Nissan Rogue (T33) 2021-Present Service Manual: Removal and Installation :: Brake Piping

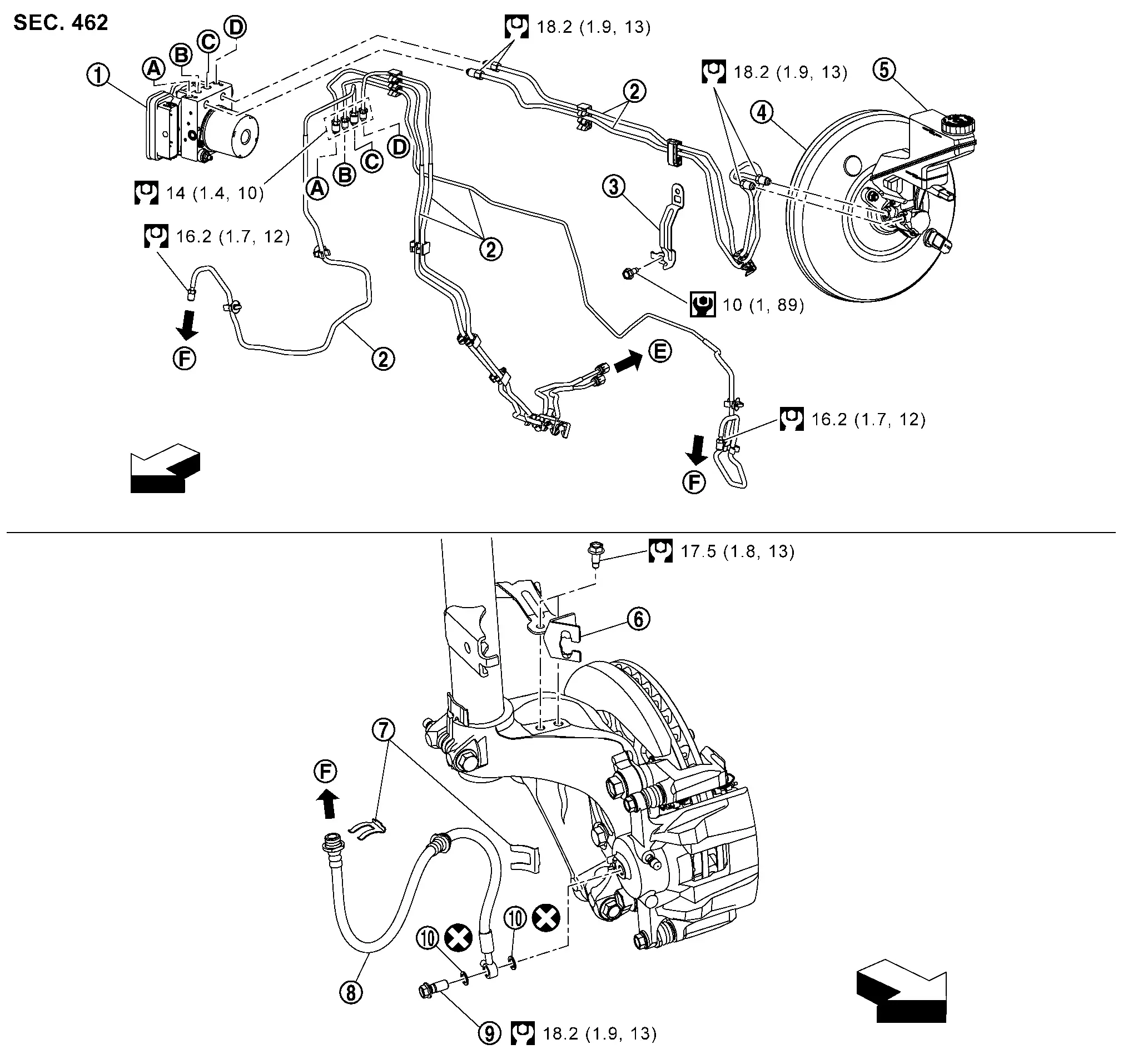

Front

Exploded View

JAPAN PRODUCTION MODELS WITHOUT ProPILOT Assist 2.1

|

ABS actuator and electric unit (control unit) |  |

Brake tube |  |

Brake tube bracket |

|

Brake booster |  |

Master cylinder assembly |  |

Bracket |

|

Lock plate |  |

Brake hose |  |

Union bolt |

|

Copper washer | ||||

|

To rear brake tube. Refer to Exploded view. | ||||

, , , ,  , ,  , ,  : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. |

|||||

|

: Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Always replace after every disassembly. | ||||

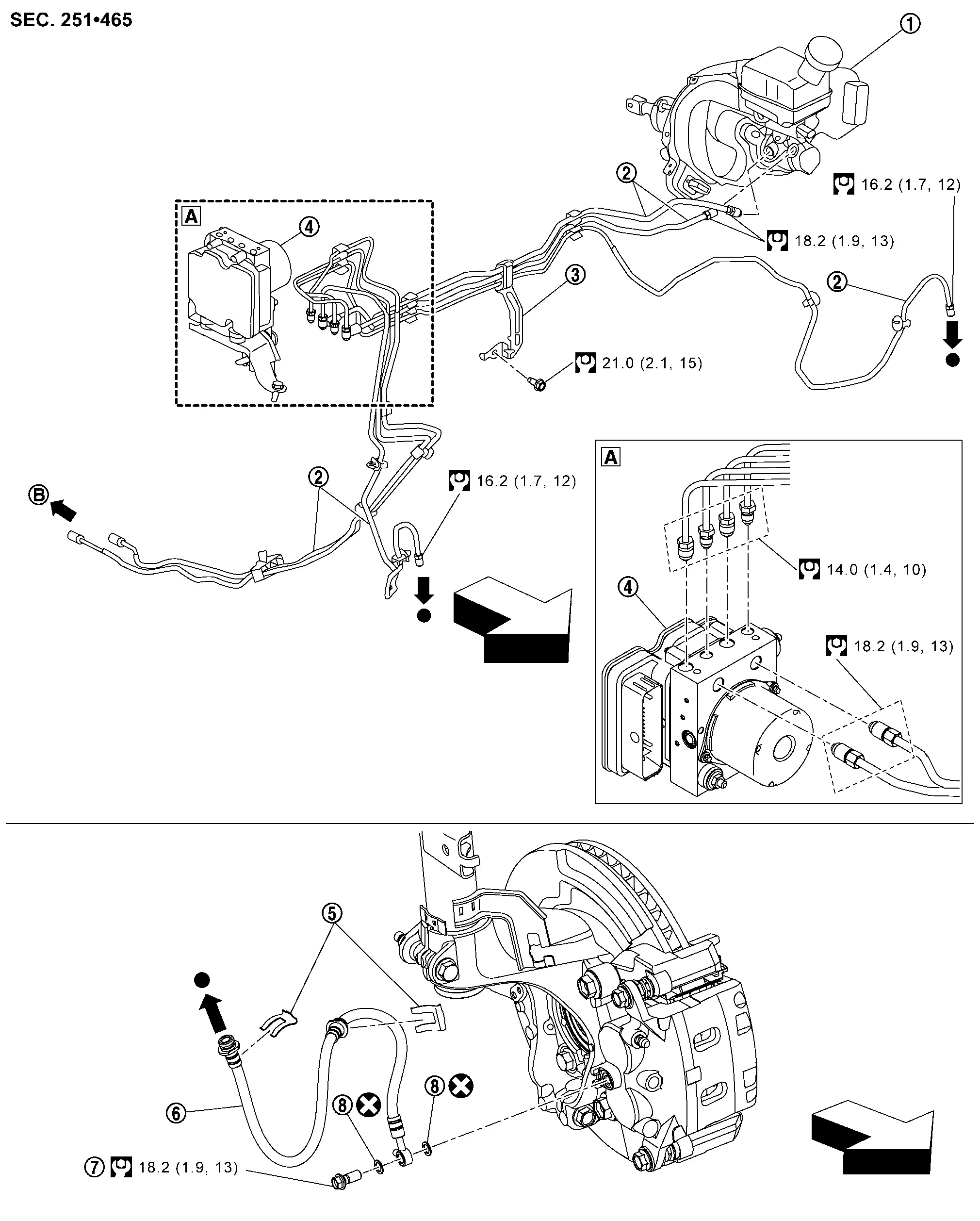

JAPAN PRODUCTION MODELS WITH ProPILOT Assist 2.1

|

Electrically-driven intelligent brake unit |  |

Brake tube |  |

Bracket |

|

ABS actuator and electric unit (control unit) |  |

Lock plate |  |

Brake hose |

|

Union bolt |  |

Copper washer | ||

|

To rear brake tube. Refer to Exploded View. | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Always replace after every disassembly. | ||||

|

: Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. | ||||

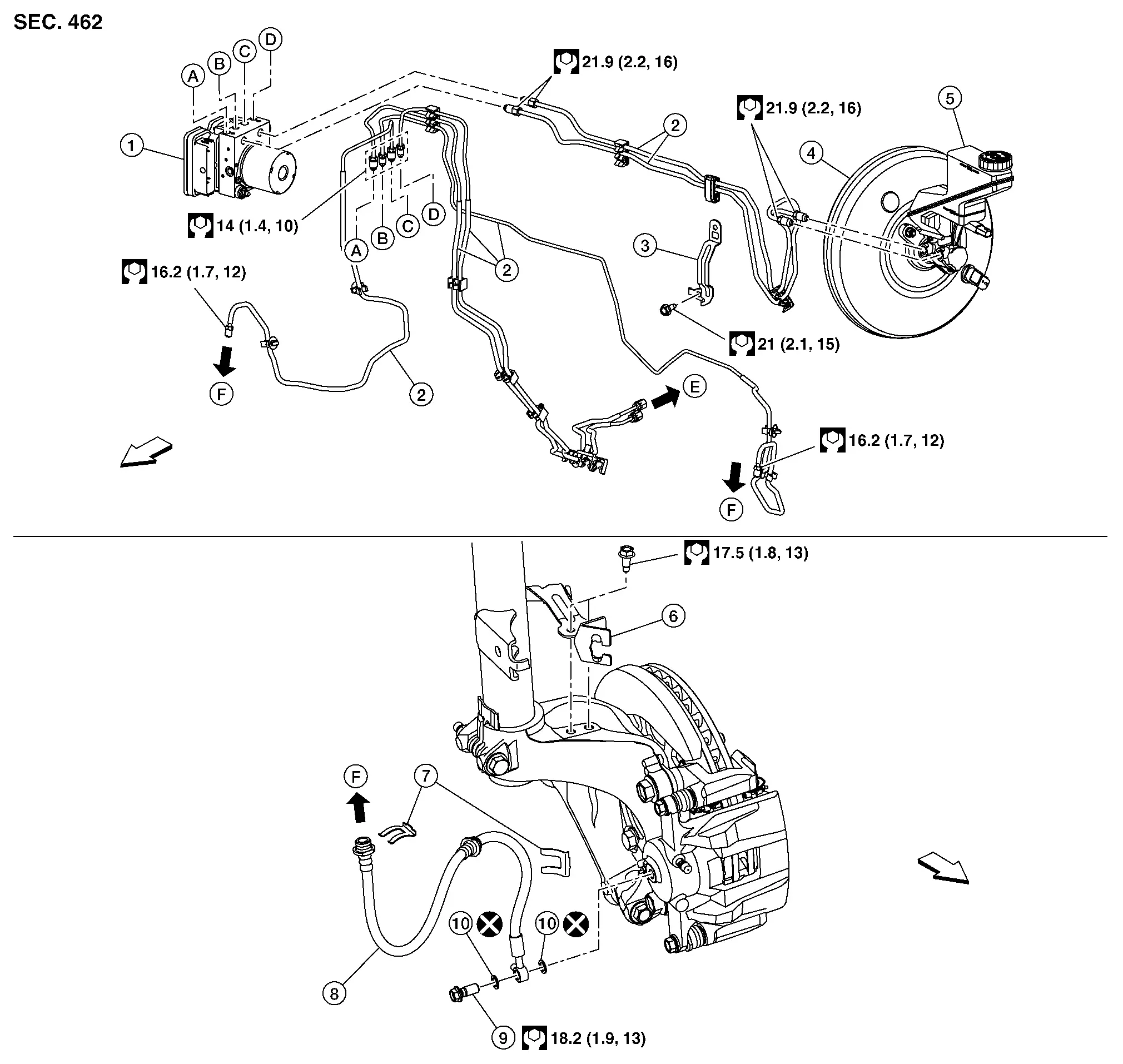

NORTH AMERICA PRODUCTION MODELS

|

ABS actuator and electric unit (control unit) |  |

Brake tube |  |

Brake tube bracket |

|

Brake booster |  |

Master cylinder assembly |  |

Bracket |

|

Lock plate |  |

Brake hose |  |

Union bolt |

|

Copper washer | ||||

|

To rear brake tube. Refer to Exploded view. | ||||

, , , ,  , ,  , ,  : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. |

|||||

|

: Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Always replace after every disassembly. | ||||

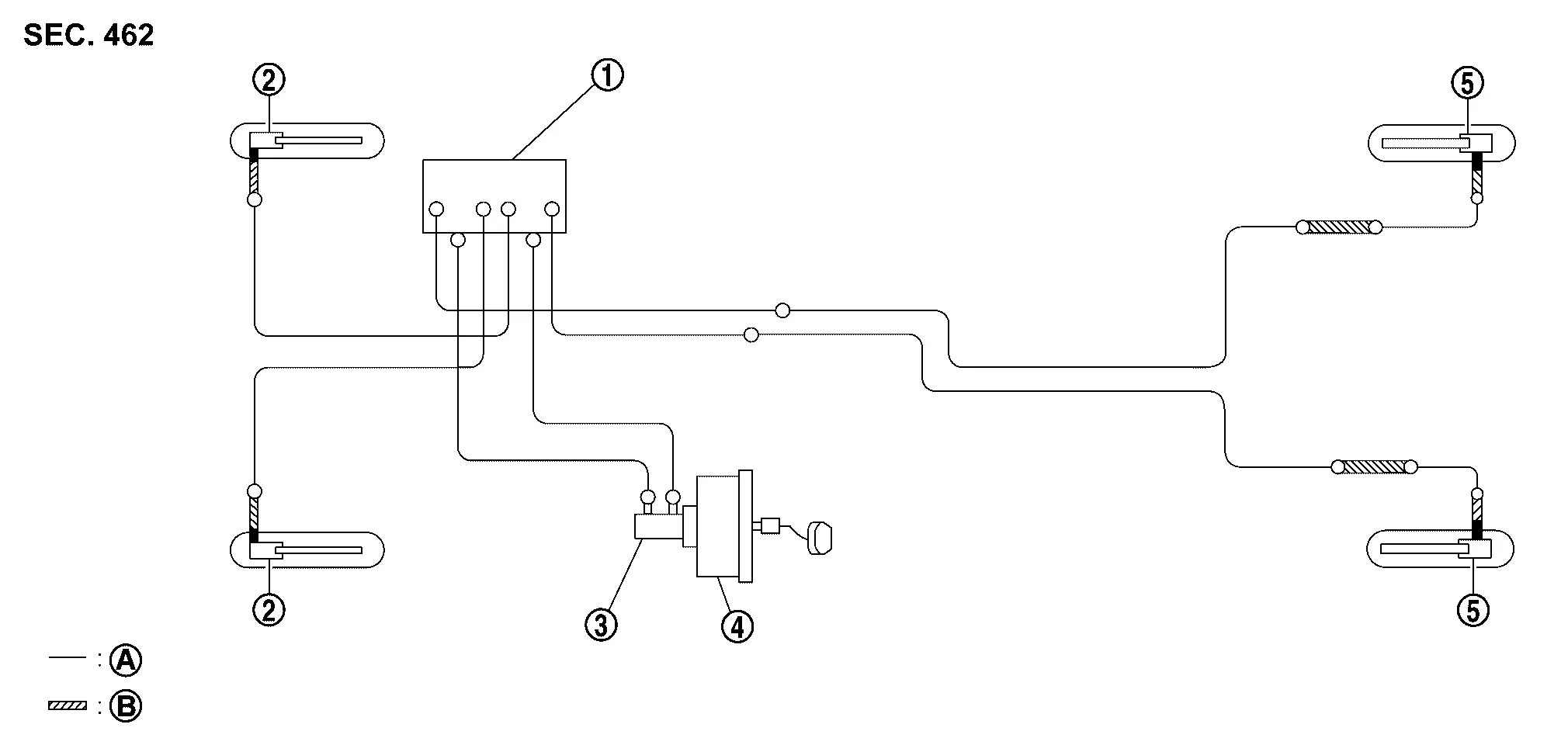

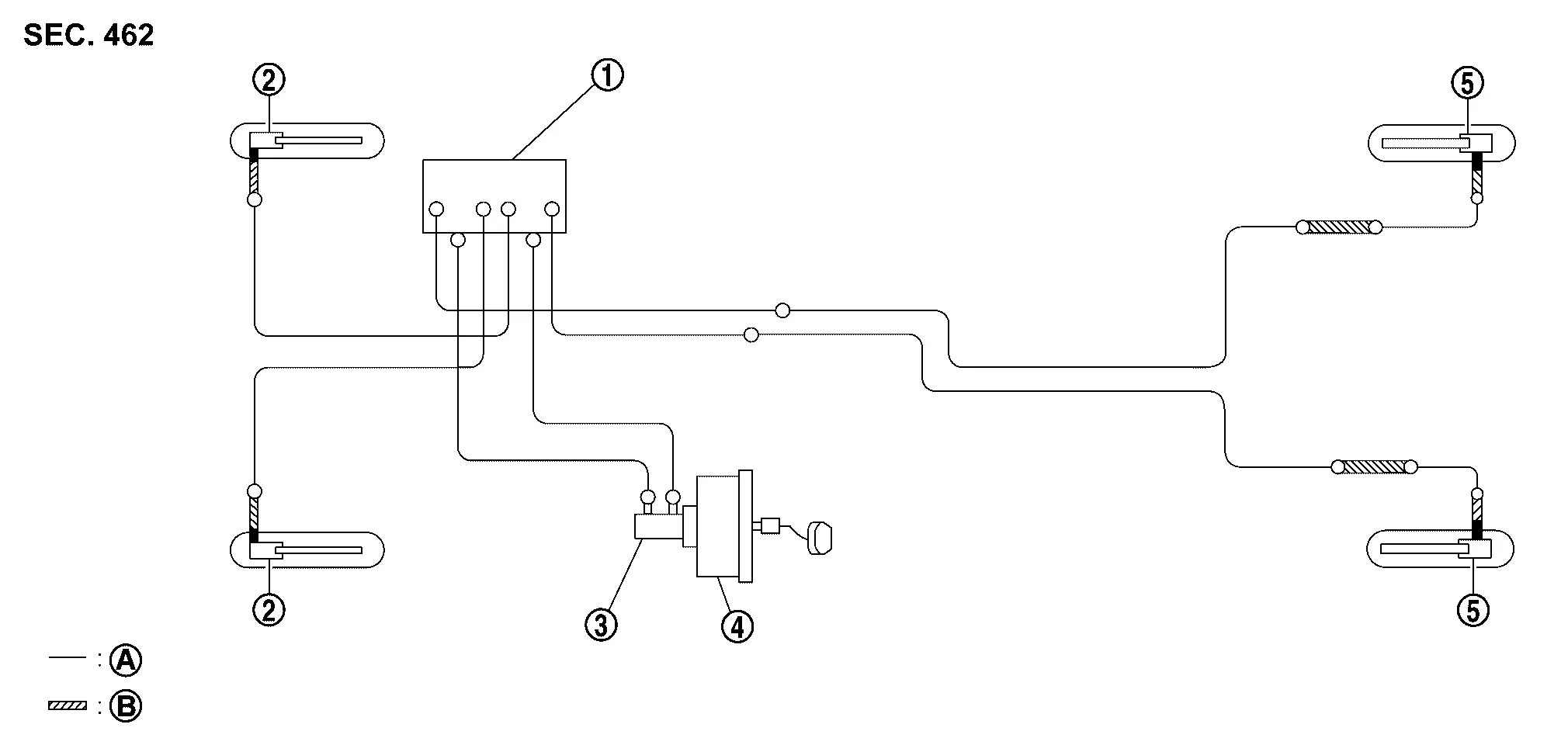

Hydraulic Piping

|

ABS actuator and electric unit (control unit) |  |

Front disc brake |  |

Master cylinder assembly |

|

Brake booster |  |

Rear disc brake | ||

|

Brake tube |  |

Brake hose | ||

|

: Flare nut | ||||

|

: Union bolt | ||||

Removal and Installation

REMOVAL

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

Remove tires.

Drain brake fluid. Refer to Draining.

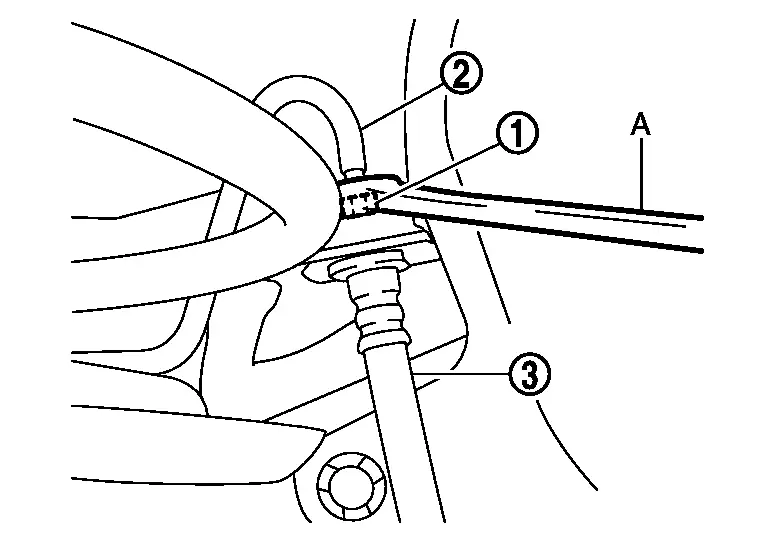

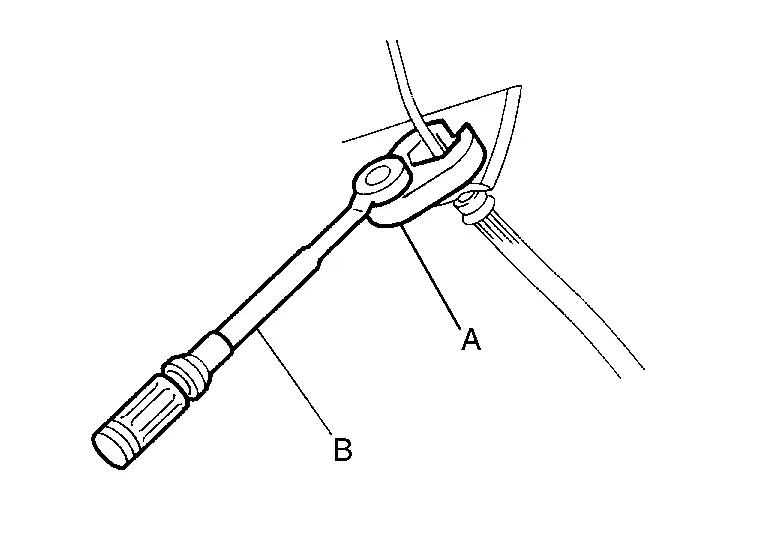

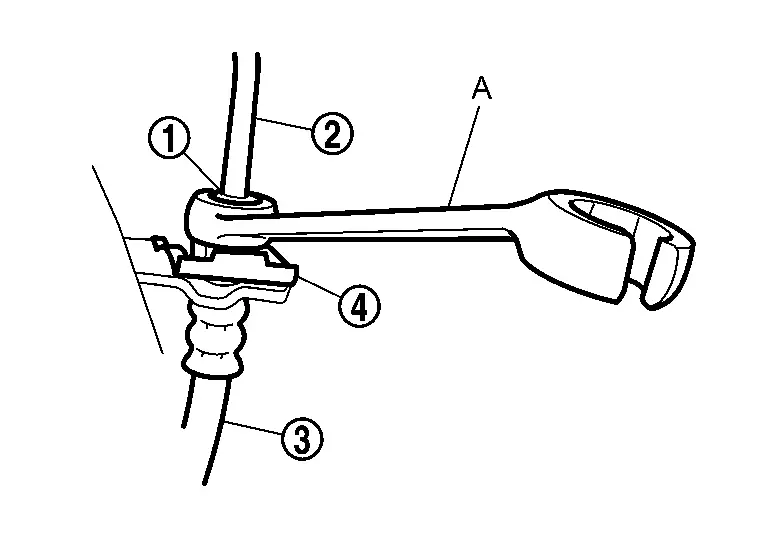

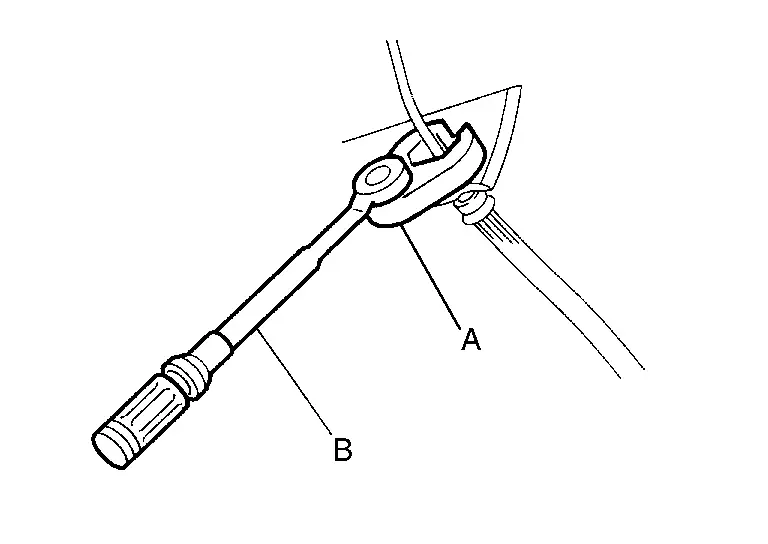

Loosen the flare nut  with a flare nut wrench (A) and separate the brake tube

with a flare nut wrench (A) and separate the brake tube  from the brake hose

from the brake hose  .

.

CAUTION:

-

Never scratch the flare nut and the brake tube.

-

Never bend sharply, twist or strongly pull out the brake hoses and tubes.

-

Cover open end of brake tubes and hoses when disconnecting to prevent entrance of dirt.

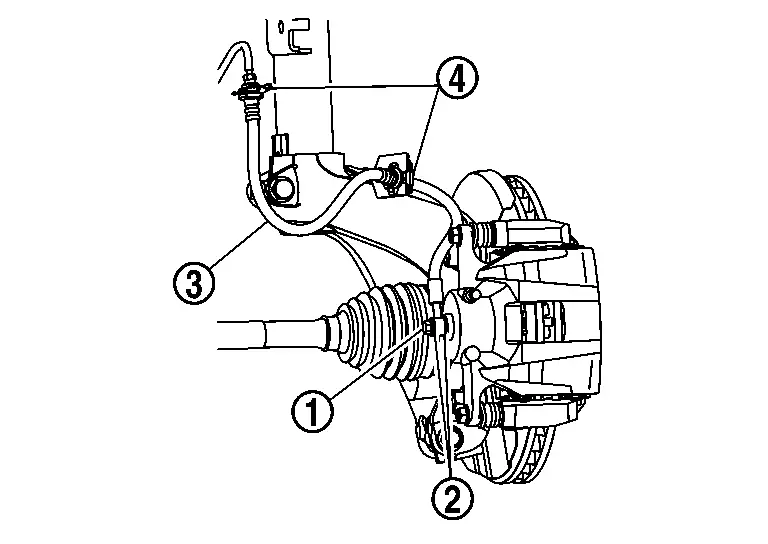

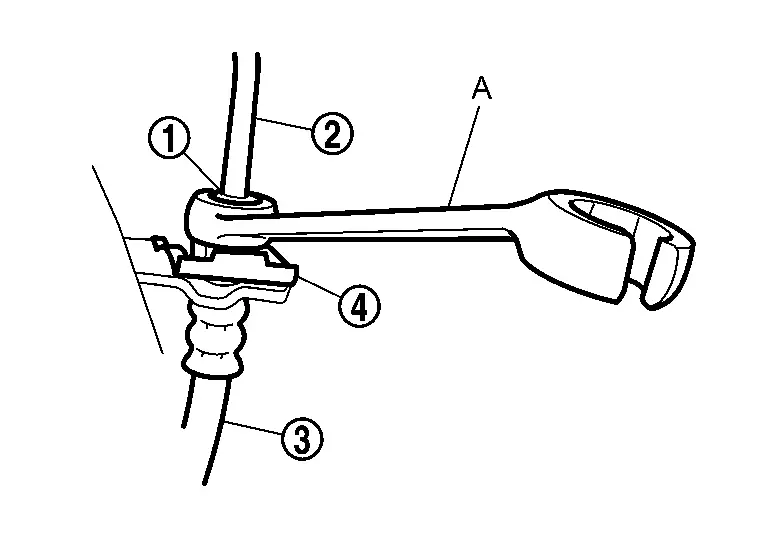

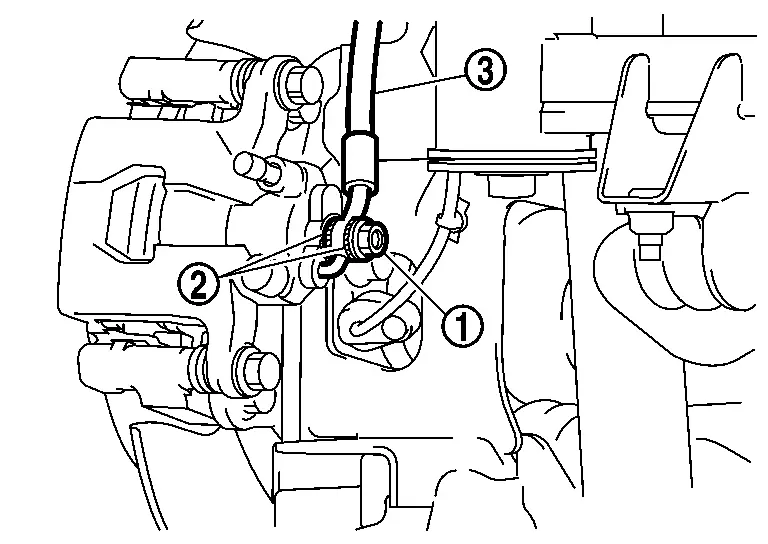

Remove the union bolt  and copper washers

and copper washers  , and remove the brake hose

, and remove the brake hose  from the brake caliper assembly.

from the brake caliper assembly.

Remove the lock plate  and remove the brake hose.

and remove the brake hose.

INSTALLATION

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

-

Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

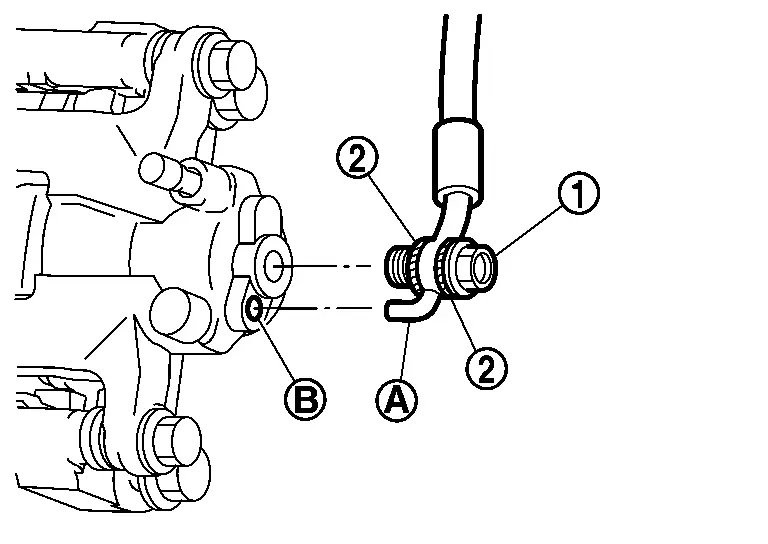

Assemble the union bolt  and the copper washer

and the copper washer  to the brake hose.

to the brake hose.

CAUTION:

Never reuse the copper washer.

Align the brake hose pin  with the brake caliper assembly projection

with the brake caliper assembly projection  , and tighten the union bolt to the specified torque.

, and tighten the union bolt to the specified torque.

Install the brake tube  to the brake hose

to the brake hose  , temporarily tighten the flare nut

, temporarily tighten the flare nut  by hand until it does not rotate further, and fix the brake hose to the bracket

by hand until it does not rotate further, and fix the brake hose to the bracket  with the lock plate

with the lock plate  .

.

CAUTION:

Check that all brake hoses and brake tubes are not twisted and bent.

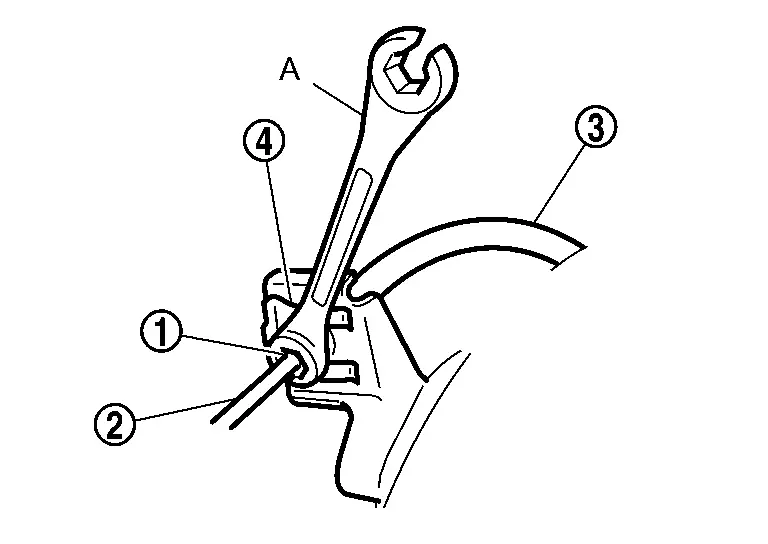

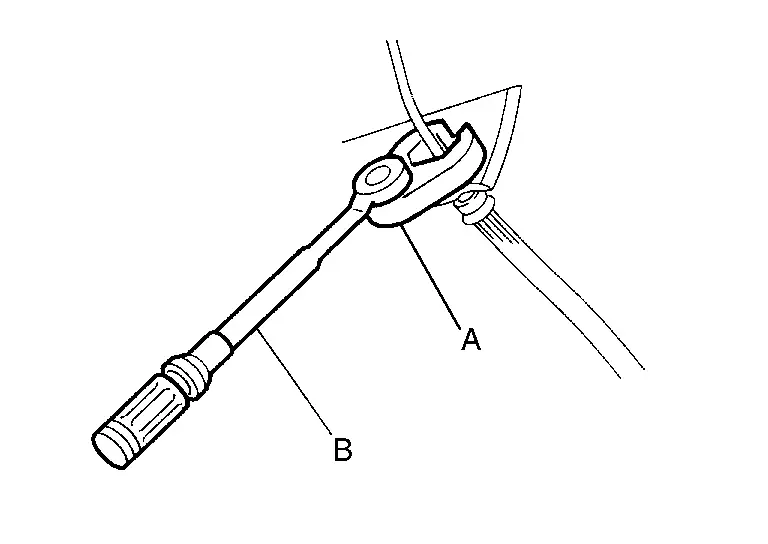

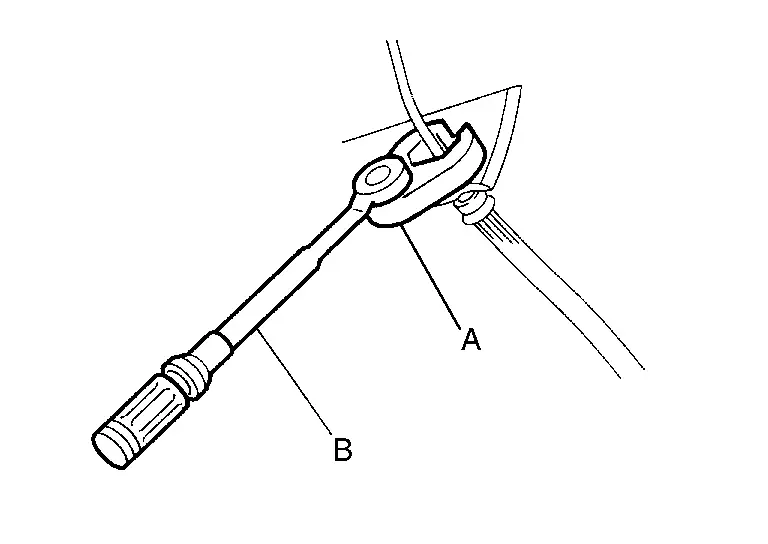

Tighten the flare nut to the specified torque with a crowfoot (A) and torque wrench (B).

CAUTION:

Never scratch the flare nut and the brake tube.

Refill with new brake fluid and perform the air bleeding. Refer to Bleeding Brake System.

CAUTION:

Never reuse drained brake fluid.

Install tires. Refer to Removal & Installation.

Perform inspection after installation. Refer to Inspection.

Inspection

INSPECTION AFTER INSTALLATION

Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interference with other components when steering the steering wheel; no looseness at connections.

CAUTION:

Clearance with brake hose and each parts being secured more than 10 mm (0.39 in) in unladen condition*.

*: Fuel, engine coolant and lubricant are quantity to specified. Spare tire, jack, hand tools and mats are brought out of Nissan Ariya vehicle.

Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approximately 5 seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged, worn or deformed) part if any brake fluid leakage is present.

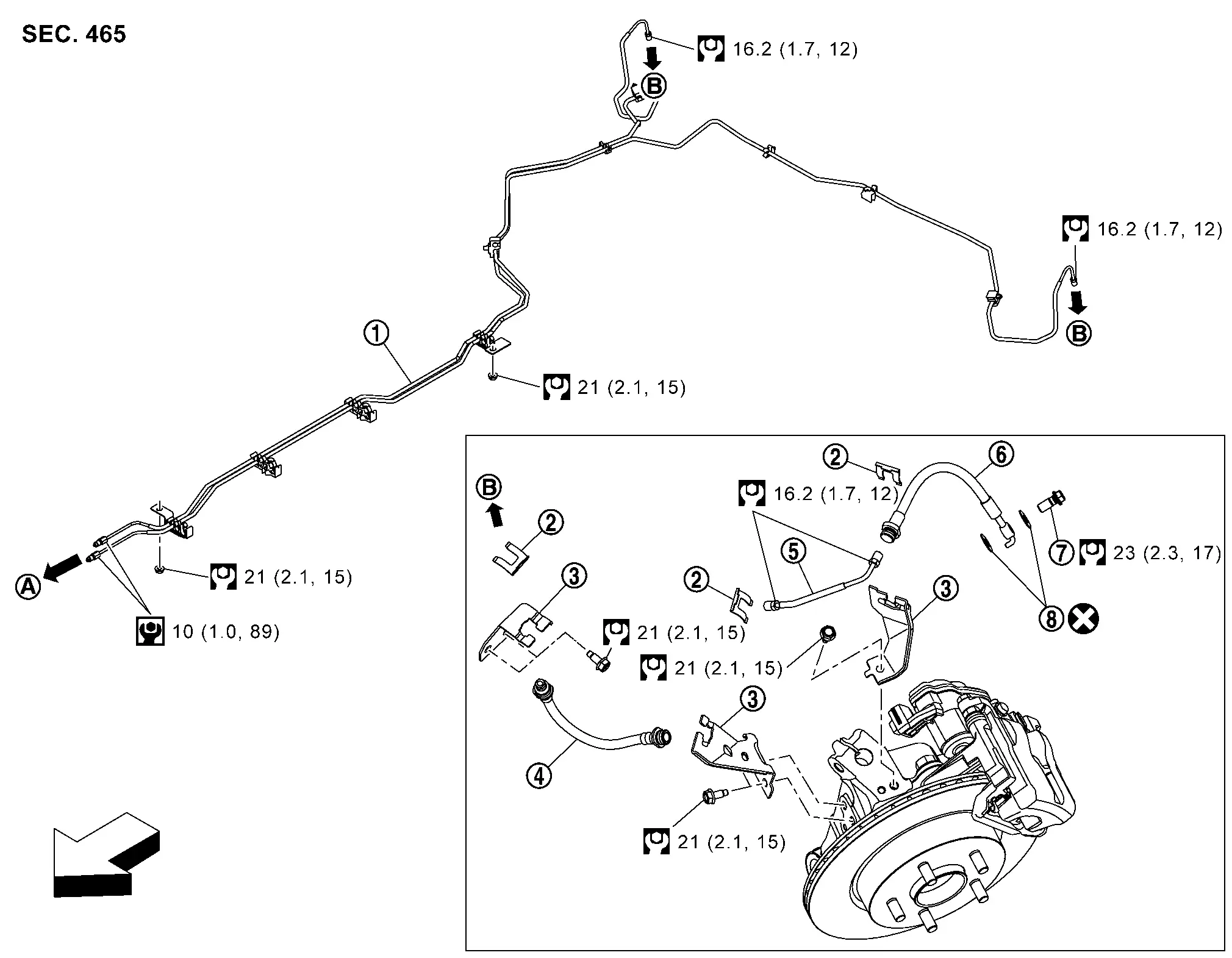

Rear

Exploded View

|

Brake tube A |  |

Lock plate |  |

Brake tube bracket |

|

Brake hose A |  |

Brake tube B |  |

Brake hose B |

|

Union bolt |  |

Copper washer | ||

|

To front brake tube |  |

To rear brake hose A | ||

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Always replace after every disassembly. | ||||

Hydraulic Piping

|

ABS actuator and electric unit (control unit) |  |

Front disc brake |  |

Master cylinder assembly |

|

Brake booster |  |

Rear disc brake | ||

|

Brake tube |  |

Brake hose | ||

|

: Flare nut | ||||

|

: Union bolt | ||||

Removal and Installation

REMOVAL

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

-

Wipe off immediately when attaching brake fluid with disc rotor and caliper assembly.

Remove tires. Refer to Removal & Installation

Drain brake fluid. Refer to Draining.

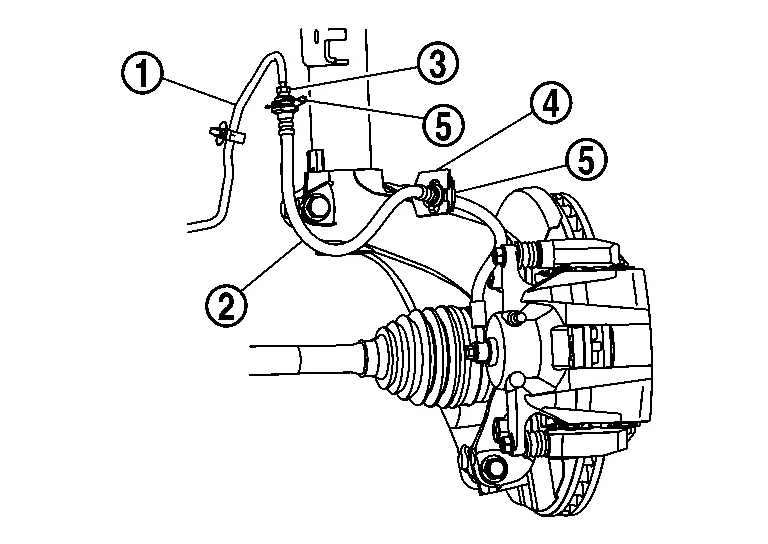

Loosen the flare nut  with a flare nut wrench (A) and separate the brake tube A

with a flare nut wrench (A) and separate the brake tube A  from the brake hose A

from the brake hose A  . And then remove the lock plate

. And then remove the lock plate  .

.

CAUTION:

-

Never scratch the flare nut and the brake tube.

-

Never bend sharply, twist or strongly pull out the brake hoses and tubes.

-

Cover open end of brake tubes and brake hoses when disconnecting to prevent entrance of dirt.

Loosen the flare nut  with a flare nut wrench (A) and separate the brake hose A

with a flare nut wrench (A) and separate the brake hose A  from the brake tube B

from the brake tube B  . And then remove the lock plate

. And then remove the lock plate  .

.

CAUTION:

-

Never scratch the flare nut and the brake tube.

-

Never bend sharply, twist or strongly pull out the brake hoses and tubes.

-

Cover open end of brake tubes and brake hoses when disconnecting to prevent entrance of dirt.

Remove the lock plate  , then remove the brake hose from the brake tube bracket.

, then remove the brake hose from the brake tube bracket.

Loosen the flare nut  with a flare nut wrench (A) and separate the brake tube B

with a flare nut wrench (A) and separate the brake tube B  from the brake hose B

from the brake hose B  .

.

CAUTION:

-

Never scratch the flare nut and the brake tube.

-

Never bend sharply, twist or strongly pull out the brake hoses and tubes.

-

Cover open end of brake tubes and brake hoses when disconnecting to prevent entrance of dirt.

Remove the lock plate  , then remove the brake tube B

, then remove the brake tube B  from the brake tube bracket.

from the brake tube bracket.

Remove the union bolt  and copper washers

and copper washers  , and remove the brake hose B

, and remove the brake hose B  from the brake caliper assembly.

from the brake caliper assembly.

INSTALLATION

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Never depress the brake pedal while removing the brake hose or brake tube. If this is not complied with, brake fluid may splash.

-

Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

-

Wipe off immediately when attaching brake fluid with disc rotor and caliper assembly.

Assemble the union bolt  and the copper washers

and the copper washers  to the brake hose B.

to the brake hose B.

CAUTION:

Never reuse the copper washer.

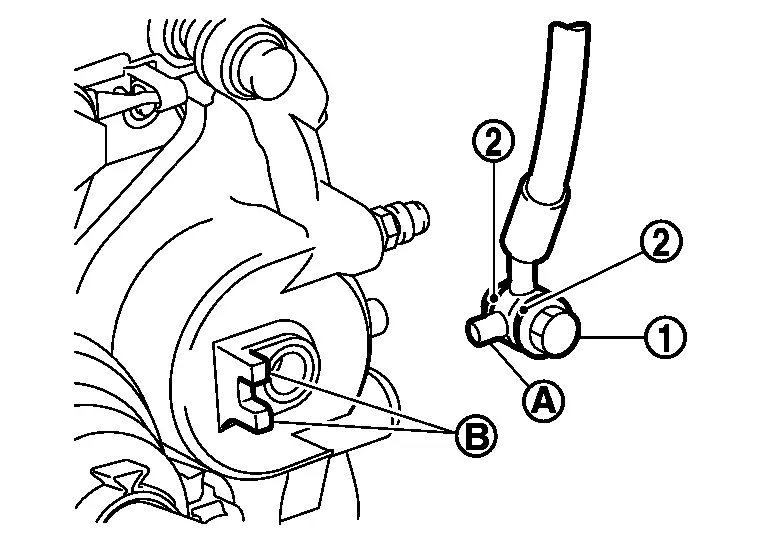

Align the brake hose L-pin  with the brake caliper assembly hole

with the brake caliper assembly hole  , and tighten the union bolt to the specified torque.

, and tighten the union bolt to the specified torque.

Install the brake hose B to the brake tube B, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose to the brake hose bracket with the lock plate.

CAUTION:

Check that all brake hoses and brake tubes are not twisted and bent.

Tighten the flare nut to the specified torque with a crowfoot (A) and torque wrench (B).

CAUTION:

Never scratch the flare nut and the brake tube.

Install the brake tube B to the brake hose A, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose to brake hose brackets with the lock plate.

CAUTION:

Check that all brake hoses and brake tubes are not twisted and bent.

Tighten the flare nut to the specified torque with a crowfoot (A) and torque wrench (B).

CAUTION:

Never scratch the flare nut and the brake tube.

Install the brake hose A to the brake tube A, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose with the lock plate.

CAUTION:

Check that all brake hoses and brake tubes are not twisted and bent.

Tighten the flare nut to the specified torque with a crowfoot (A) and torque wrench (B).

CAUTION:

Never scratch the flare nut and the brake tube.

Refill with new brake fluid and perform the air bleeding. Refer to Bleeding Brake System.

CAUTION:

Never reuse drained brake fluid.

Install tires. Refer to Removal & Installation

Perform inspection after installation. Refer to Inspection.

Inspection

INSPECTION AFTER INSTALLATION

Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no looseness at connections.

CAUTION:

Clearance with brake hose and each parts being secured more than 10 mm (0.39 in) in unladen condition*.

*: Fuel, engine coolant and lubricant are quantity to specified. Spare tire, jack, hand tools and mats are brought out of Nissan Ariya vehicle.

Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approximately 5 seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged, worn or deformed) part if any brake fluid leakage is present.

Other materials:

Repair Information. Preparation

Repairing Material

Foam Repair

During factory body assembly, foam insulators are installed in

certain body panels and locations around the Nissan Ariya vehicle. Use

the following procedure(s) to replace any factory-installed foam

insulators.URETHANE FOAM APPLICATIONSUse commercially availabl ...

Laser/radar (distance Sensor)

C2580-45 Distance Sensor

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

C2580

45

Distance sensor

(Distance sensor)

Diagnosis condition

When engine is running

Signal (terminal)

—

Threshol ...

Paint

Scratch Shield

Scratch Shield

Scratch shield is a clear coat that is more scratch resistant

compared with conventional clear coats, helping a Nissan Ariya vehicle

maintain its new look for a longer period of time. The paint also

repairs fine scratches, restoring a Nissan Ariya vehicle's su ...