Nissan Rogue (T33) 2021-Present Service Manual: Removal and Installation :: Coil Spring

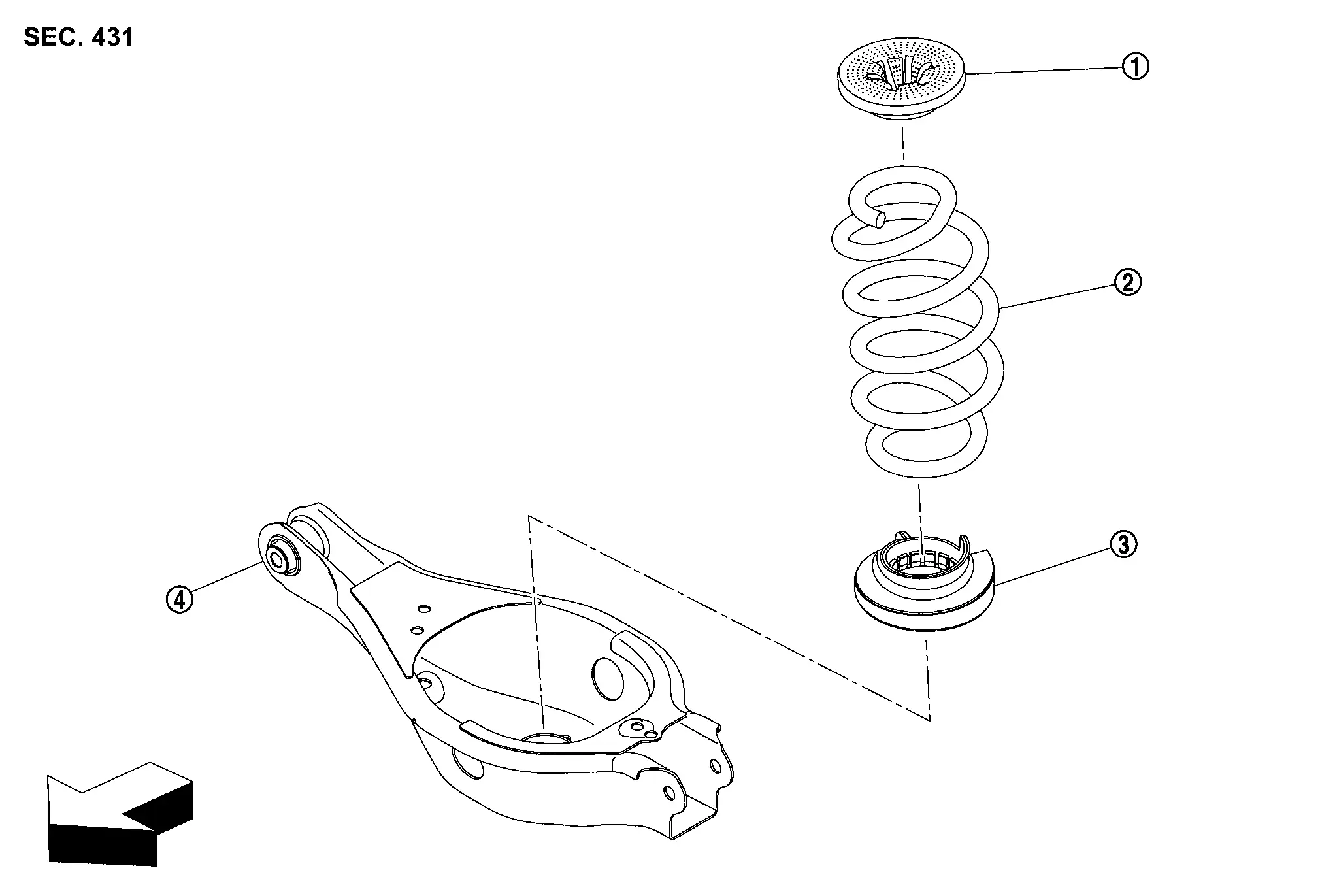

Exploded View

|

Upper rubber seat |  |

Coil spring |  |

Lower rubber seat |

|

Rear lower link | ||||

|

: Nissan Ariya Vehicle front |

Removal and Installation

REMOVAL

Remove tires. Refer to Removal & Installation..

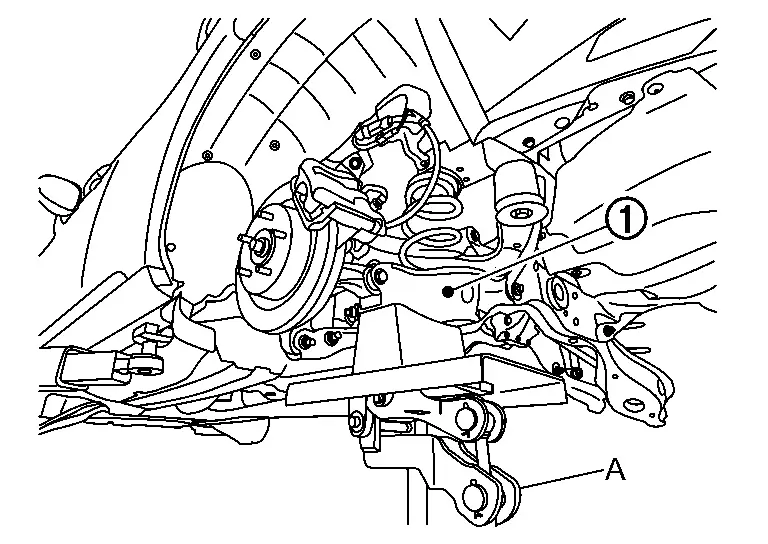

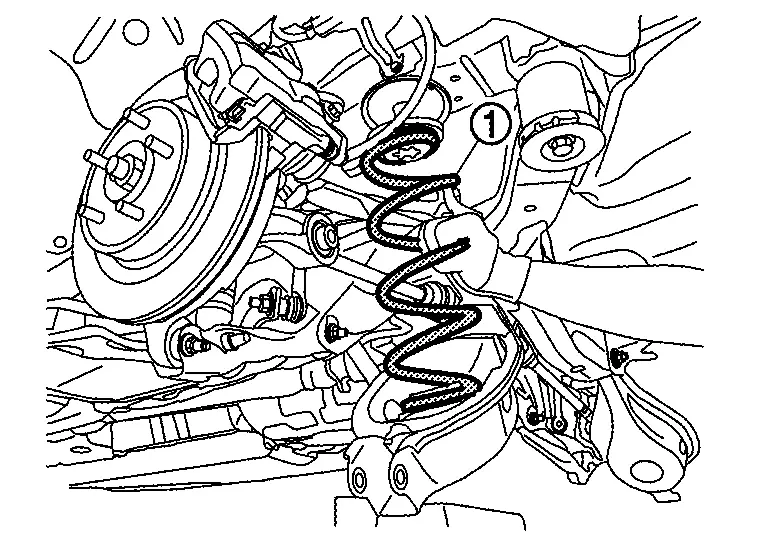

Using jack (A) to rear lower link  .

.

CAUTION:

-

Never damage the rear lower link with a jack.

-

Check the stable condition when using a jack.

Loosen the rear lower link mounting bolts and nuts  (rear suspension member side).

(rear suspension member side).

Remove the rear lower link mounting bolts and nuts  (axle housing side).

(axle housing side).

Slowly lower jack, remove upper rubber seat and coil spring  .

.

CAUTION:

Operate while checking that jack supporting status is stable.

Remove lower rubber seat from rear lower link.

Perform inspection after removal. Refer to Inspection.

INSTALLATION

Note the following, and install in the reverse order of removal.

-

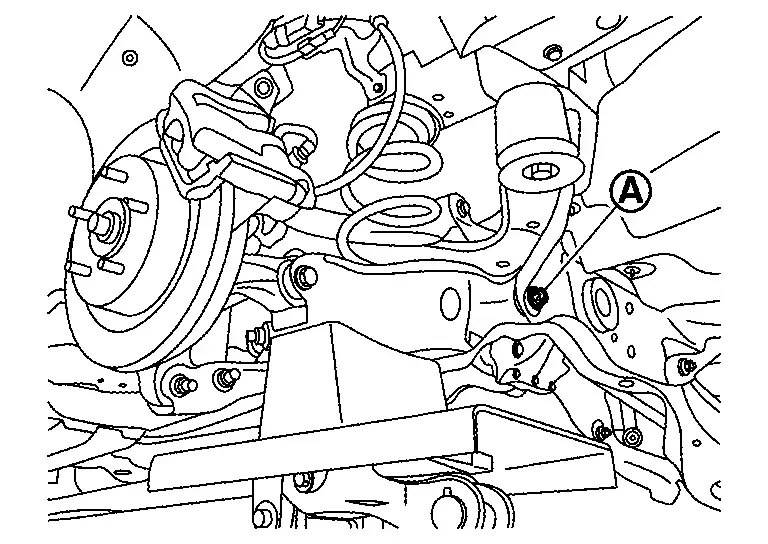

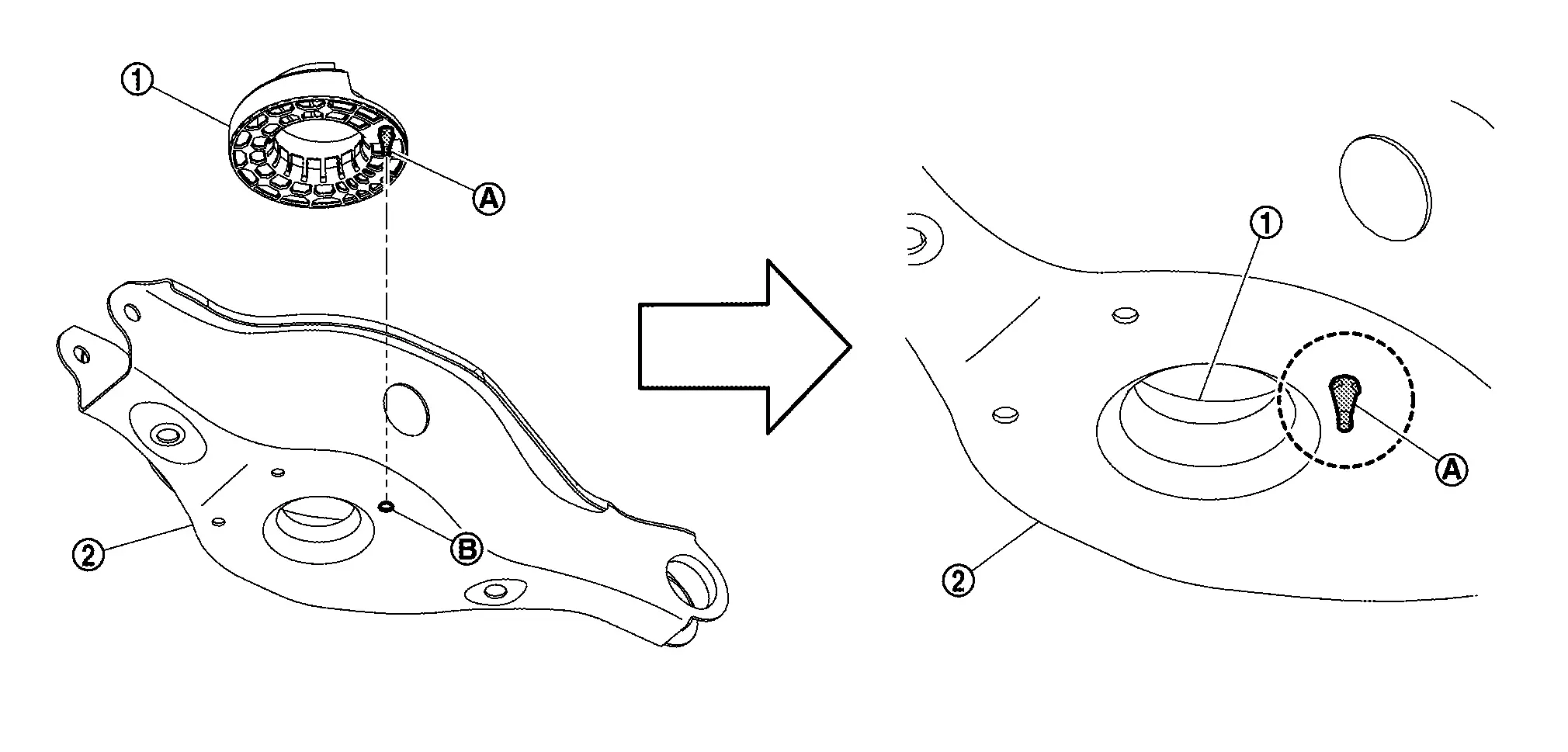

Install lower rubber seat

with its protrusion

with its protrusion  on the lower area aligned with the hole

on the lower area aligned with the hole  of rear lower link

of rear lower link .

.

CAUTION:

The lower rubber seat protrusion

must be securely inserted into the hole

must be securely inserted into the hole  of rear lower link

of rear lower link .

. -

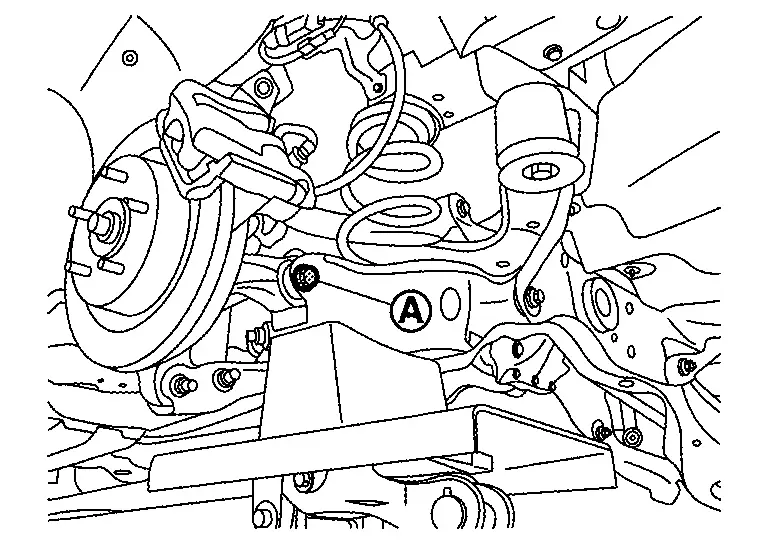

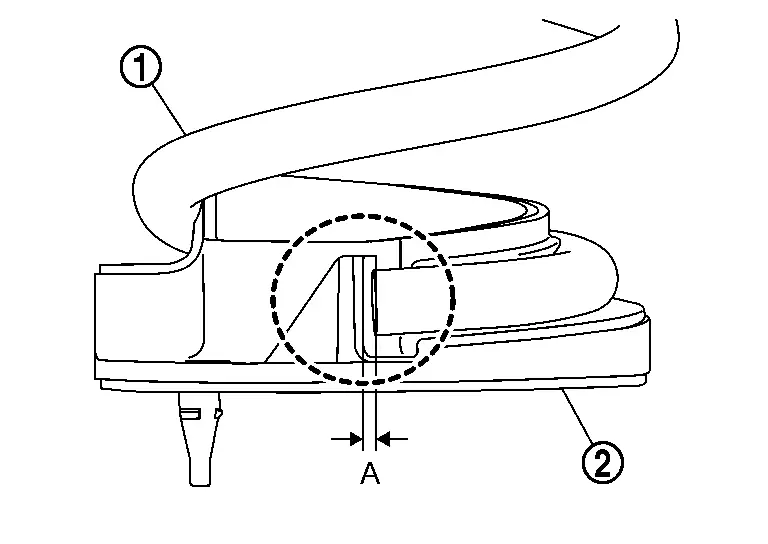

Install coil spring

by aligning lower end of coil spring with lower rubber seat

by aligning lower end of coil spring with lower rubber seat  as shown in the figure.

as shown in the figure.

Dimension (A) : 5 mm (0.20 in) or less CAUTION:

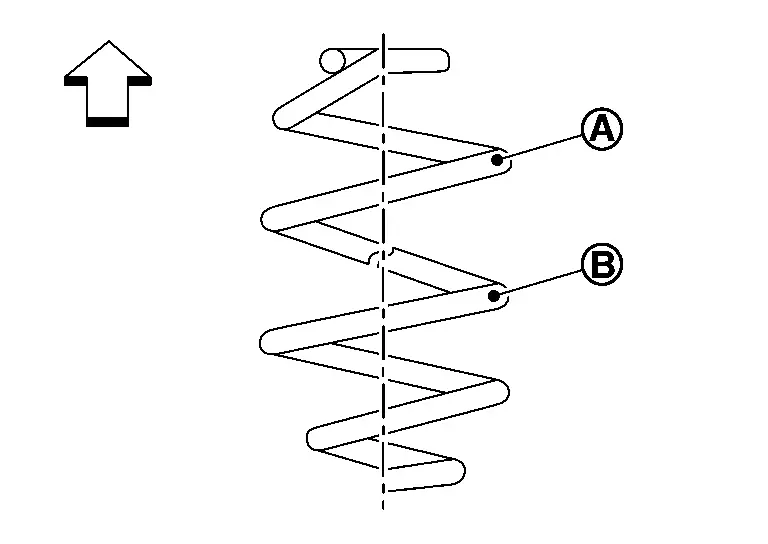

Set coil spring so that its paint marks

and

and  are aligned with the position from the bottom end of the coil spring shown in the figure.

are aligned with the position from the bottom end of the coil spring shown in the figure.

: Upper side Japan production models

: 2.75 turns

: 1.80 turns North America production models

: 3.5 turns

: 2.5 turns -

Perform final tightening of fixing parts at the Nissan Ariya vehicle installation position (rubber bushing), under unladen conditions with tires on level ground.

-

Perform inspection after installation. Refer to Inspection.

Inspection

INSPECTION AFTER REMOVAL

Check rear lower link, rubber seat, upper seat, and coil spring for deformation, crack, and damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

Check wheel alignment. Refer to Inspection.

Other materials:

Dtc/circuit Diagnosis. U0073-00 Control Module Comm Bus a Off

DTC Description

DESCRIPTIONCAN (Controller Area Network) is a serial

communication line for real time applications. It is an on-Nissan Ariya

vehicle multiplex communication line with high data communication speed

and excellent error detection ability. Modern Nissan Ariya vehicle is

equipped ...

U2140-87 Can Comm Err (ecm)

DTC Description

DESCRIPTIONCAN (Controller Area Network) is a serial

communication line for real time applications. It is an on-Nissan Ariya

vehicle multiplex communication line with high data communication speed

and excellent error detection ability. Modern Nissan Ariya vehicle is

equipped ...

Preparation

Special Service Tools

The actual shapes of TechMate tools may differ from those of special service tools illustrated here.

Tool number

(TechMate No.)

Tool name Description

(NI-39570)

Chassis ear

Locates the noise

(NI-50397)

Squeak and Rattle Kit

Repairs the c ...