Nissan Rogue (T33) 2021-Present Service Manual: Shift Actuator

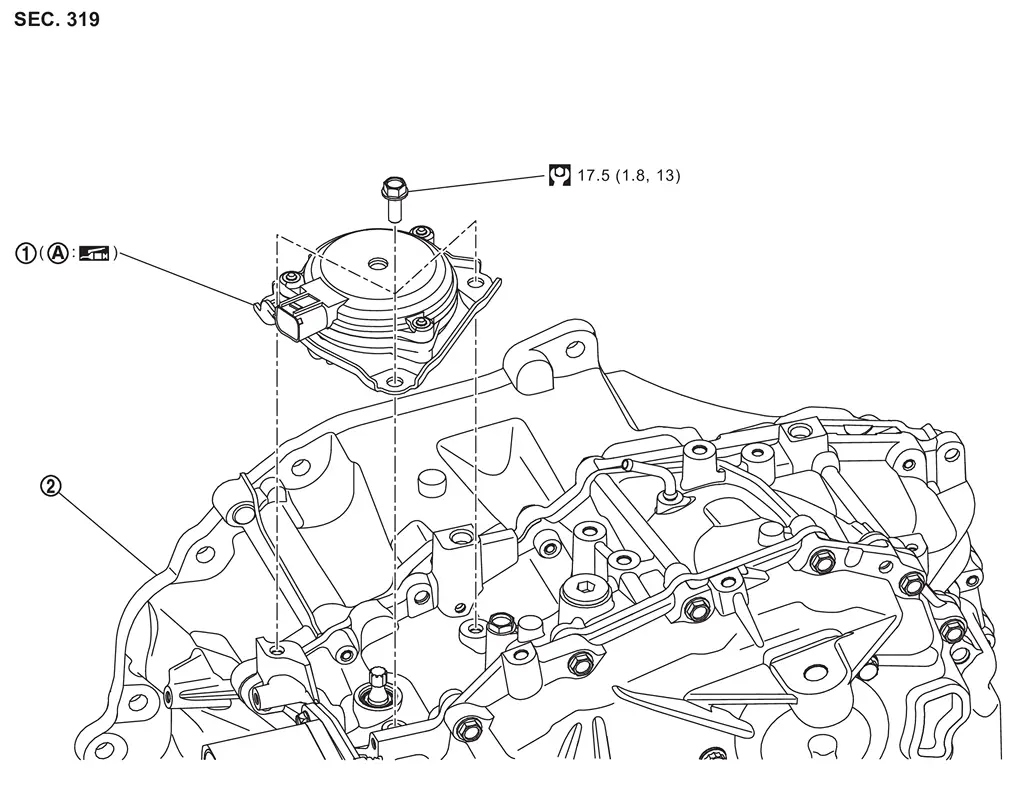

Exploded View

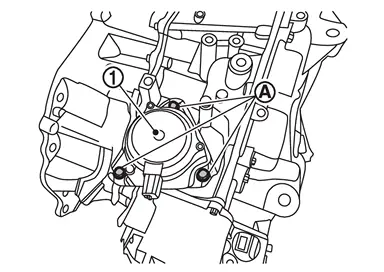

| 1. | Shift actuator | 2. | Transaxle assembly | ||

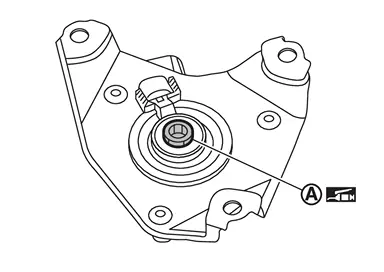

| A | Spline part |

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Apply lithium-based grease including molybdenum disulphide

: Apply lithium-based grease including molybdenum disulphide

Removal and Installation

REMOVAL

CAUTION:

Be sure that vehicle does not move before removing shift actuator.

-

Apply the parking brake.

-

Shift to the P position (if electric shift system is normal).

Remove 12V battery. Refer to Removal and Installation.

Remove battery tray 1. Refer to Removal and Installation

Remove air cleaner and air duct. Refer to Removal and Installation.

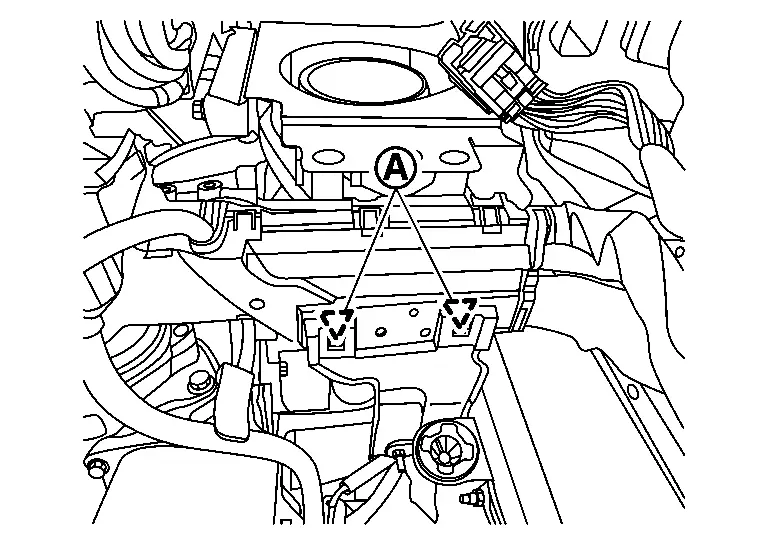

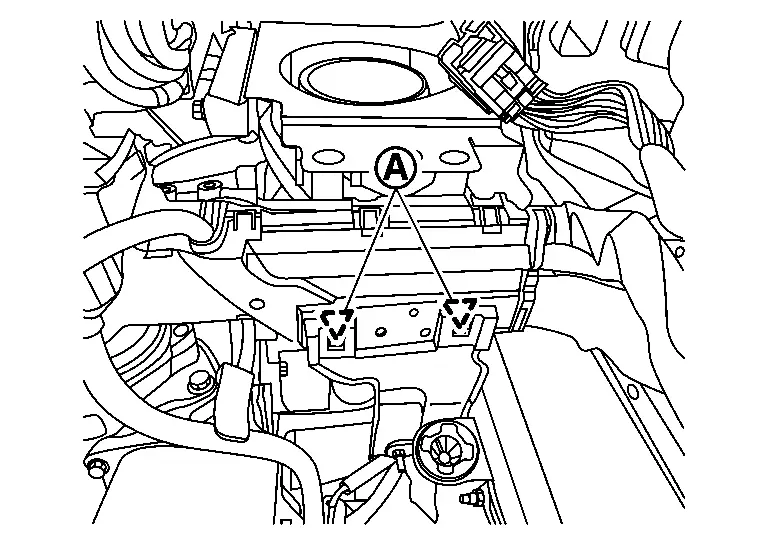

Remove harness clips (A) .

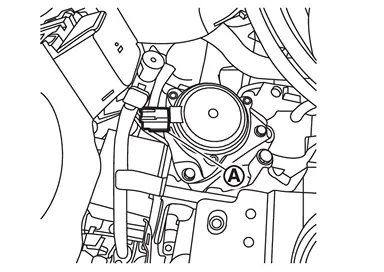

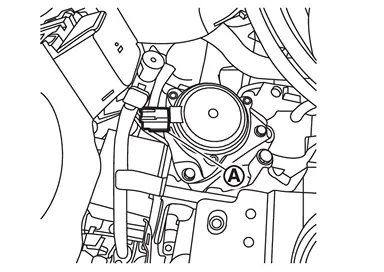

Disconnect the harness connector (A) from the shift actuator.

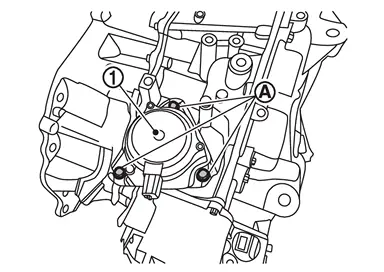

Remove bolts (A) from shift actuator and remove shift actuator (1).

INSTALLATION

CAUTION:

Apply the parking brake.

CAUTION:

Note when the shift actuator is removed while the range is in the P position, and installed while the range is in the N position:

-

Never use remote engine start system immediately after installing shift actuator.

-

Adjust to P range after pressing P switch without operating shift selector after ignition switch ON.

-

Unless the above points are performed, the electric shift control module does not accept the request from the shift lever.

Clean splines of manual shaft and shift actuator before installing shift actuator.

Apply grease evenly to the shift actuator spline (A).

|

: Lithium-based grease including molybdenum disulphide |

Install shift actuator (1) and then tighten shift actuator mounting bolts (A) to the specified torque. Refer to Exploded View.

NOTE:

NOTE:

Set the manual shaft to the N position before installing the shift actuator.

Connect the harness connectors (A) to the shift actuator.

Install harness clips (A) .

Install air duct and air cleaner. Refer toExploded View.

Install battery tray. Refer to Removal and Installation.

Install 12V battery. Refer to Removal and Installation.

Connect the negative battery terminal. Refer to Exploded View.

Ignition switch ON and press the P position switch.

Learn shift actuator after installation. Refer to Description.

Perform inspection after installation. Refer to Inspection.

Inspection

INSPECTION AFTER INSTALLATION

Check the CVT position. Refer to Inspection.

Other materials:

System

Propilot Assist

System Description

SYSTEM DIAGRAM

Component Description

ECM

ECM

TCM

TCM

ABS actuator and electric unit (control unit)

ABS Actuator and Electric Unit (Control Unit)

BCM

System Description

Steering angle sensor

Steering Angle Sensor

Pow ...

Basic Inspection. Configration (intelligent Key Unit)

Description

Vehicle specification needs to be written with CONSULT because it is not written after replacing the Intelligent Key unit.The

configuration requires network connection. CONSULT connects to network

and then it downloads the configuration data from the server. Then

CONSULT writes th ...

System Description. Component Parts. Active Grille Shutter System

Active Grille Shutter System

Component Parts Location

No. Component Function

IPDM E/R

Refer to Component Parts Location for detailed component location.

ECM

Refer to ECM for detailed component location.

Active grille shutter

Refer to Active grille shutter.

For th ...