lithium-based grease including molybdenum disulphide | ||||

|

: Apply petroleum jelly | *: There are one O-ring and two O-rings depending on the specifications. | |||

|

Transaxle assembly |  |

Electric oil pump gasket |  |

Electric oil pump |

|

Electric oil pump bracket |  |

TCM |  |

Gasket |

|

Terminal assembly B |  |

Terminal assembly A | ||

|

O-ring | ||||

|

: Always replace after every disassembly. | ||||

|

: Apply petroleum jelly | ||||

|

: N·m (kg-m, in-lb) |

|

Transaxle case |  |

O-ring |  |

Belt and pulley assembly |

|

Lubrication cap |  |

Secondary pulley shim |  |

Side cover |

|

O-ring | ||||

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Apply petroleum jelly | ||||

|

: Apply CVT fluid | ||||

Disassembly & Assembly

DISASSEMBLY

CAUTION:

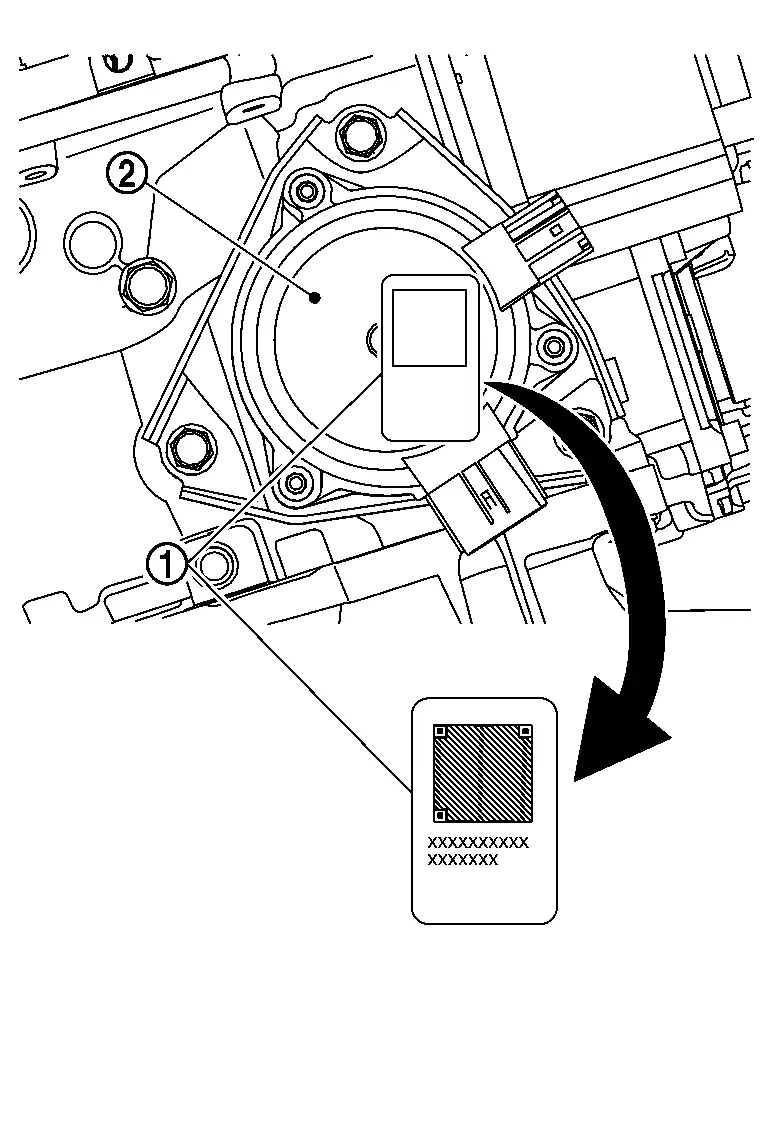

If old serial number sticker is affixed to shift actuator, remove the serial number sticker and affix new serial number sticker included with new control valve.

NOTE:

NOTE:

New control valve assemblies may come with a CD-ROM, which is not used.

Remove the CVT from the vehicle. Refer to Removal and Installation.

Remove drain plug from oil pan and then drain the CVT fluid.

Remove drain plug gasket.

Mount the CVT on a workbench with the oil pan side down.

NOTE:

NOTE:

Use plastic or wood blocks to stabilize the transaxle assembly on the work bench if needed.

CAUTION:

Be sure not to deform the oil pan.

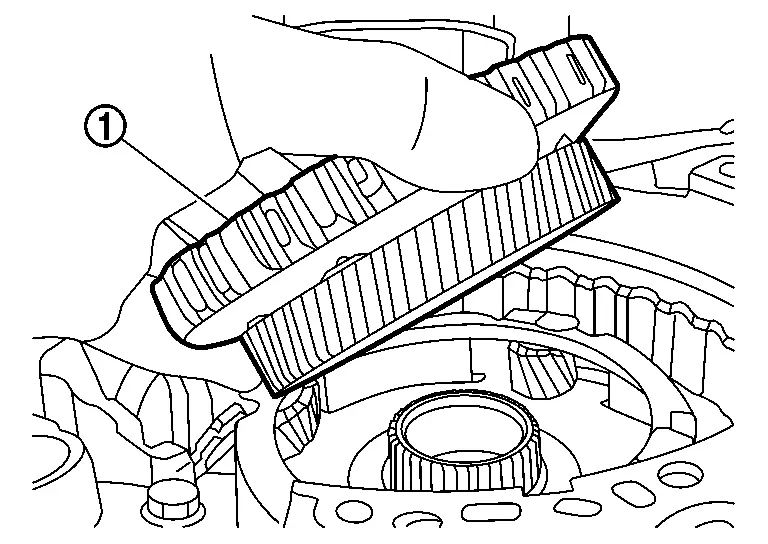

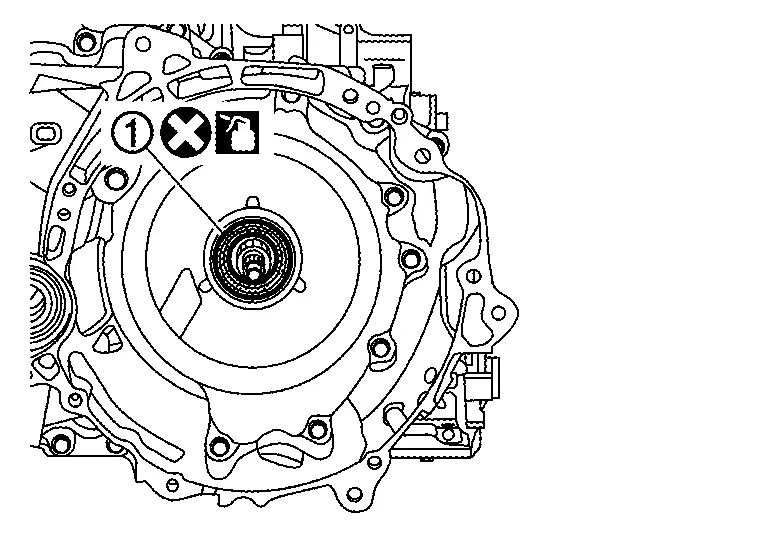

Remove torque converter from transaxle assembly.

NOTE:

NOTE:

Wipe out remaining CVT fluid in torque converter.

CAUTION:

-

While removing torque converter, never damage the bush in the sleeve of torque converter.

-

Completely drain CVT fluid from torque converter by tilting right and left several times until no fluid coming out.

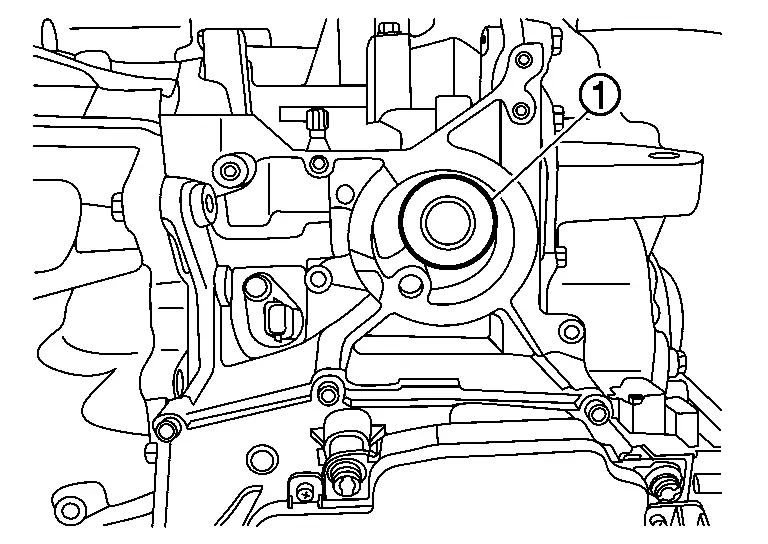

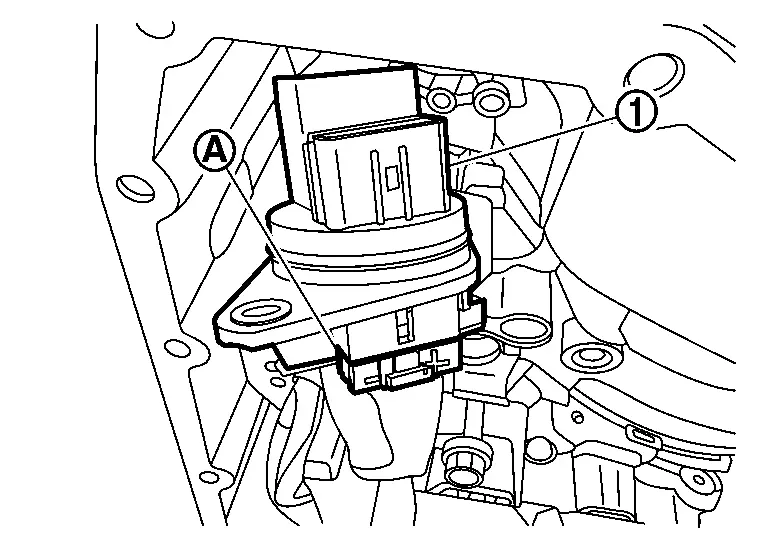

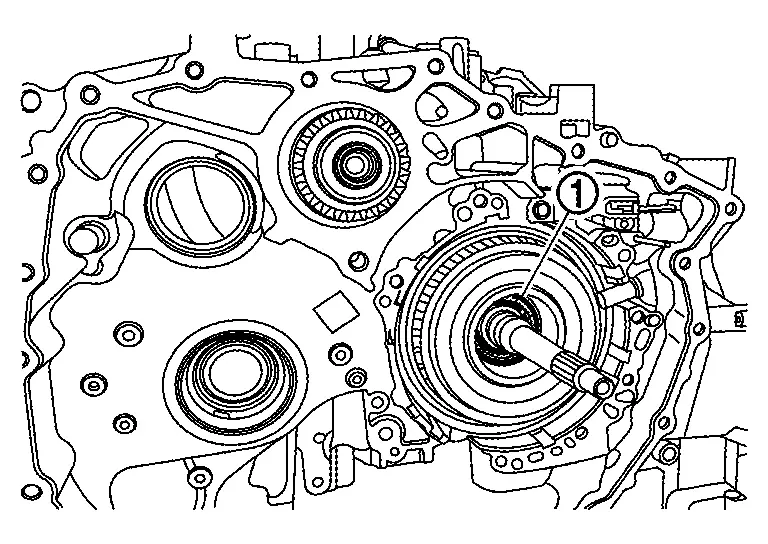

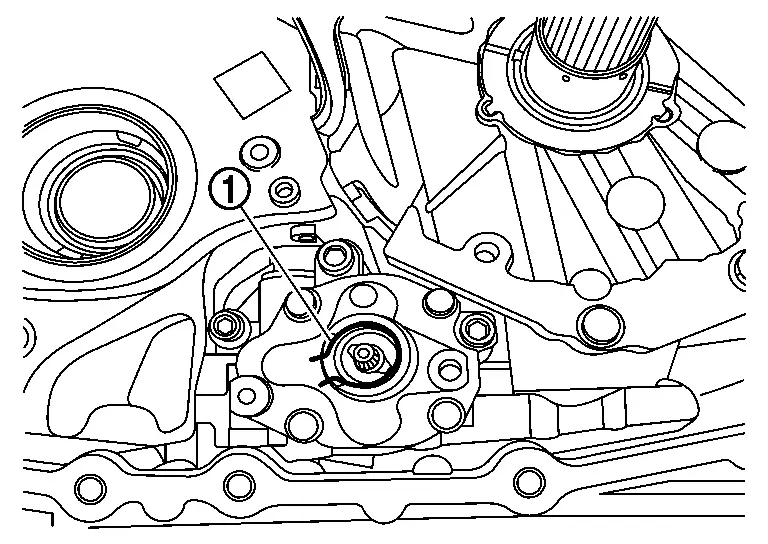

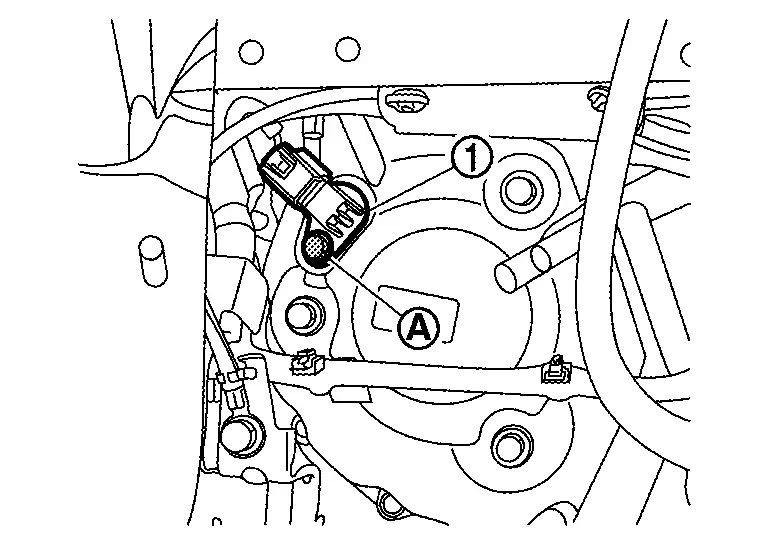

Remove primary pulley speed sensor mounting bolt  and then remove primary pulley speed sensor

and then remove primary pulley speed sensor  .

.

Remove O-Ring from primary speed sensor.

Remove input speed sensor mounting bolt  and then remove input speed sensor

and then remove input speed sensor  .

.

Remove O-ring from input speed sensor.

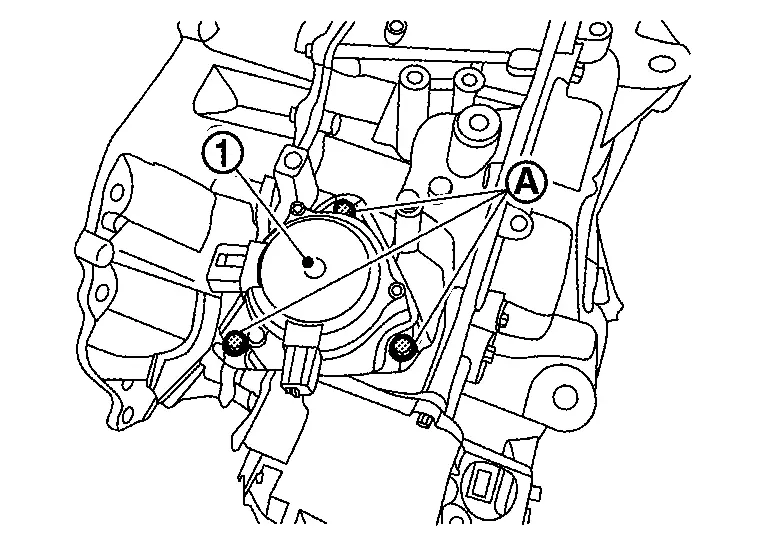

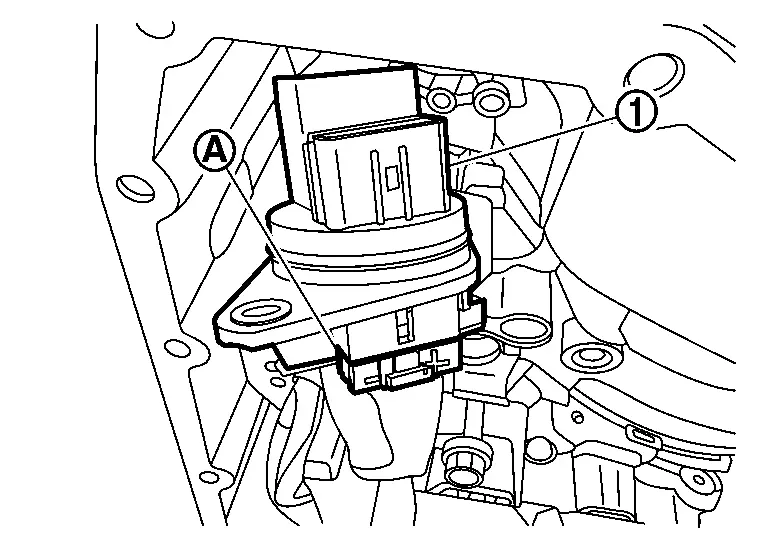

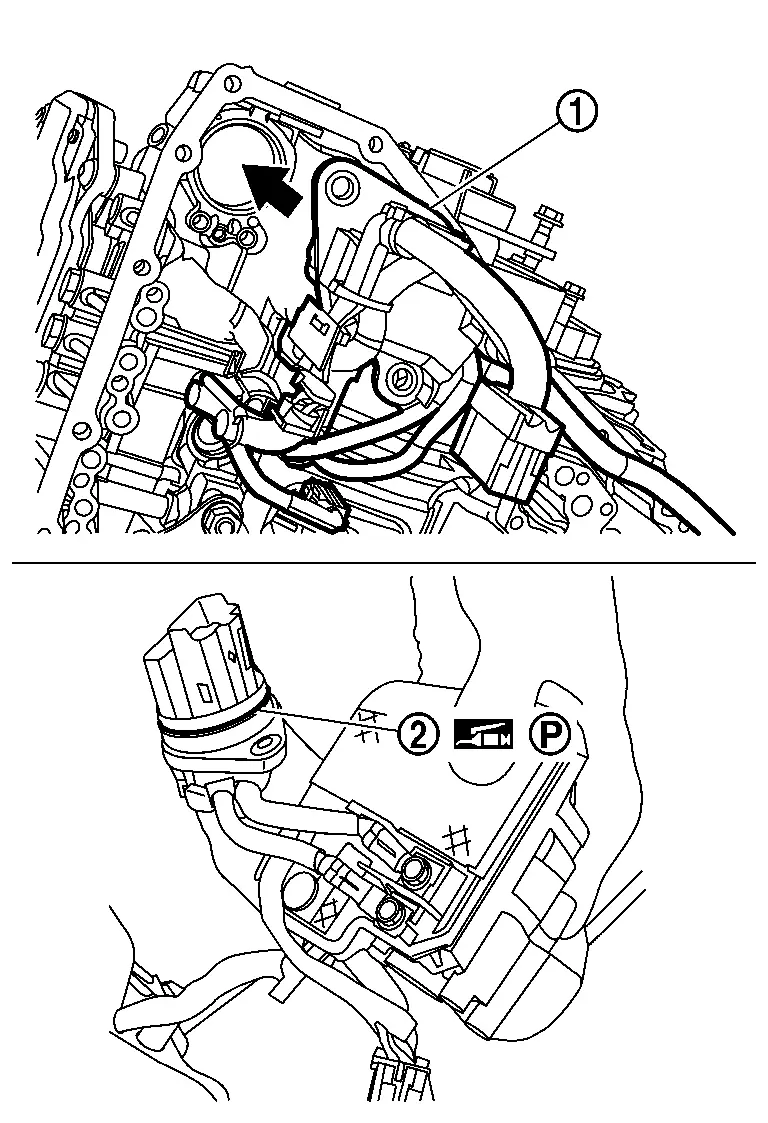

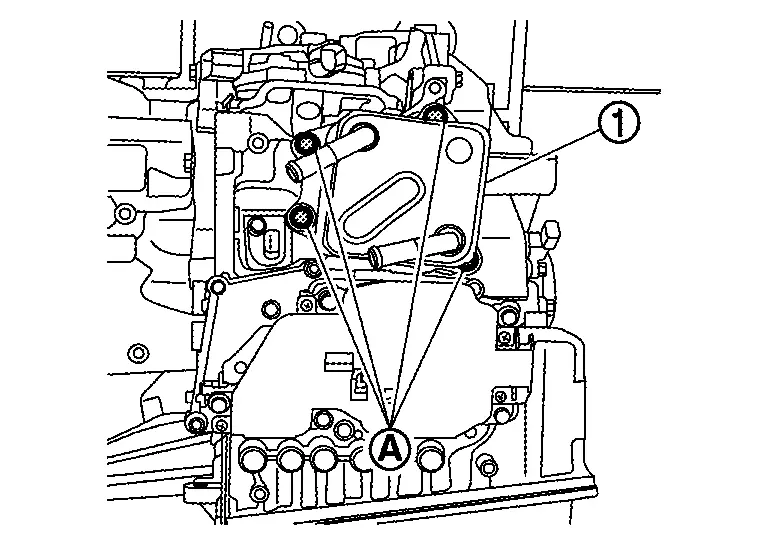

Remove shift actuator mounting bolt  and then remove shift actuator

and then remove shift actuator  .

.

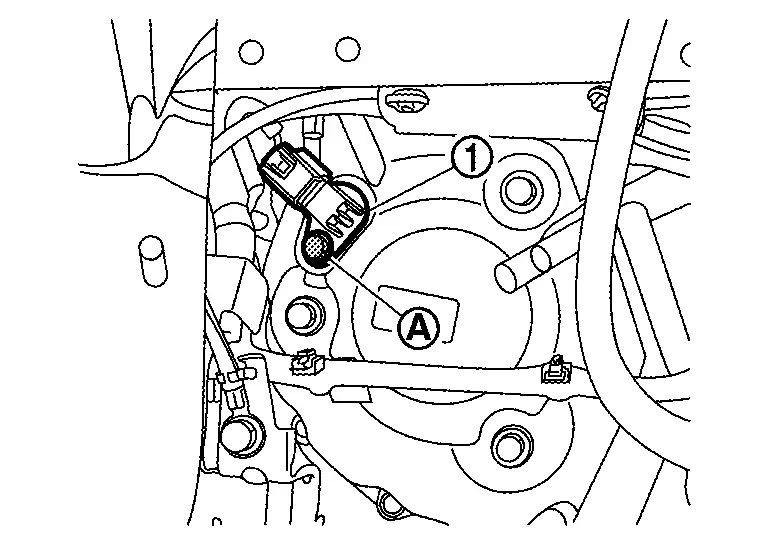

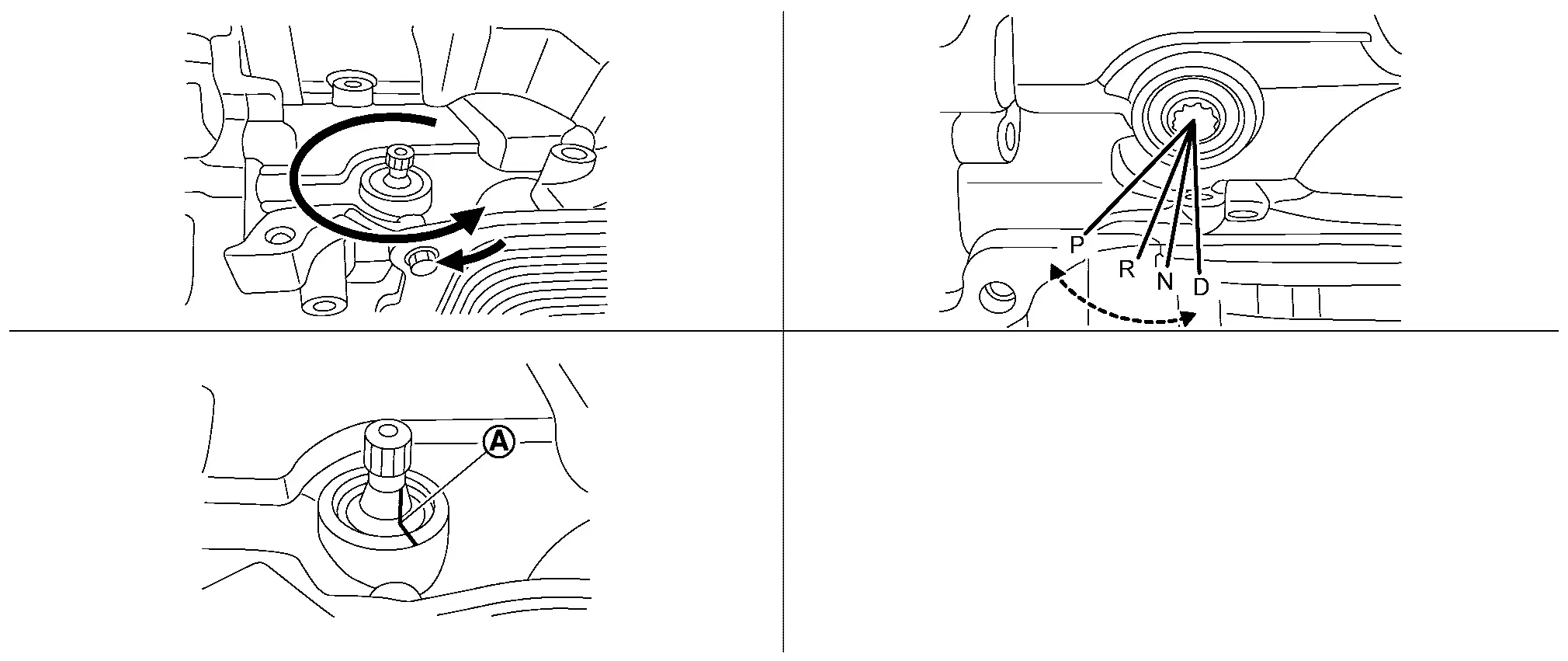

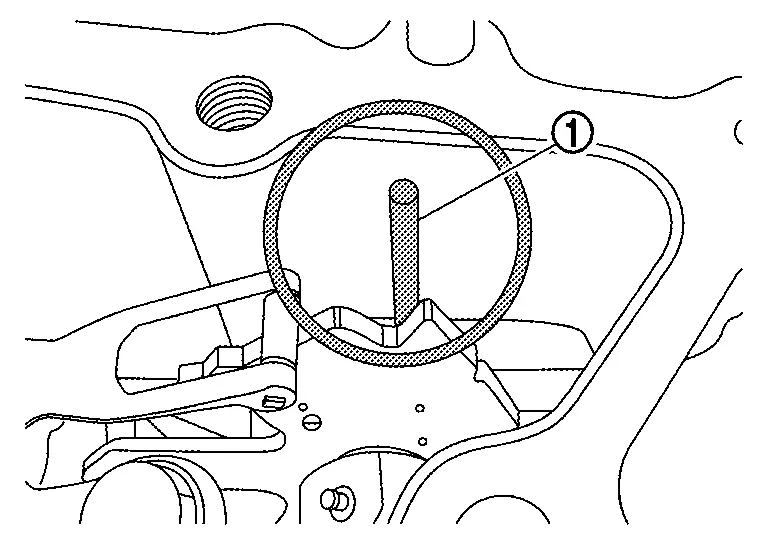

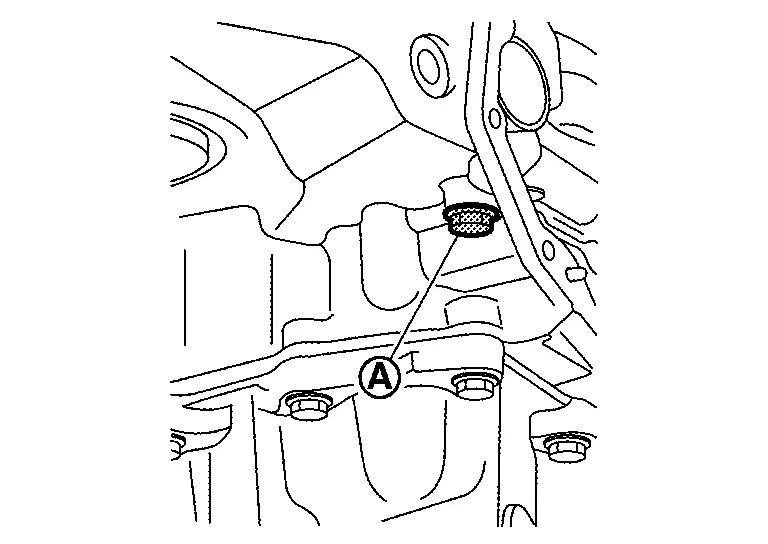

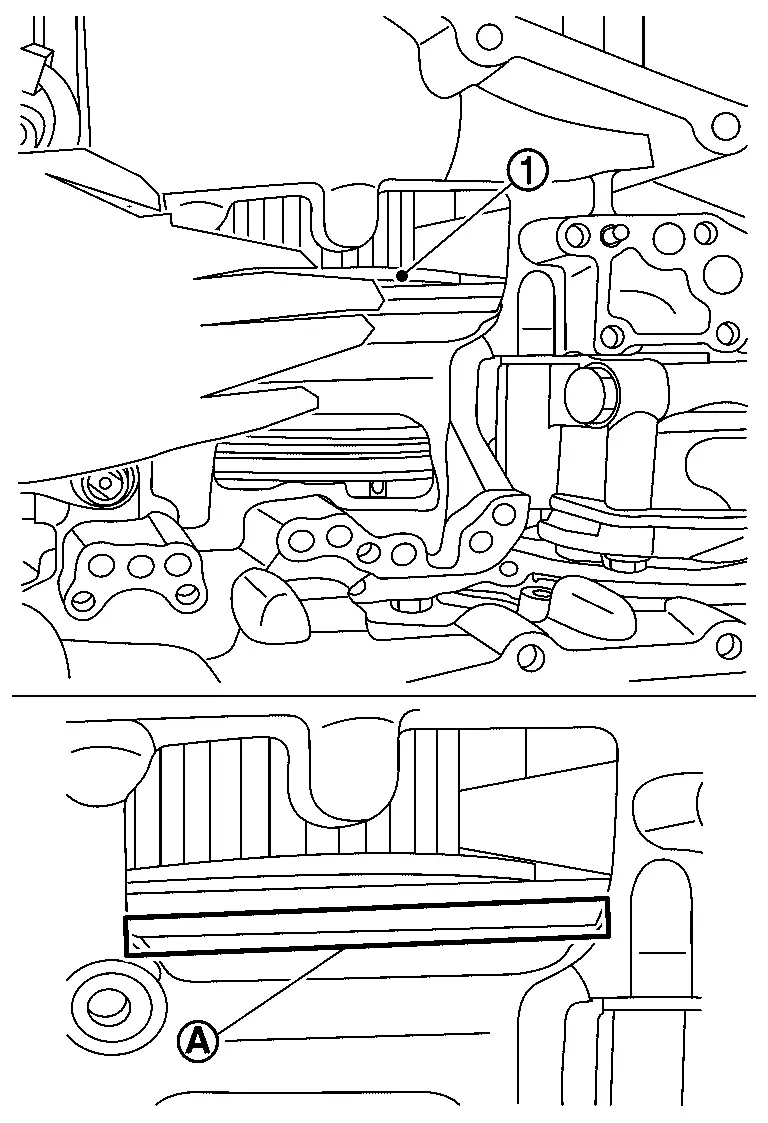

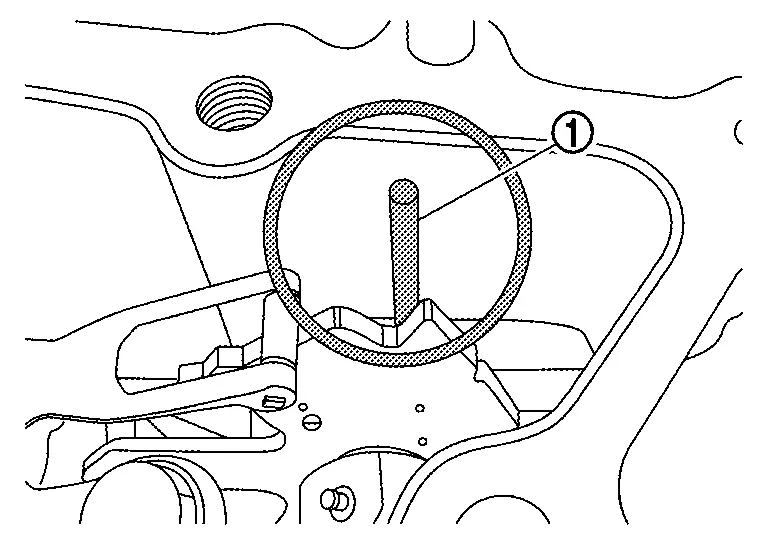

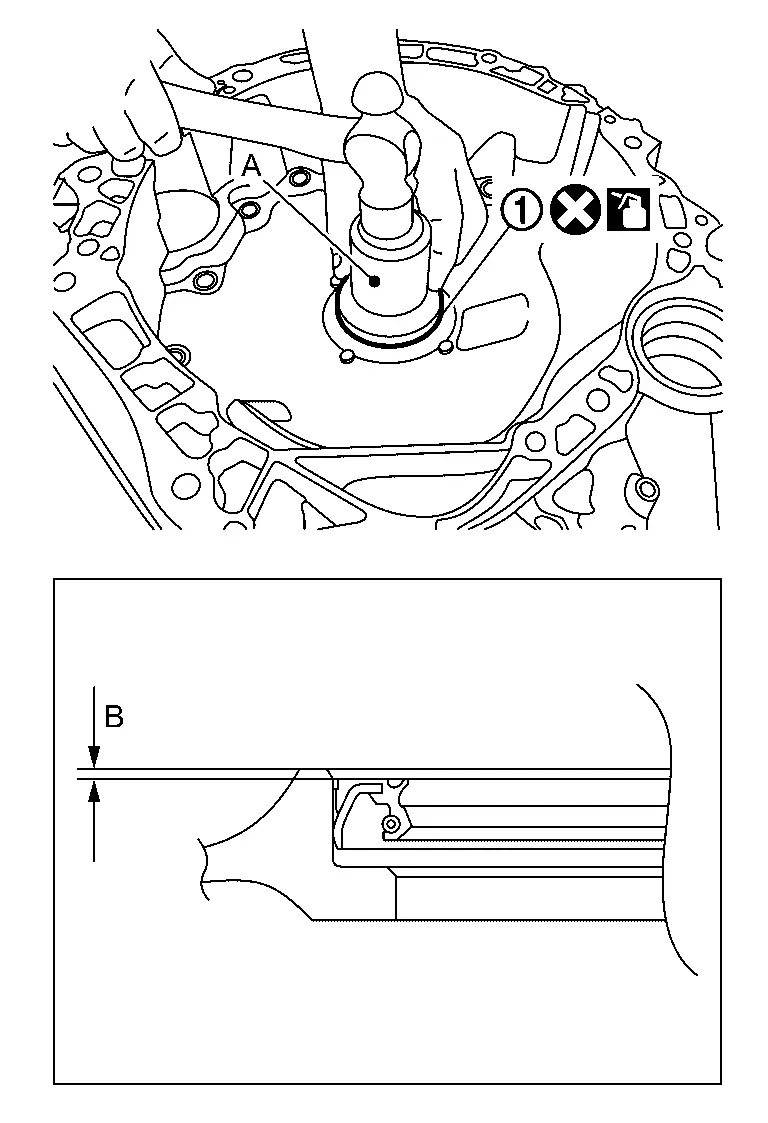

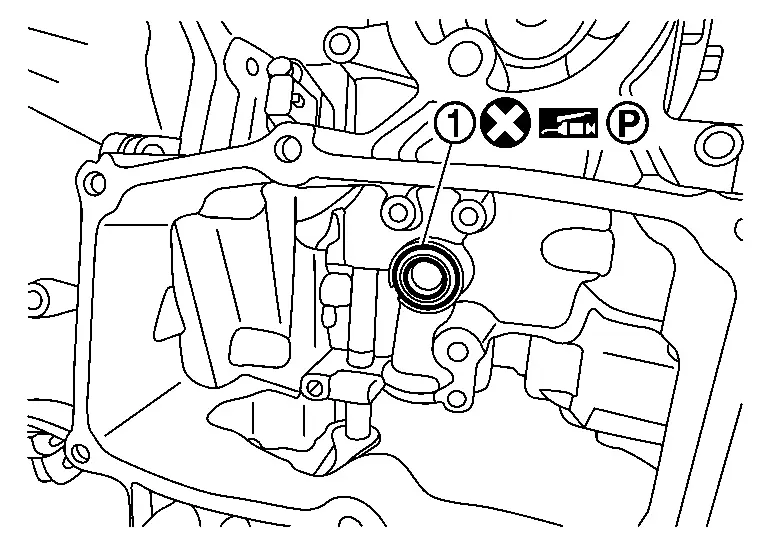

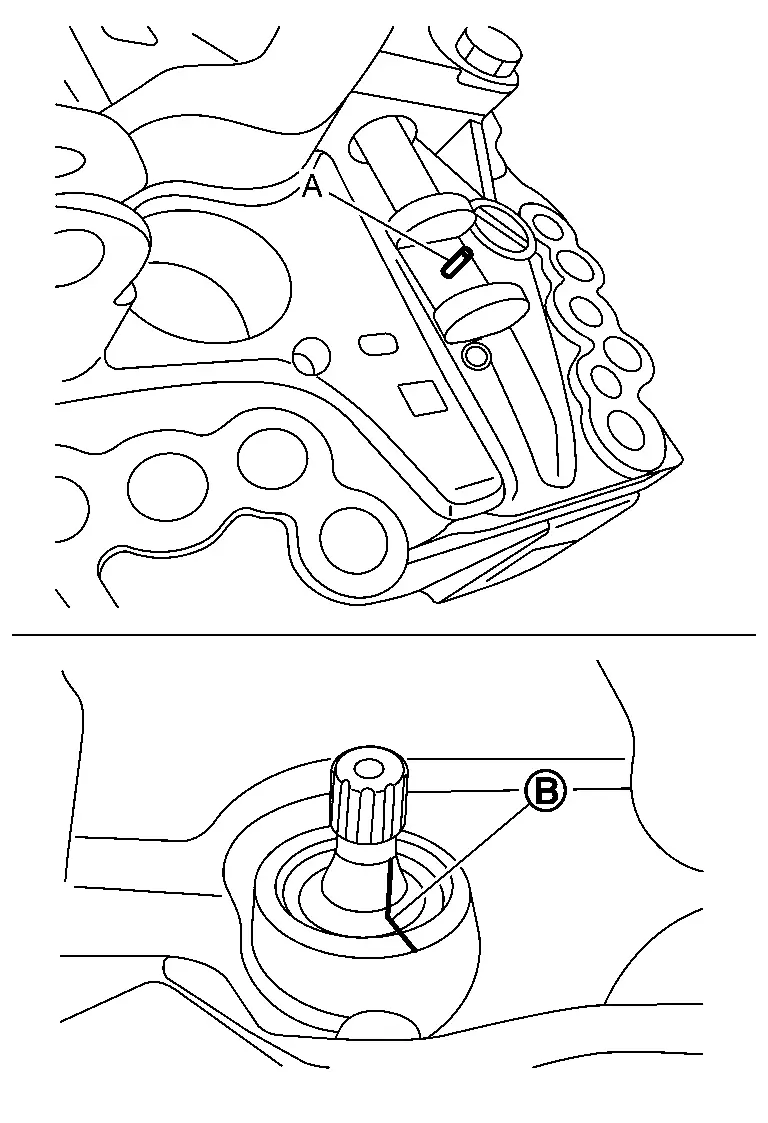

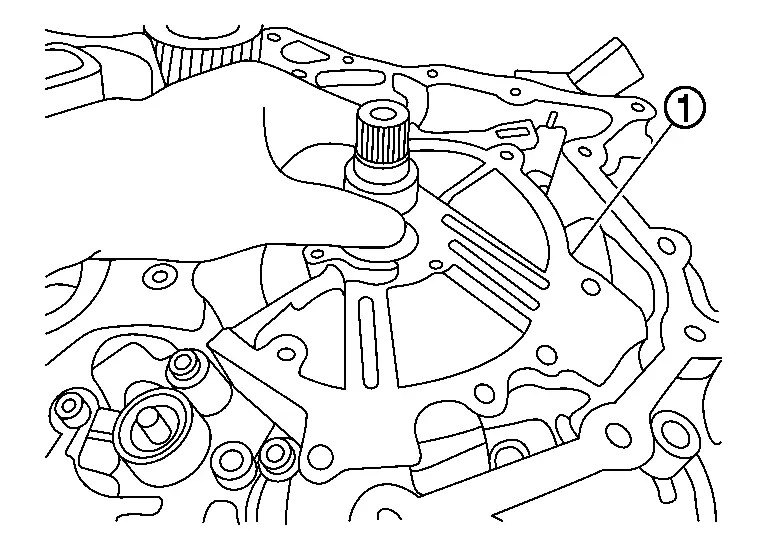

Marking  is made to mark the

range position of the manual shaft.Turn the manual shaft by CVT range

switch adjuster (SST: NI-53061) counterclockwise until it hits, return

one position, and set to the N range. Put align mark on both of the

manual shaft and the case. Use this marking as a guide when align the

manual shaft with the N range.

is made to mark the

range position of the manual shaft.Turn the manual shaft by CVT range

switch adjuster (SST: NI-53061) counterclockwise until it hits, return

one position, and set to the N range. Put align mark on both of the

manual shaft and the case. Use this marking as a guide when align the

manual shaft with the N range.

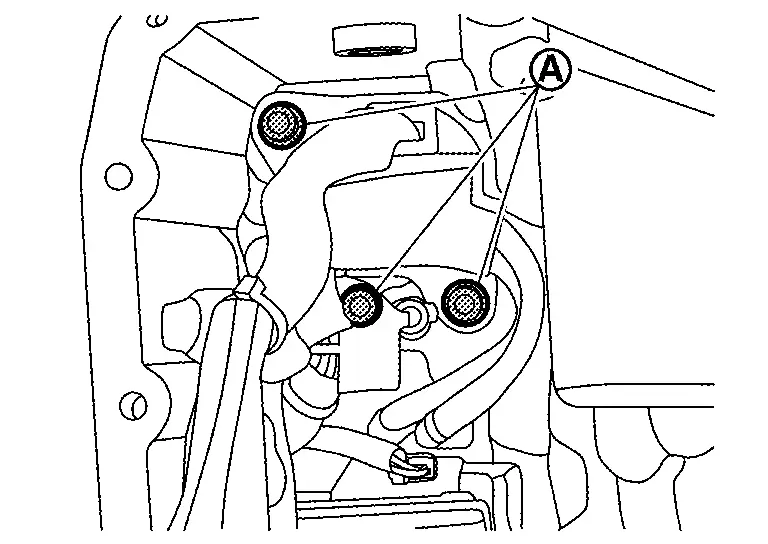

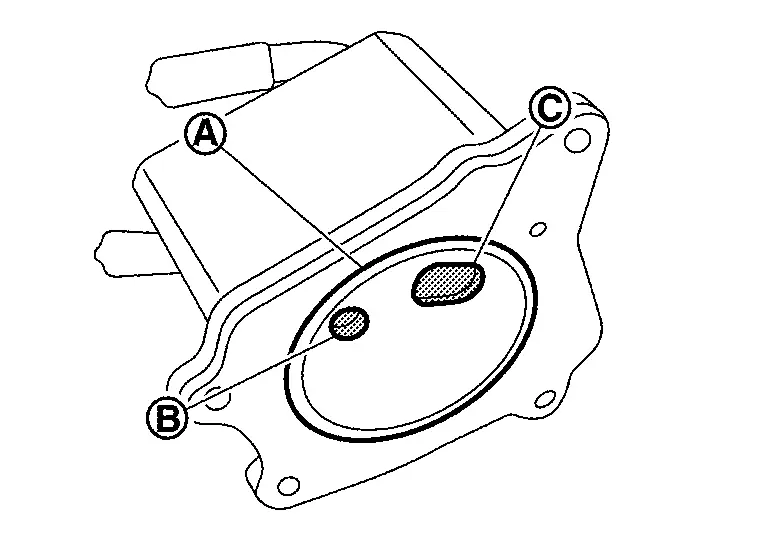

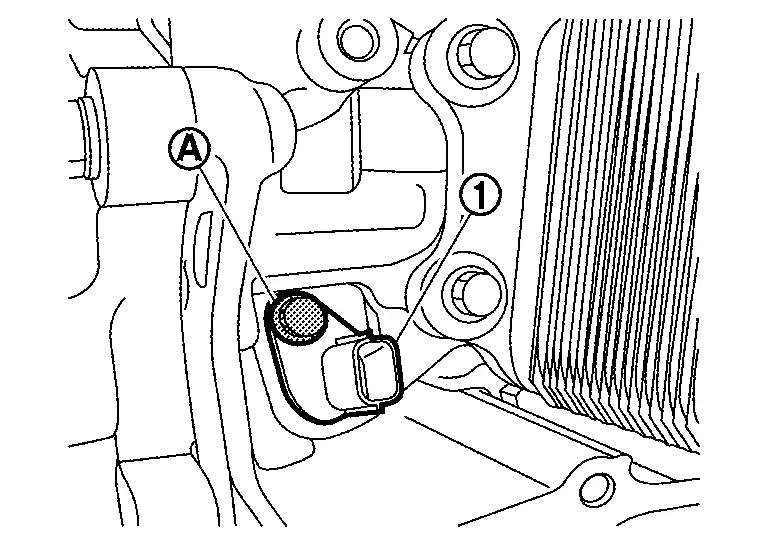

Remove CVT oil warmer mounting bolts  and then remove CVT oil warmer

and then remove CVT oil warmer  .

.

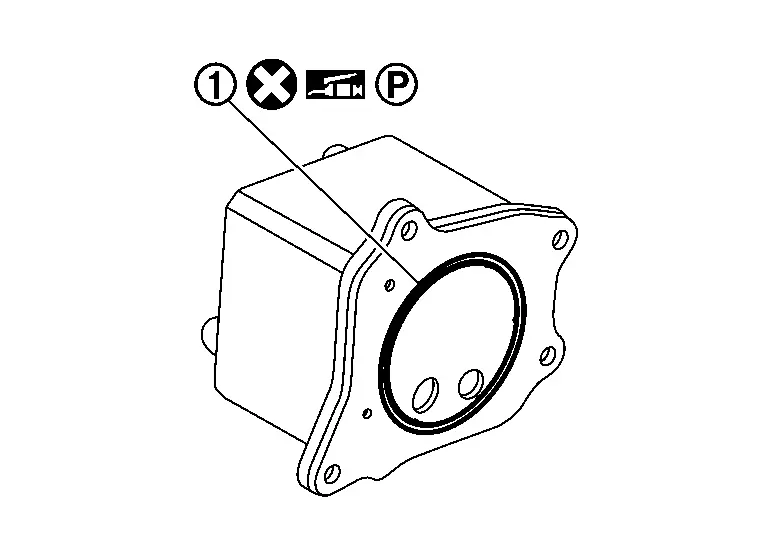

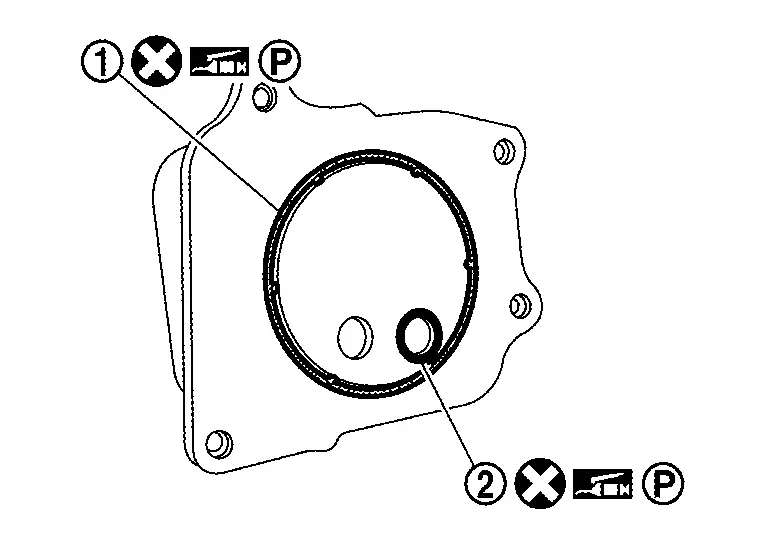

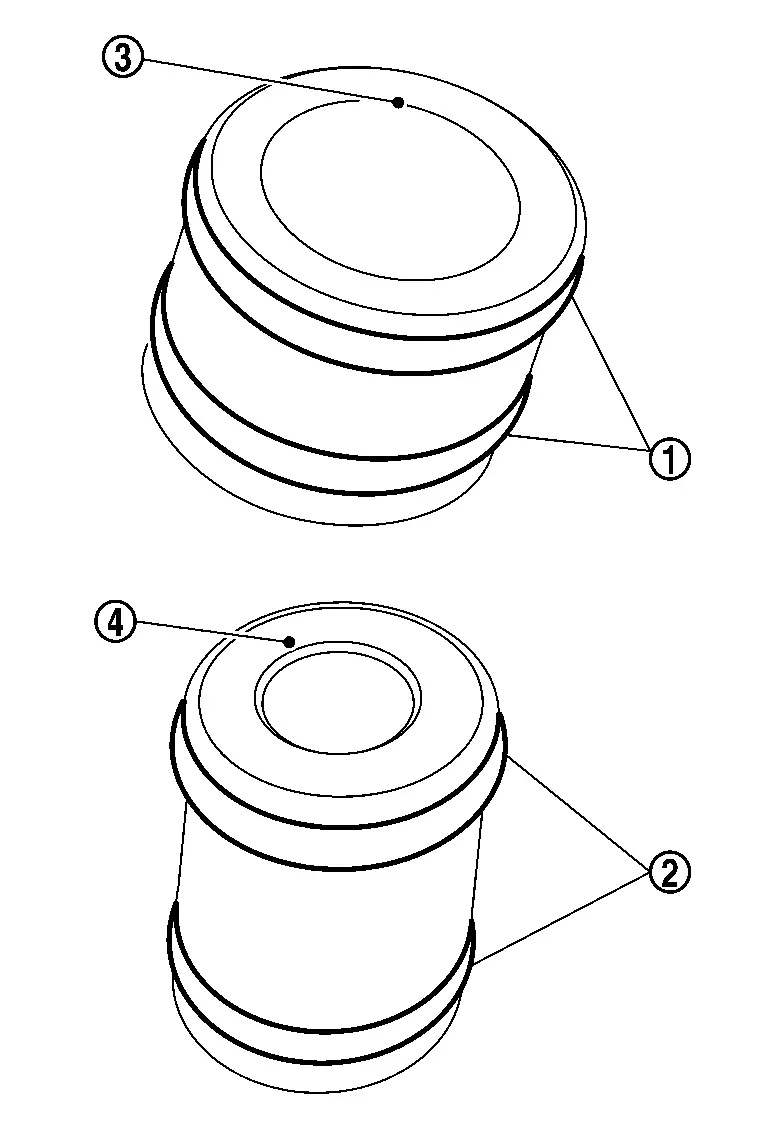

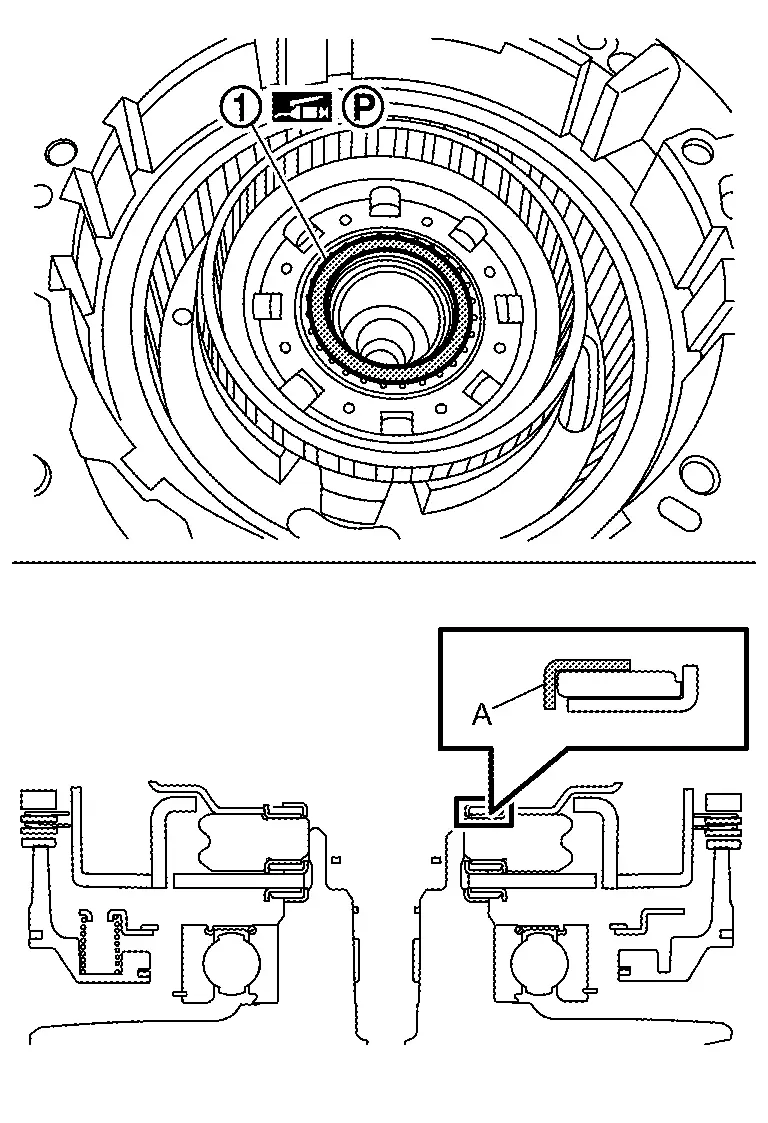

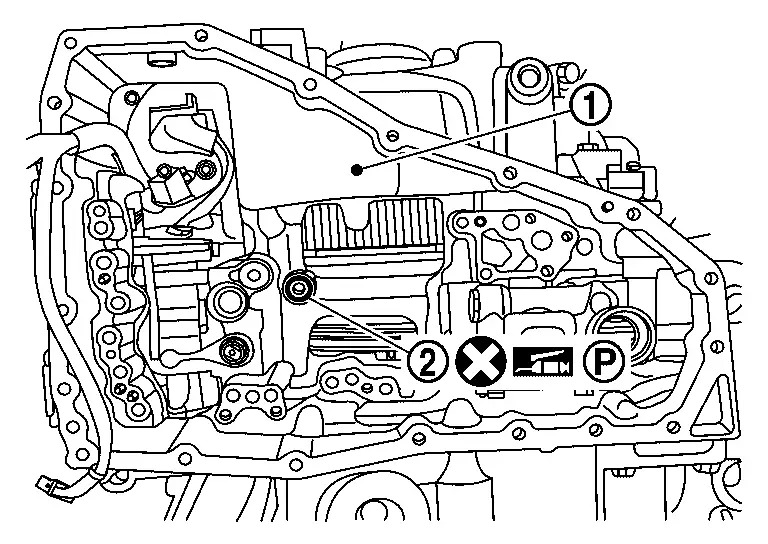

Remove O-ring  and

and  from CVT oil warmer.

from CVT oil warmer.

NOTE:

NOTE:

There are one O-ring and two O-rings depending on the specifications. When reusing oil warmer, check the number of O-rings and use the same number of O-rings as the removed number.

-

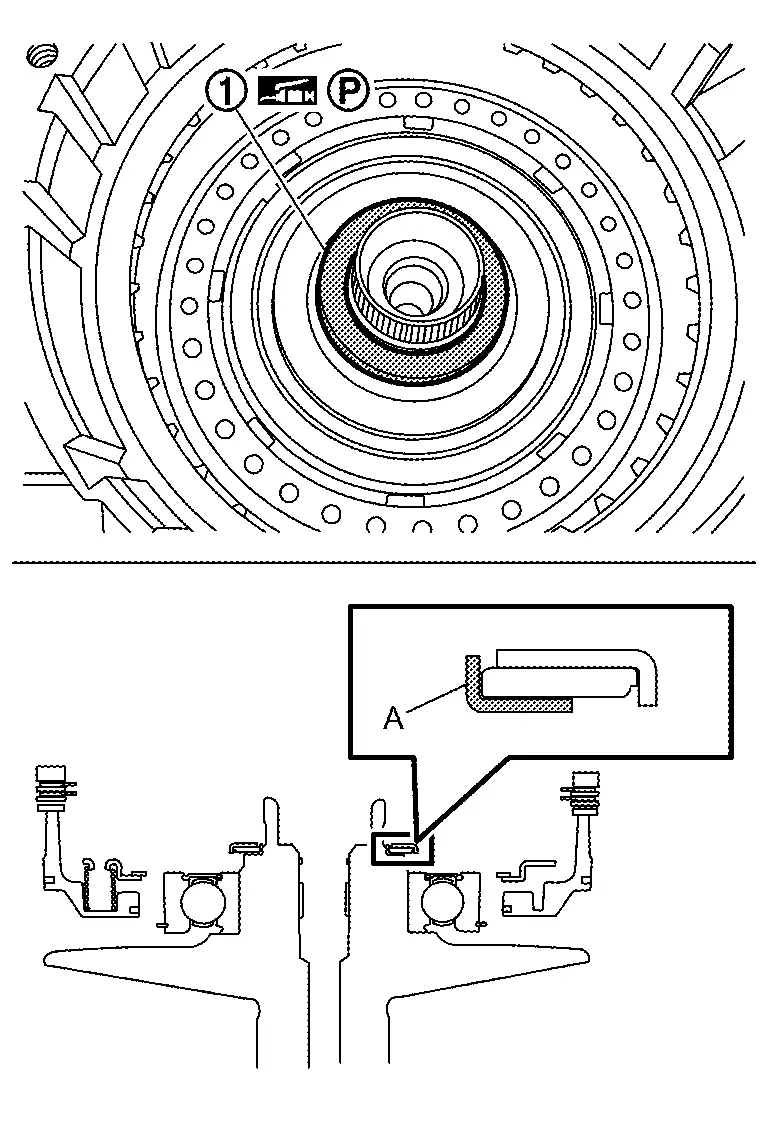

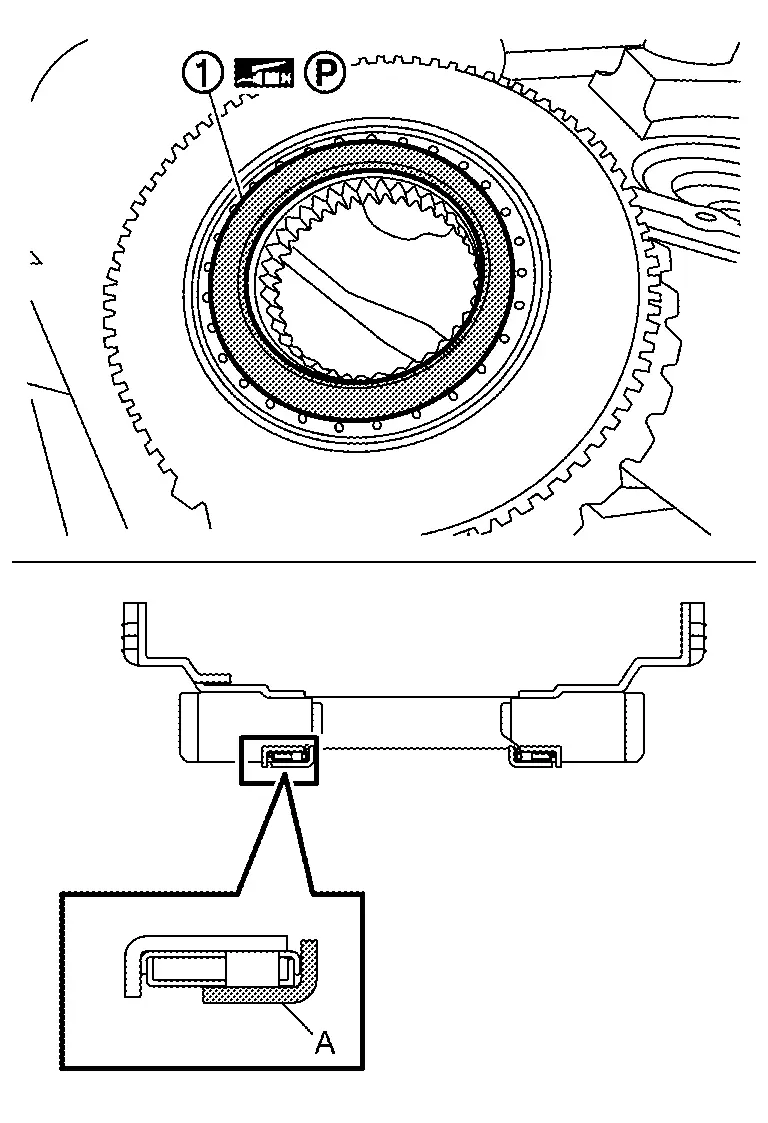

Type with one O-ring

-

Type with two O-ring

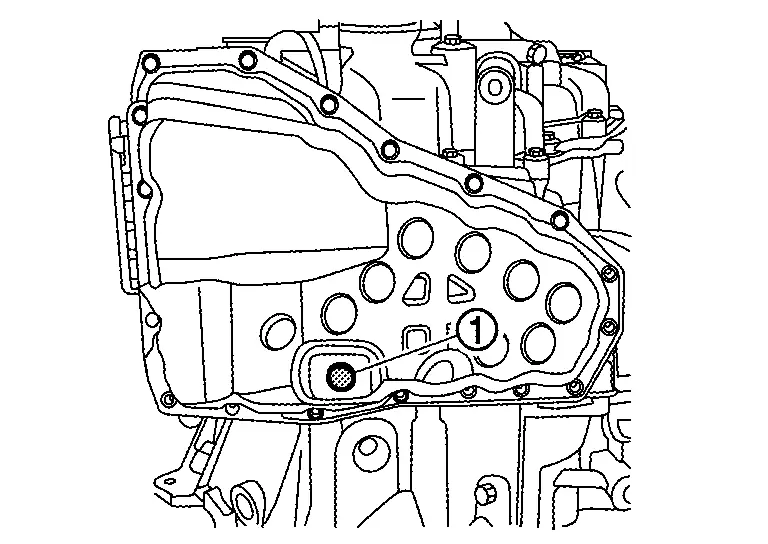

Remove oil filter  .

.

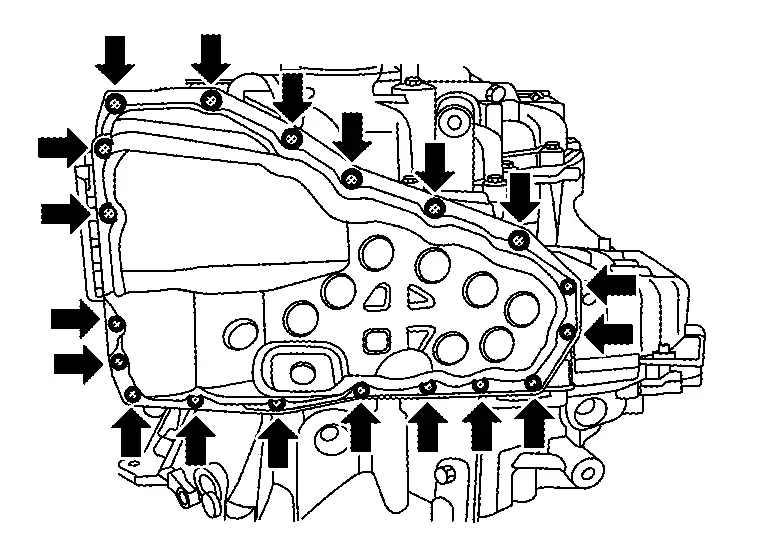

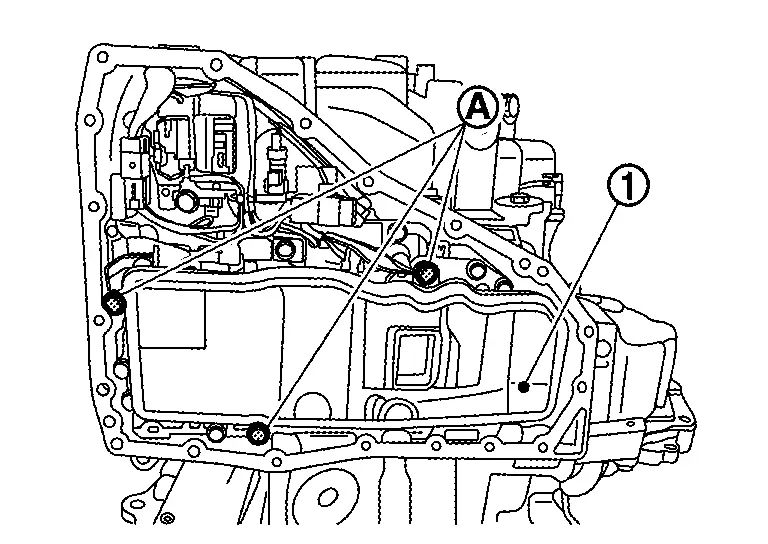

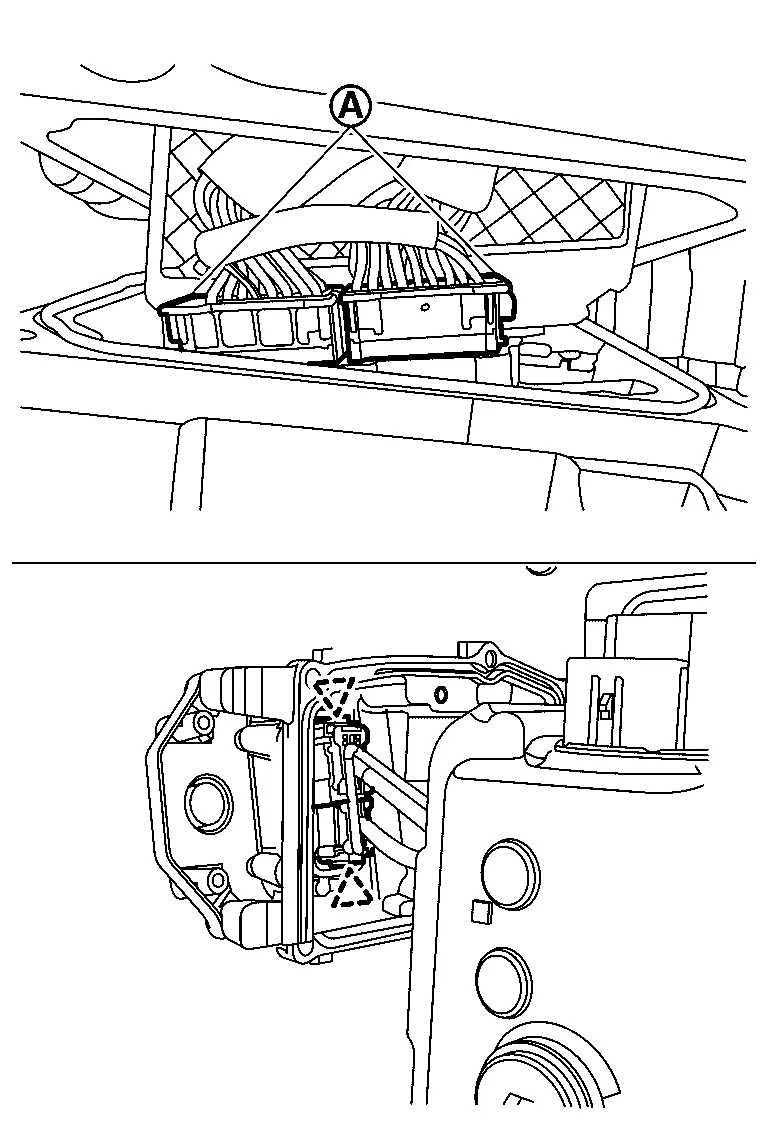

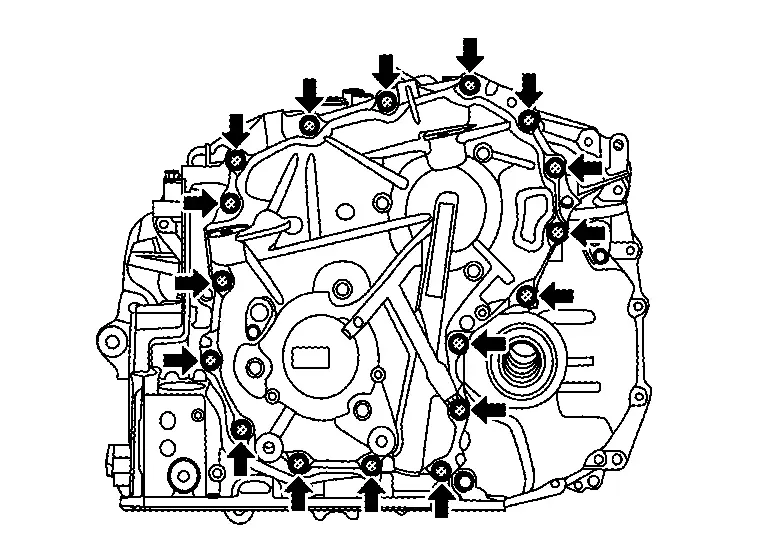

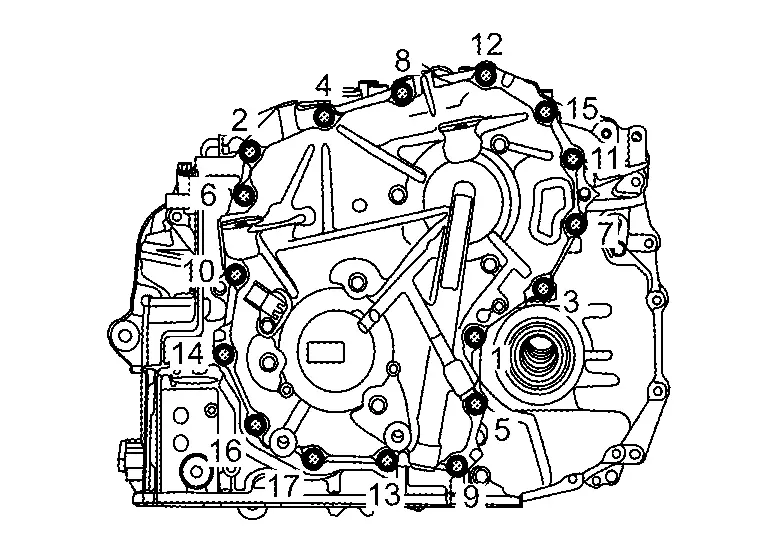

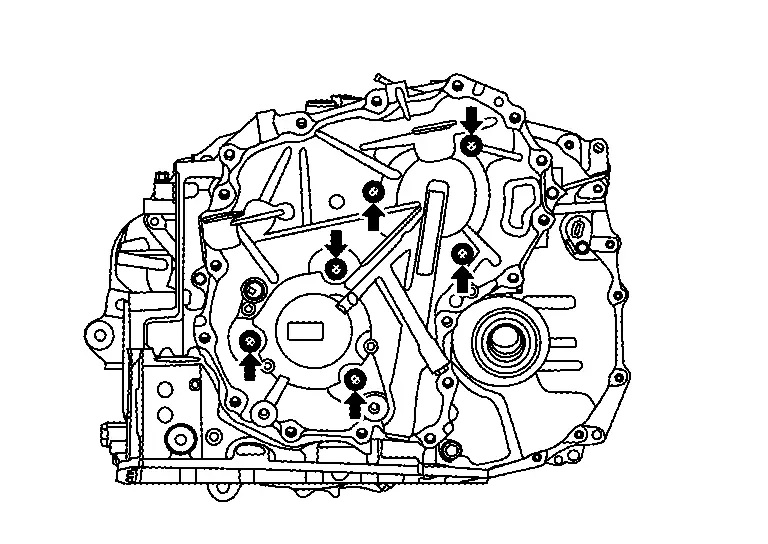

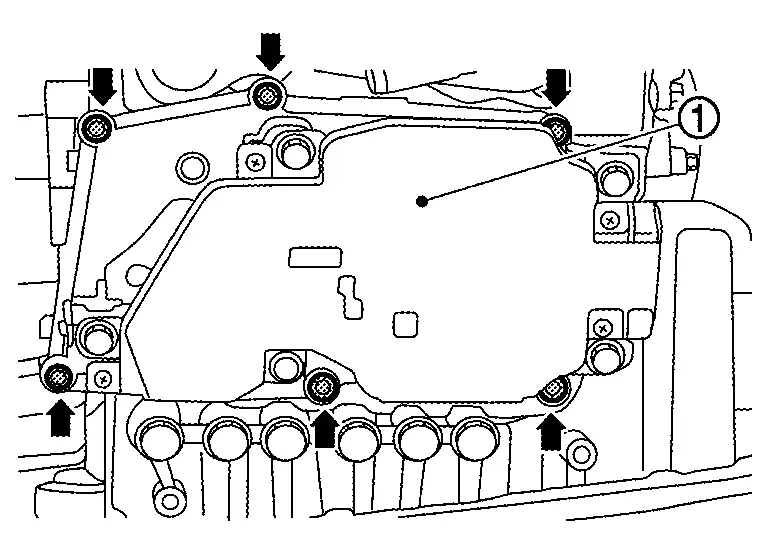

Remove oil pan mounting bolts ( 19 pieces) and then remove oil pan.

19 pieces) and then remove oil pan.

Remove oil pan gasket  .

.

Remove oil pan magnets ( 9 pieces) from the oil pan.

9 pieces) from the oil pan.

Remove oil strainer assembly mounting bolts  and then remove oil strainer assembly

and then remove oil strainer assembly  .

.

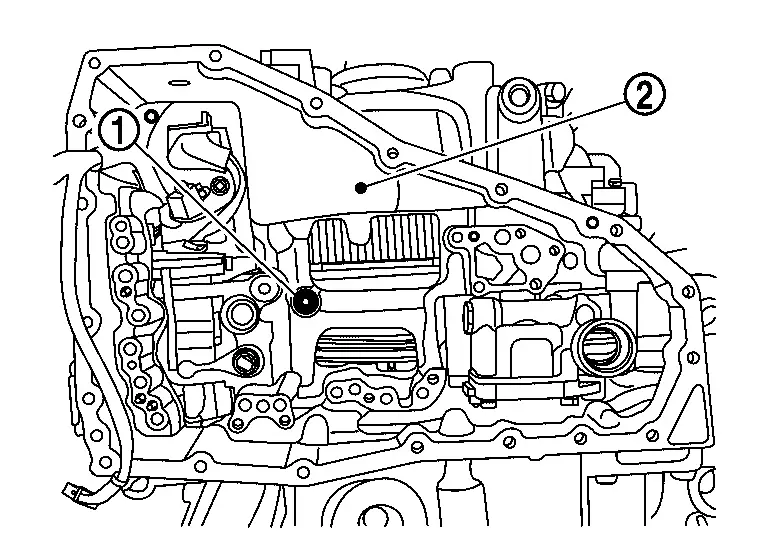

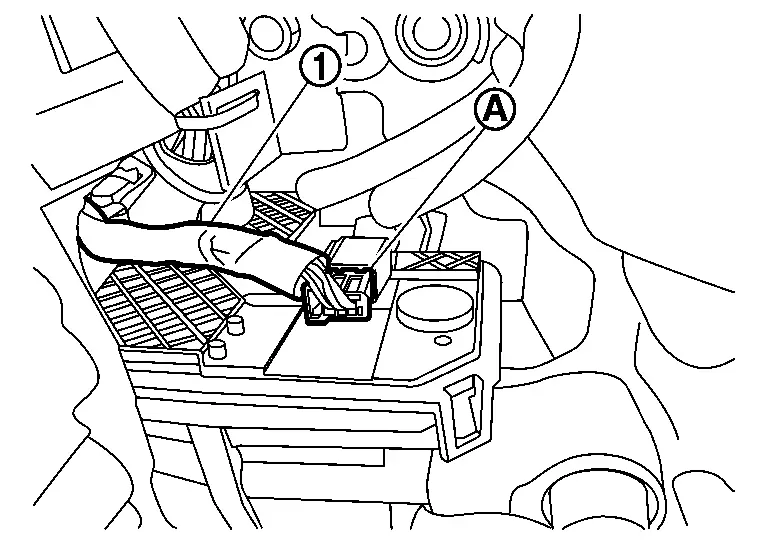

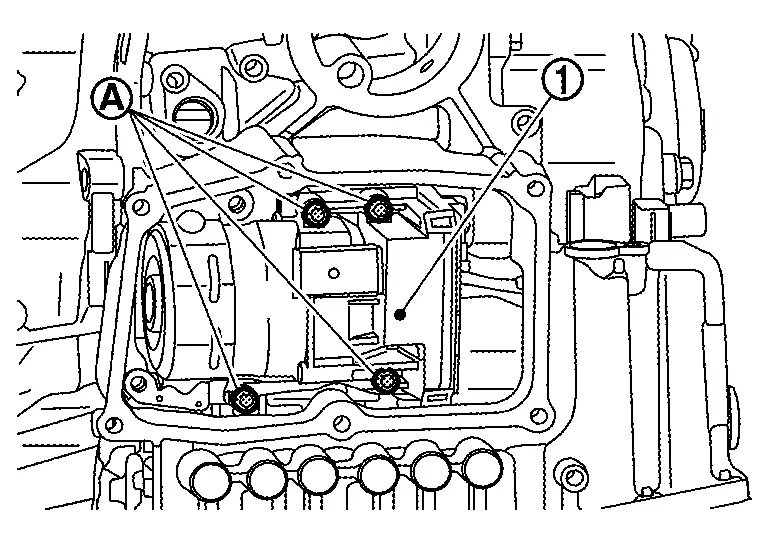

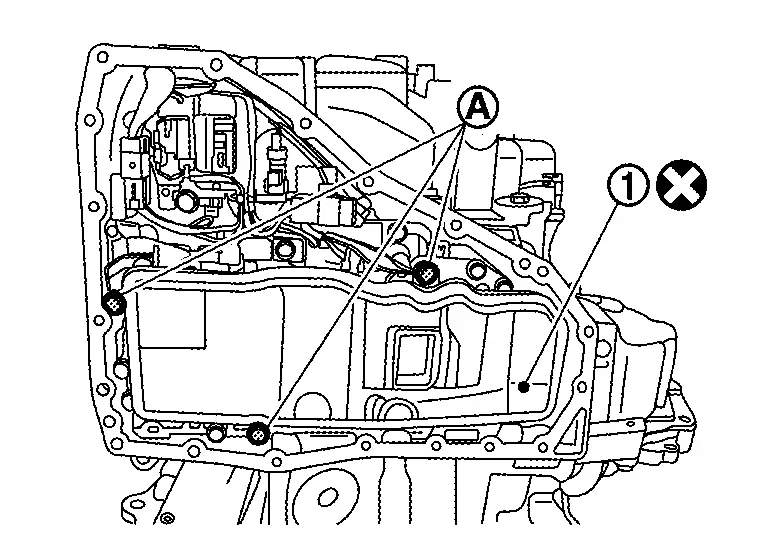

Remove harness connectors  and harness clip

and harness clip  .

.

CAUTION:

Never pull with excessive force when removing harness clip. Push tabs on the both side of harness clip properly to avoid damage.

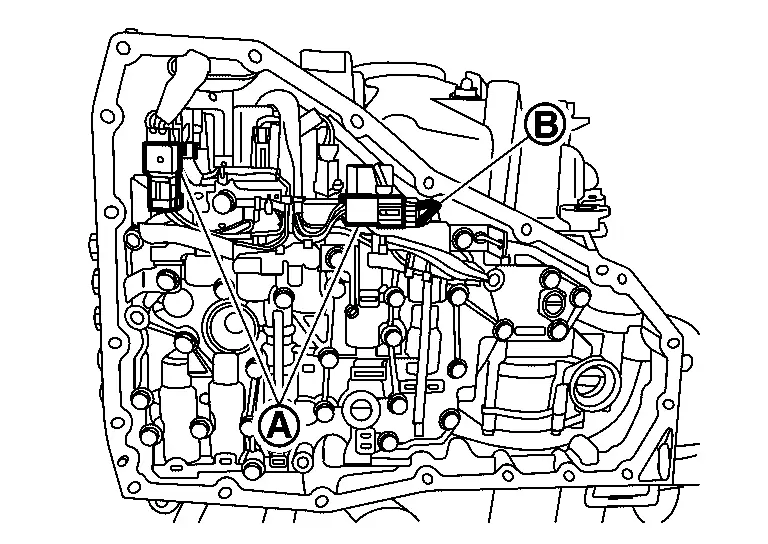

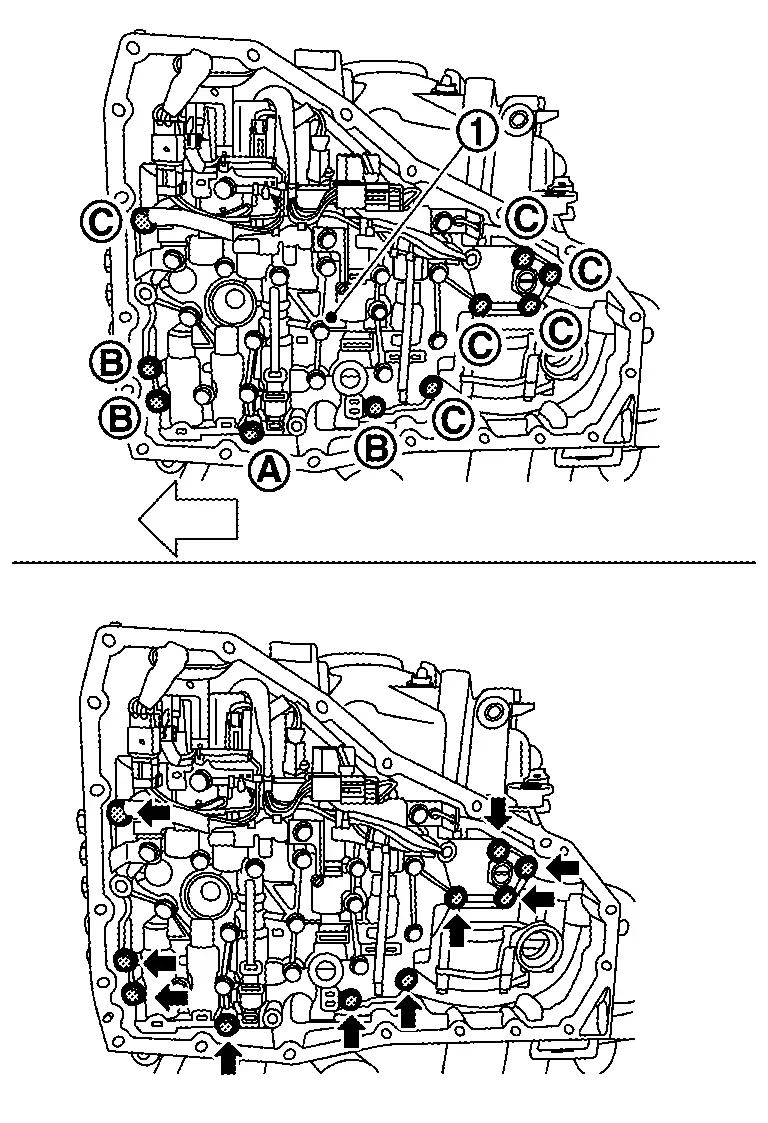

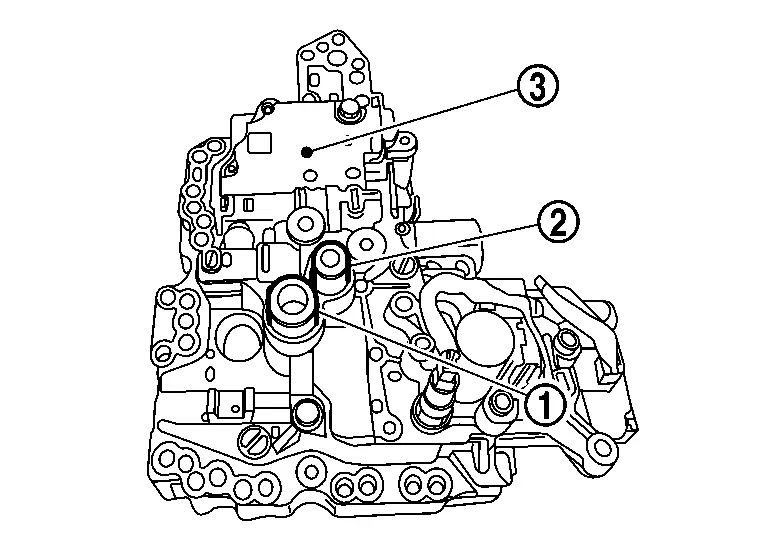

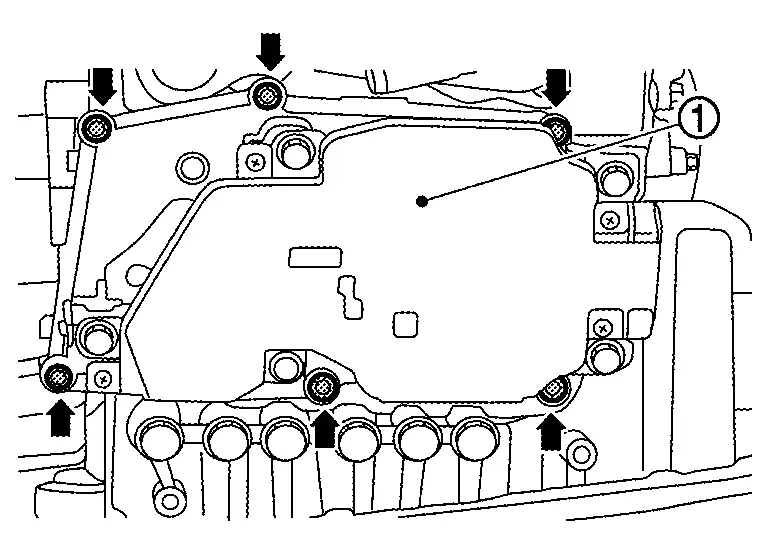

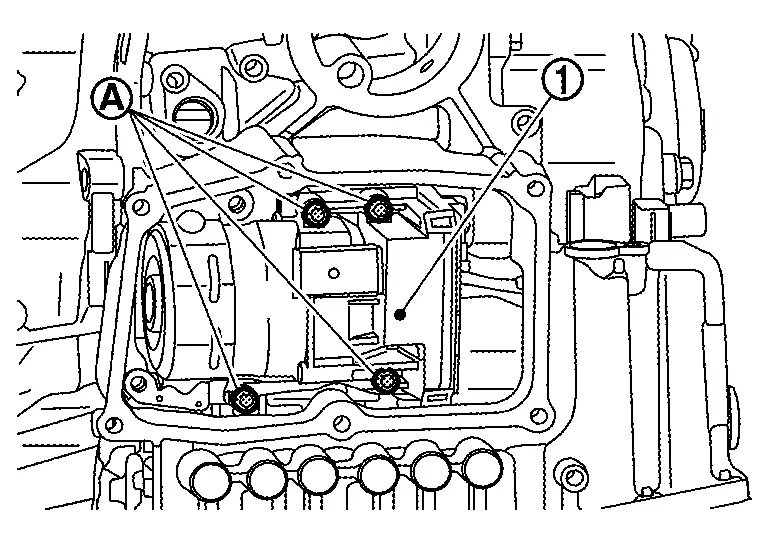

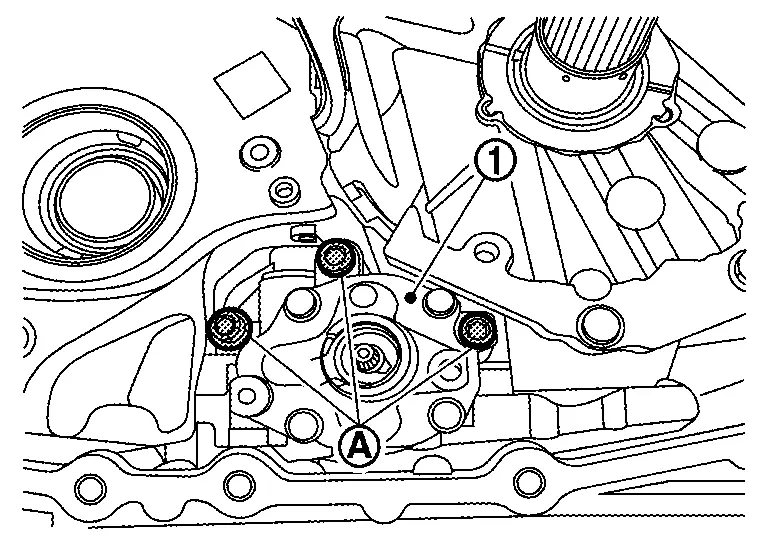

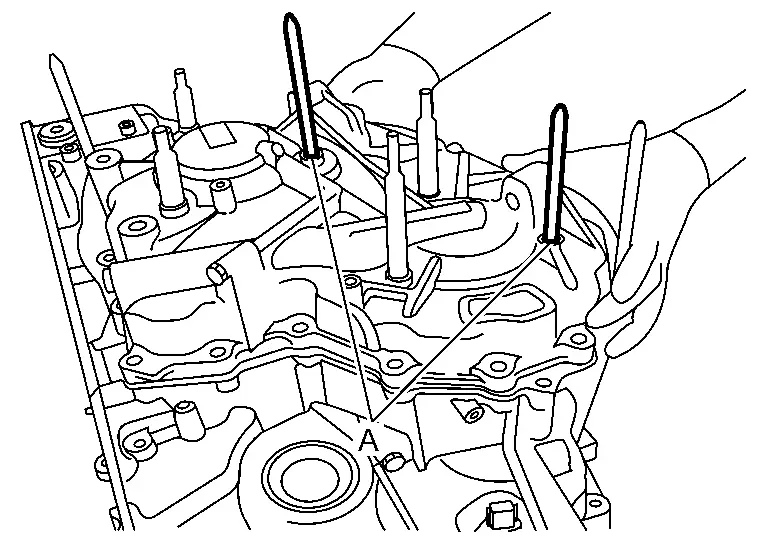

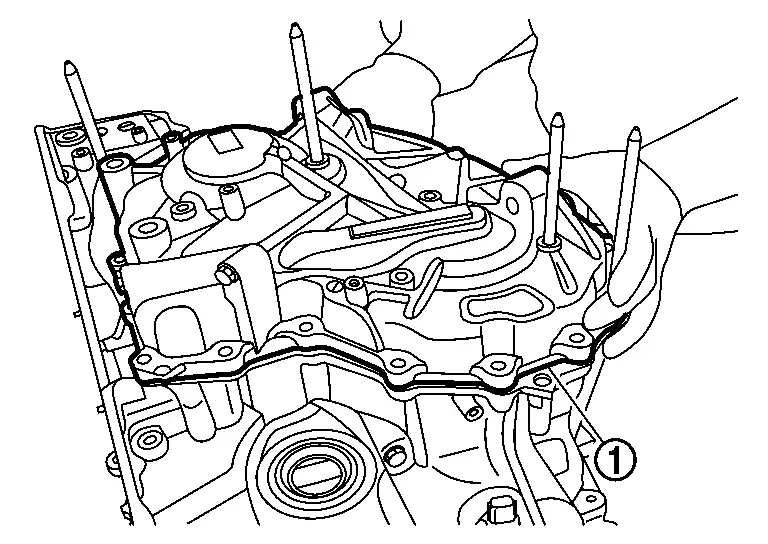

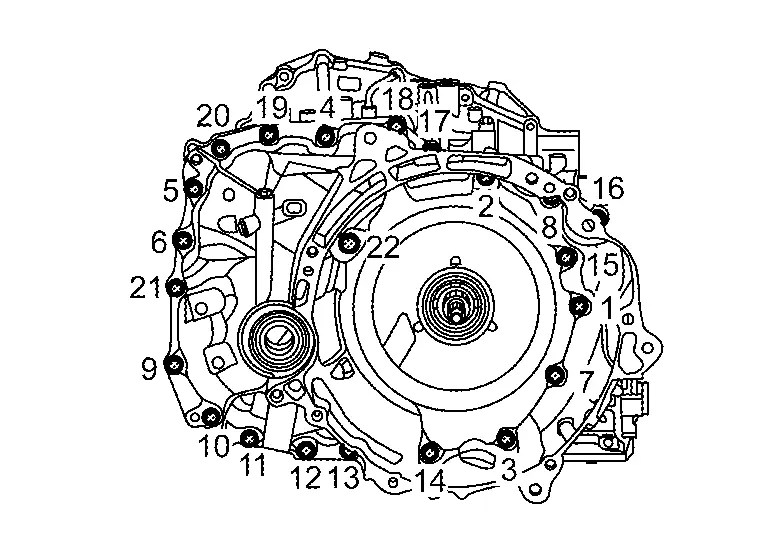

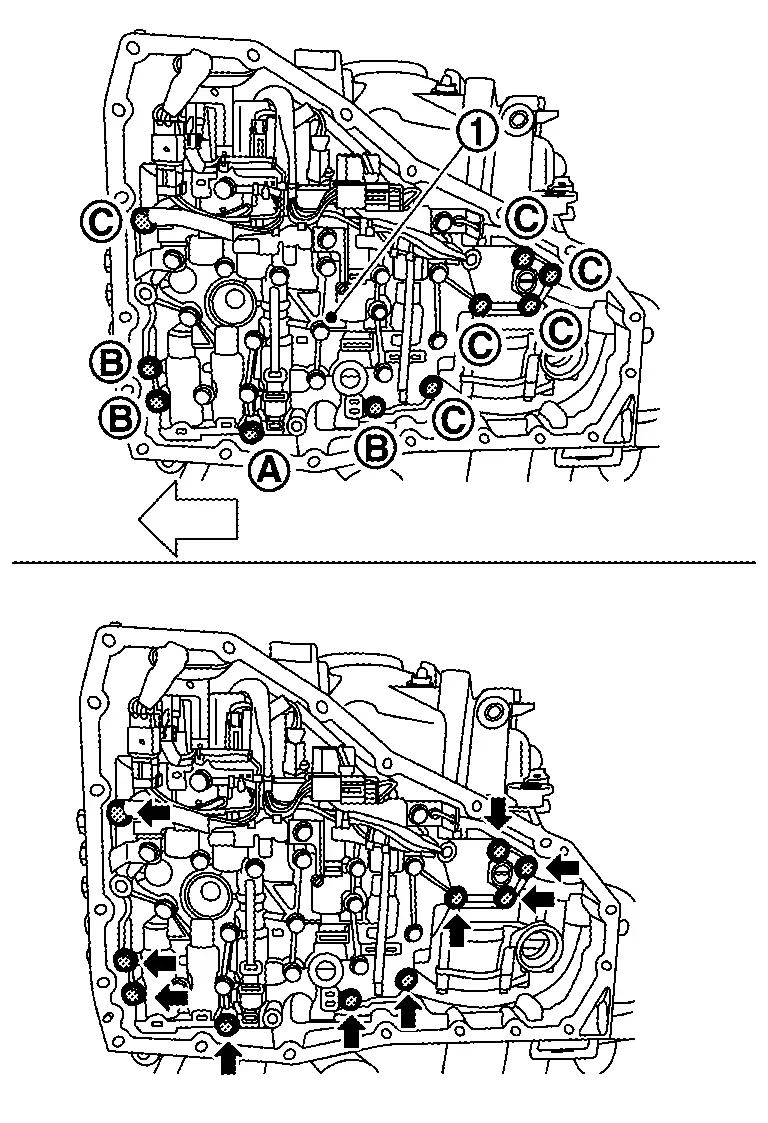

Remove bolts ( 10 pieces) which exists on the outline of control valve

10 pieces) which exists on the outline of control valve  according to the sequence of

according to the sequence of  ,

,  and

and  .

.

|

: Nissan Ariya Vehicle front |

CAUTION:

Do not mix 3 types of bolts which were removed from control valve, and keep them separately.

| Bolt | Bolt length mm (in) | Number of bolt |

|---|---|---|

|

54 (2.13) | 1 |

|

44 (1.73) | 3 |

|

40 (1.57) | 6 |

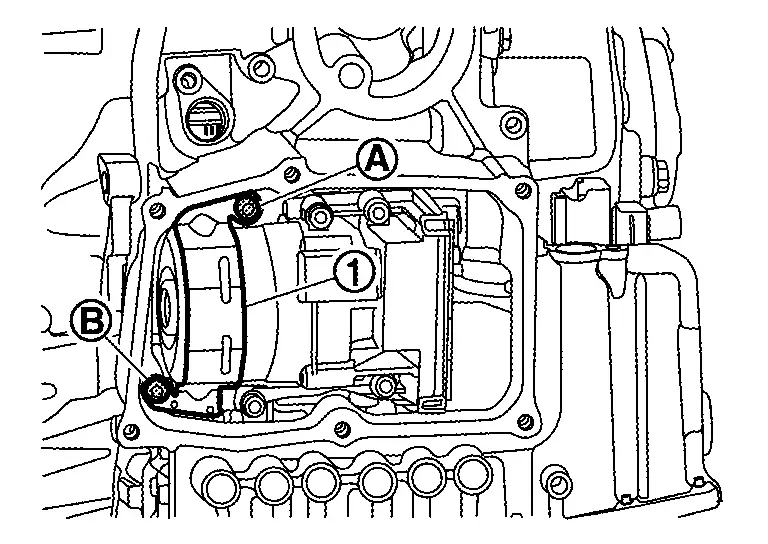

Remove the control valve  from transaxle case.

from transaxle case.

CAUTION:

Never drop the control valve.

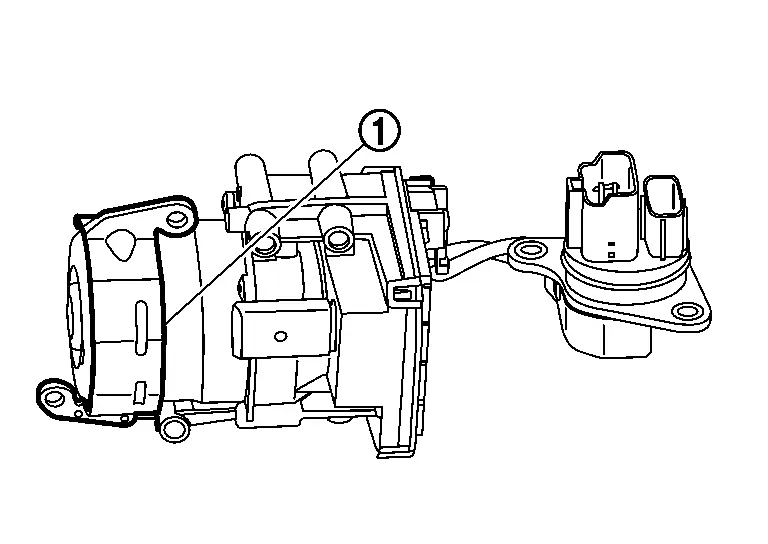

Remove tubes  and

and  from control valve

from control valve  .

.

CAUTION:

-

While removing control valve, never drop tube if it is remaining with transaxle assembly.

-

Never reuse dropped and damaged tube.

-

Place the removed control valve with the oil pressure sensor facing up to prevent damage to the oil pressure sensor.

Remove O-rings  and

and  from tubes

from tubes  and

and  .

.

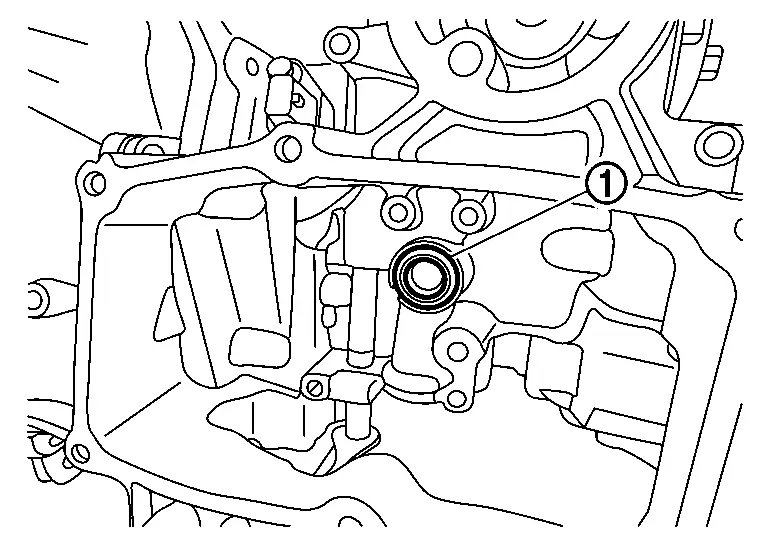

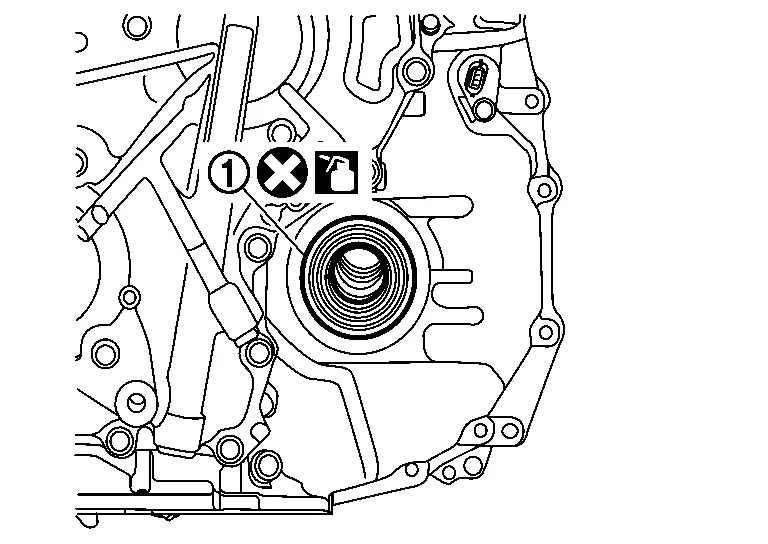

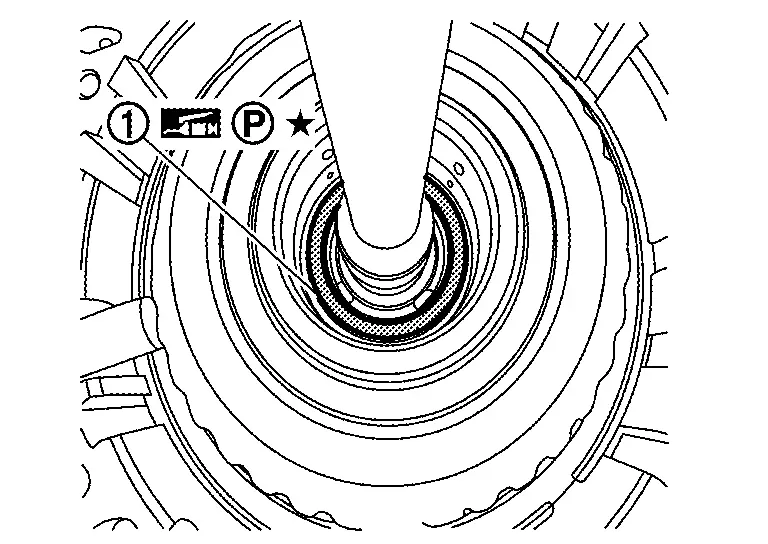

Remove lip seal  from transaxle assembly

from transaxle assembly  .

.

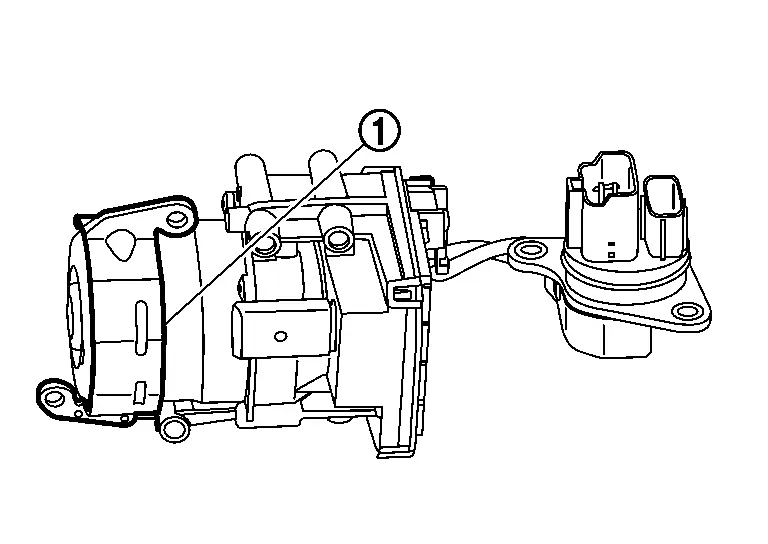

Remove TCM mounting hexagon bolt ( 6 pieces) and then remove TCM

6 pieces) and then remove TCM  .

.

CAUTION:

Never remove any hexagon bolt other than the specified bolt ( 6 pieces).

6 pieces).

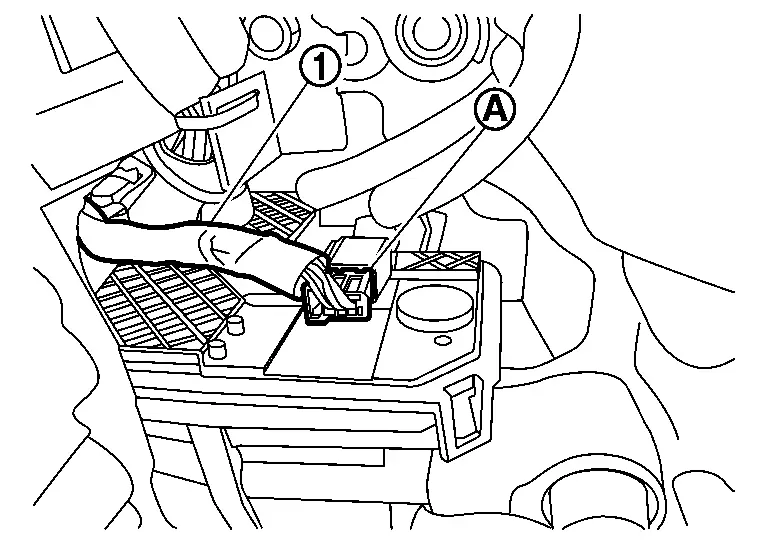

Remove connectors  of terminal assembly B from TCM and then remove TCM from transaxle assembly.

of terminal assembly B from TCM and then remove TCM from transaxle assembly.

NOTE:

NOTE:

Terminal assembly B connector claws are located on the upper and lower sides of the connector while connected to the TCM.

Remove gasket  from TCM.

from TCM.

Remove fixing bolt  of terminal assembly A and terminal assembly B to the case.

of terminal assembly A and terminal assembly B to the case.

Press terminal assembly A  into the transaxle case.

into the transaxle case.

CAUTION:

Before handling terminal assembly A, clean around the exterior of it to prevent foreign materials from entering into the transaxle case.

Disconnect harness connector  from terminal assembly A

from terminal assembly A  .

.

Disconnect harness connector  of terminal assembly B

of terminal assembly B  from the electric oil pump.

from the electric oil pump.

Remove terminal assembly B.

Remove electric oil pump bracket mounting bolts  .

.

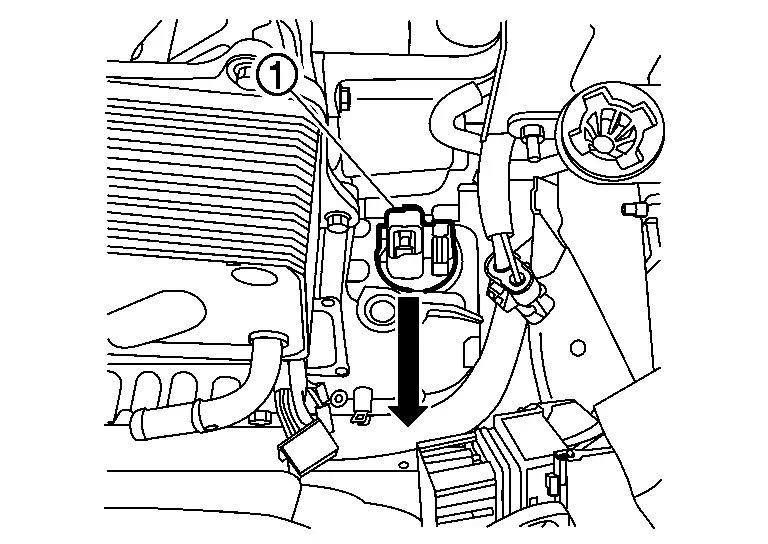

Remove electric oil pump mounting bolts  and then remove electric oil pump

and then remove electric oil pump  and terminal assembly A from transaxle assembly.

and terminal assembly A from transaxle assembly.

NOTE:

NOTE:

Take out electric oil pump from the opening for installing TCM.

Remove electric oil pump bracket  from electric oil pump.

from electric oil pump.

Remove electric oil pump gasket  .

.

Remove Terminal assembly A mounting bolts  and then remove Terminal assembly A from electric oil pump.

and then remove Terminal assembly A from electric oil pump.

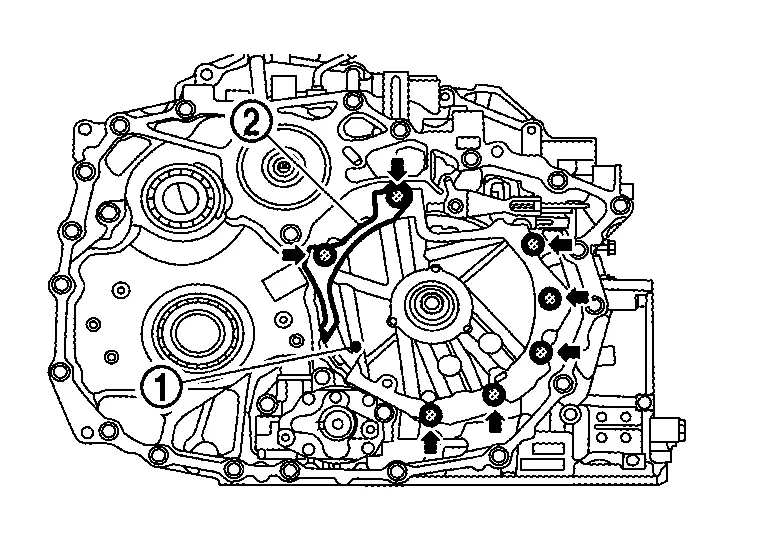

Place CVT with the converter housing side as the top.

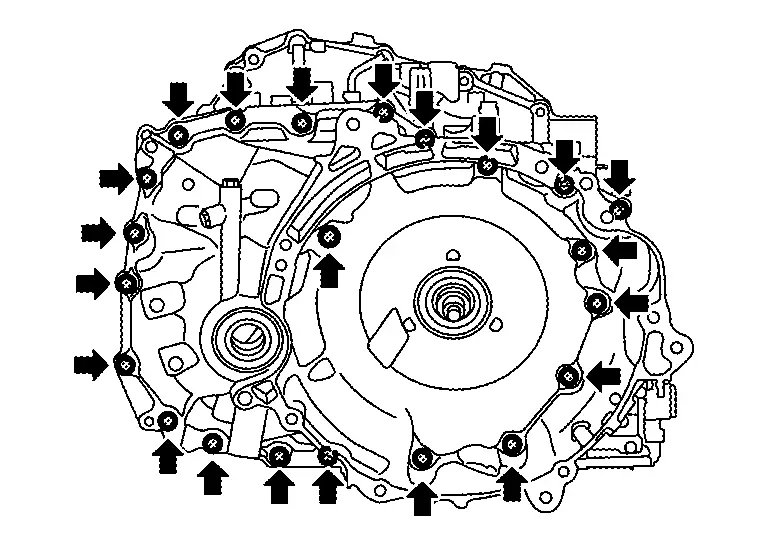

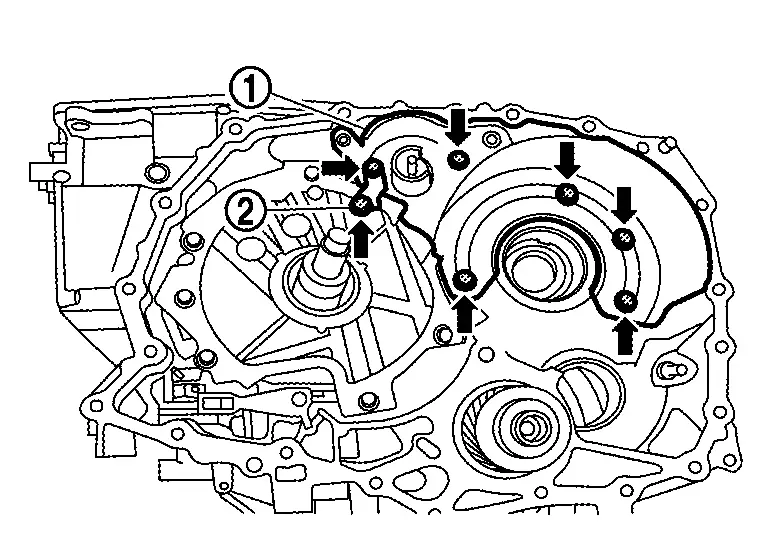

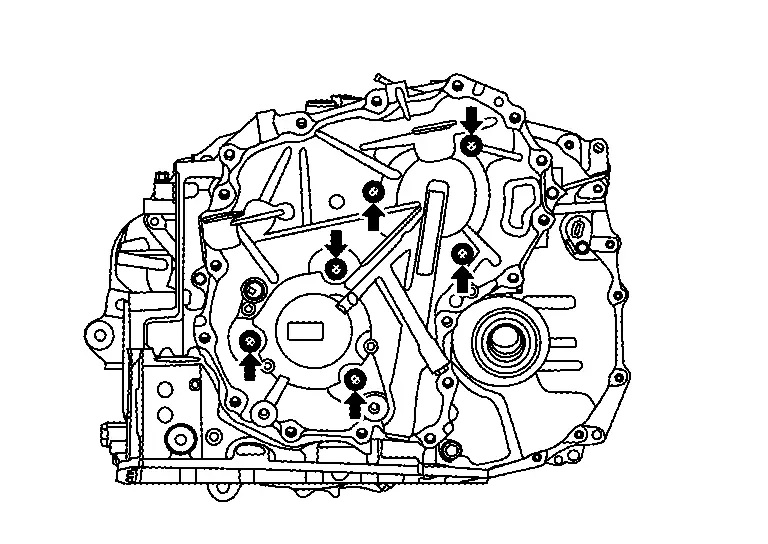

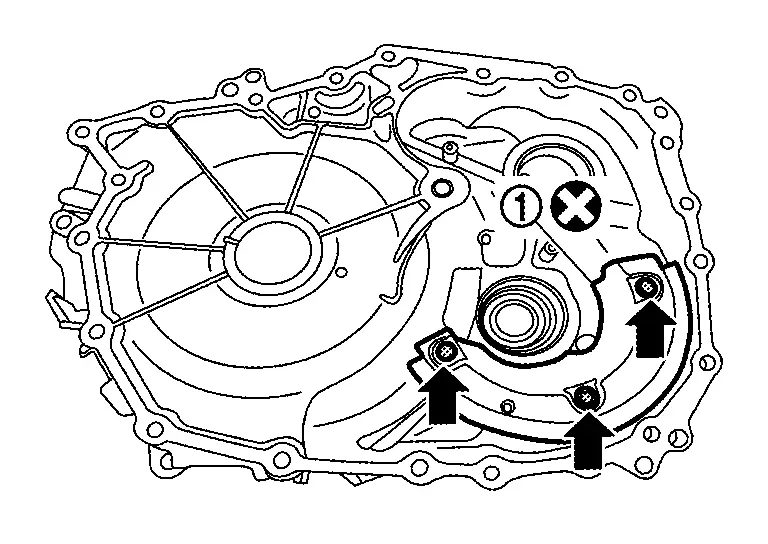

Remove converter housing mounting bolts ( 22 pieces).

22 pieces).

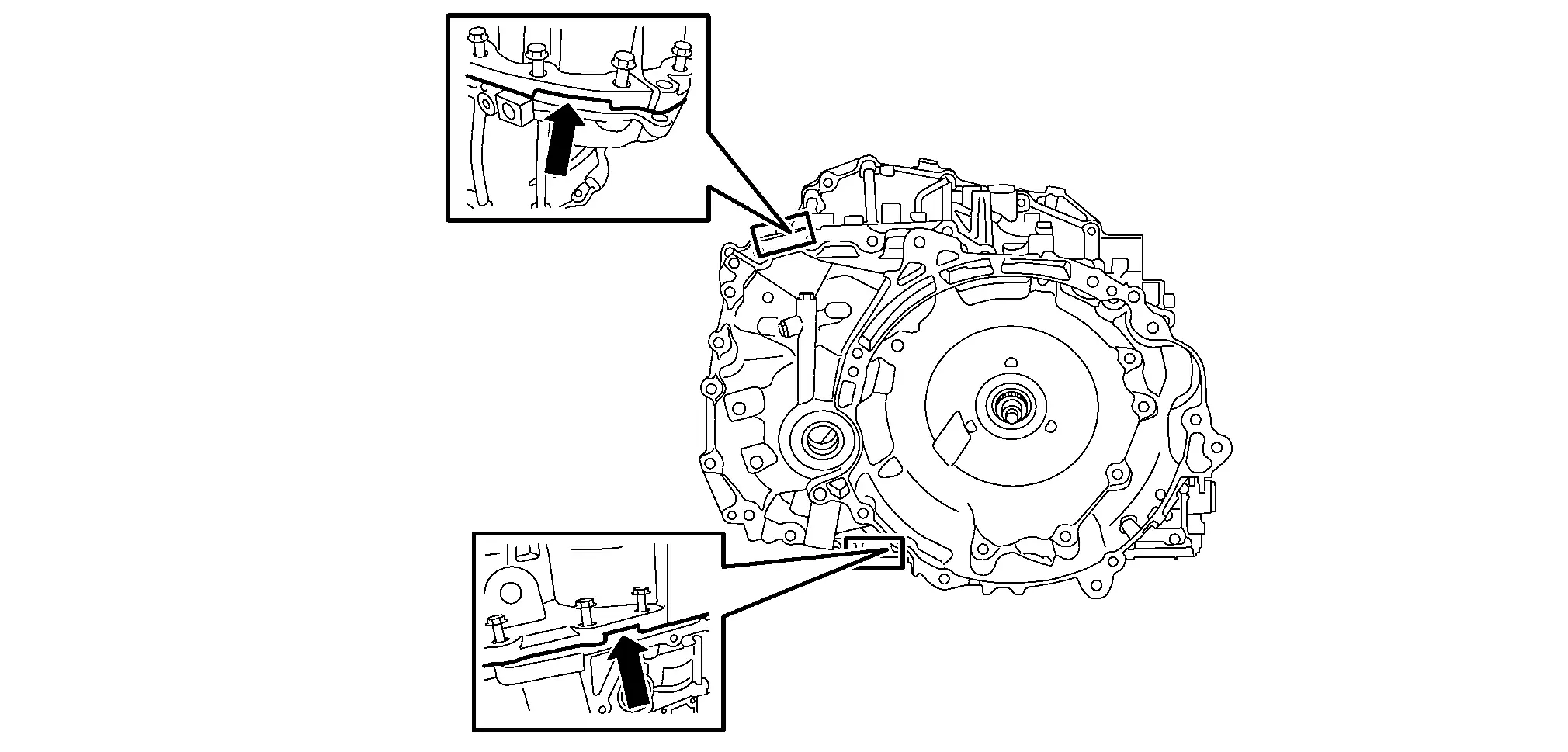

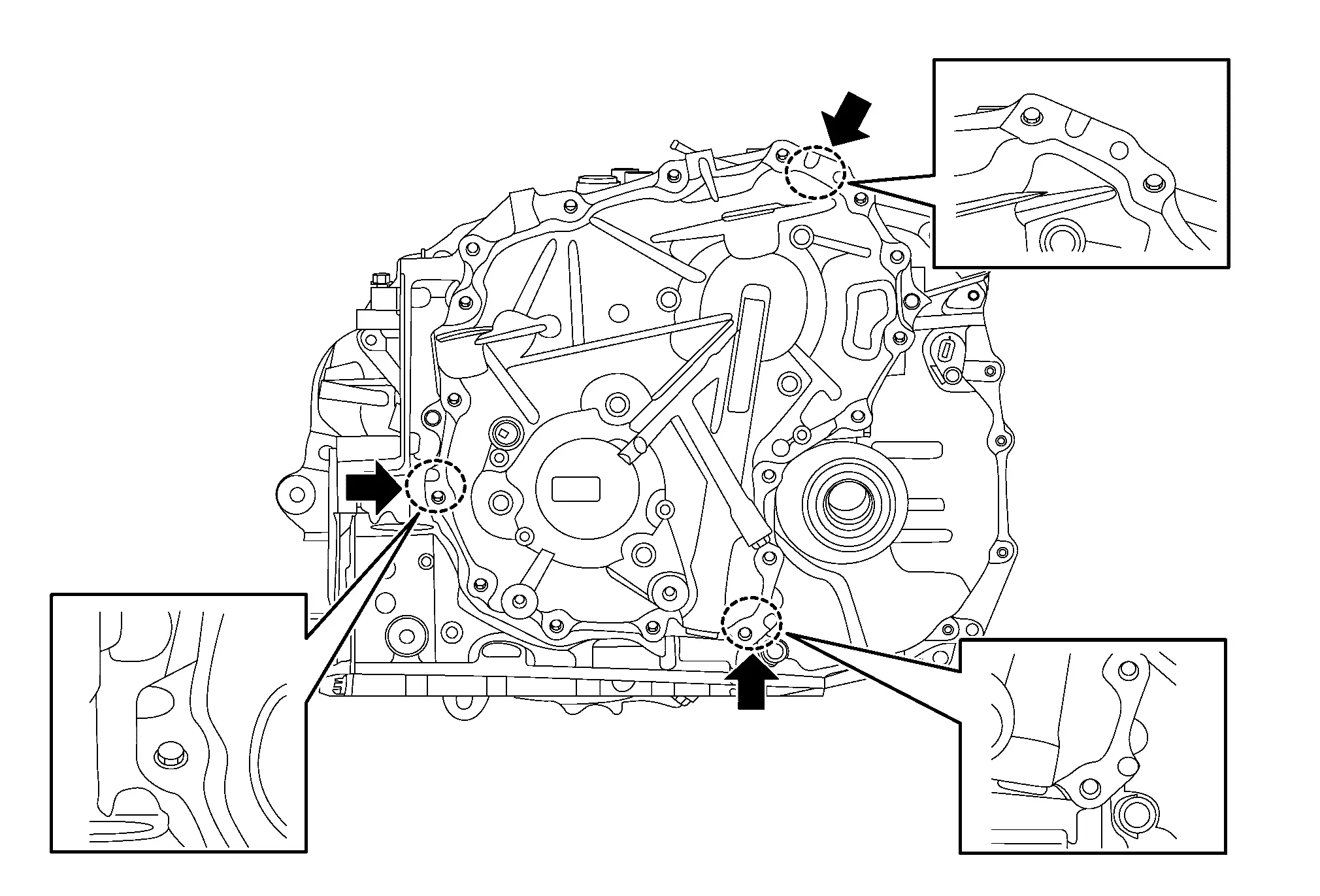

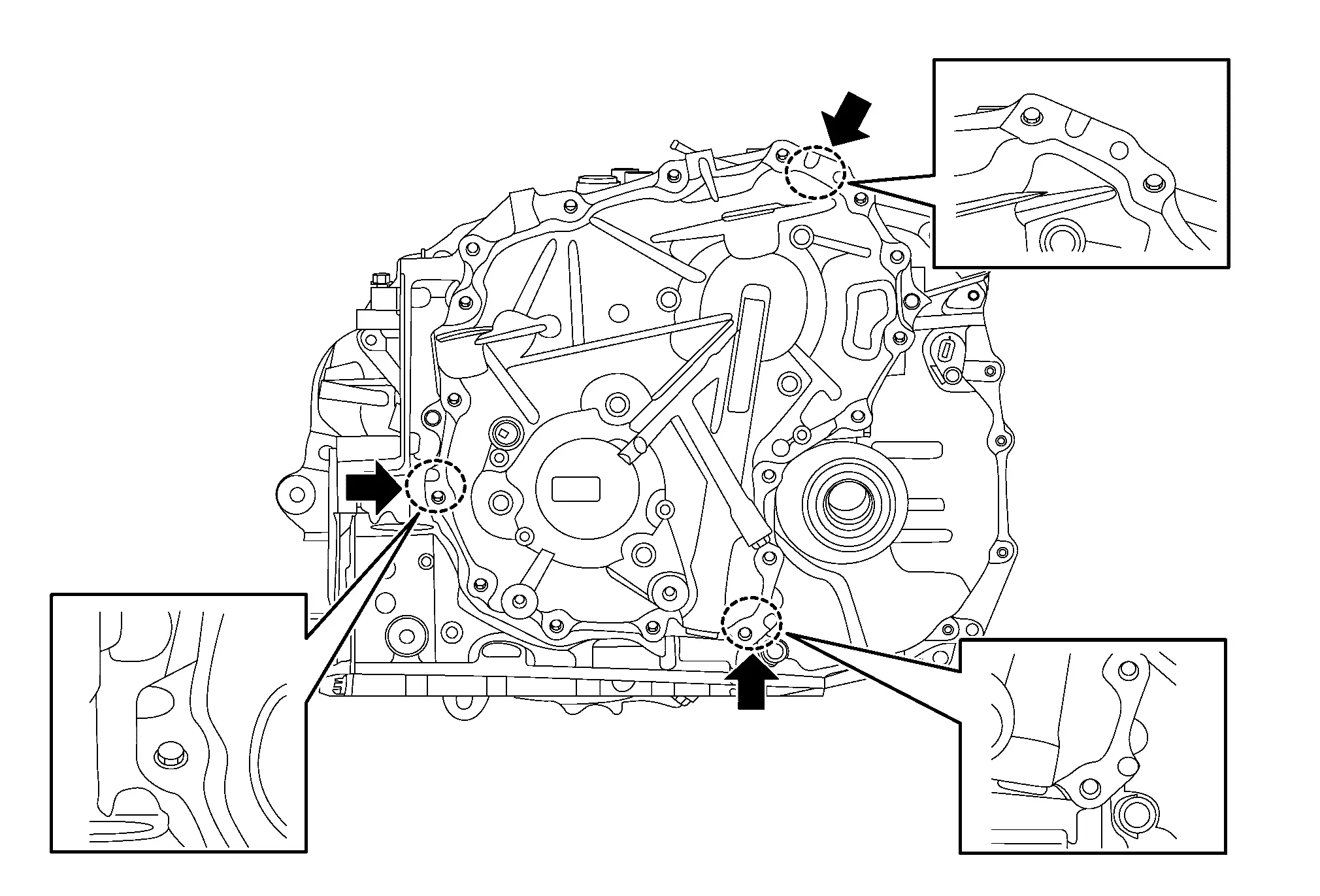

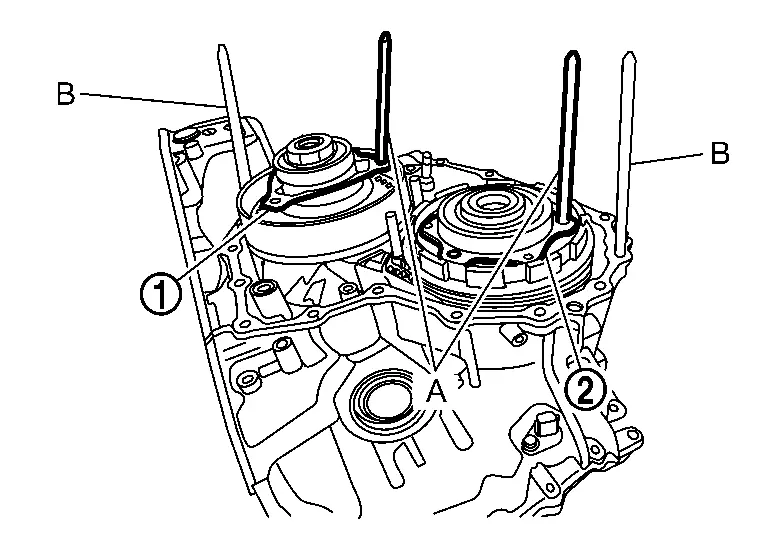

Remove converter housing by applying slide hammer [SST: KV315J0610

(NI-25721-A) ], slide hammer nut and bolt kit [SST: KV315J0630

(NI-50255-UPD)] and J hook case separator [SST: KV315J0620 (NI-51923)]

to two positions with arrow marks (  ).

).

Remove mounting bolt ( 3 pieces) remove the baffle plate C

3 pieces) remove the baffle plate C  from the converter housing.

from the converter housing.

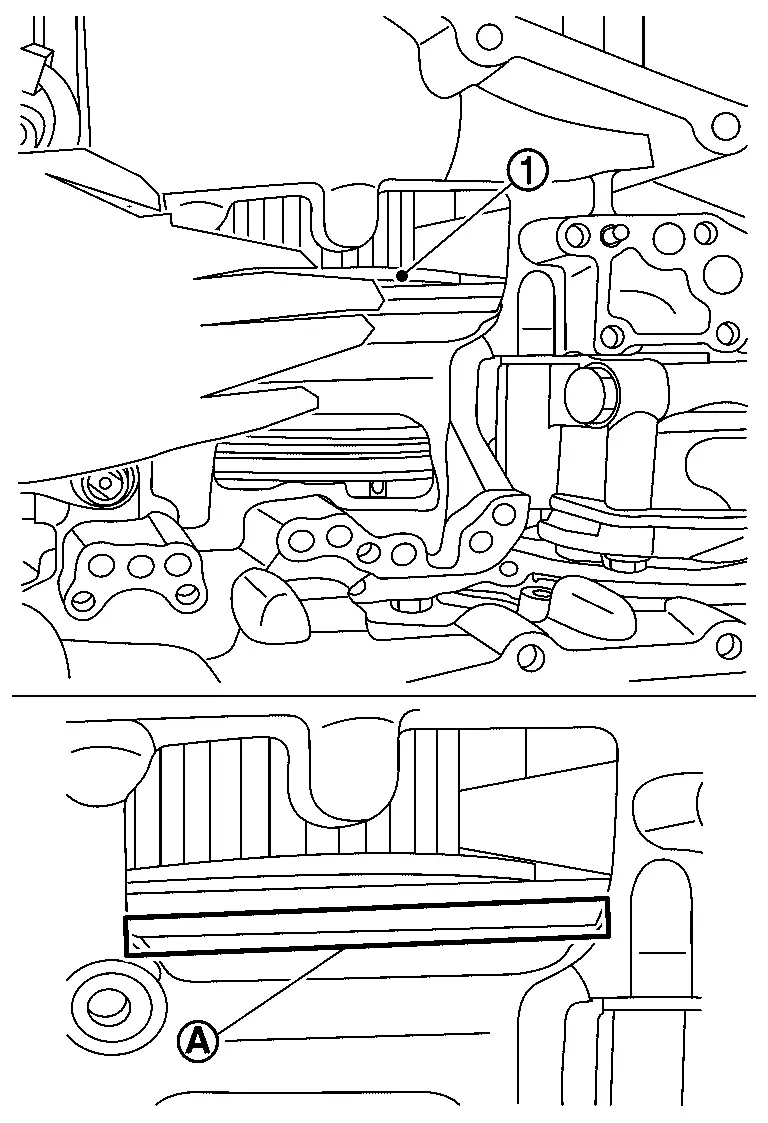

Check that retaining pin  of manual shaft locates on the original position.

of manual shaft locates on the original position.

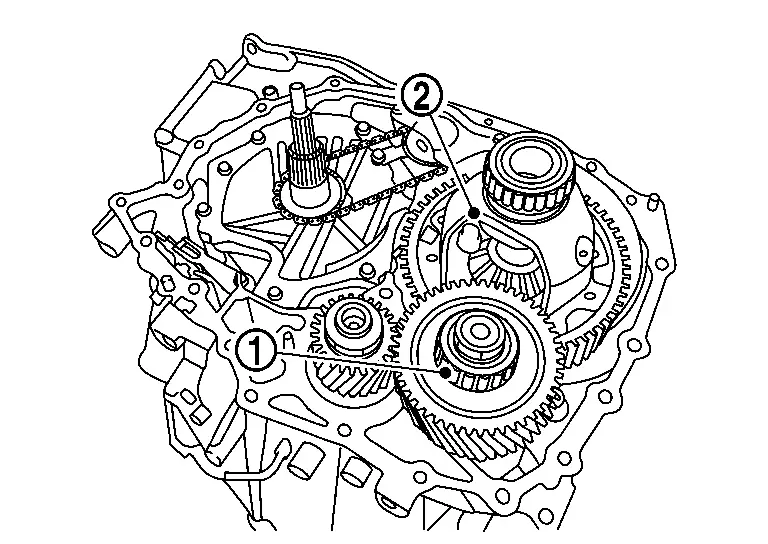

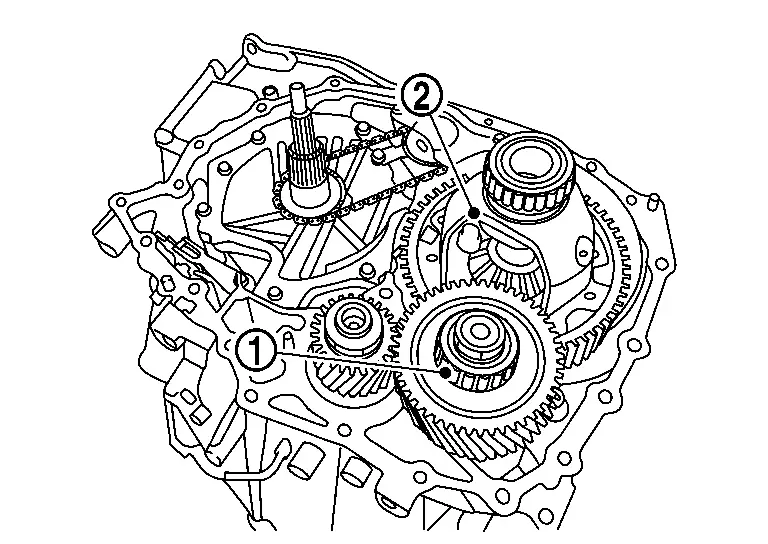

Remove reduction gear assembly  and differential assembly

and differential assembly  together.

together.

CAUTION:

Handle parts with care. Never reuse damaged parts, if dropped.

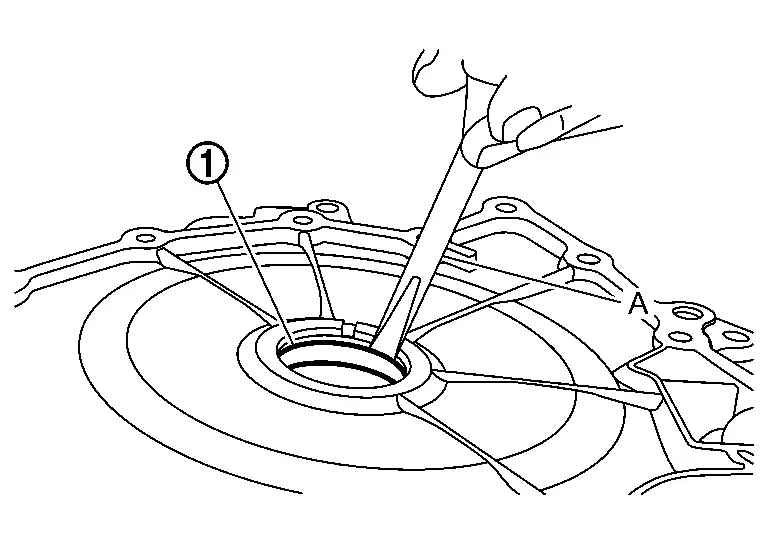

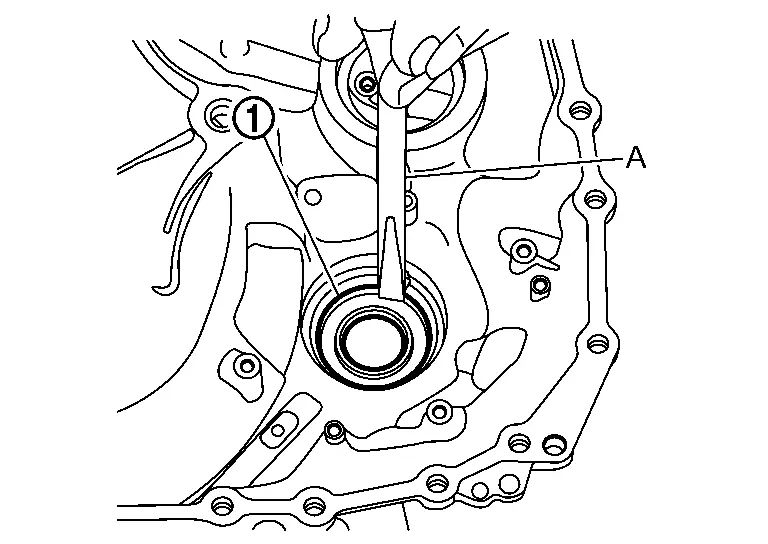

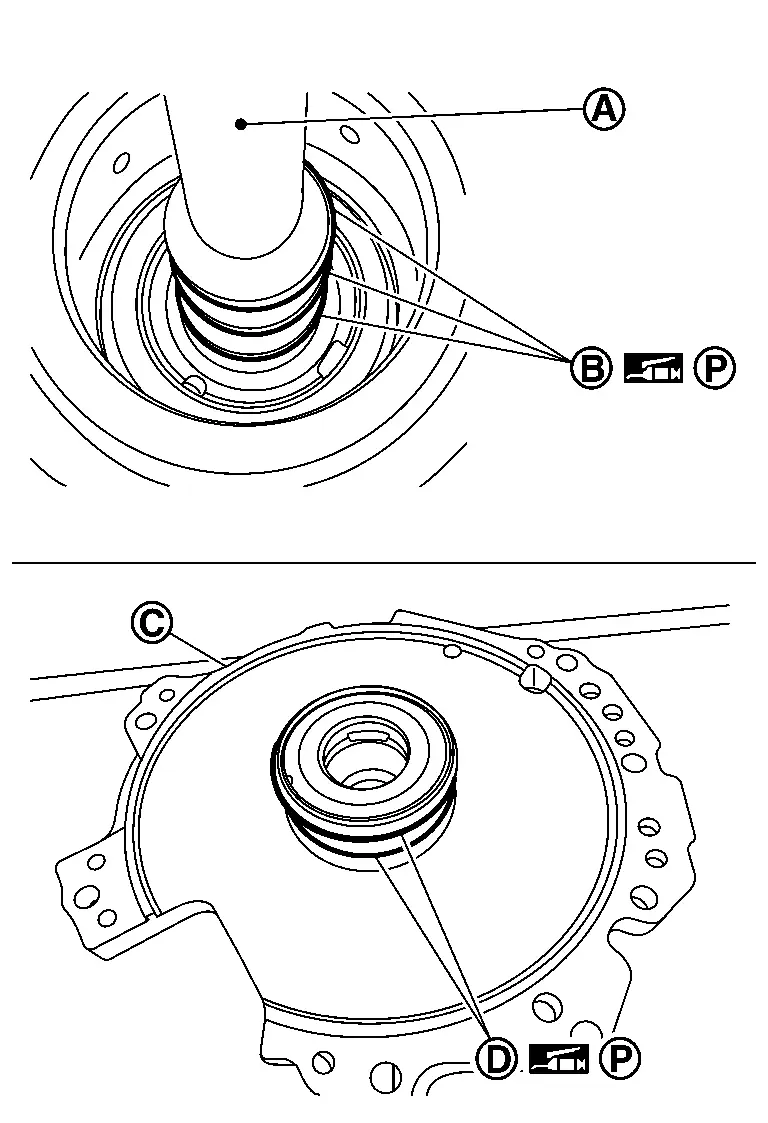

Remove converter housing oil seal  from converter housing using a suitable tool

from converter housing using a suitable tool  .

.

Remove differential oil seal  from converter housing using a suitable tool

from converter housing using a suitable tool  .

.

Remove differential oil seal  from transaxle assembly using a suitable tool

from transaxle assembly using a suitable tool  .

.

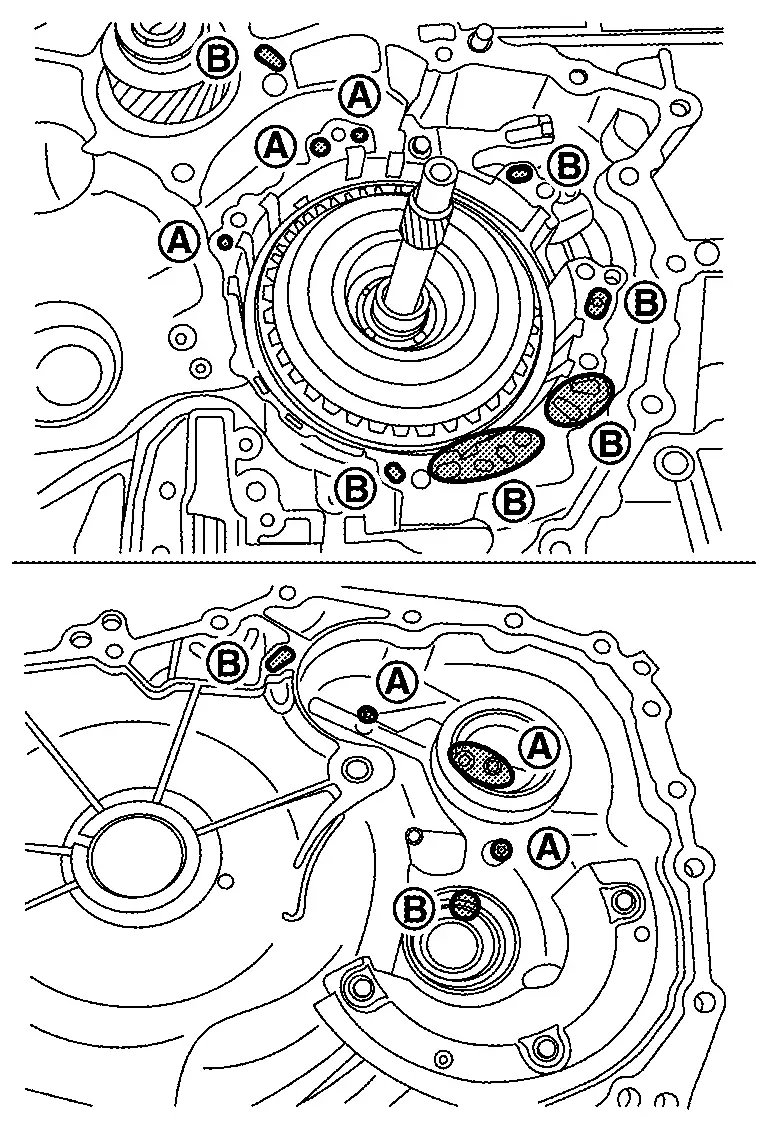

Remove mounting bolts  of baffle plate A and then remove baffle plate A

of baffle plate A and then remove baffle plate A  .

.

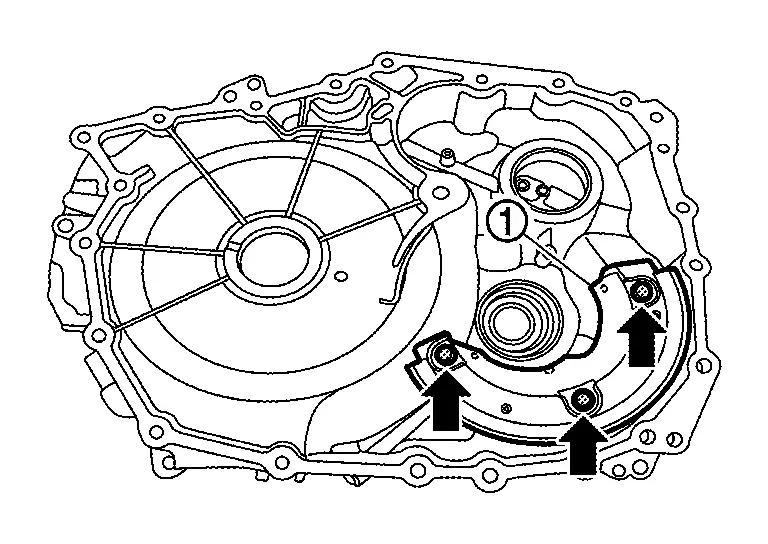

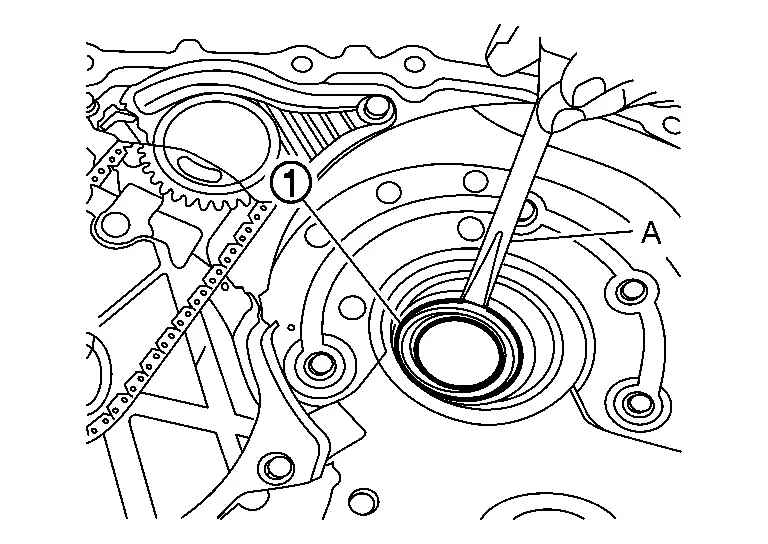

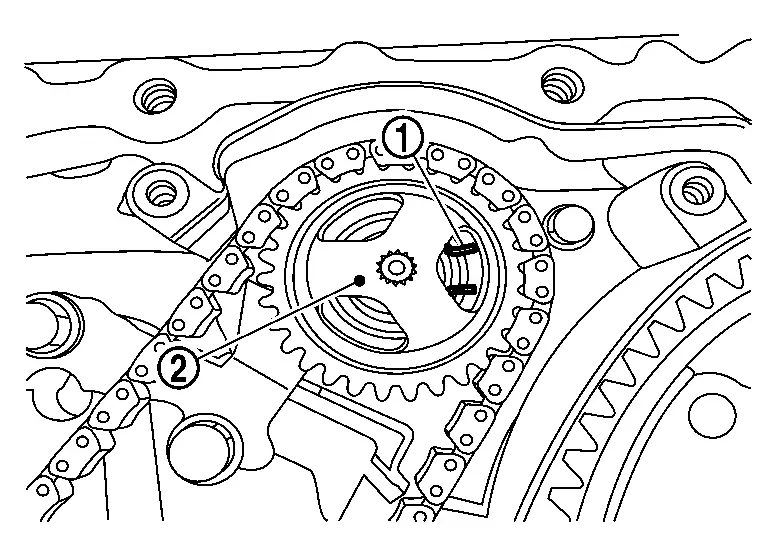

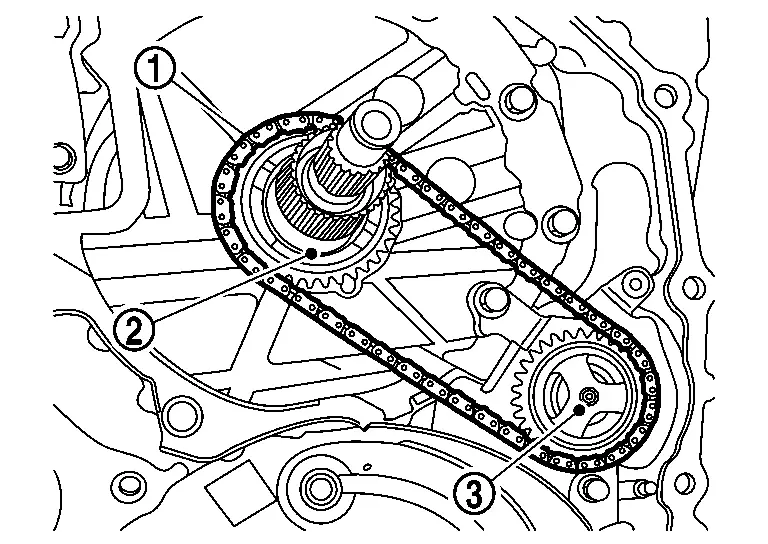

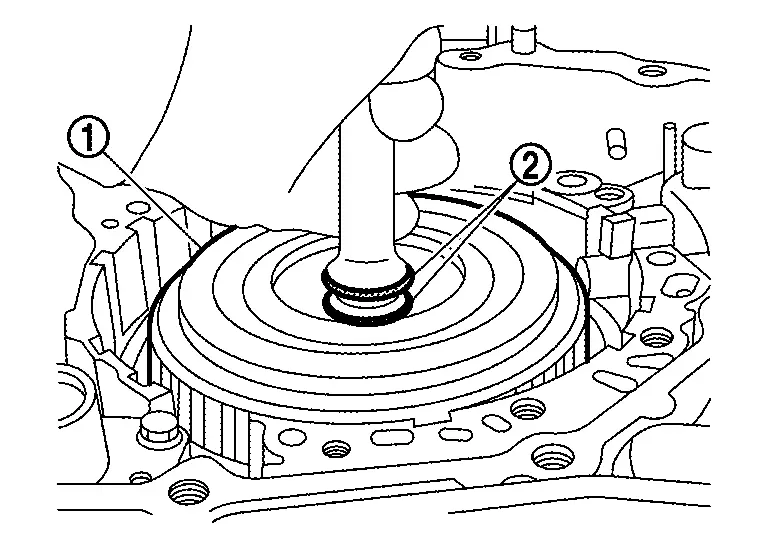

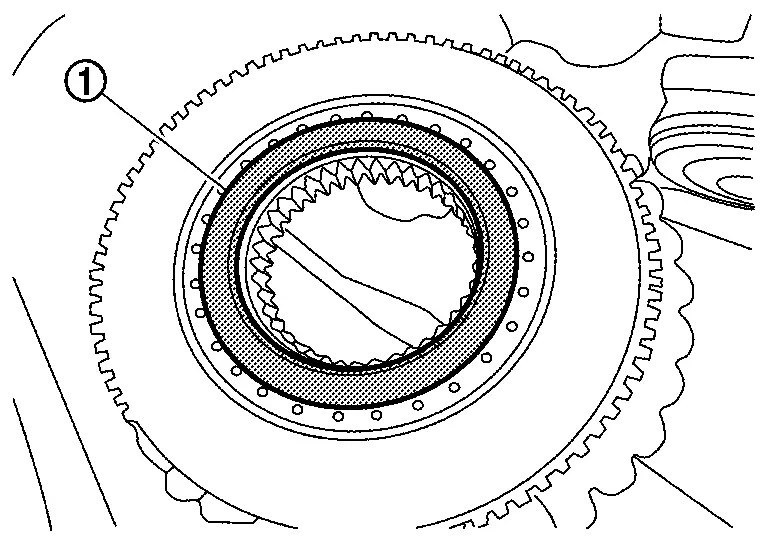

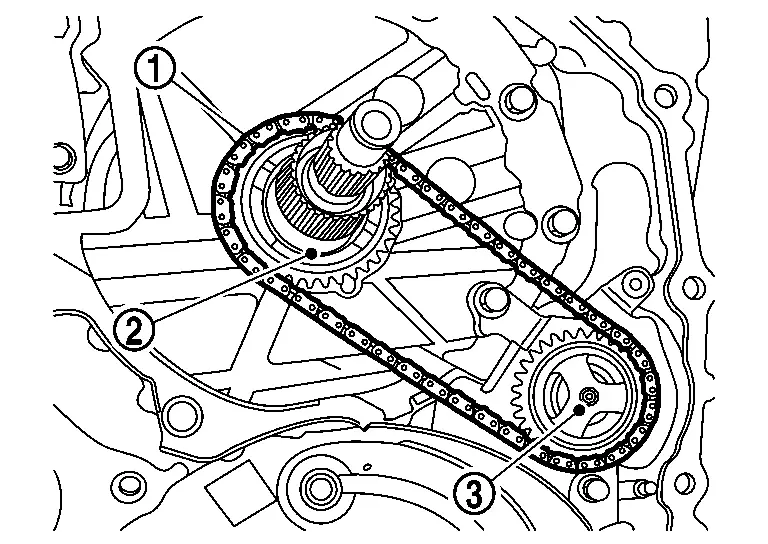

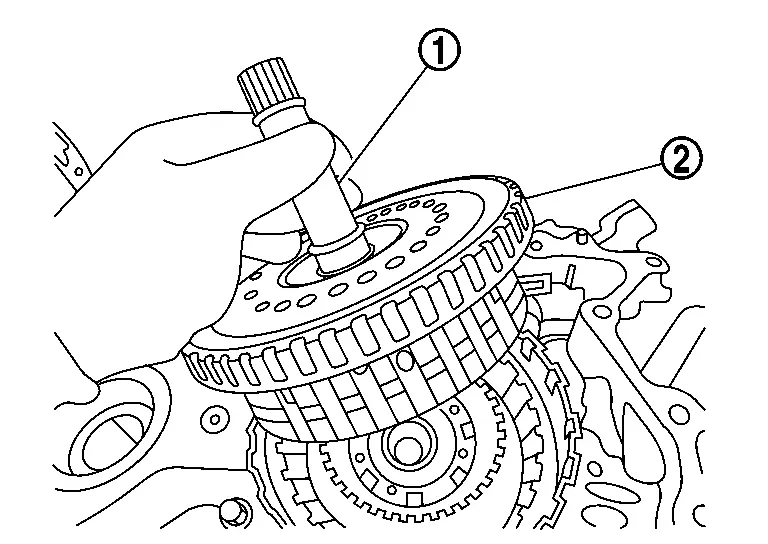

While expanding snap ring  of the oil pump with snap ring pliers, lift driven sprocket

of the oil pump with snap ring pliers, lift driven sprocket  and remove it.

and remove it.

Remove chain  , drive sprocket

, drive sprocket  and driven sprocket

and driven sprocket  all together.

all together.

Remove mounting bolts ( 7 pieces) of oil pump bracket and baffle plate B and then remove baffle plate B

7 pieces) of oil pump bracket and baffle plate B and then remove baffle plate B  and oil pump bracket

and oil pump bracket  .

.

Remove oil pump snap ring  .

.

Remove oil pump mounting bolt  .

.

CAUTION:

Remove O-ring because it cannot be reused.

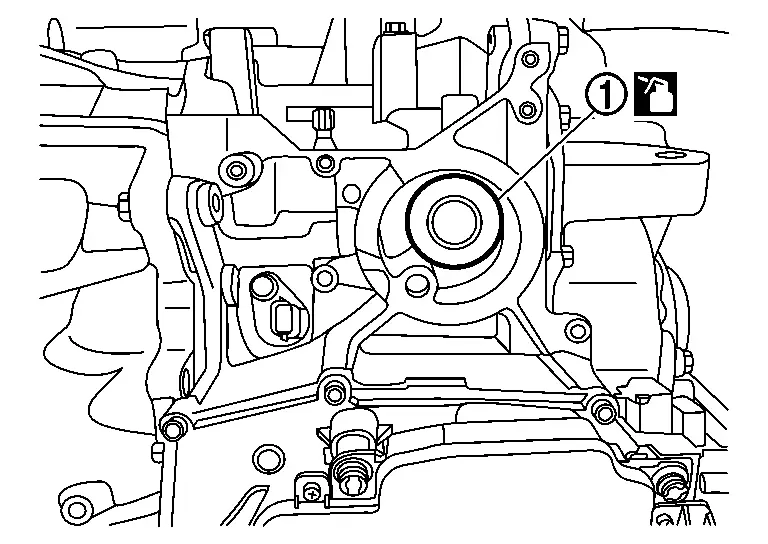

Remove oil pump mounting bolts  and then remove oil pump

and then remove oil pump  .

.

Remove thrust washer  .

.

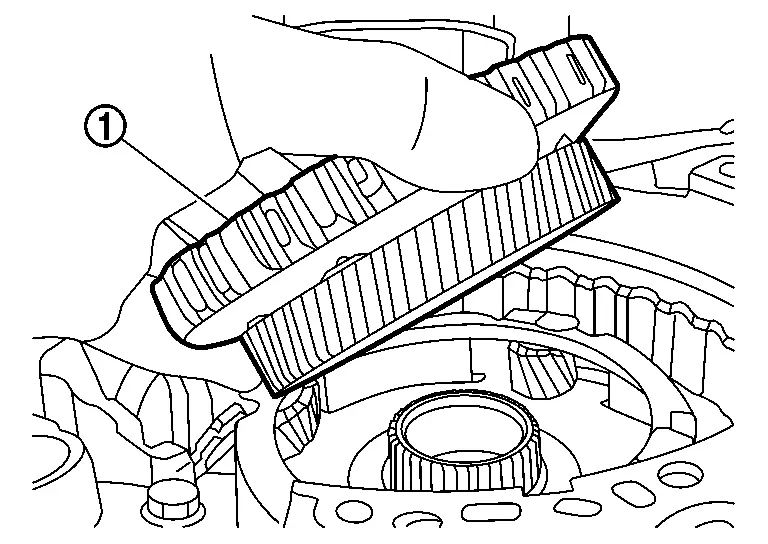

Remove mounting bolts ( 7 pieces) of dummy cover and baffle plate D, and then remove baffle plate D

7 pieces) of dummy cover and baffle plate D, and then remove baffle plate D  and dummy cover

and dummy cover  .

.

CAUTION:

-

Lift the dummy cover only.

-

Never lift input shaft because it causes lifting clutch pack assembly out.

-

Never remove lathe cut seals

from dummy cover. These seals will be reused.

from dummy cover. These seals will be reused.

Remove thrust bearing  from forward clutch assembly.

from forward clutch assembly.

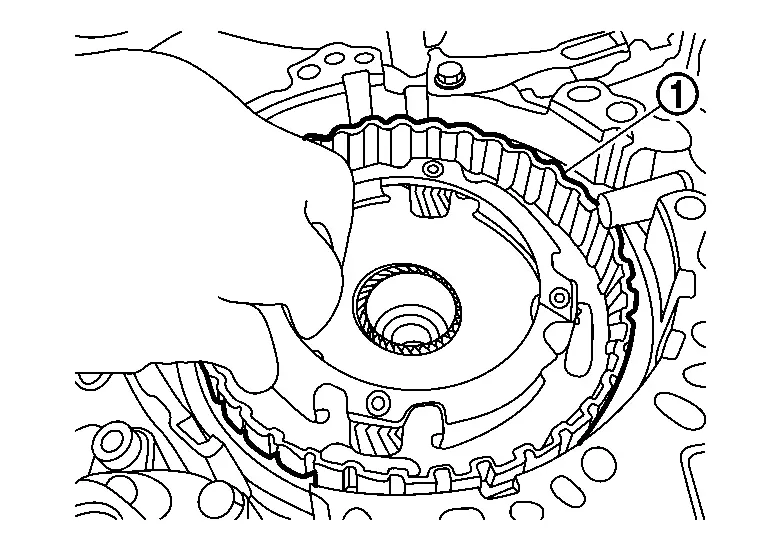

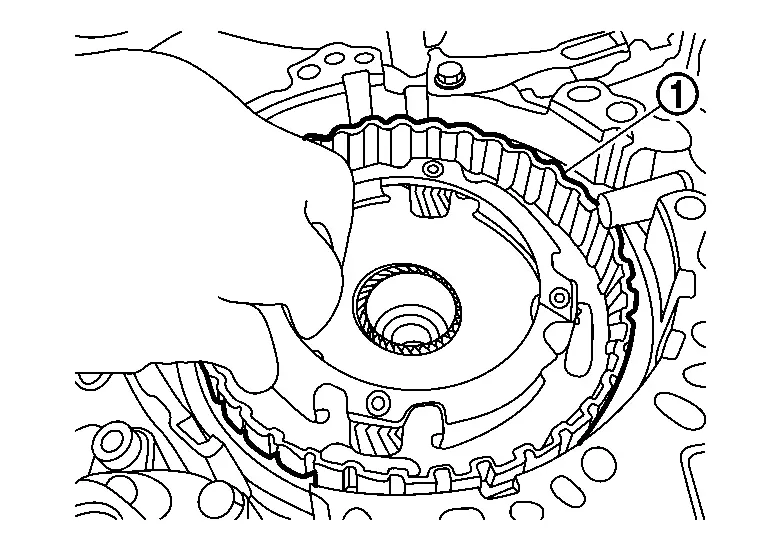

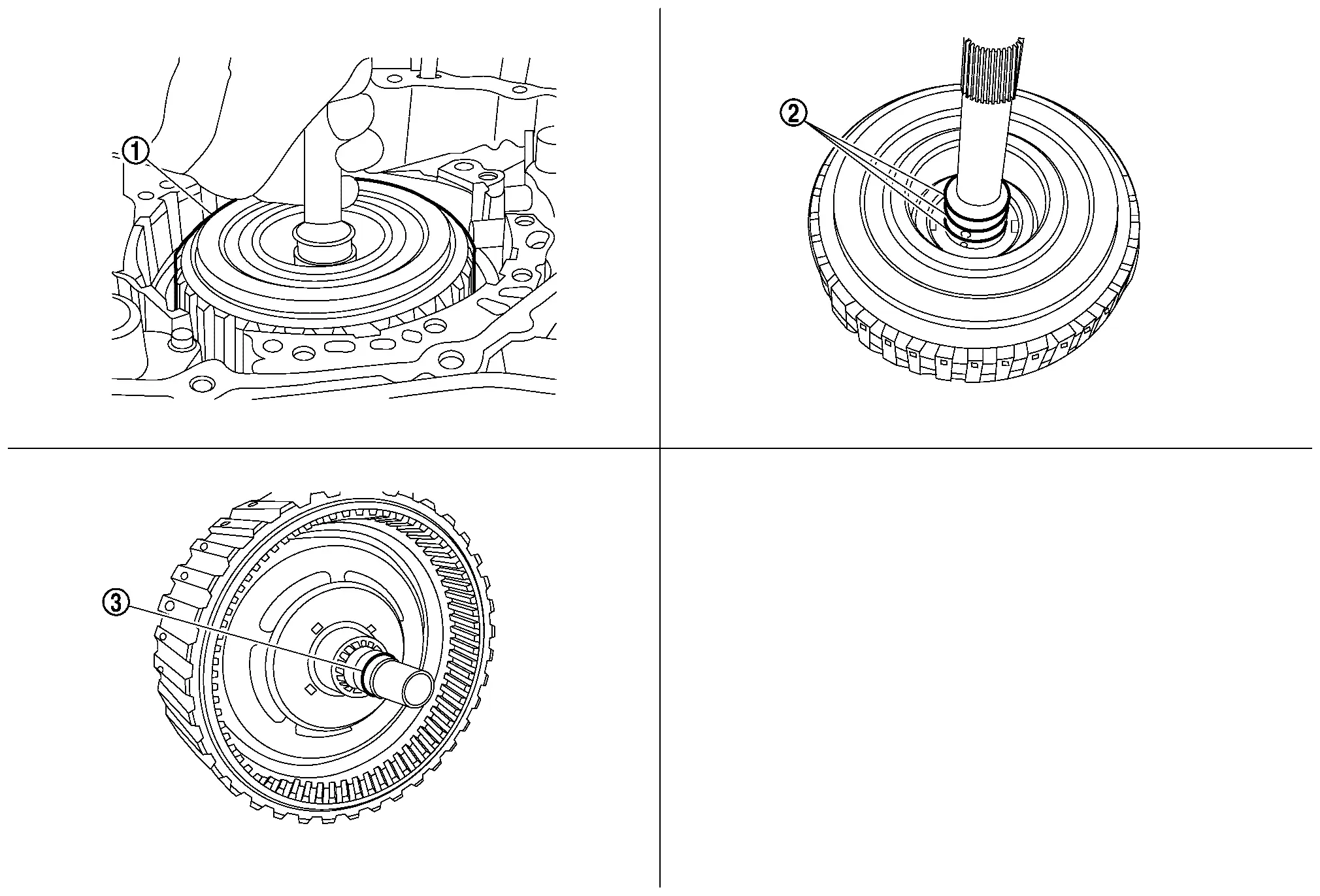

Remove forward clutch assembly  from transaxle case.

from transaxle case.

CAUTION:

Never handle lathe cut seals  on the input shaft when removing clutch assembly. These seals will be reused.

on the input shaft when removing clutch assembly. These seals will be reused.

Remove thrust bearing  which exists between forward clutch assembly and sun gear.

which exists between forward clutch assembly and sun gear.

NOTE:

NOTE:

The thrust bearing has two sides. Memorize or take a note of the original surface before removing for assembling procedure.

Remove sun gear  from planetary carrier.

from planetary carrier.

Remove thrust bearing  which exists on primary pulley side of sun gear.

which exists on primary pulley side of sun gear.

NOTE:

NOTE:

The thrust bearing has two sides. Memorize or take a note of the original surface before removing for assembling procedure.

Remove planetary carrier  from transaxle case.

from transaxle case.

Remove thrust bearing  from planetary carrier.

from planetary carrier.

NOTE:

NOTE:

-

The thrust bearing has two sides. Memorize or take a note of the original surface before removing for assembling procedure.

-

Thrust bearing may remain on the transaxle case.

Thoroughly clean the mating surfaces of the transaxle case and torque converter housing.

NOTE:

NOTE:

A plastic scraper can be used.

CAUTION:

-

Never use sanding discs, similar abrasive tools, or metal blades.

-

Use parts cleaner or equivalent solvent and lint-free paper only.

-

Make sure the parts cleaner or solvents used are compatible with local regulations.

-

Prevent debris from entering in the CVT.

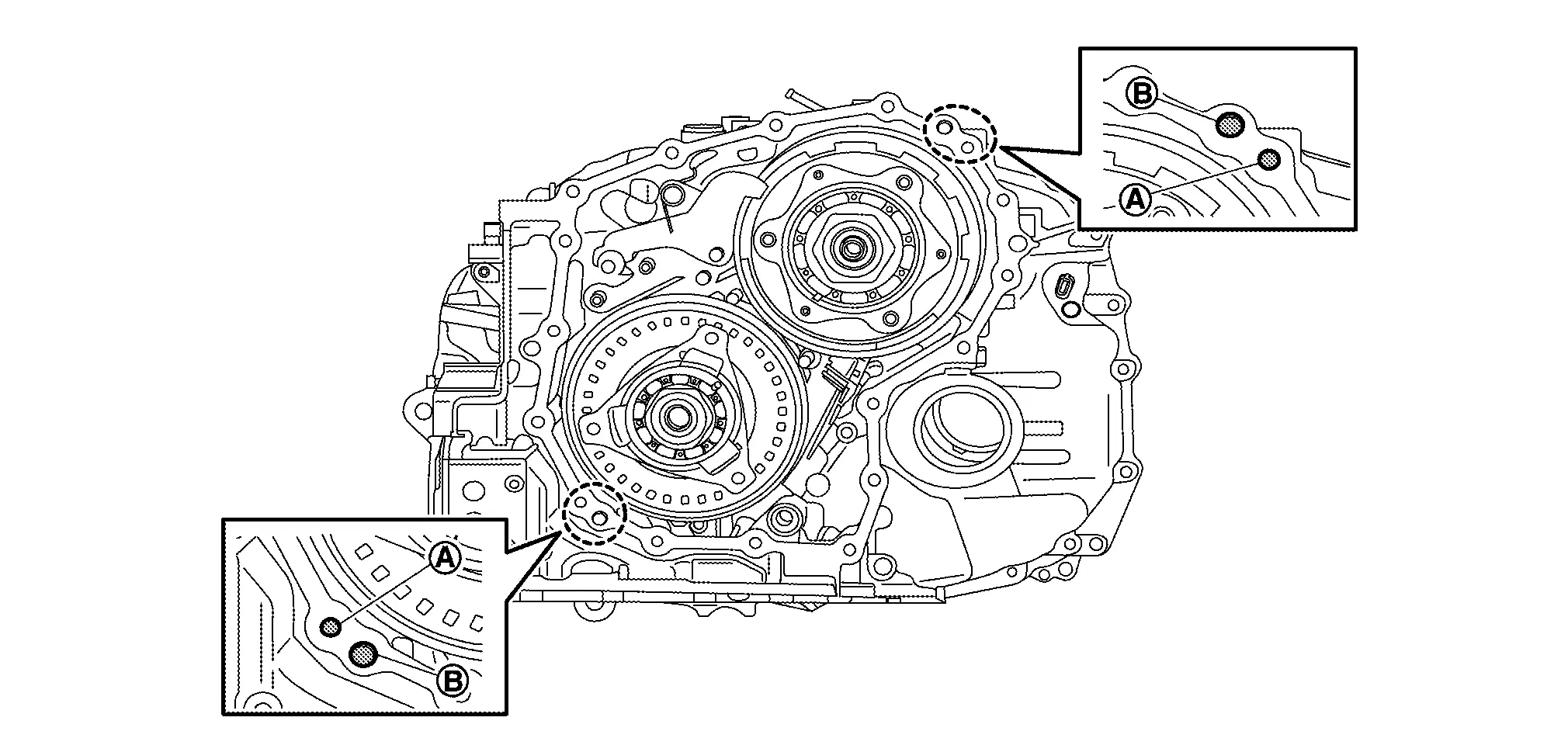

Make sure rust and foreign materials have been cleaned off of dowel pins  and receiving holes

and receiving holes  .

.

NOTE:

NOTE:

Use small wire brush or similar tool at the inside surface of dowel pin holes. Never scrape transaxle case mating surfaces.

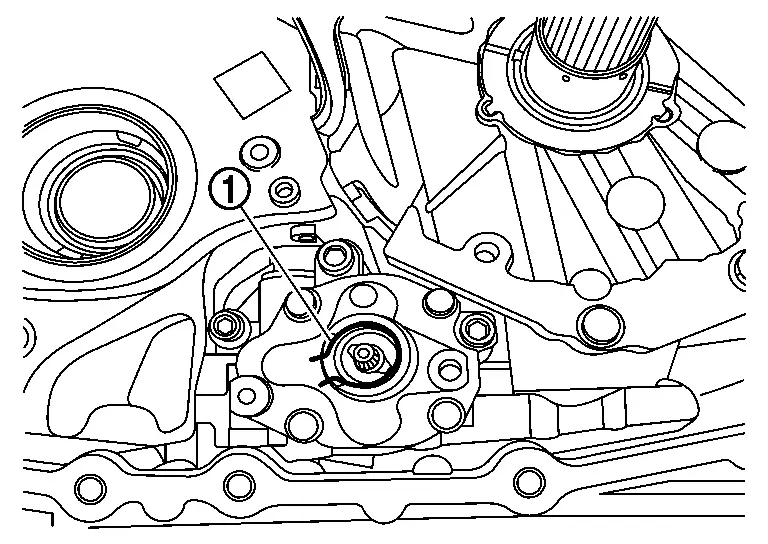

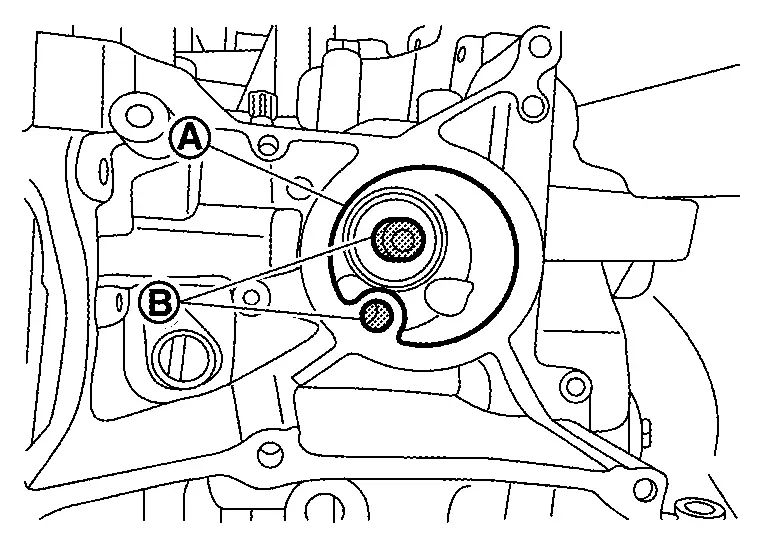

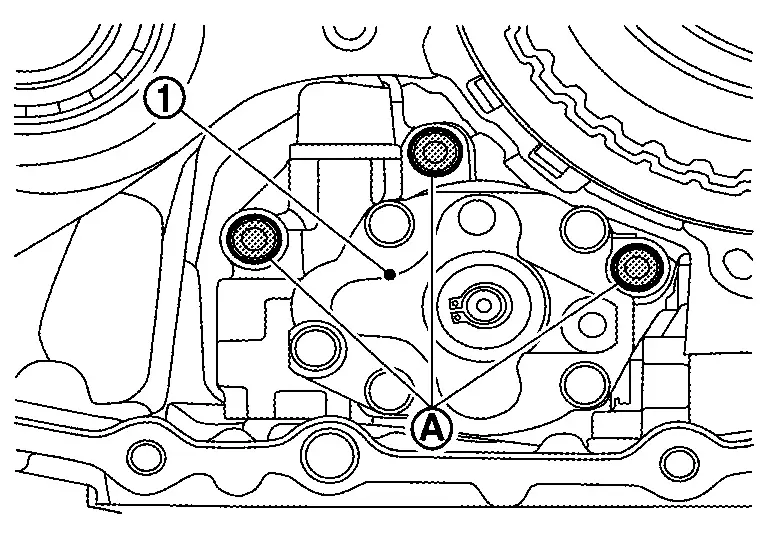

Clean around oil filter  and hydraulic circuits

and hydraulic circuits  with parts cleaner and compressed air

with parts cleaner and compressed air

WARNING:

Wear eye and face protection when using compressed air and cleaning fluid.

CAUTION:

-

Regulate air pressure up to a maximum of 517 kPa (5.27 kg/cm2, 75 psi).

-

Prevent foreign materials from entering the CVT.

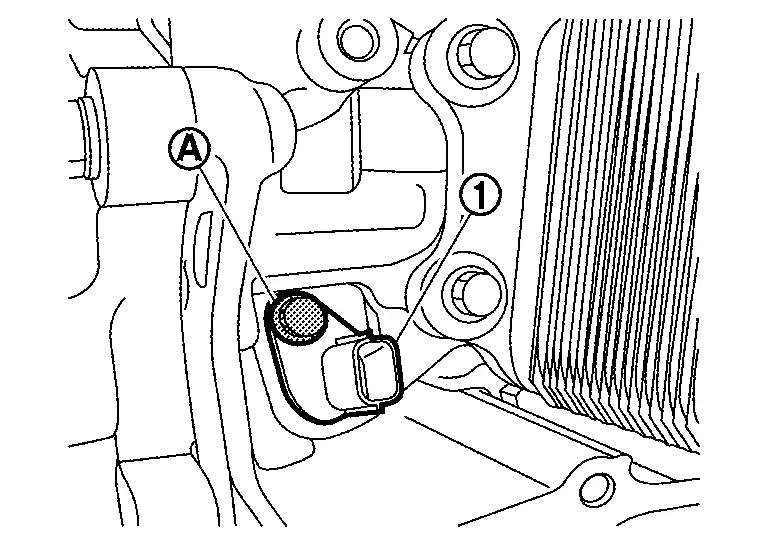

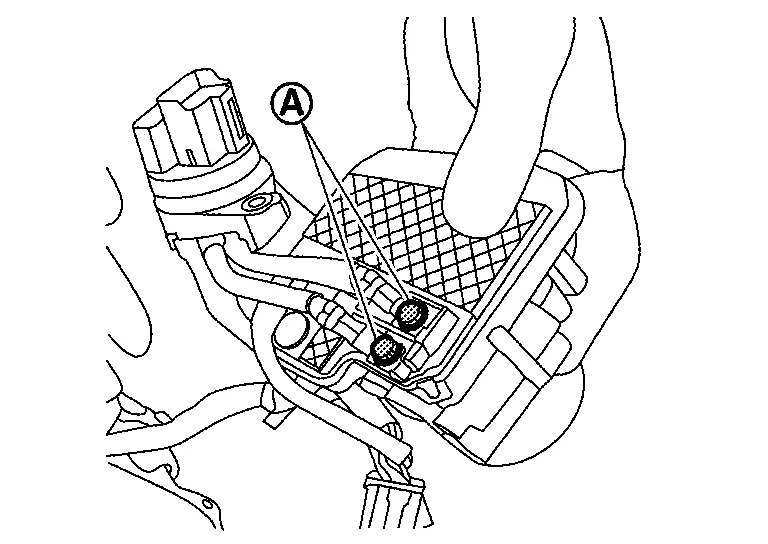

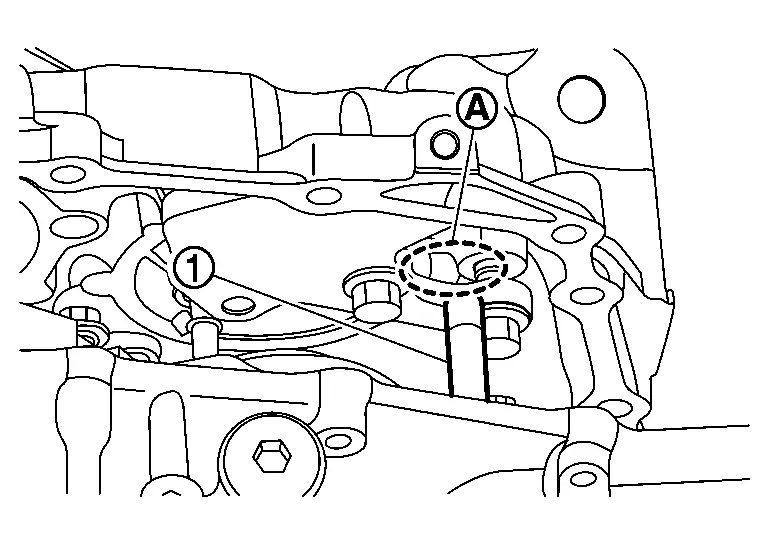

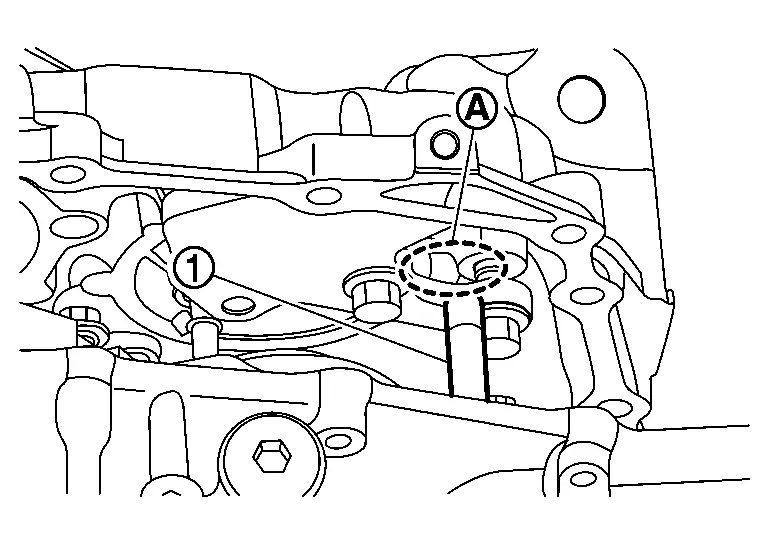

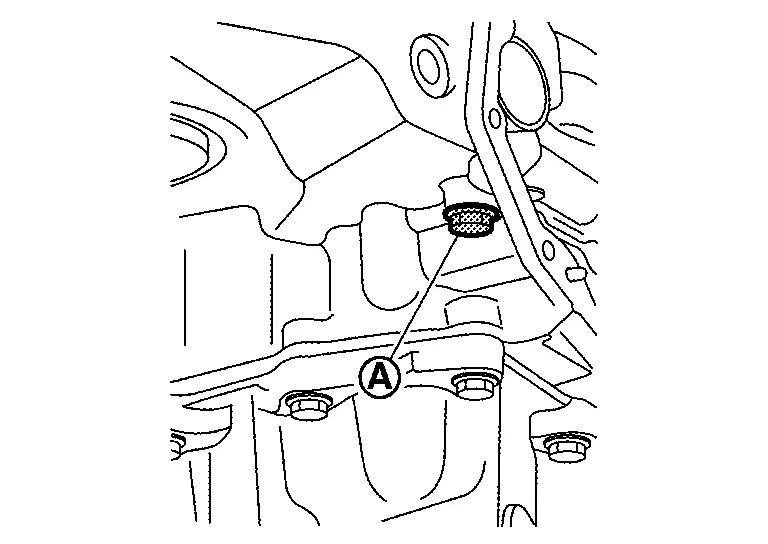

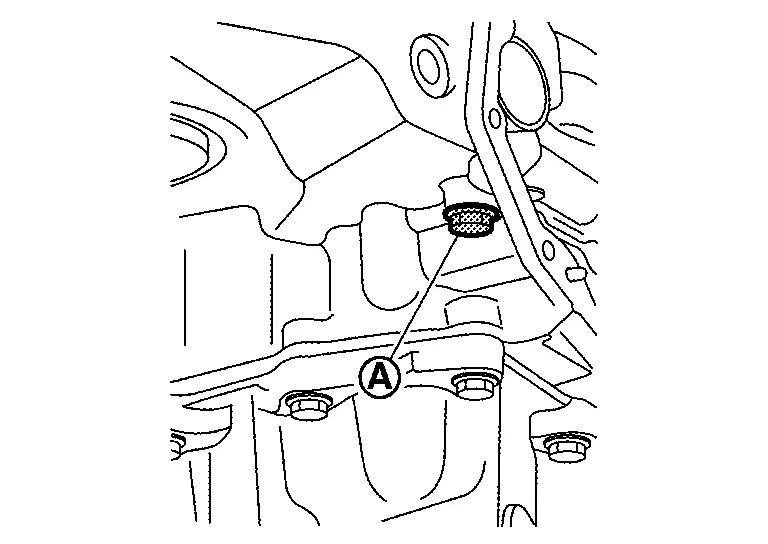

While cleaning around CVT oil warmer  and hydraulic circuit

and hydraulic circuit  with parts cleaner and blowing air.

with parts cleaner and blowing air.

Check hole  for blowing air.

for blowing air.

CAUTION:

When blowing air, be careful not to get foreign materials in the eyes.

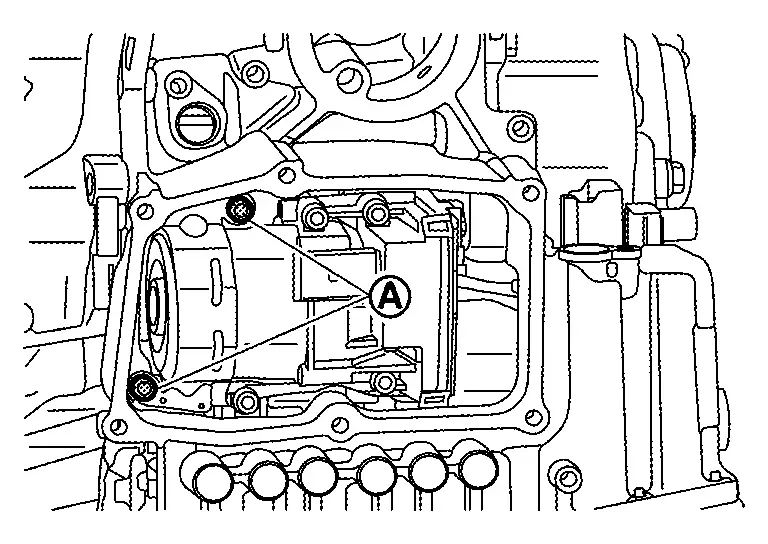

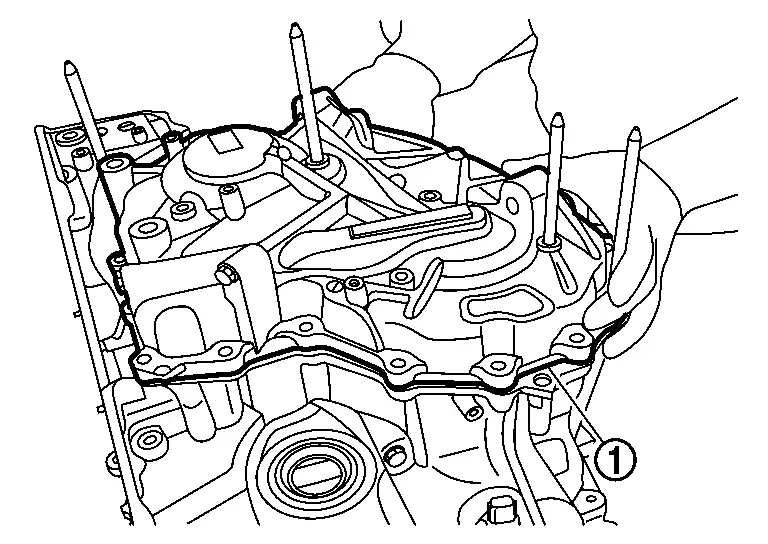

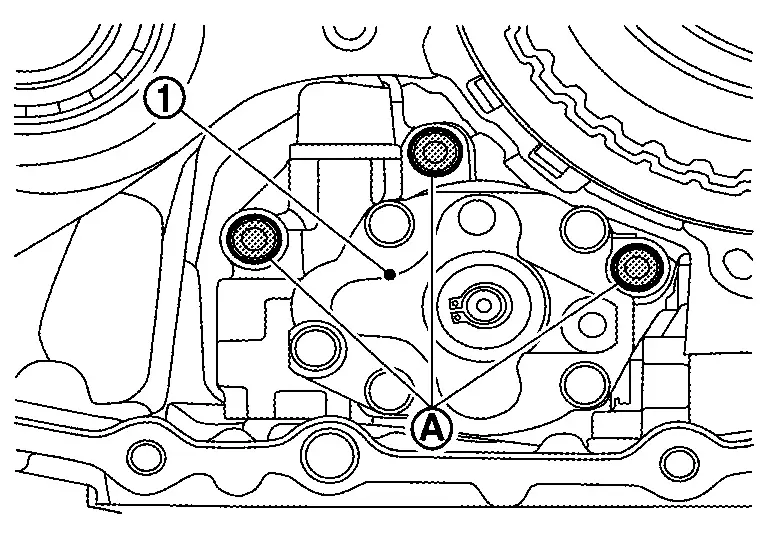

While cleaning mating surface of control valve and control valve hydraulic circuits  with parts cleaner and blowing air.

with parts cleaner and blowing air.

Check holes  for blowing air.

for blowing air.

CAUTION:

-

When blowing air, be careful not to get foreign materials in the eyes.

-

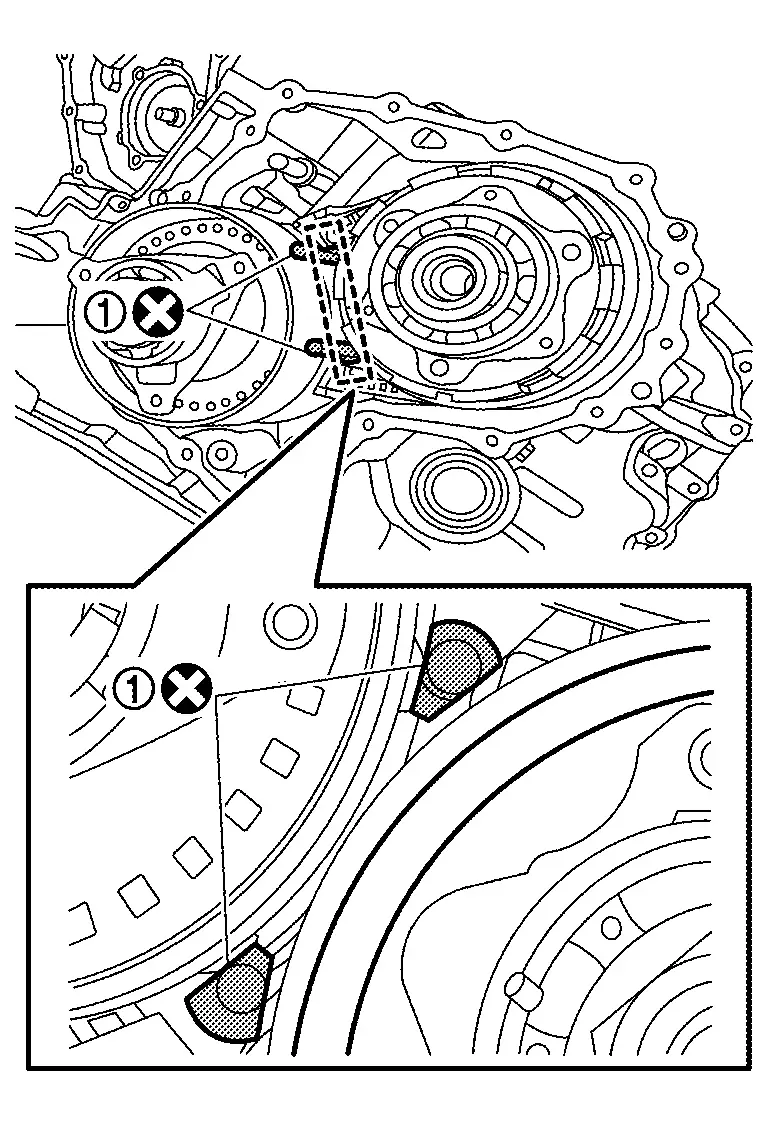

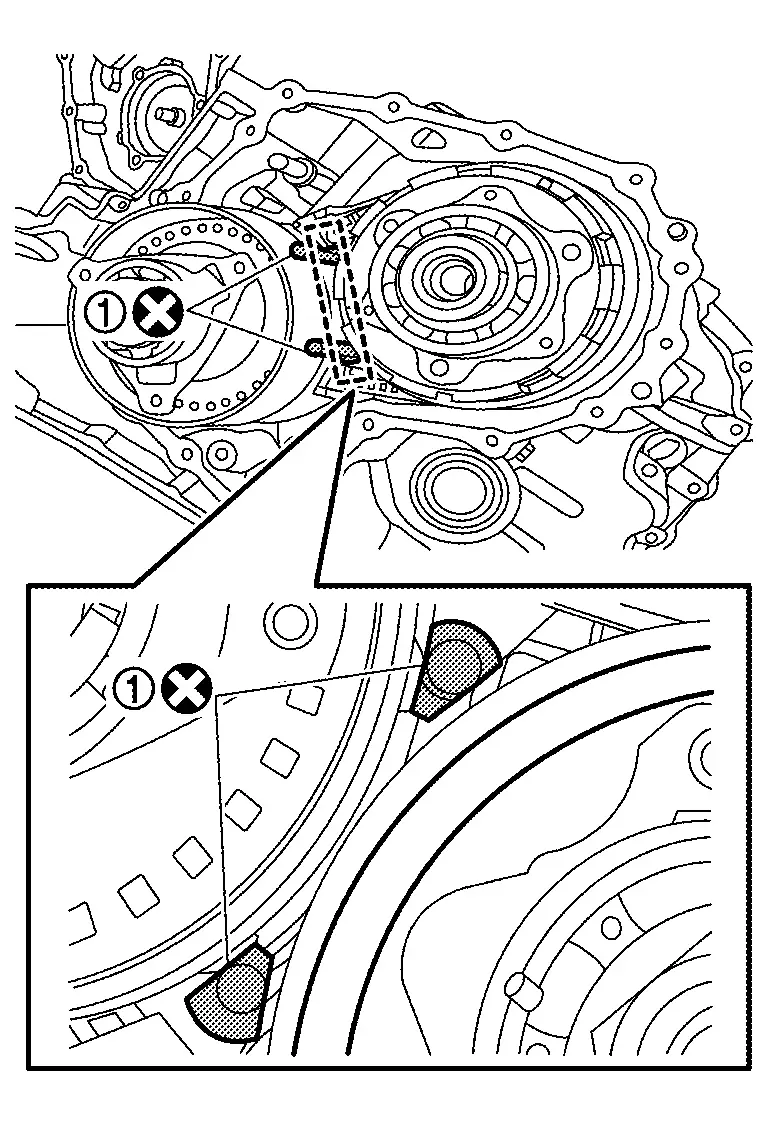

Never blow air in the clutch circuit

.

.

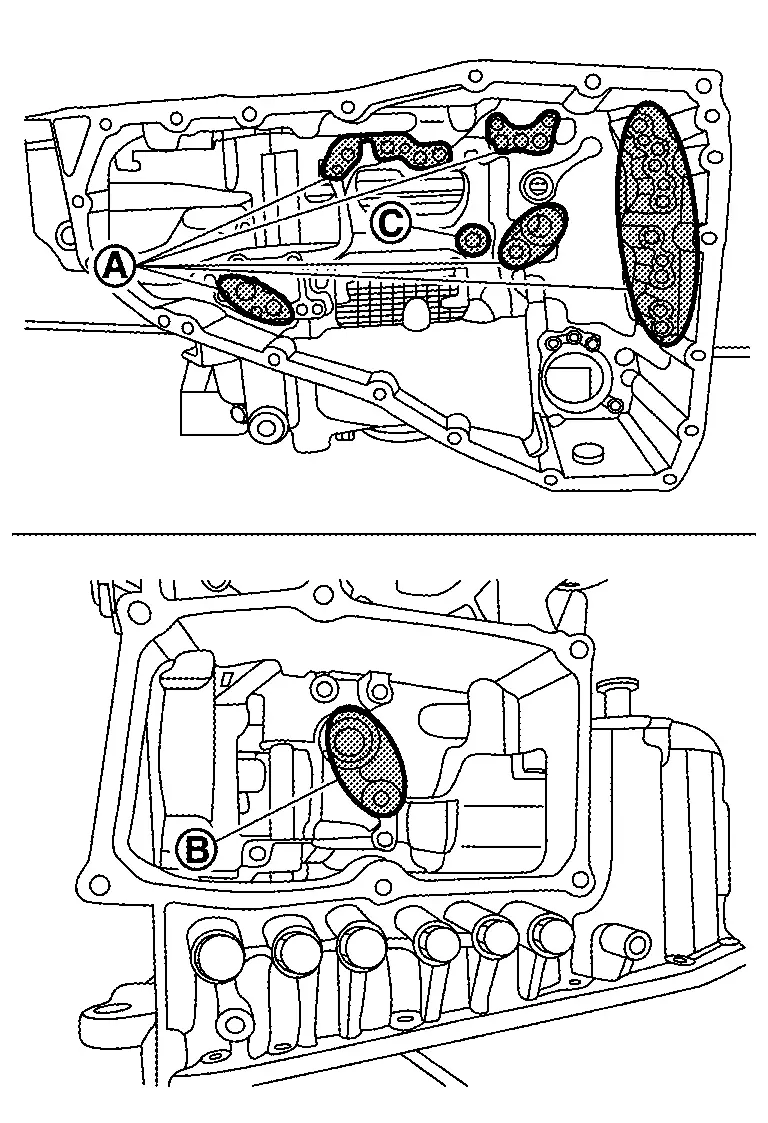

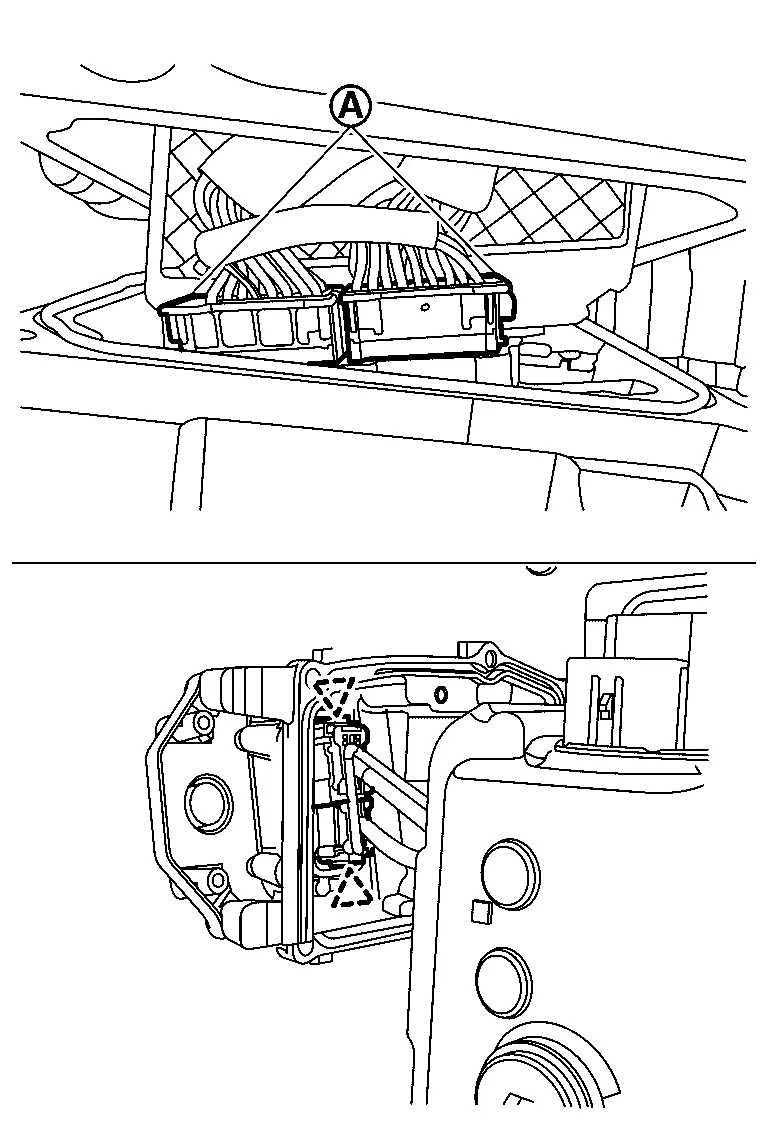

Clean hydraulic circuits  of converter housing with parts cleaner and blowing air.

of converter housing with parts cleaner and blowing air.

Check holes  for blowing air.

for blowing air.

CAUTION:

When blowing air, be careful not to get foreign materials in the eyes.

Clean hydraulic circuit  of dummy cover with parts cleaner and blowing air.

of dummy cover with parts cleaner and blowing air.

Check holes  for blowing air.

for blowing air.

CAUTION:

When blowing air, be careful not to get foreign materials in the eyes.

Temporarily install converter housing to transaxle case by using only three of old converter housing mounting bolts to tighten them in a triangular shape.

NOTE:

NOTE:

Two bolts are oppositely tightened.

Temporarily install converter housing to transaxle case by using only four of the old converter housing mounting bolts to tighten them in a square shape.

Place transaxle assembly with converter housing side as the bottom.

Remove the temporarily fixed oil pan.

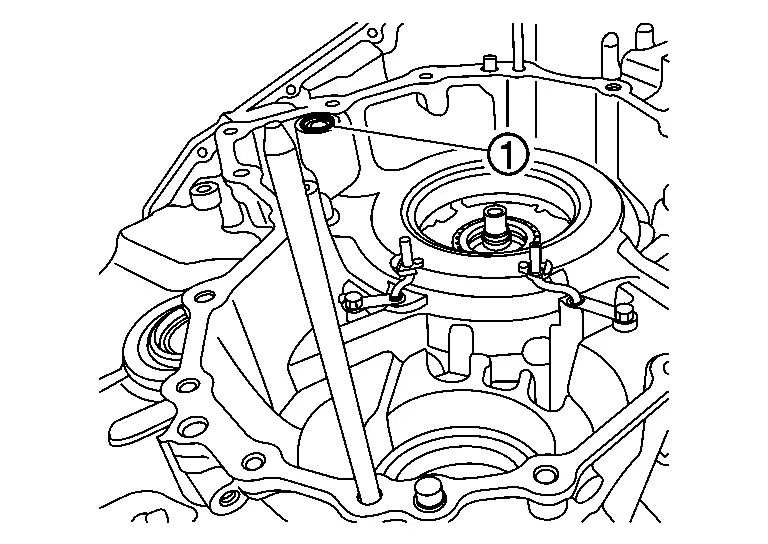

Rotate the primary pulley  by hand to check the pulley's rotational characteristics.

by hand to check the pulley's rotational characteristics.

CAUTION:

Never place fingers between the pulley and the transaxle case  .

.

NOTE:

NOTE:

Memorize the pulley's rotational characteristics.

This is used as a reference after the sub assembled new side cover, pulleys and belt were installed.

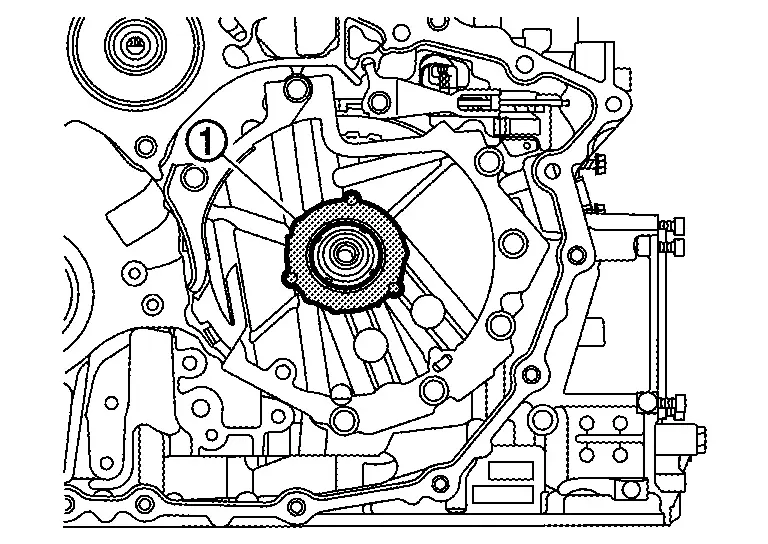

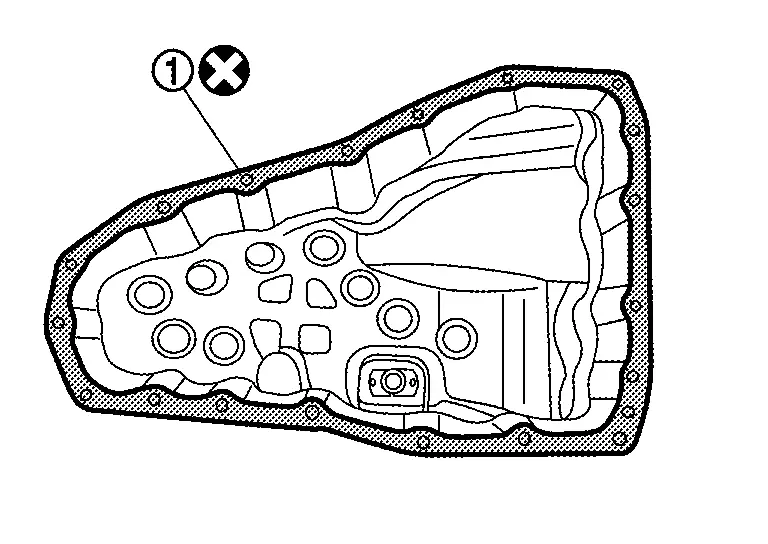

Remove side cover mounting bolts ( 17 pieces).

17 pieces).

Remove pulley retainer mounting bolts ( 6 pieces).

6 pieces).

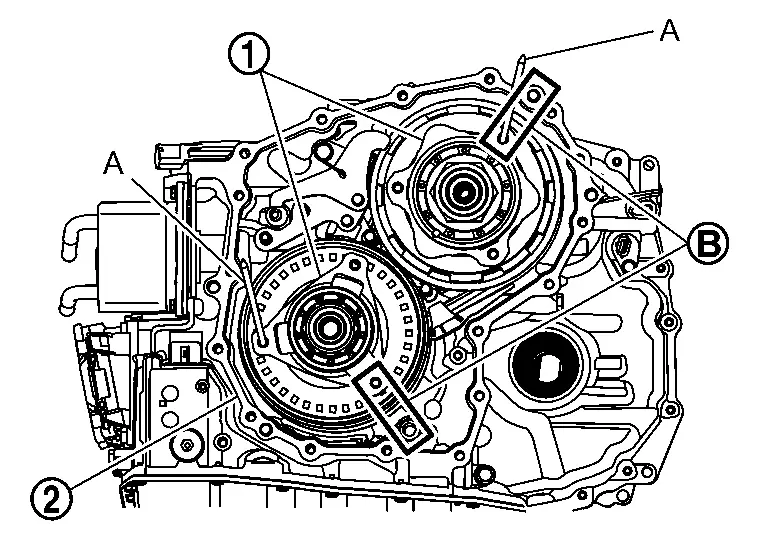

Remove side cover by applying slide hammer [SST: KV315J0610

(NI-25721-A) ], slide hammer nut and bolt kit [SST: KV315J0630

(NI-50255-UPD)] to three positions with arrow marks ( ).

).

Remove lubrication caps  .

.

CAUTION:

Never reuse the lubrication cap.

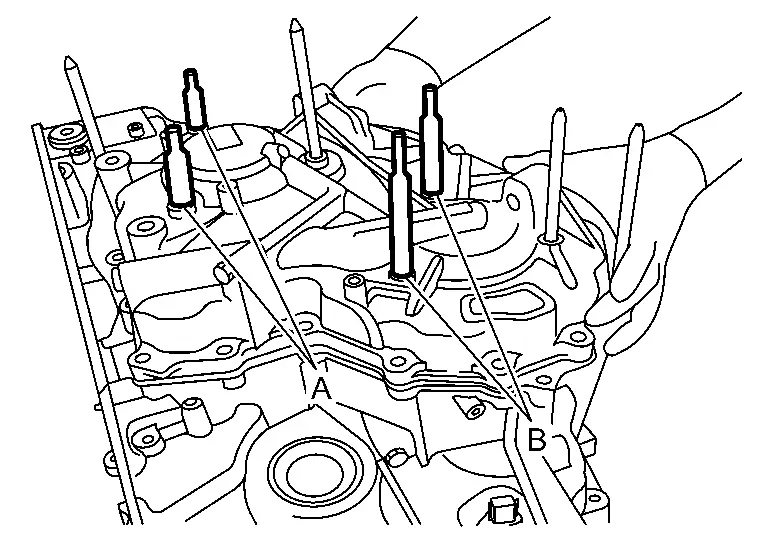

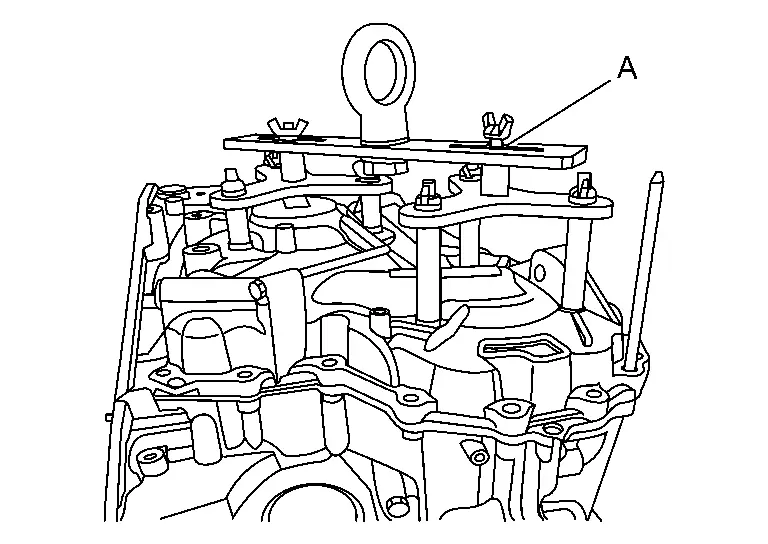

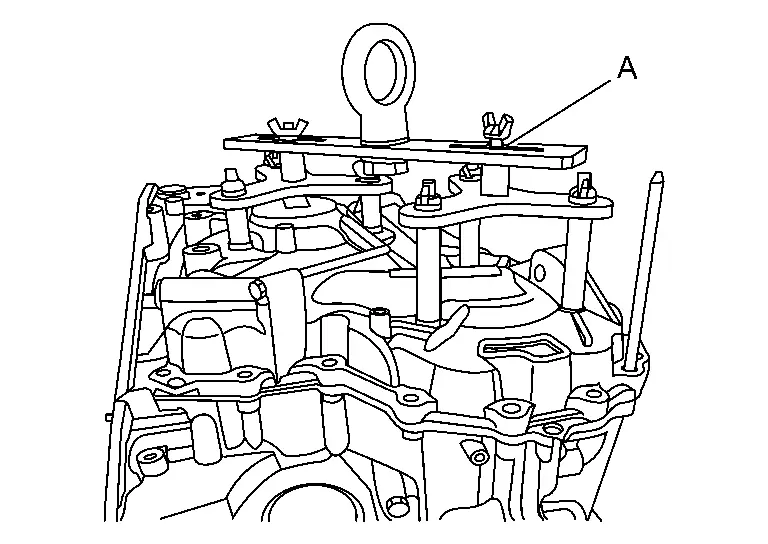

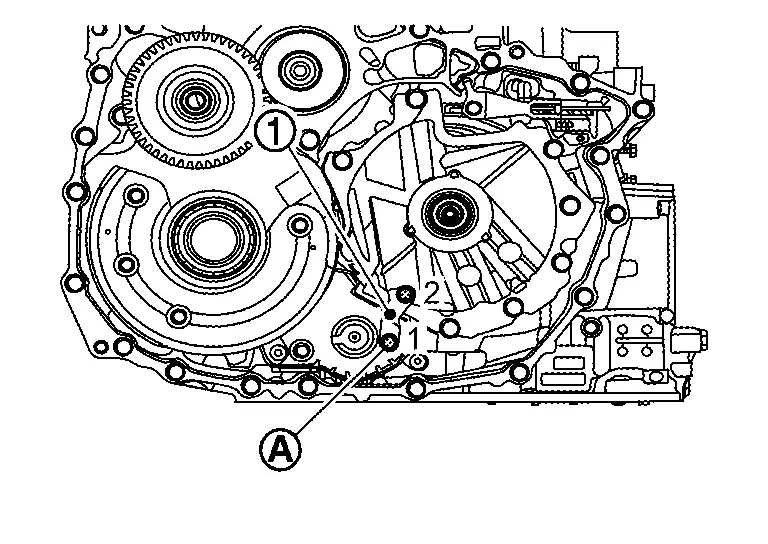

Attach the locator guide pin (SST: NI-53066) to the specified bolt holes  .

.

NOTE:

NOTE:

Guide pins must be placed next to dowel pins  .

.

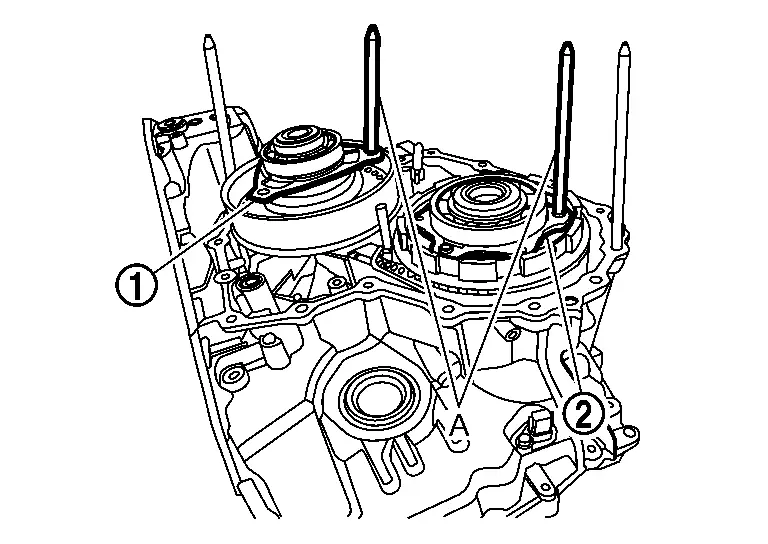

Install pulley bracket guide pin [SST: KV31500300 (NI-52272)]  to primary pulley bearing retainer

to primary pulley bearing retainer  and secondary pulley retainer

and secondary pulley retainer  .

.

CAUTION:

Be careful not to let guide pin to touch the bottom.

Rotate each pulley bracket  to align with holes and assembly guide pins, pulley bracket [SST: KV31500300 (NI-52272)]

to align with holes and assembly guide pins, pulley bracket [SST: KV31500300 (NI-52272)]  in the transaxle case

in the transaxle case  .

.

|

: Align holes |

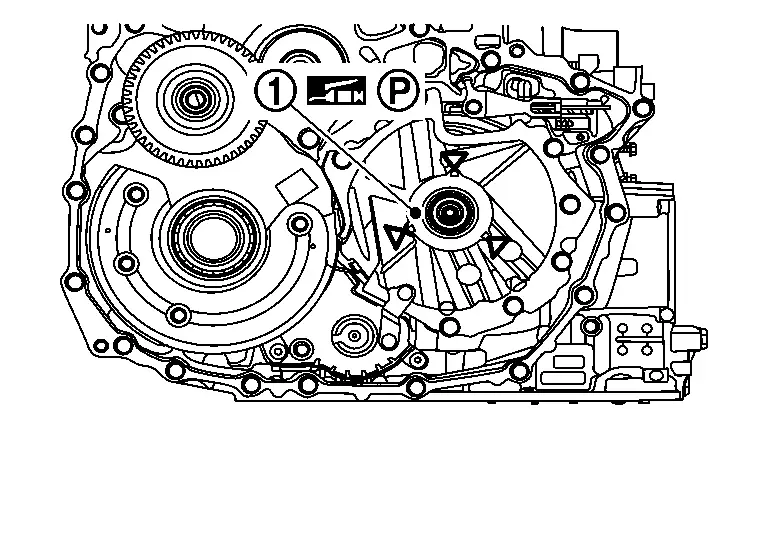

Install side cover  .

.

NOTE:

NOTE:

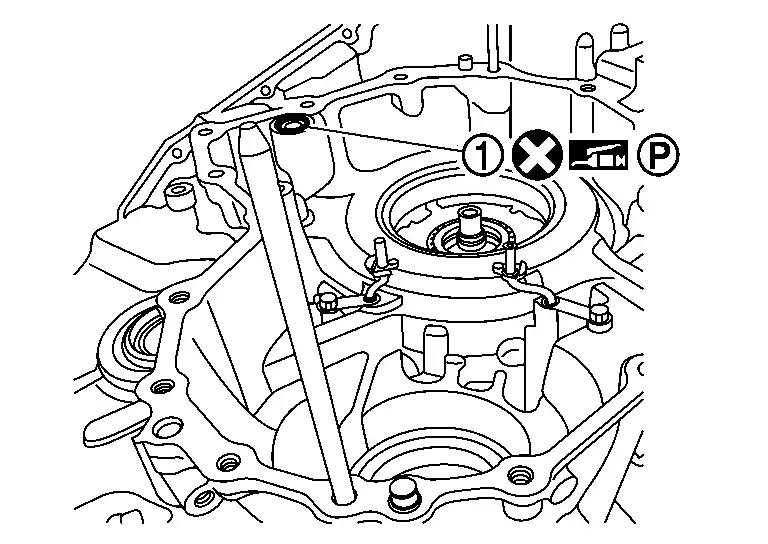

When installing side cover, insert parking rod  to parking pawl area

to parking pawl area  .

.

CAUTION:

Check that manual shaft is 'N' position.

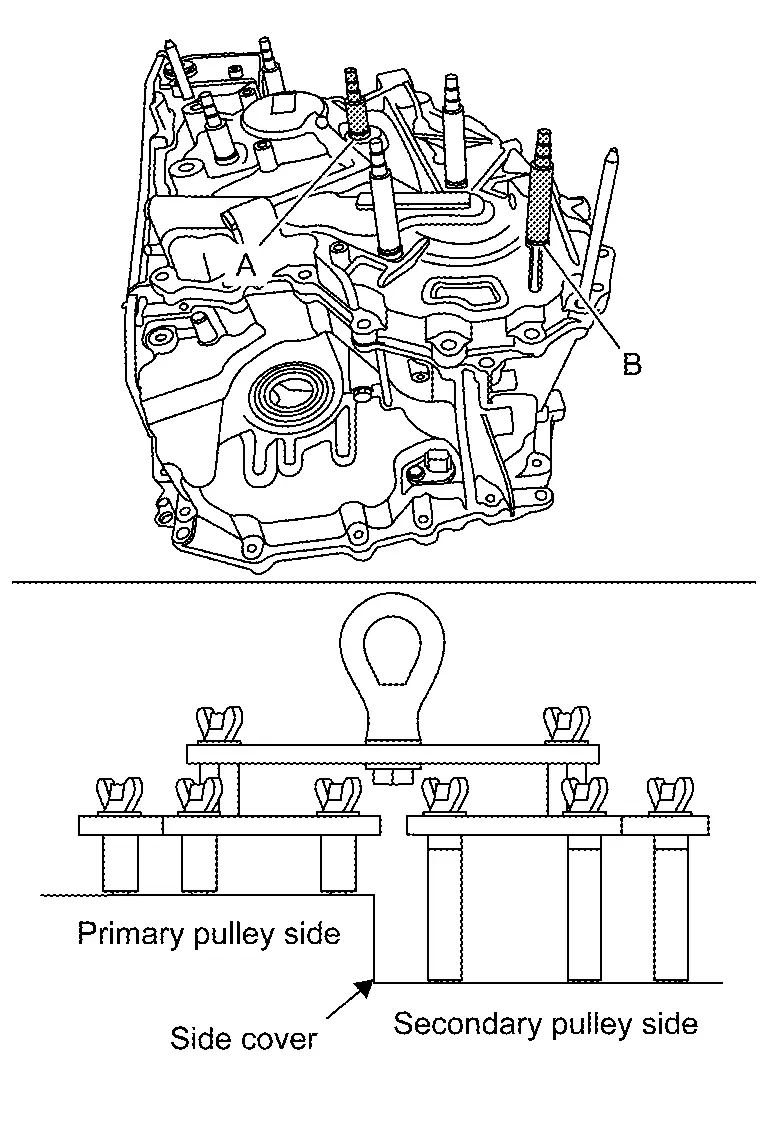

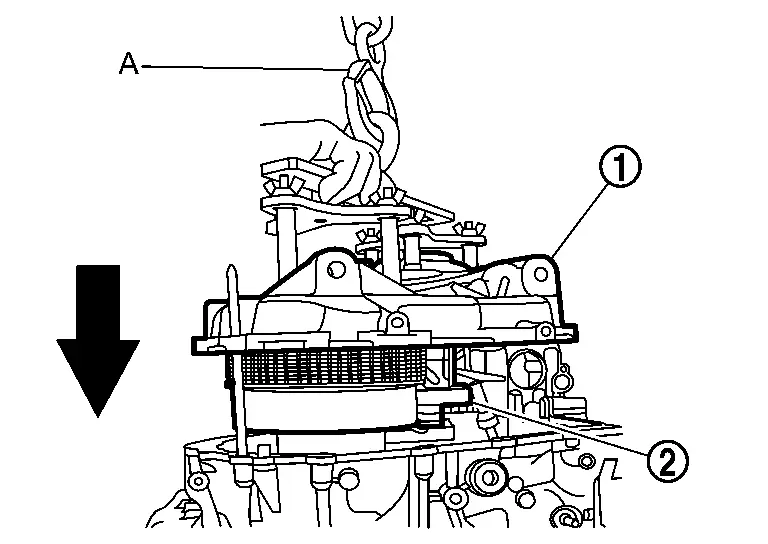

Install medium  and long

and long  shafts of CVT universal lifting fixture [KV315J0100 (NI-52082-A)].

shafts of CVT universal lifting fixture [KV315J0100 (NI-52082-A)].

Remove guide pins  from the pulley bracket [SST: KV31500300 (NI-52272)].

from the pulley bracket [SST: KV31500300 (NI-52272)].

Install medium  and long

and long  shafts of CVT universal lifting fixture [SST:KV315J0100 (NI-52082-A)].

shafts of CVT universal lifting fixture [SST:KV315J0100 (NI-52082-A)].

Install CVT universal lifting fixture [KV315J0100 (NI-52082-A)]  to bearing retainer mounting hole.

to bearing retainer mounting hole.

CAUTION:

Install CVT universal lifting properly.

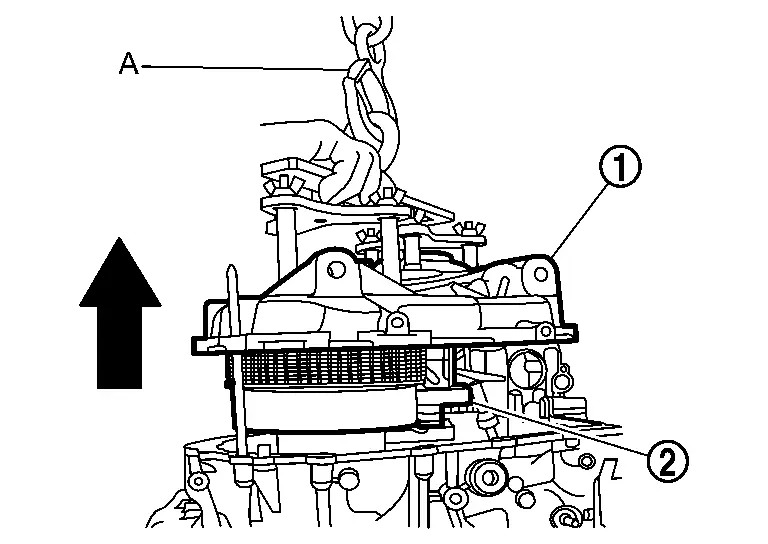

While lifting CVT universal lifting with crane  , side cover

, side cover  , belt and pulleys

, belt and pulleys as a unit.

as a unit.

Remove O-ring  .

.

Completely remove old liquid gasket from transaxle case.

ASSEMBLY

Install CVT universal lifting fixture [SST:KV315J0100 (NI-52082-A)] to new side cover, belt and pulleys kit.

CAUTION:

As soon as removing a bearing retainer mounting bolt, install a shaft of universal lifting.(Exchange one by one. If all bearing retainer mounting bolts are removed at once, CVT universal lifting may not be installed well.)

While lifting CVT universal lifting with crane  , install side cover

, install side cover  , belt and pulleys

, belt and pulleys all together to transaxle case at the same time.

all together to transaxle case at the same time.

CAUTION:

-

Apply CVT fluid to primary front bearing and secondary front bearing before assembling.

-

Never drop parts with care. If dropped, parts may be damaged and can not be reused.

While lowering transaxle universal lifting, install pulley sub-assembly to CVT case.

NOTE:

NOTE:

When installing side cover, insert parking rod  to parking pawl area

to parking pawl area  .

.

CAUTION:

Check that manual shaft is 'N' position.

Remove CVT universal lifting  .

.

Remove side cover by applying slide hammer [SST: KV315J0610

(NI-25721-A) ], slide hammer nut and bolt kit [SST: KV315J0630

(NI-50255-UPD)] and J hook case separator [SST: KV315J0620 (NI-51923)]

to three positions with arrow marks ( ).

).

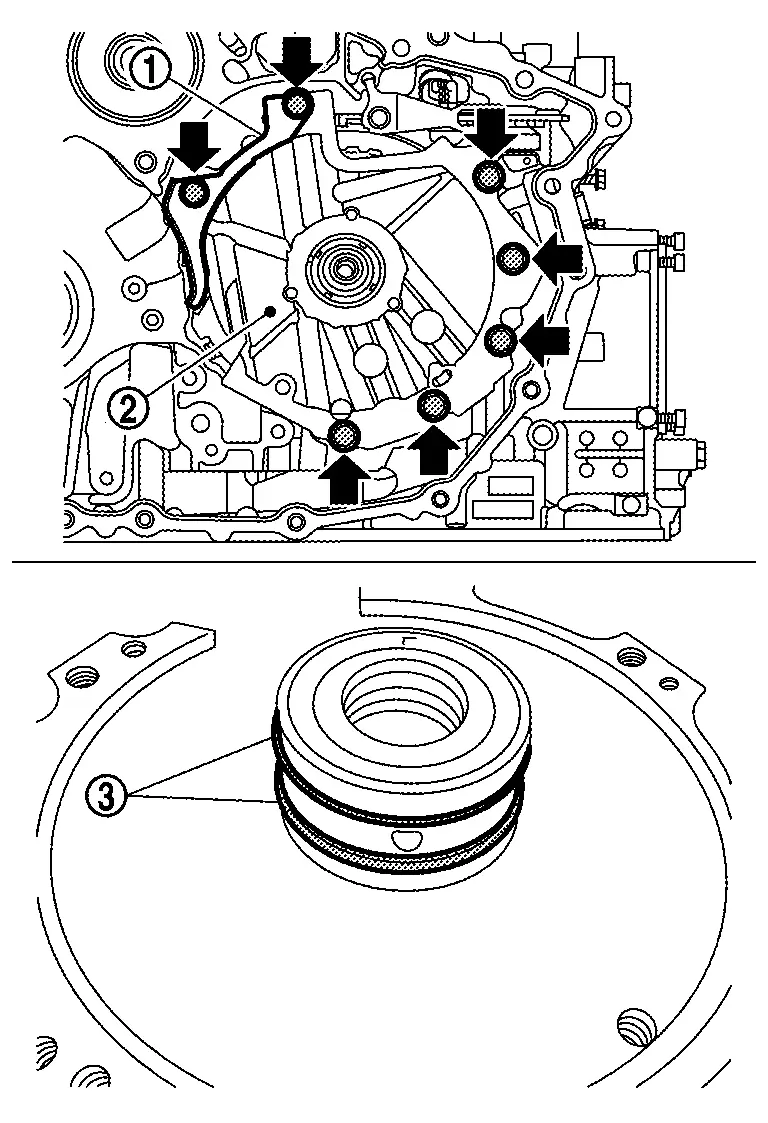

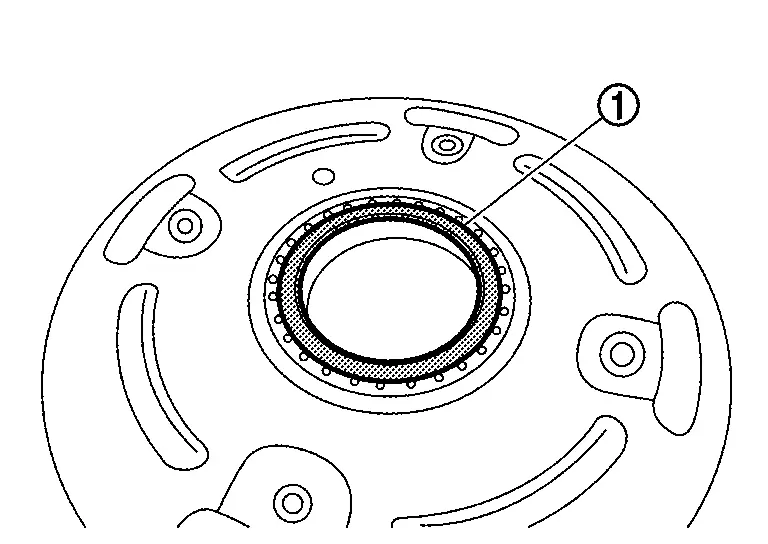

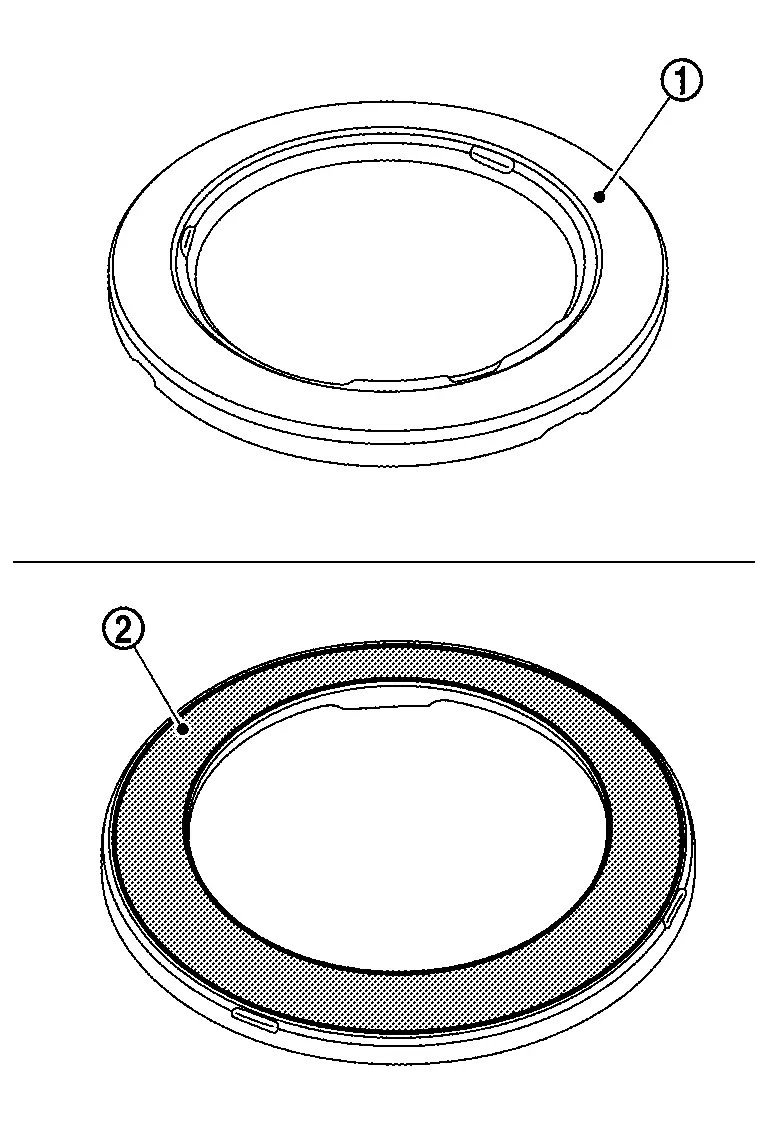

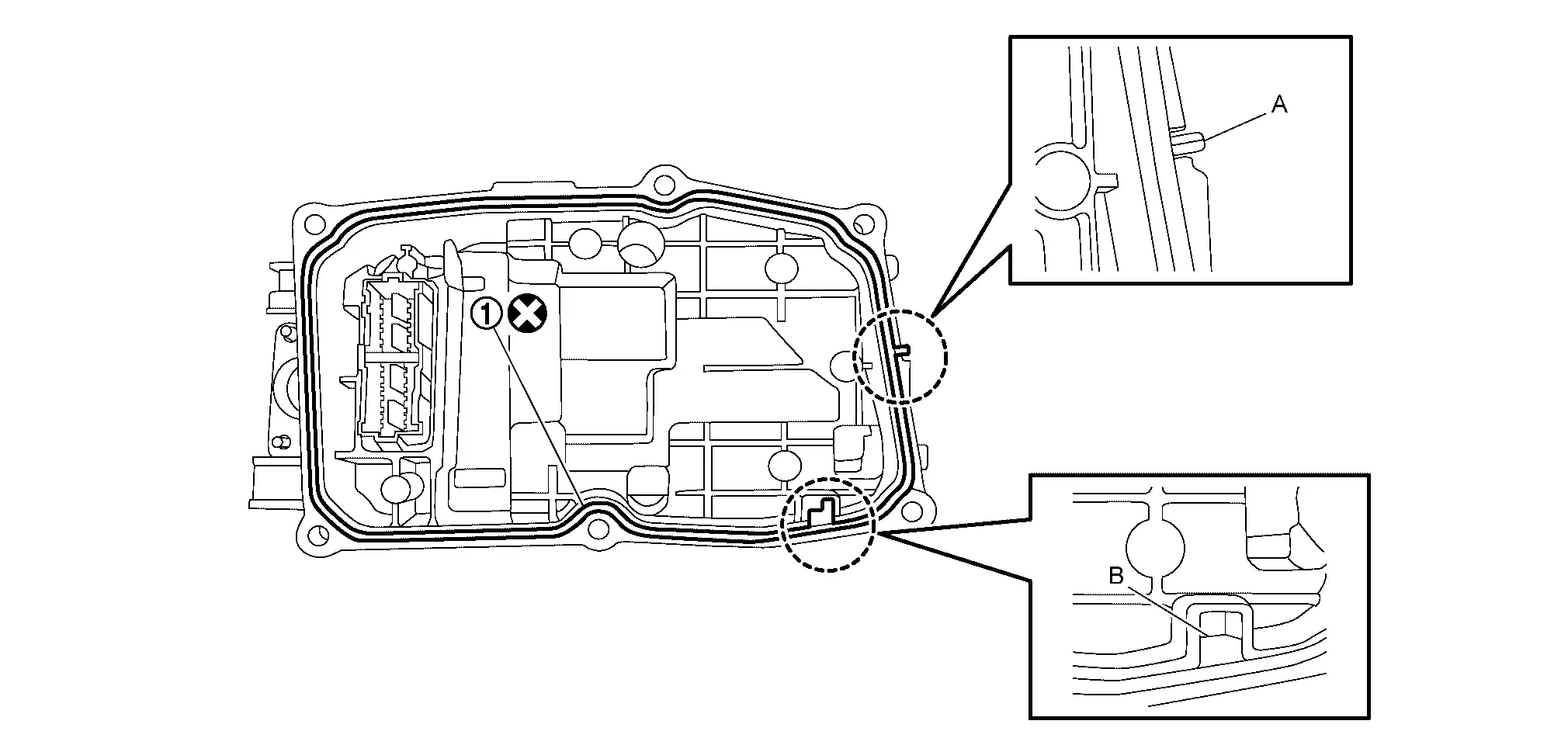

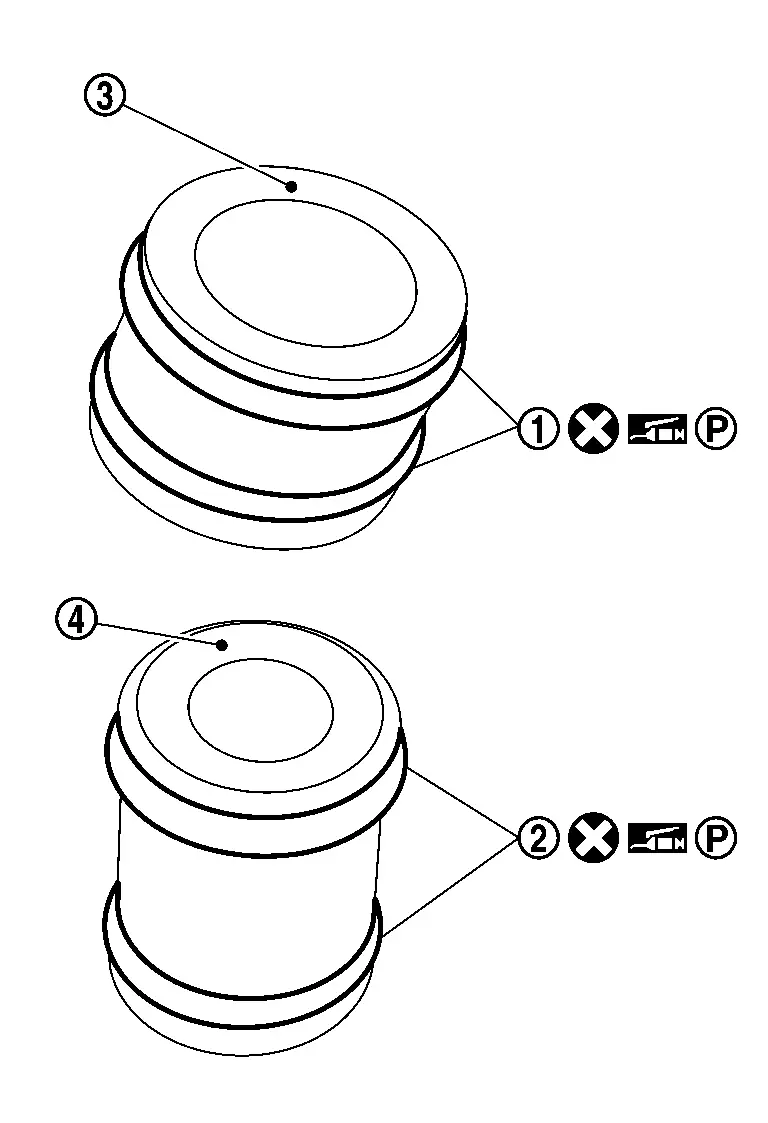

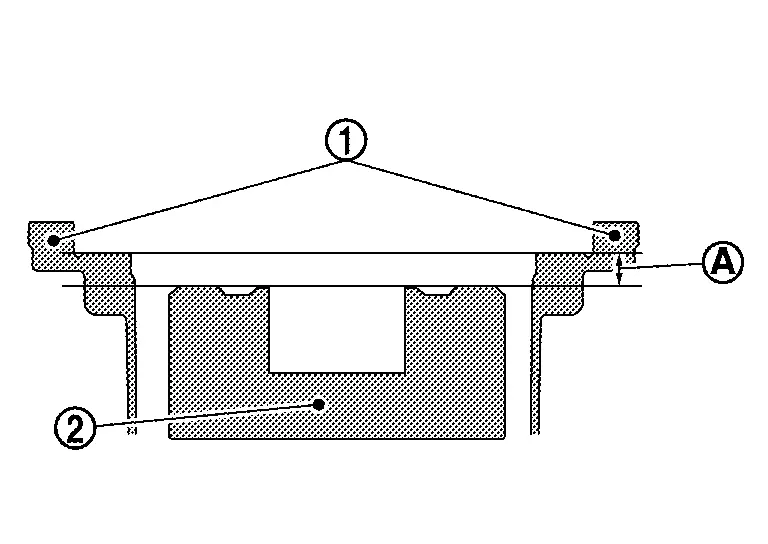

Install lubrication caps  .

.

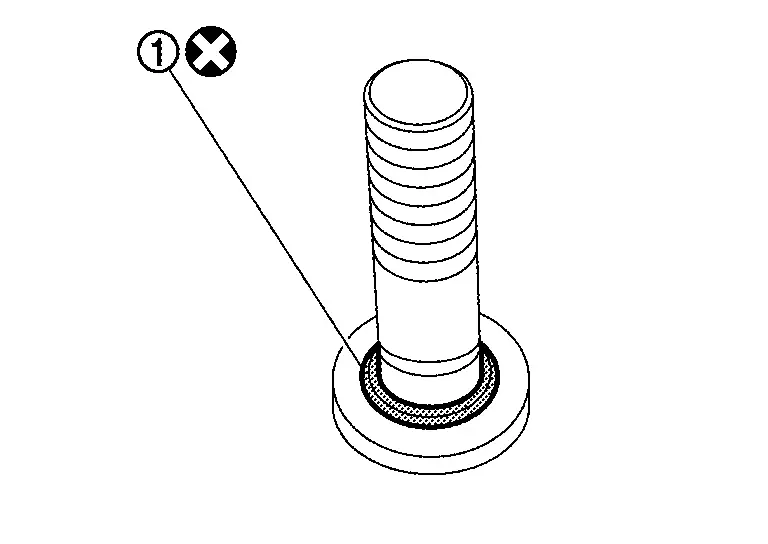

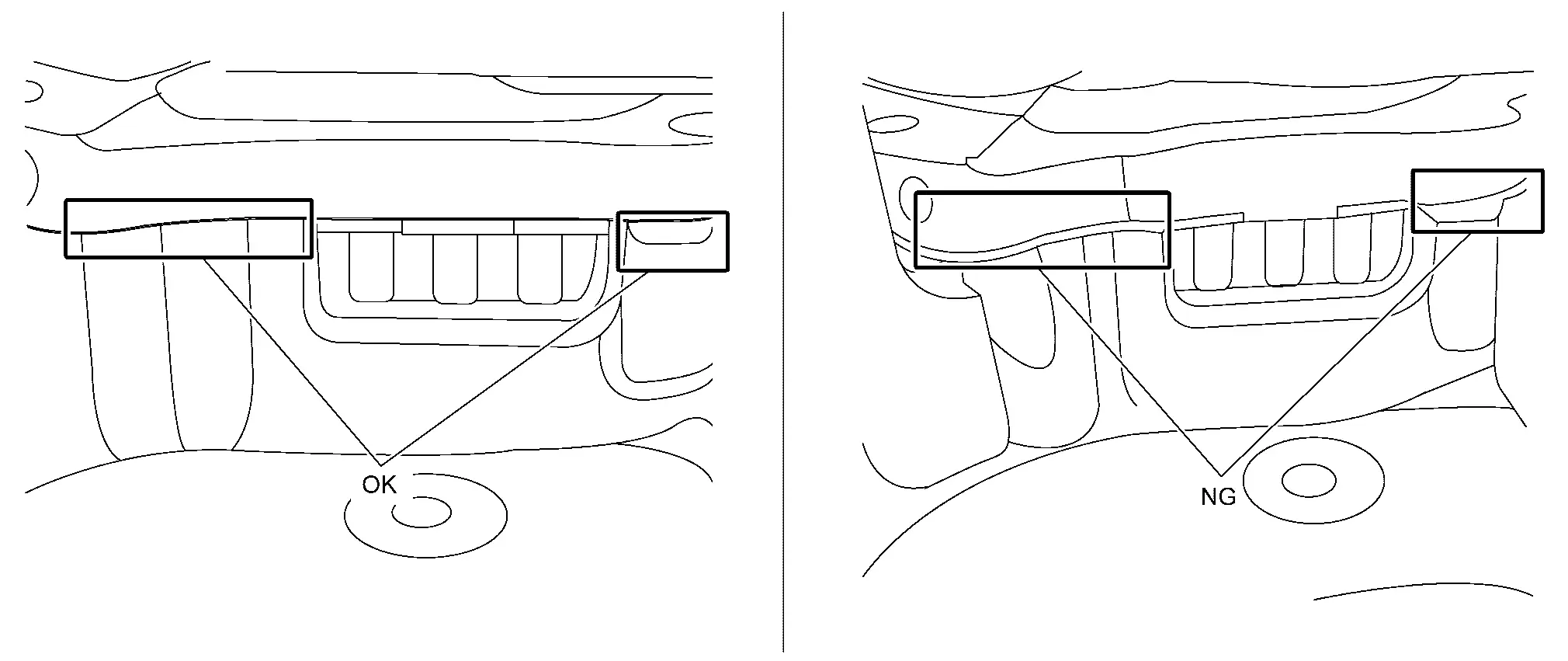

CAUTION:

-

Never reuse the lubrication cap.

-

Assemble the lubrication cap

as shown in the figure.

as shown in the figure.

Install O-ring  .

.

CAUTION:

-

Never reuse the O-ring.

-

Apply petroleum jelly to O-ring.

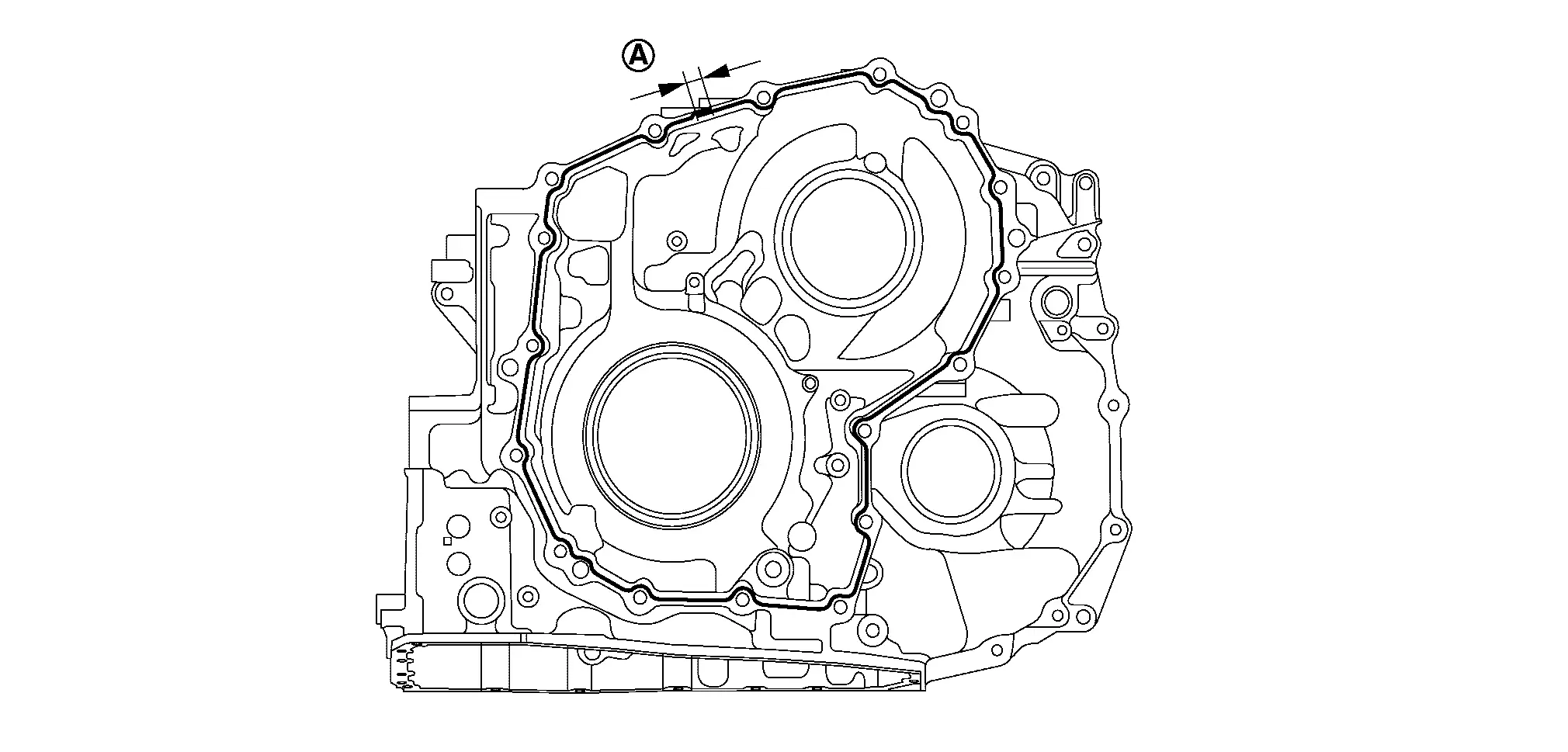

Apply Loctite 5460 on the transaxle case installation surface of the side cover.

CAUTION:

-

Completely remove all moisture, oil and old sealant, etc. from the transaxle case and converter housing mounting surfaces.

-

The sealant width is 2 - 3 mm (0.08 - 0.12 in).

-

Check that the starting point and the ending point are about the middle between the bolts. The overlap both ends of the bead by 3 - 5 mm (0.12 - 0.20 in)

.

. -

Be careful not to contact or contaminate the sealant. If the sealant has been disturbed or contaminated in any way before case assembly, thoroughly clean the mating surfaces of the transaxle case.

Install pulley bracket guide pin [[SST: KV31500300 (NI-52272)]  to primary pulley bearing retainer

to primary pulley bearing retainer  and secondary pulley retainer

and secondary pulley retainer  , and then install locator guide pin (SST: NI-53066)

, and then install locator guide pin (SST: NI-53066)  of side cover.

of side cover.

Rotate each pulley bracket  to align with holes and assembly guide pins, pulley bracket [SST: KV31500300 (NI-52272)]

to align with holes and assembly guide pins, pulley bracket [SST: KV31500300 (NI-52272)]  in the transaxle case

in the transaxle case  .

.

|

: Align holes |

Check that the shim  on the bottom side of the side cover

on the bottom side of the side cover  .

.

NOTE:

NOTE:

Apply petroleum jelly as needed to keep the shim in place while lowering the side cover to the transaxle case.

Install side cover  .

.

NOTE:

NOTE:

-

When installing side cover, insert parking rod

to parking pawl area

to parking pawl area  .

. -

Clean and degrease mating surface of the side cover with case.

CAUTION:

-

Check that manual shaft is 'N' position.

-

Never touch mating surfaces after cleaning and degreasing.

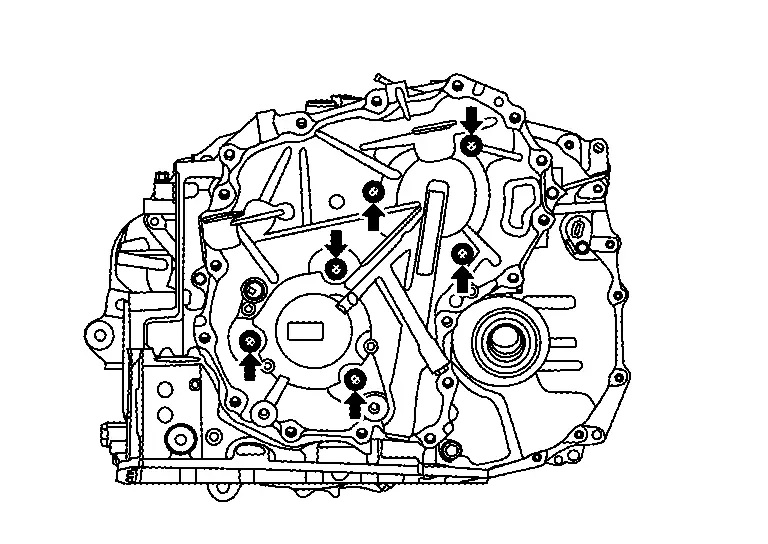

Tighten side cover mounting bolts to the specified torque in numerical order shown in the figure. Refer to Exploded View.

CAUTION:

-

Never reuse the side cover mounting bolts.

-

Apply CVT fluid to the mounting bolts.

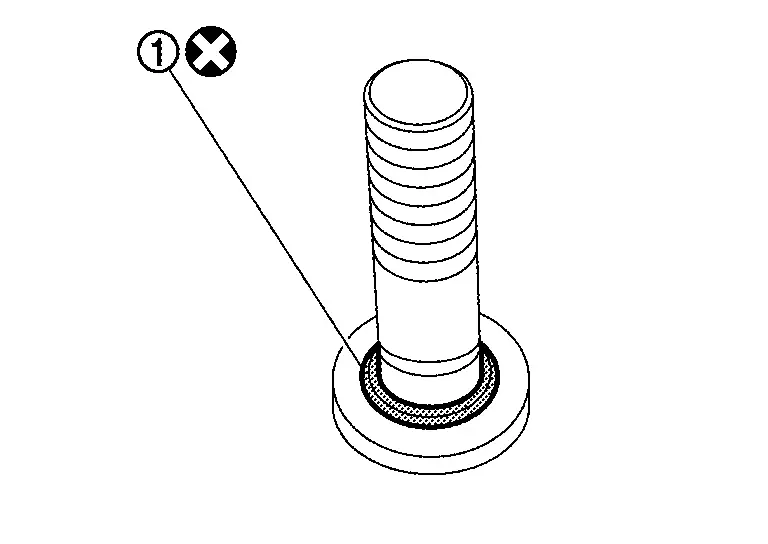

Install O-ring  to pulley retainer bolt.

to pulley retainer bolt.

CAUTION:

-

Never reuse the O-ring.

-

Never reuse the pulley retainer bolt.

Before removing guide pin, install bearing retainer mounting bolts (4 pieces) and temporarily tighten them. Then, pull out guide pin, install bearing retainer mounting bolts (2 pieces), and temporarily tighten them.

Rotate the primary pulley  by hand to check the pulley's rotational characteristics.

by hand to check the pulley's rotational characteristics.

CAUTION:

Never place fingers between the pulley and the transaxle case  .

.

NOTE:

NOTE:

Confirm that the characteristic is the same as previously checked at step 76 of disassembly.

Tighten bearing retainer mounting bolts ( 6 pieces) to the specified torque. Refer to Exploded View.

6 pieces) to the specified torque. Refer to Exploded View.

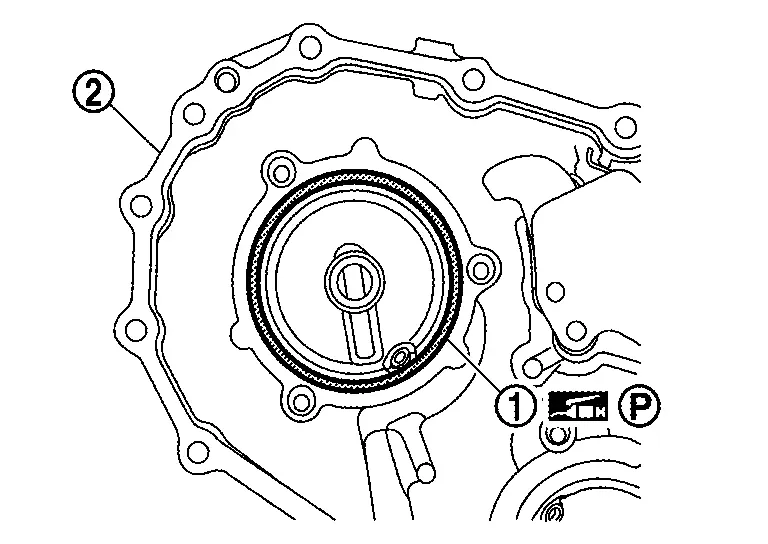

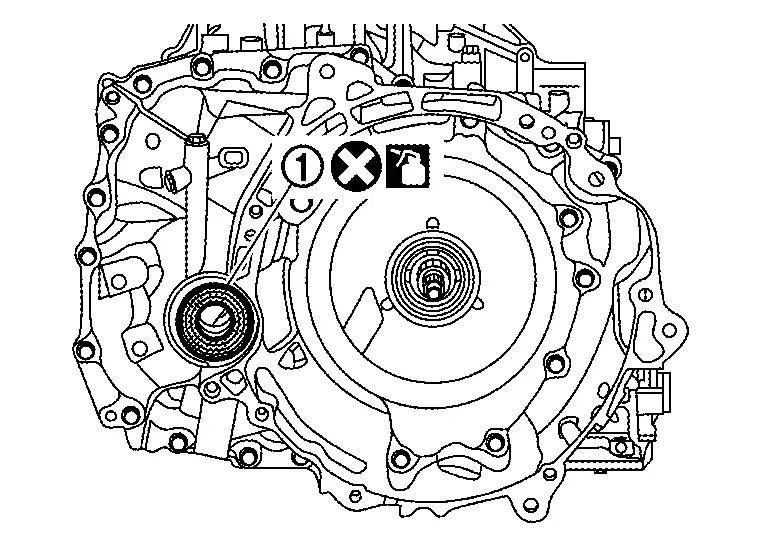

Install differential oil seal  to the case with seal installer (SST: NI-52284) until it is flush.

to the case with seal installer (SST: NI-52284) until it is flush.

Height or depth of differential oil seal from the surface : 0 ± 0.5 mm (0 ± 0.020 mm)

CAUTION:

-

Never reuse differential oil seal.

-

Apply the CVT fluid to the differential oil seal.

Temporarily install converter housing to transaxle case by using only four of the old converter housing mounting bolts to tighten them in a square shape.

Place CVT with the converter housing side as the top.

Remove temporarily installed converter housing.

Remove the temporarily fixed oil pan.

Install oil pump  and then tighten oil pump mounting bolts

and then tighten oil pump mounting bolts  to the temporary torque.

to the temporary torque.

Install O-ring  to oil pump mounting bolt.

to oil pump mounting bolt.

CAUTION:

-

Never reuse the O-ring.

Tighten oil pump mounting bolt  to the temporary torque.

to the temporary torque.

Tighten oil pump mounting bolts  to thespecified torque. Refer to Exploded View.

to thespecified torque. Refer to Exploded View.

Tighten oil pump mounting bolt  to the specified torque. Refer to Exploded View.

to the specified torque. Refer to Exploded View.

Install oil pump snap ring  .

.

Install thrust bearing  to the transaxle assembly.

to the transaxle assembly.

NOTE:

NOTE:

-

Make sure thrust bearing is installed in the correct direction.

-

Apply petroleum jelly to the thrust bearing to hold it in place on the primary pulley.

-

Assemble with the colored surface

side down.

side down.

Install planetary carrier  to the transaxle assembly.

to the transaxle assembly.

Install thrust bearing  to sun gear.

to sun gear.

NOTE:

NOTE:

-

Make sure thrust bearing is installed in the correct direction.

-

Apply petroleum jelly to the thrust bearing to hold it in place on the sun gear.

-

Assemble so that the colored surface

side can be seen.

side can be seen.

Install the sun gear  to the transaxle assembly.

to the transaxle assembly.

Install thrust bearing  to sun gear.

to sun gear.

NOTE:

NOTE:

-

Make sure thrust bearing is installed in the correct direction.

-

Apply petroleum jelly to the thrust bearing to hold it in place on the sun gear.

-

Assemble so that the colored surface

side can be seen.

side can be seen.

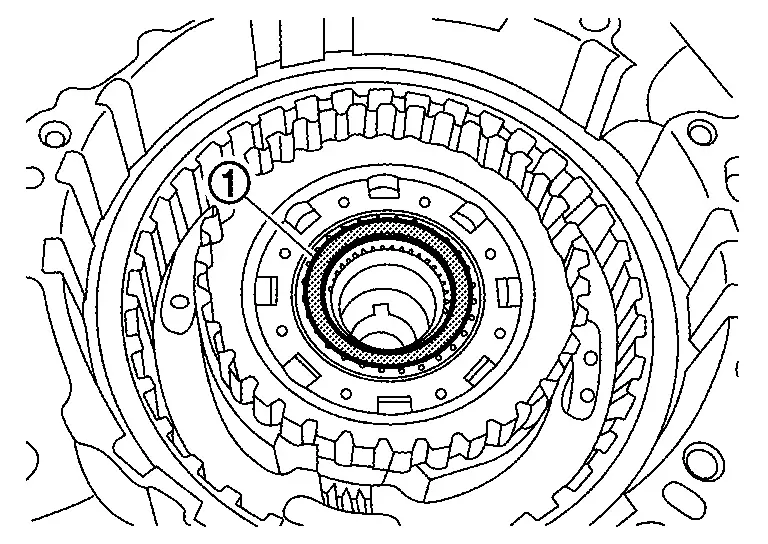

Install forward clutch assembly  to the transaxle assembly.

to the transaxle assembly.

NOTE:

NOTE:

-

Check that the lathe cut seals

are in the specified positions before clutch assembly installation.

are in the specified positions before clutch assembly installation. -

Check that the lathe cut seal

is in the specified position before clutch assembly installation.

is in the specified position before clutch assembly installation. -

Lathe cut seal must be in its appropriate slot. Carefully reposition the seal as necessary.

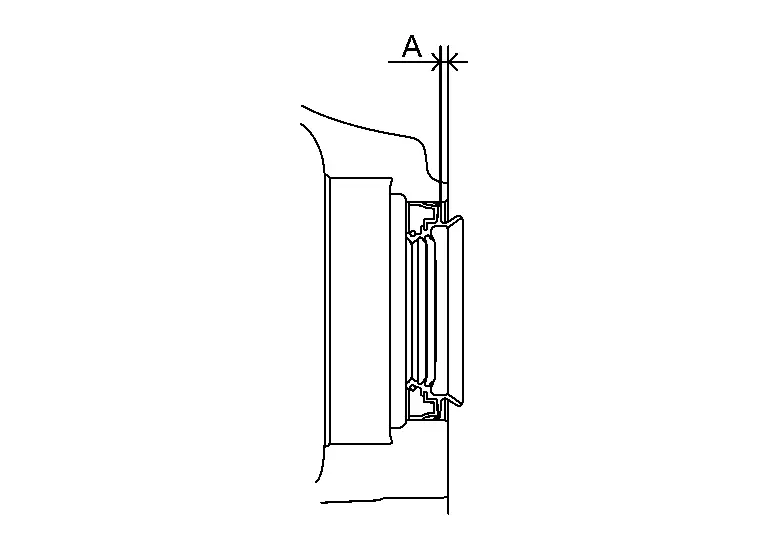

Make sure that clutch assembly is completely entered.

-

The forward clutch is 2-3 mm (0.08 - 0.12 in) below the oil pump cover surface.

-

If the gap is more than 2-3 mm (0.08 - 0.12 in), the component parts may be improperly installed. Refer to Trouble Shooting.

-

If the gap is less than 2-3 mm (0.08 - 0.12 in), the component parts may be missing or damaged.

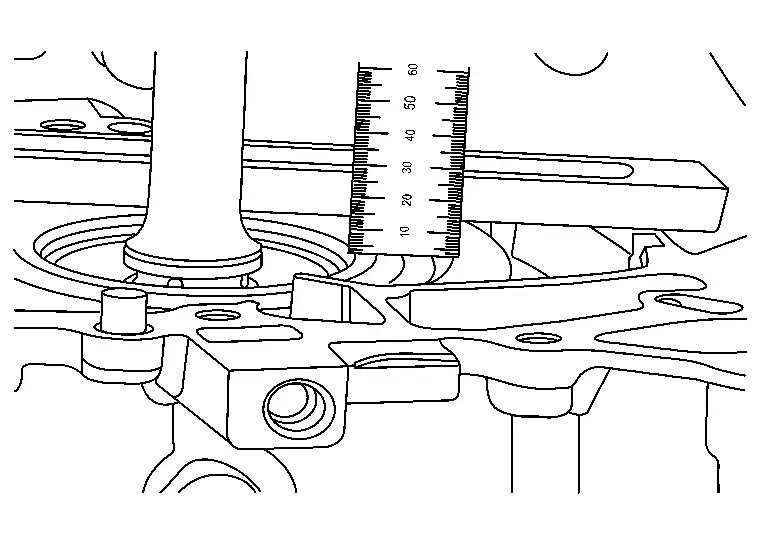

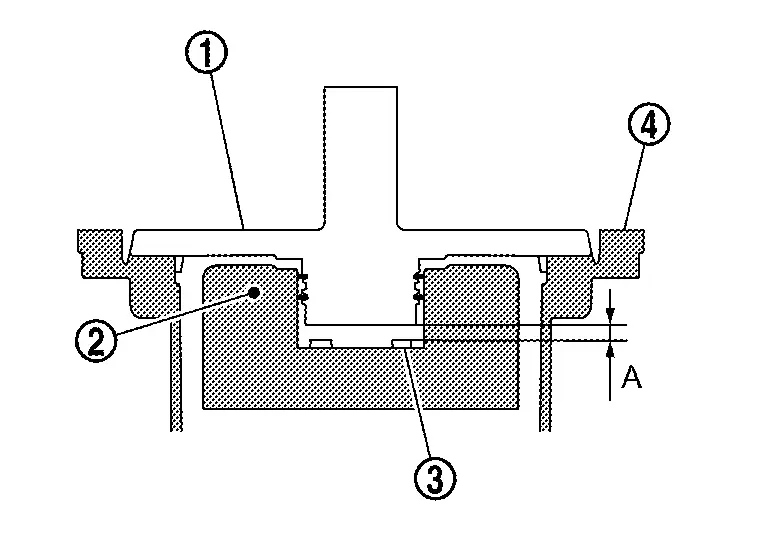

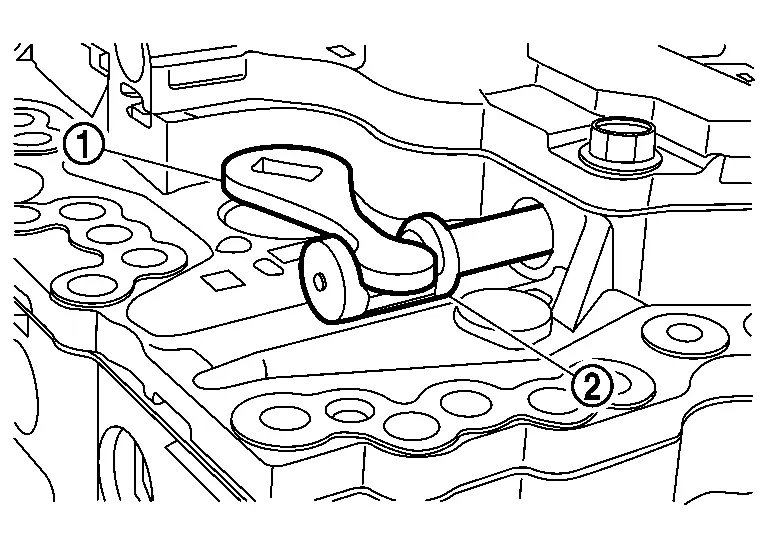

Calculate total end play  with the following procedure.

with the following procedure.

|

: Dummy cover |

|

: Forward clutch drum |

|

: Thrust bearing |

|

: Transaxle case |

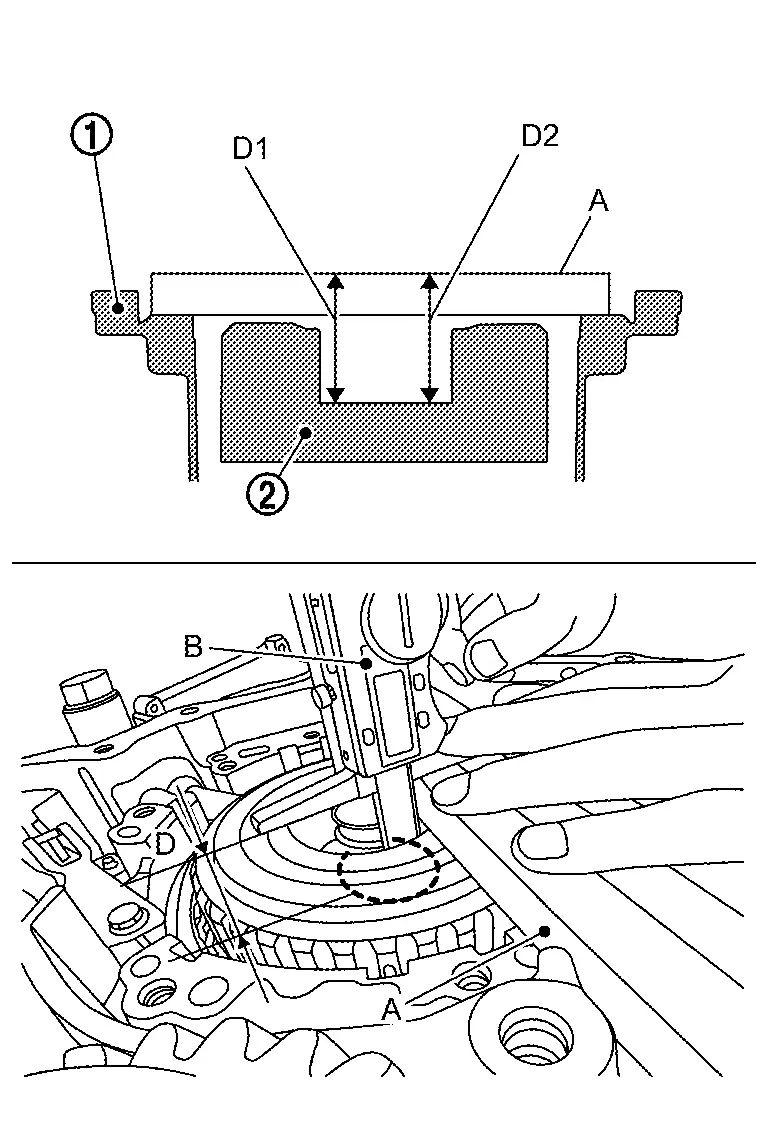

Measure the average distance  from the dummy cover installation surface of the transaxle case

from the dummy cover installation surface of the transaxle case  to the needle bearing installation surface of the forward clutch drum

to the needle bearing installation surface of the forward clutch drum  .

.

Average distance  |

: (D1 + D2)/2 |

| A | : Gauge block [SST: KV315J0400 (NI-50271)] |

| B | : Digital Depth Gauge [SST:KV315J0500 (NI-50272)] |

Clean the dummy cover surfaces  that contact the transaxle case and thrust beaning.

that contact the transaxle case and thrust beaning.

CAUTION:

-

Use parts cleaner or equivalent solvent and lint-free paper only.

-

Make sure the parts cleaner or solvents used are compatible with local requlations.

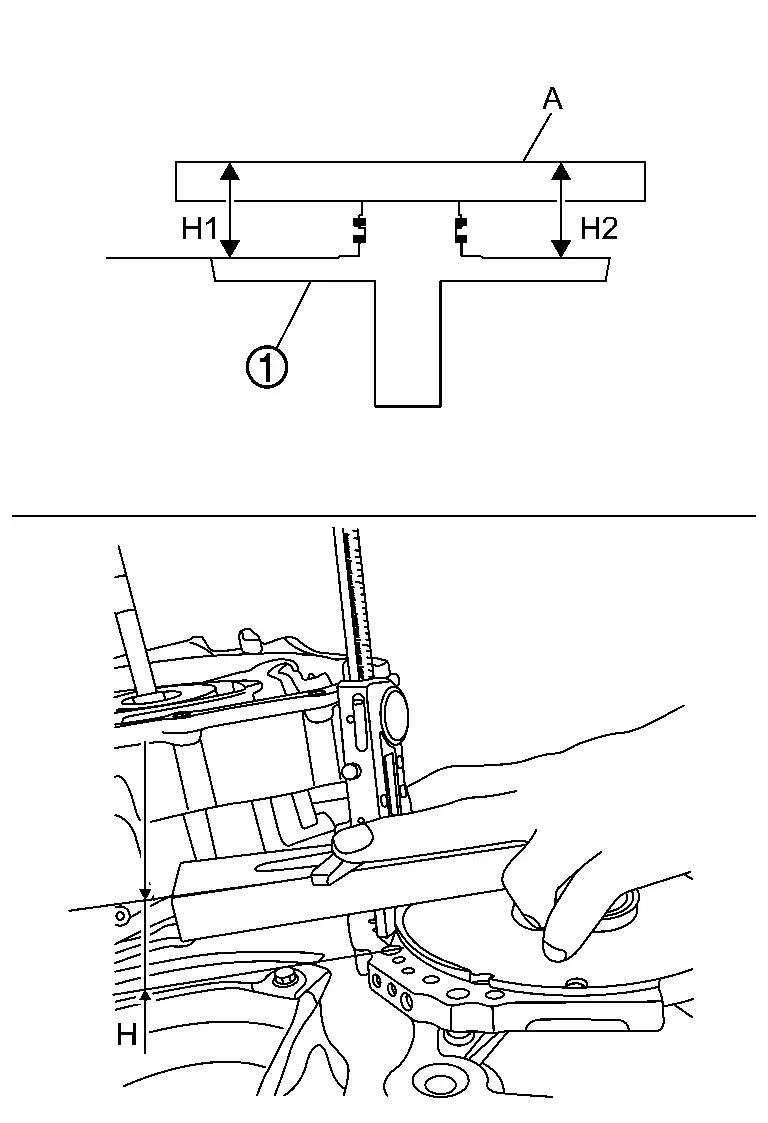

Measure the distance  from the edge of the dummy cover

from the edge of the dummy cover  to the installation surface on the transaxle case.

to the installation surface on the transaxle case.

Average distance  |

: (H1 + H2)/2 |

| A | : Gauge block [SST: KV315J0400 (NI-50271)] |

Calculate the total end play with the following formula, and choose the appropriate bearing from the following table.

-

-  = Total end play

= Total end play

Total end play  |

Bearing thickness |

| 3.87 - 4.06 mm | 3.57 mm |

| 4.07 - 4.24 mm | 3.75 mm |

| 4.25 - 4.41 mm | 3.93 mm |

| 4.42 - 4.59 mm | 4.1 mm |

| 4.60 - 4.77 mm | 4.28 mm |

| 4.78 - 4.93 mm | 4.46 mm |

| 4.94 - 5.10 mm | 4.61 mm |

| 5.11 - 5.29 mm | 4.79 mm |

Install the thrust bearing  to the clutch assembly bore.

to the clutch assembly bore.

CAUTION:

-

Apply petroleum jelly when installing the thrust bearing .

-

Pay attention to the direction of the thrust bearing when installing it. When installing thrust bearing, its brown plate should be facing to forward clutch.

|

: Upper side |

|

: Lower side (Colored surface) |

Install dummy cover  and baffle plate D

and baffle plate D  .

.

And then tighten dummy cover and baffle plate D mounting bolts ( 7 pieces) to the specified torque. Refer to Exploded View.

7 pieces) to the specified torque. Refer to Exploded View.

CAUTION:

-

Apply petroleum jelly to the input shaft's

lathe cut seals

lathe cut seals  before installing the dummy cover to the transaxle case.

before installing the dummy cover to the transaxle case. -

Check that the input shaft's

lathe cut seals

lathe cut seals  are in the specified position.

are in the specified position. -

Lathe cut seals

(white seals) must be in their appropriate slots. Carefully reposition seals as necessary.

(white seals) must be in their appropriate slots. Carefully reposition seals as necessary. -

Lathe cut seals

must be in specified positions during final assembly to prevent drivability issues.

must be in specified positions during final assembly to prevent drivability issues. -

Apply petroleum jelly to the dummy cover's

lathe cut seals

lathe cut seals  before installing the dummy cover to the transaxle case.

before installing the dummy cover to the transaxle case. -

Check that the dummy cover's lathe cut seals are in the specified positions.

-

Lathe cut seals

(white seals) must be in their appropriate slots. Carefully reposition seals as necessary.

(white seals) must be in their appropriate slots. Carefully reposition seals as necessary. -

Lathe cut seals

must be in specified positions during final assembly to prevent drivability issues.

must be in specified positions during final assembly to prevent drivability issues. -

After installing dummy cover and before tightening bolts, make sure that mating surfaces of dummy cover and case are seated without any gaps.

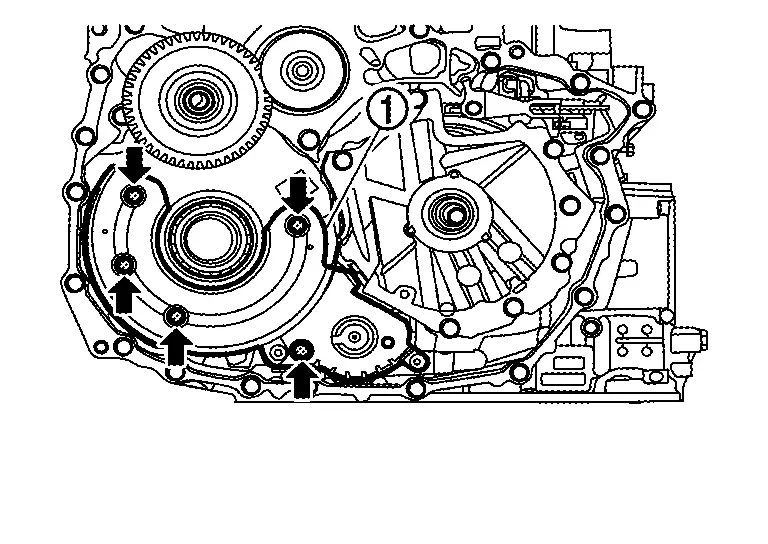

Install baffle plate B  and then tighten baffle plate B mounting bolts (

and then tighten baffle plate B mounting bolts ( 5 pieces) to the specified torque. Refer to Exploded View.

5 pieces) to the specified torque. Refer to Exploded View.

Install oil pump bracket  and

then tighten oil pump bracket mounting bolts to the specified torque

each in numerical order 1 and 2 shown in the figure. Refer to Exploded

View.

and

then tighten oil pump bracket mounting bolts to the specified torque

each in numerical order 1 and 2 shown in the figure. Refer to Exploded

View.

CAUTION:

As the internal thread of the oil pump bolt may be damaged, please follow the below cautions when installing bolt  .

.

-

Do not use air or electric power tools when tightening the bolt.

-

Use hands to tighten the bolt until you feel the torque. When applying torque, slowly tighten the bolt using more then 1 second to tighten a 90 degrees angle.

Install thrust washer  .

.

NOTE:

NOTE:

-

Use petroleum jelly to hold the thrust washer in place.

-

Make sure the tabs (

) fit into the holes.

) fit into the holes.

Install chain  , drive sprocket

, drive sprocket  and driven sprocket

and driven sprocket  all together.

all together.

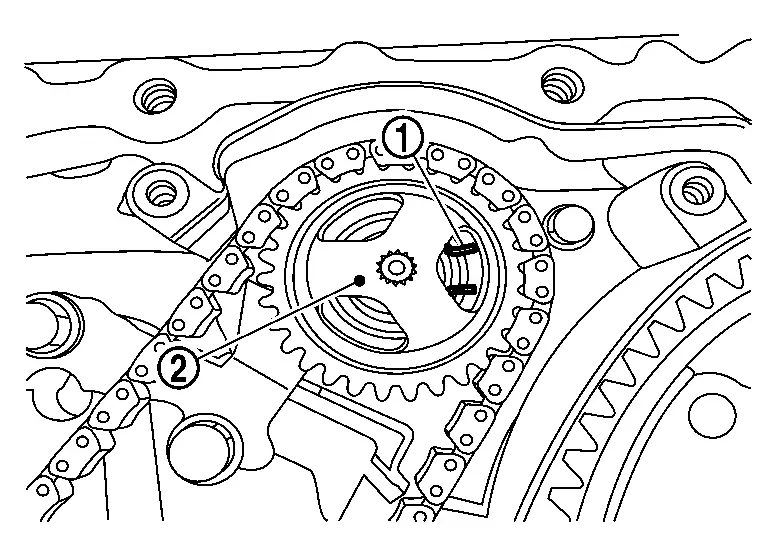

While expanding snap ring  of oil pump with snap ring pliers , fix driven sprocket

of oil pump with snap ring pliers , fix driven sprocket  .

.

CAUTION:

Lift driven sprocket and check that it does not come off.

Install baffle plate A  and then tighten baffle plate A mounting bolts

and then tighten baffle plate A mounting bolts  to the specified torque. Refer to Exploded View.

to the specified torque. Refer to Exploded View.

CAUTION:

Never reuse the baffle plate A.

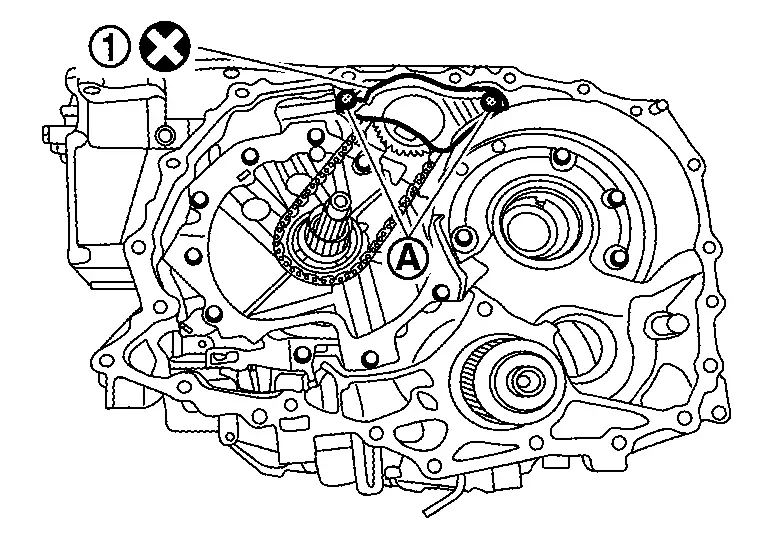

Install reduction gear  assembly together with differential assembly

assembly together with differential assembly  .

.

CAUTION:

Handle parts with care. If dropped, parts may be damaged and can not be reused.

Check that retaining pin  of manual shaft locates on the original position.

of manual shaft locates on the original position.

nstall baffle plate C  to the converter housing and then tighten baffle plate C mounting bolts (

to the converter housing and then tighten baffle plate C mounting bolts ( 3 pieces) to the specified torque. Refer to Exploded View.

3 pieces) to the specified torque. Refer to Exploded View.

CAUTION:

Never reuse baffle plate C.

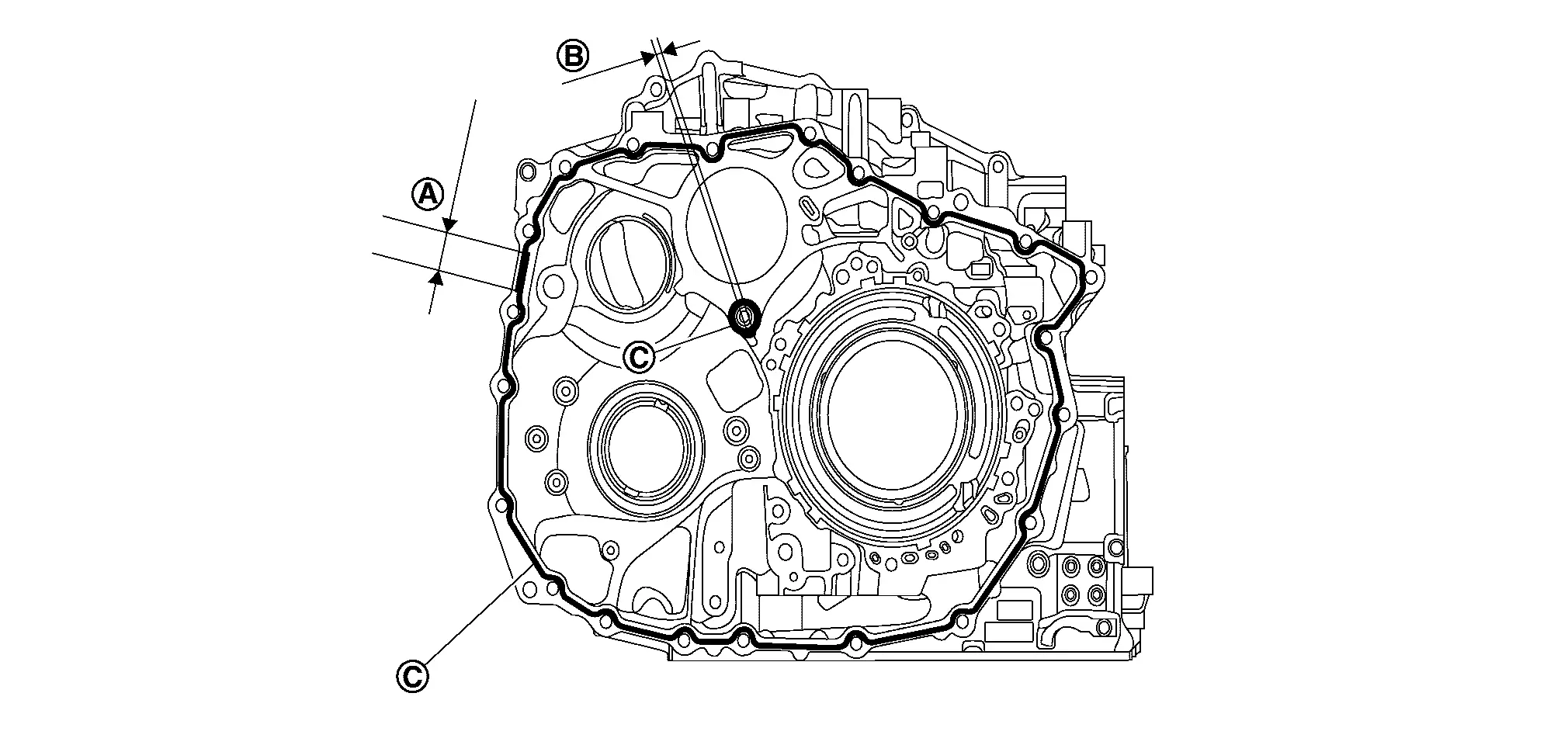

Apply Loctite 5460 on the converter housing installation surface of the transaxle case.

CAUTION:

-

Be sure to apply, first sealant around the center bolt hole

, and next around the mating surfaces

, and next around the mating surfaces  .

. -

Completely remove all moisture, oil and old sealant, etc. from the transaxle case and converter housing mounting surfaces.

-

Apply sealant to this portion at first

, to prevent skipping applying sealant to this area.

, to prevent skipping applying sealant to this area. -

The sealant width is 2 - 3 mm (0.08 - 0.12 in).

-

Check that the starting point and the ending point are about the middle between the bolts. The overlap both ends of the bead by 25 - 30 mm (0.98 - 1.18 in)

.

. -

The overlap both ends of the bead by 3 - 5 mm (0.12 - 0.20 in)

.

.

Install converter housing.

CAUTION:

Completely remove all moisture, oil and old sealant, etc. from the transaxle case and converter housing mounting surfaces.

Tighten converter housing mounting bolts to the specified torque in numerical order shown in the figure. Refer to Exploded View.

NOTE:

NOTE:

Apply CVT fluid to the bolts when installing.

CAUTION:

Never reuse the converter housing mounting bolts.

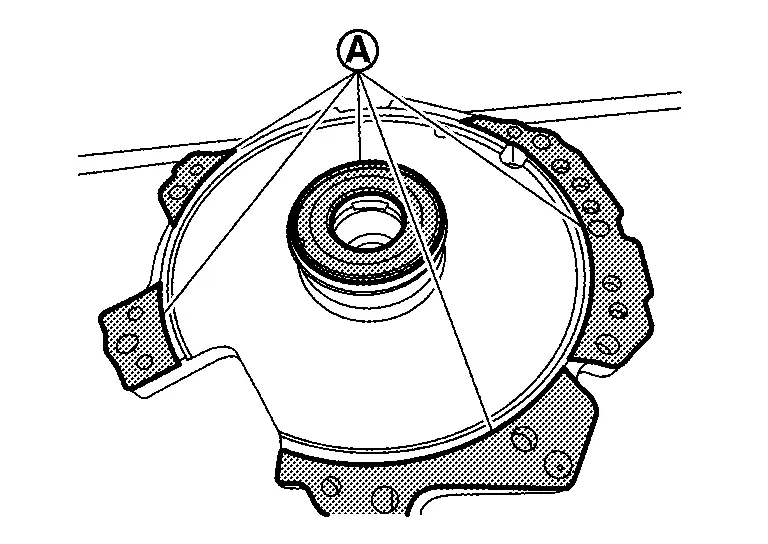

Install converter housing oil seal to the converter housing with seal installer (SST: NI-53062) until it is flush.

Height or depth of converter housing oil seal from the surface  |

mm (0.04±0.020 in) |

CAUTION:

-

Never reuse converter housing oil seal.

-

Apply the CVT fluid to the converter housing oil seal.

Install differential oil seal  to the converter housing with seal installer (SST: NI-52283) until it is flush. (2WD models)

to the converter housing with seal installer (SST: NI-52283) until it is flush. (2WD models)

| Height or depth of differential oil seal from the surface | mm (0±0.020 in) |

CAUTION:

-

Never reuse differential oil seal.

-

Apply the CVT fluid to the differential oil seal.

Check that the O-ring  is installed on terminal assembly A.

is installed on terminal assembly A.

CAUTION:

Never reuse terminal assembly A.

Connect terminal assembly A  and

and  to electric oil pump. Tighten mounting bolts

to electric oil pump. Tighten mounting bolts  of terminal assembly A to the specified torque. Refer to Exploded View.

of terminal assembly A to the specified torque. Refer to Exploded View.

CAUTION:

Never install terminals in the opposite direction.

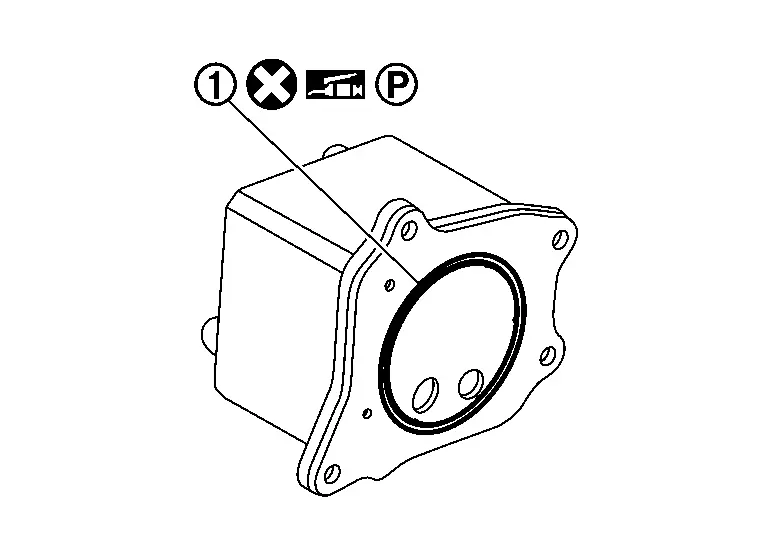

Install electric oil pump gasket  .

.

CAUTION:

-

Apply petroleum jelly to oil pump gasket.

-

Never reuse the oil pump gasket.

Install electric oil pump bracket  to electric oil pump.

to electric oil pump.

CAUTION:

Never reuse electric oil pump bracket when replacing electric oil pump with a new one.

Install electric oil pump  and terminal assembly A to transaxle case. Tighten mounting bolts

and terminal assembly A to transaxle case. Tighten mounting bolts  of electric oil pump to the specified torque. Refer to Exploded View.

of electric oil pump to the specified torque. Refer to Exploded View.

Tighten mounting bolts of electric oil pump bracket  to the specified torque in numerical order

to the specified torque in numerical order  and

and  shown in the figure. Refer to Exploded View.

shown in the figure. Refer to Exploded View.

Install harness connector  to terminal assembly A

to terminal assembly A  .

.

CAUTION:

When installing, never include any moisture, contamination into harness connector.

Install herness connector  of terminal assembly B

of terminal assembly B  to the electric oil pump.

to the electric oil pump.

CAUTION:

-

Never reuse terminal assembly B.

-

When installing, never include any moisture, contamination into harness connector.

Insert the terminal assembly A  to the hole of transaxle case, and then push it to seat completely.

to the hole of transaxle case, and then push it to seat completely.

CAUTION:

Apply petroleum jelly to O-ring  of terminal assembly A.

of terminal assembly A.

NOTE:

NOTE:

Completely push CVT unit connector until click noise is made.

Tighten each mounting bolt  and

and  for terminal assembly A and terminal assembly B with specified torque. Refer to Exploded View.

for terminal assembly A and terminal assembly B with specified torque. Refer to Exploded View.

Install gasket  to TCM.

to TCM.

CAUTION:

Never reuse the gasket

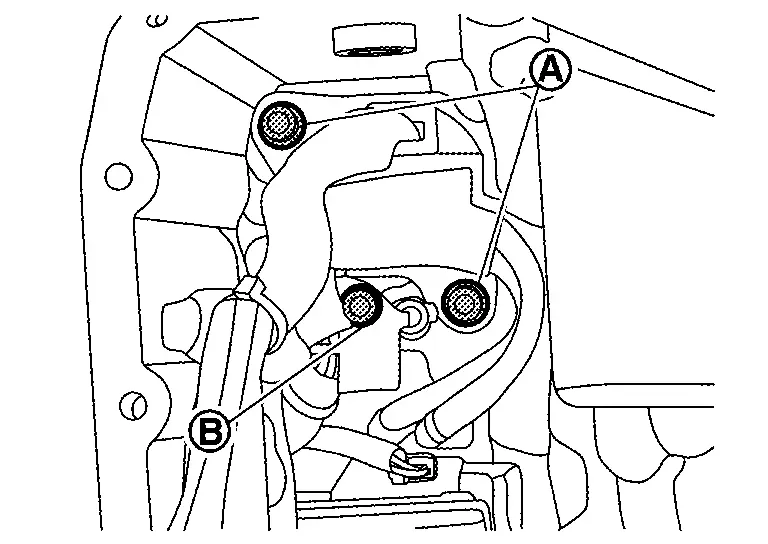

NOTE:

NOTE:

Two tabs (A and B) on TCM gasket need to be set to notches on TCM case.

Install connectors  of terminal assembly B to TCM.

of terminal assembly B to TCM.

NOTE:

NOTE:

Terminal assembly B connector claws are located on the upper and lower sides of the connector while connected to the TCM.

Tighten TCM mounting bolts ( 6 pieces) to the specified torque. Refer to Exploded View.

6 pieces) to the specified torque. Refer to Exploded View.

|

: TCM |

Install lip seal  to transaxle assembly

to transaxle assembly  .

.

CAUTION:

-

Apply petroleum jelly to lip seal.

-

Never reuse the lip seal.

Remove O-rings  and

and  from tubes

from tubes  and

and  .

.

CAUTION:

-

Apply petroleum jelly to O-ring.

-

Never reuse the O-ring.

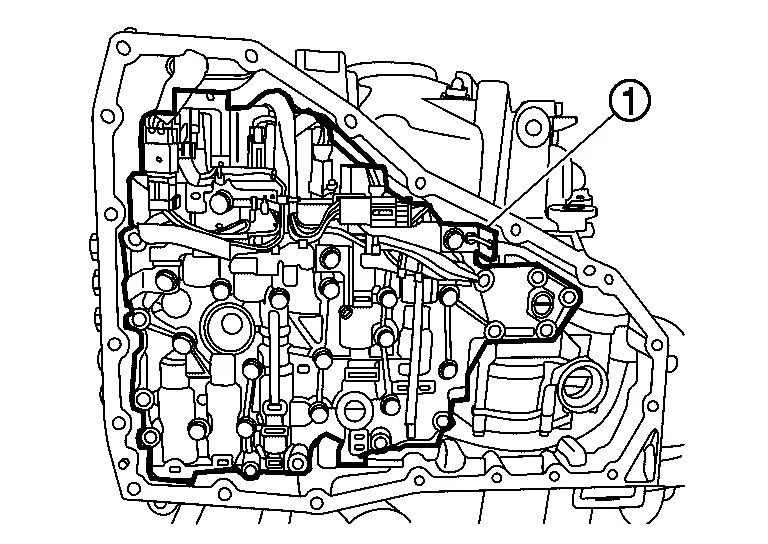

Install tubes  and

and  to transaxle assembly

to transaxle assembly  .

.

CAUTION:

-

While installing, never drop tube.

-

Never reuse dropped and damaged tube.

-

Apply petroleum jelly to the tubes to keep them in place on the transaxle case.

NOTE:

NOTE:

Fully push tubes to reach to the end.

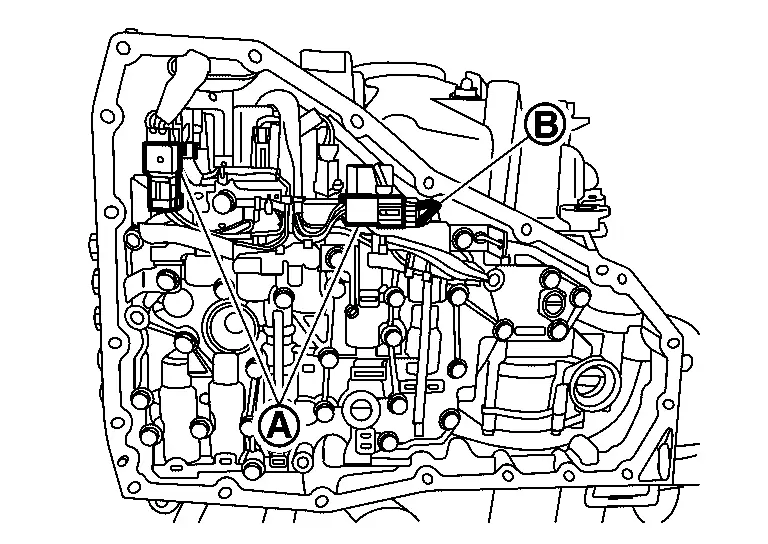

Set position of manual shaft and manual valve to "N", before installing control valve.

NOTE:

NOTE:

-

While inserting valve body alignment tool (SST:NI-53064)

etc. through both holes of control valve body and manual valve, set manual valve position to "N" . After that pull out a rod.

etc. through both holes of control valve body and manual valve, set manual valve position to "N" . After that pull out a rod. -

Align matching marks

.

.

-

Install the control valve

with mounting bolts (

with mounting bolts ( 10 pieces) which exists on the outline of control valve according to the sequence of

10 pieces) which exists on the outline of control valve according to the sequence of  ,

,  and

and  .

.

: Nissan Ariya Vehicle front Bolt Bolt length mm (in) Number of bolt

54 (2.13) 1

44 (1.73) 3

40 (1.57) 6  NOTE:

NOTE:

Install mounting bolts by hand tightening.

CAUTION:

-

There are 3 types of bolts for control valve installation. Install the bolts to appropriate position.

-

When installing the control valve, prevent it from tilting with respect to the case, and ensure positioning with the dowel pin.

-

-

Tighten ten control valve mounting bolts to the specified torque. Refer to Exploded View.

-

After tightening the control valve mounting bolts, check that the manual plate

engages with the manual valve

engages with the manual valve  and that the manual shaft rotates normally.

and that the manual shaft rotates normally.

Install harness connectors  and harness clip

and harness clip  .

.

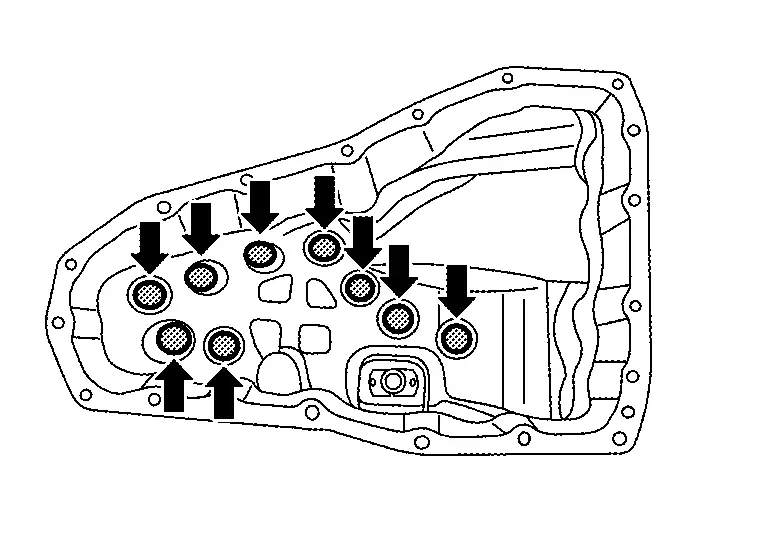

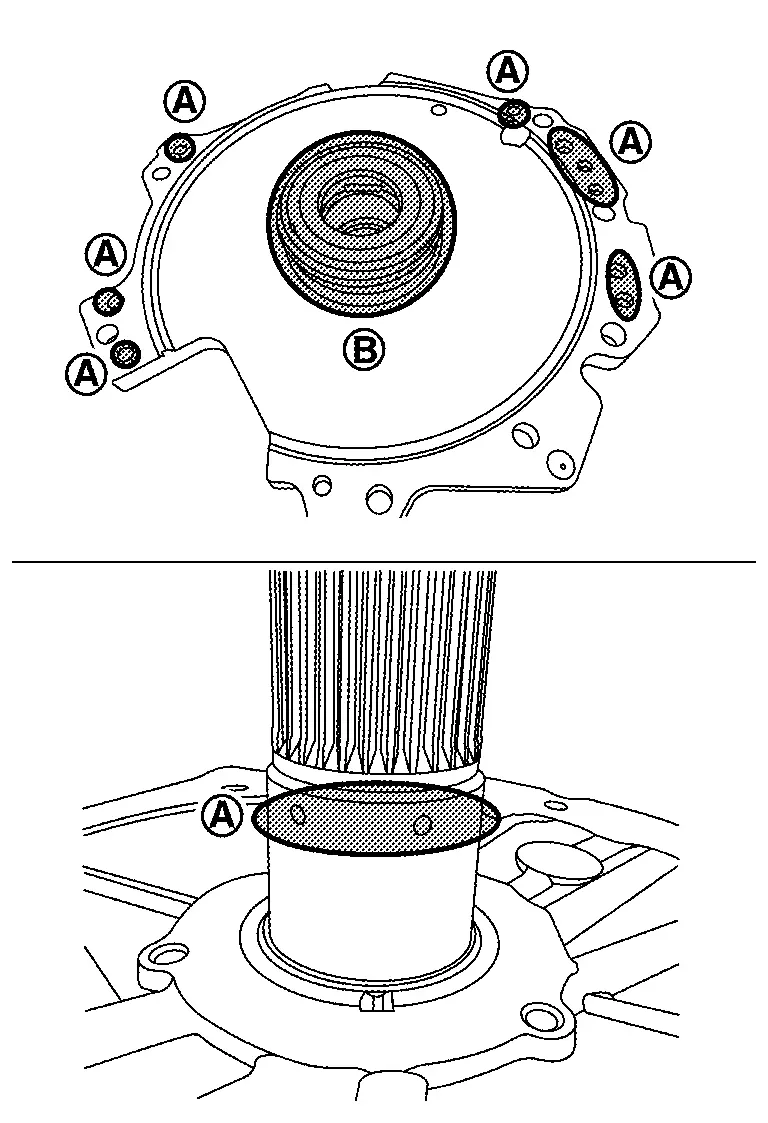

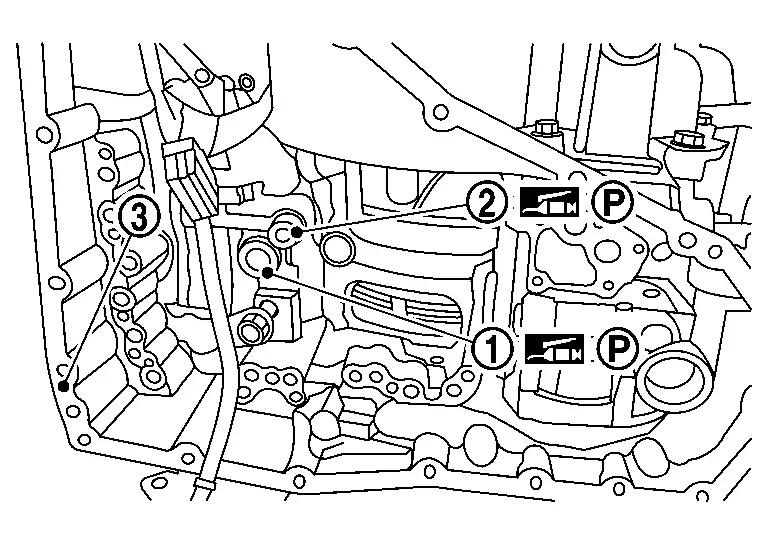

Install oil strainer assembly  and then tighten oil strainer assembly mounting bolts

and then tighten oil strainer assembly mounting bolts  to the specified torque. Refer to Exploded View.

to the specified torque. Refer to Exploded View.

CAUTION:

-

Never reuse oil strainer assembly.

-

Apply CVT fluid to O-ring

and

and  of new oil strainer assembly.

of new oil strainer assembly.

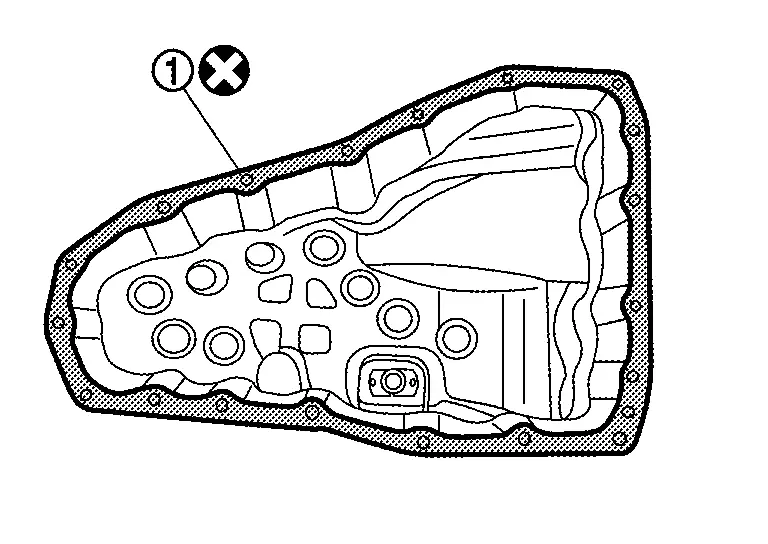

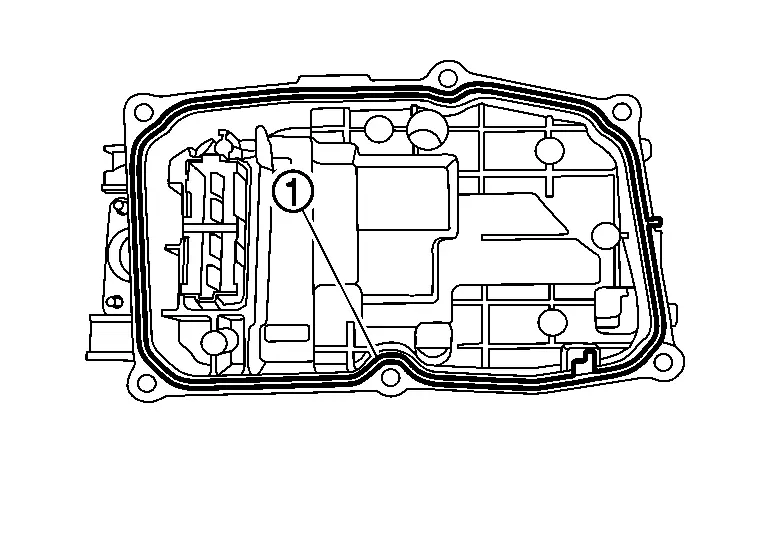

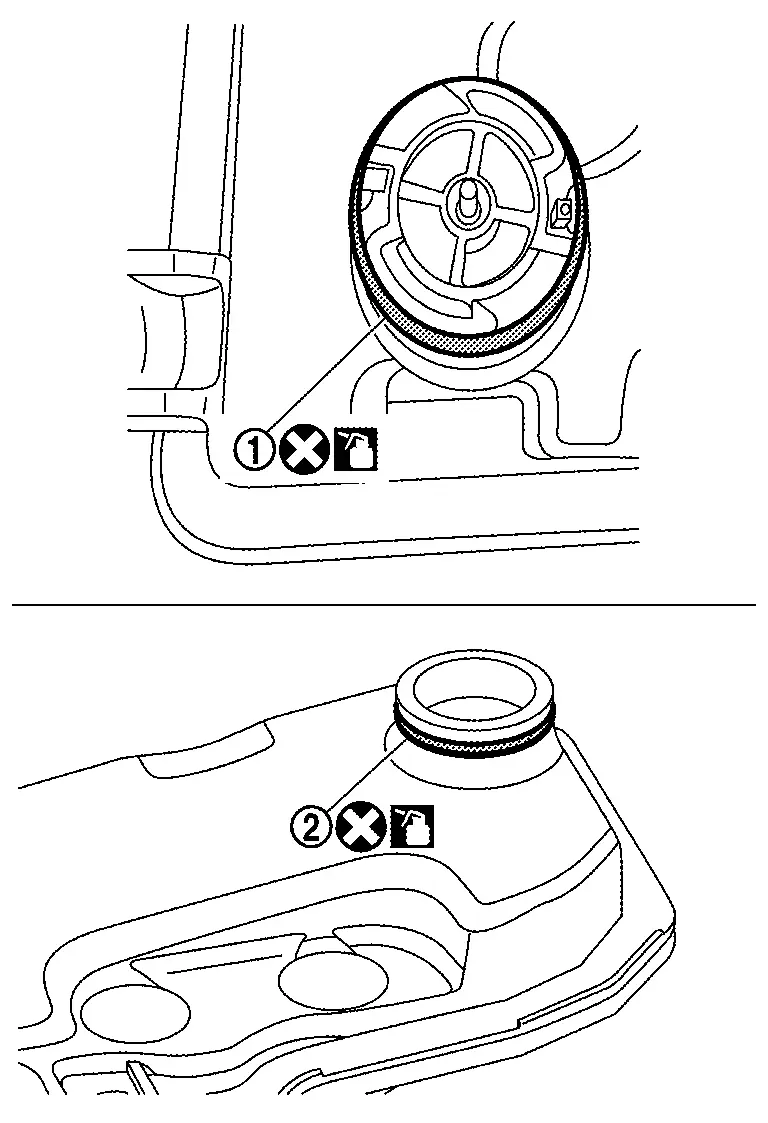

Install oil pan magnets ( 9 pieces).

9 pieces).

CAUTION:

-

Clean the magnets.

-

Clean the oil pan.

-

Align the magnets with the recesses in the oil pan to install them as shown in the figure.

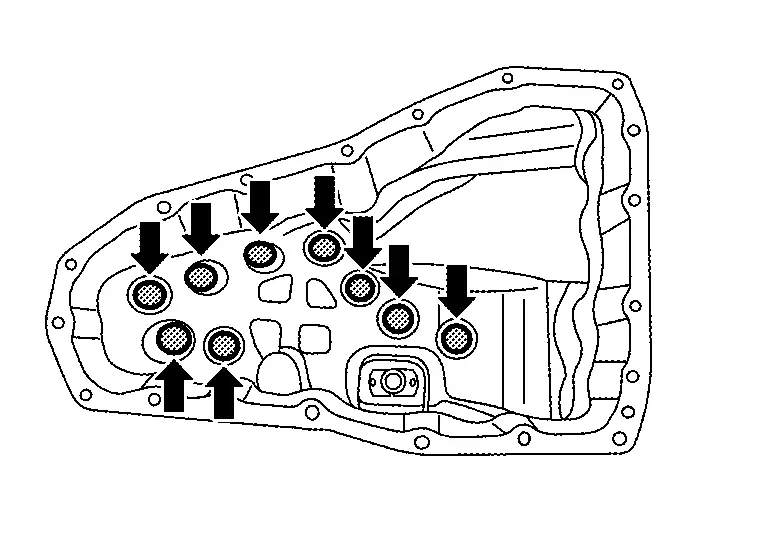

Install oil pan gasket  .

.

CAUTION:

Never reuse the oil pan gasket.

Install oil pan and then tighten oil pan mounting bolts to the specified torque in numerical order shown in the figure. Refer to Exploded View.

CAUTION:

Apply CVT fluid to the bolts when installing.

|

: Nissan Ariya Vehicle front |

Install drain plug gasket and drain plug  to the specified torque. Refer to Exploded View.

to the specified torque. Refer to Exploded View.

CAUTION:

Never reuse the drain plug gasket.

Install oil filter  .

.

CAUTION:

-

Never reuse the oil filter.

-

Apply CVT fluid to the grommet seal.

Install O-ring to  and

and  from CVT oil warmer.

from CVT oil warmer.

NOTE:

NOTE:

There are one O-ring and two O-rings depending on the specifications. When reusing oil warmer, check the number of O-rings and use the same number of O-rings as the removed number.

-

Type with one O-ring.

-

Type with two O-ring

Install oil warmer  and then tighten oil warmer mounting bolts

and then tighten oil warmer mounting bolts  to the specified torque. Refer to Exploded View.

to the specified torque. Refer to Exploded View.

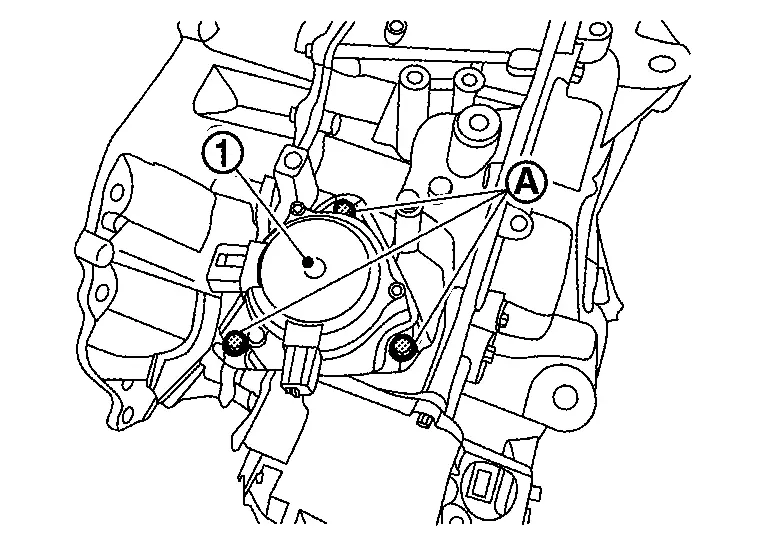

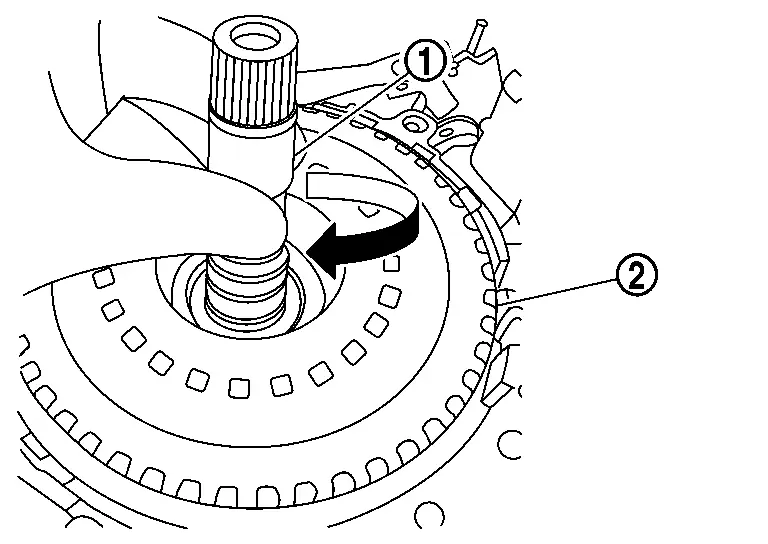

Install shift actuator  and then tighten shift actuator mounting bolts

and then tighten shift actuator mounting bolts  to the specified torque. Refer to Exploded View.

to the specified torque. Refer to Exploded View.

NOTE:

NOTE:

-

Check that position of manual shaft side is 'N' before installing shift actuator.

-

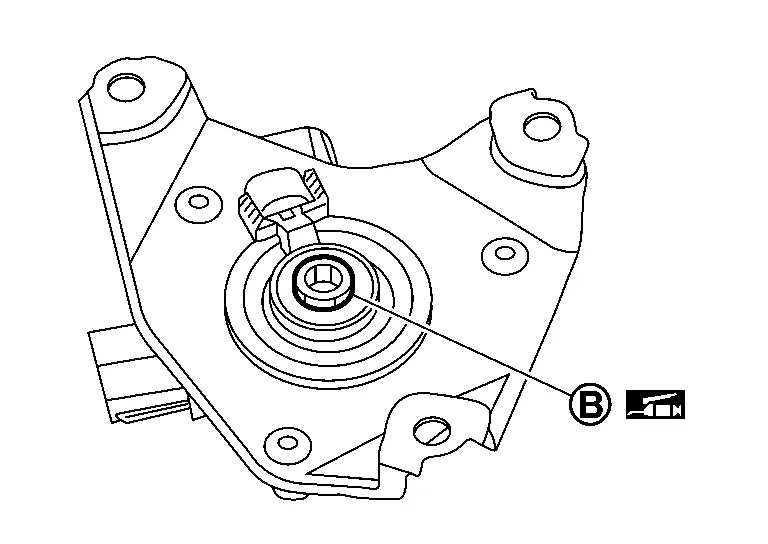

Apply grease evenly to the shift actuator spline

before installing shift actuator.

before installing shift actuator.

Install O-ring to primary pulley speed sensor.

CAUTION:

-

Apply petroleum jelly to O-ring.

-

Never reuse the O-ring.

Install primary speed sensor  , and then tighten primary speed sensor mounting bolt

, and then tighten primary speed sensor mounting bolt  to the specified tightening torque. Refer to Exploded View.

to the specified tightening torque. Refer to Exploded View.

Install O-ring to input speed sensor.

CAUTION:

-

Apply petroleum jelly to O-ring.

-

Never reuse the O-ring.

Install input speed sensor  , and then tighten input speed sensor mounting bolt

, and then tighten input speed sensor mounting bolt  to the specified tightening torque. Refer to Exploded View.

to the specified tightening torque. Refer to Exploded View.

Install new serial number sticker  on shift actuator

on shift actuator  .

.

Install torque converter. Refer to Assembly.

Install the transaxle assembly to the Nissan Ariya vehicle. Refer to Removal and Installation.

Fill the transaxle assembly with CVT fluid. Refre to Refilling.

Perform "ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE". Refer to Description.

Trouble Shooting

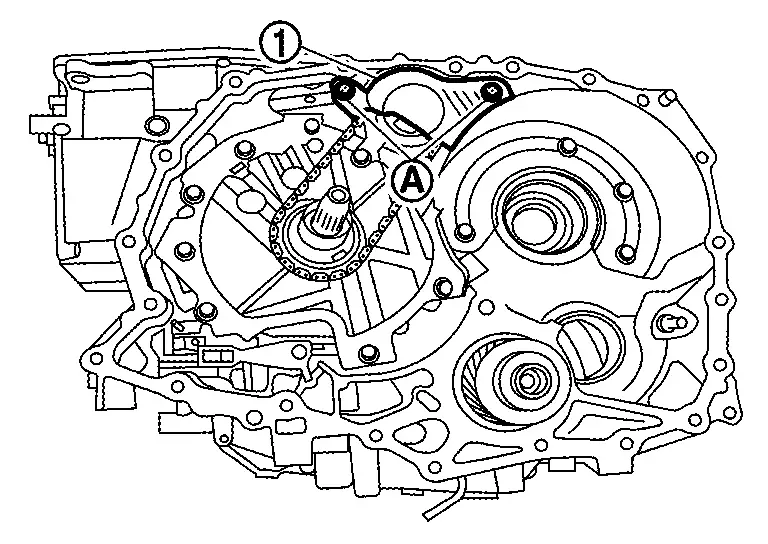

The Dummy Cover Will Not Sit Flush

NOTE:

NOTE:

-

If the dummy cover does not sit flush, the forward clutch assembly may not be fully seated. The forward clutch assembly is not fully seated if it is not below the surface that the dummy cover bolts to.

: Transaxle case

: Forward clutch assembly

: The clearance between the dummy cover and the forward clutch assembly -

Always handle the forward clutch assembly by the input shaft.

-

Remove the dummy cover

.

.

-

Pull up the forward clutch assembly

by the input shaft

by the input shaft  to remove the entire forward clutch assembly.

to remove the entire forward clutch assembly.

-

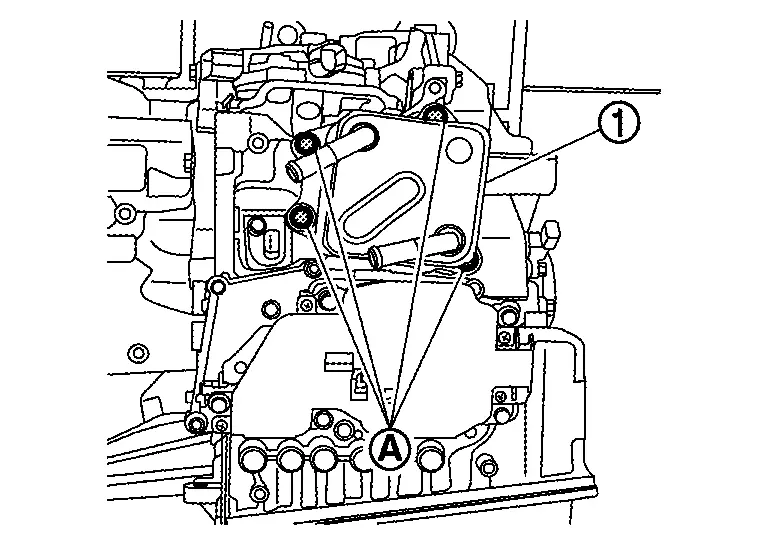

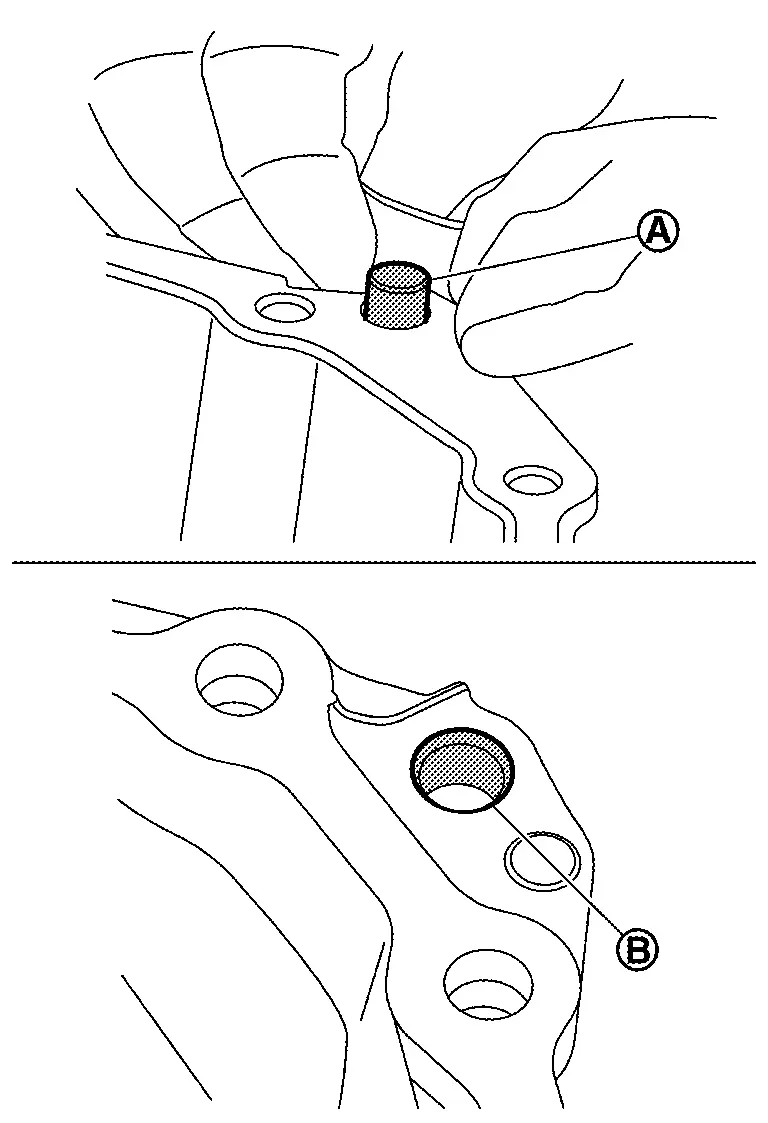

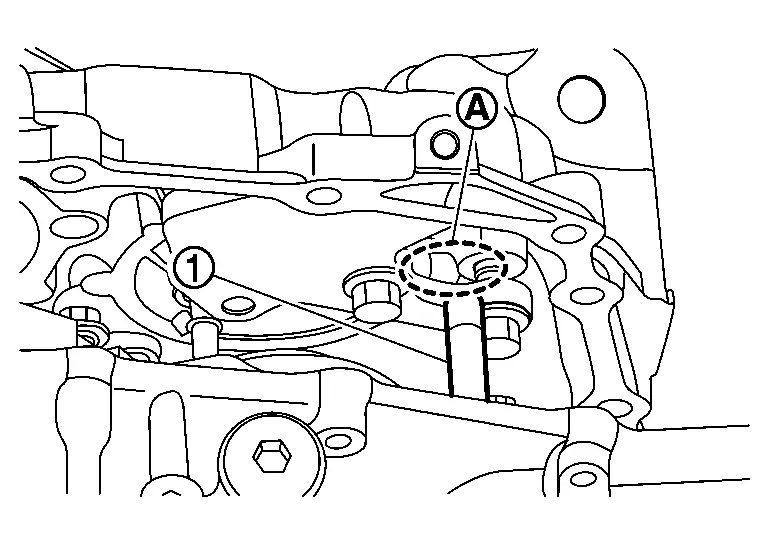

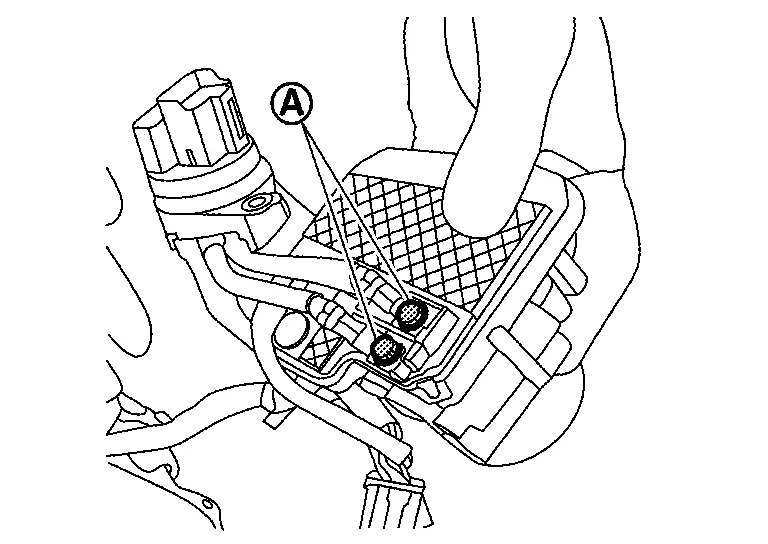

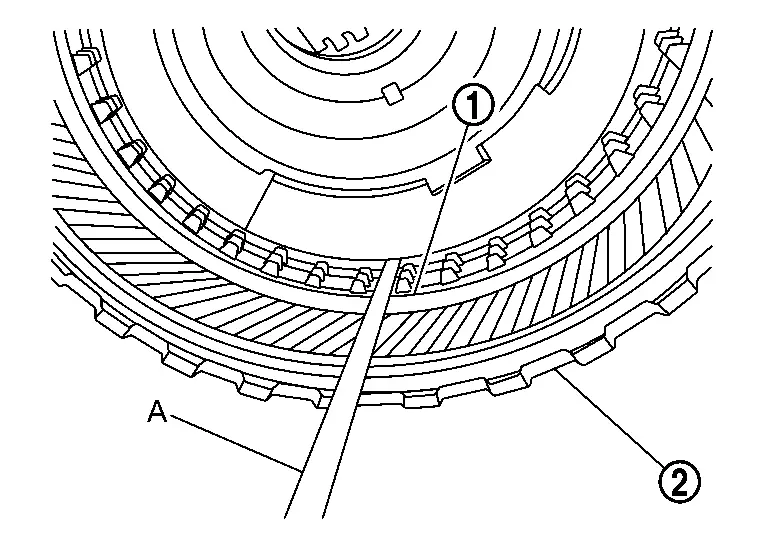

Using a suitable tool (A) gently align the layers

of the forward clutch assembly

of the forward clutch assembly  .

.

-

Re-insert the entire forward clutch assembly

while holding the input shaft

while holding the input shaft  .

.

NOTE:

NOTE:

-

Gently jiggle the input shaft until the forward clutch assembly seats below case lip.

-

If the forward clutch assembly does not seat, rotate back and forth from the input shaft and jiggle.

-

If the clutch pack still does not seat, repeat from step 3.

-

Other materials:

Anc (active Noise Control Unit)

B1a01-11 Front Door Speaker Lh

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

B1A01-11

FL-DOOR woofer OUT

(Front left door woofer)

Diagnosis condition

When ignition switch is ON

Signal (terminal)

Soun ...

Ecu Diagnosis Information. Electrically-Driven Intelligent Brake Unit

DTC Index

DTC Display item Brake warning lamp Brake system warning lamp Refer to

B14E0-02

Wheel sensor

OFF

ON

DTC Description

B14E0-09

Wheel sensor

OFF

ON

DTC Description

B14E0-11

Wheel sensor

OFF

ON

DTC Description

B14E0-12

Wheel sensor ...

Memory seat

Basic information

The memory seat system in the Nissan Rogue has the following

features:

Memory storage function

Entry/exit function

Memory storage function

Two positions for the driver's seat and

outside mirrors can be stored in the

memory switch. Follow these procedures

to use the memory sys ...