Nissan Rogue (T33) 2021-Present Service Manual: Removal and Installation :: Brake Master Cylinder

Without Propilot Assist 2.1

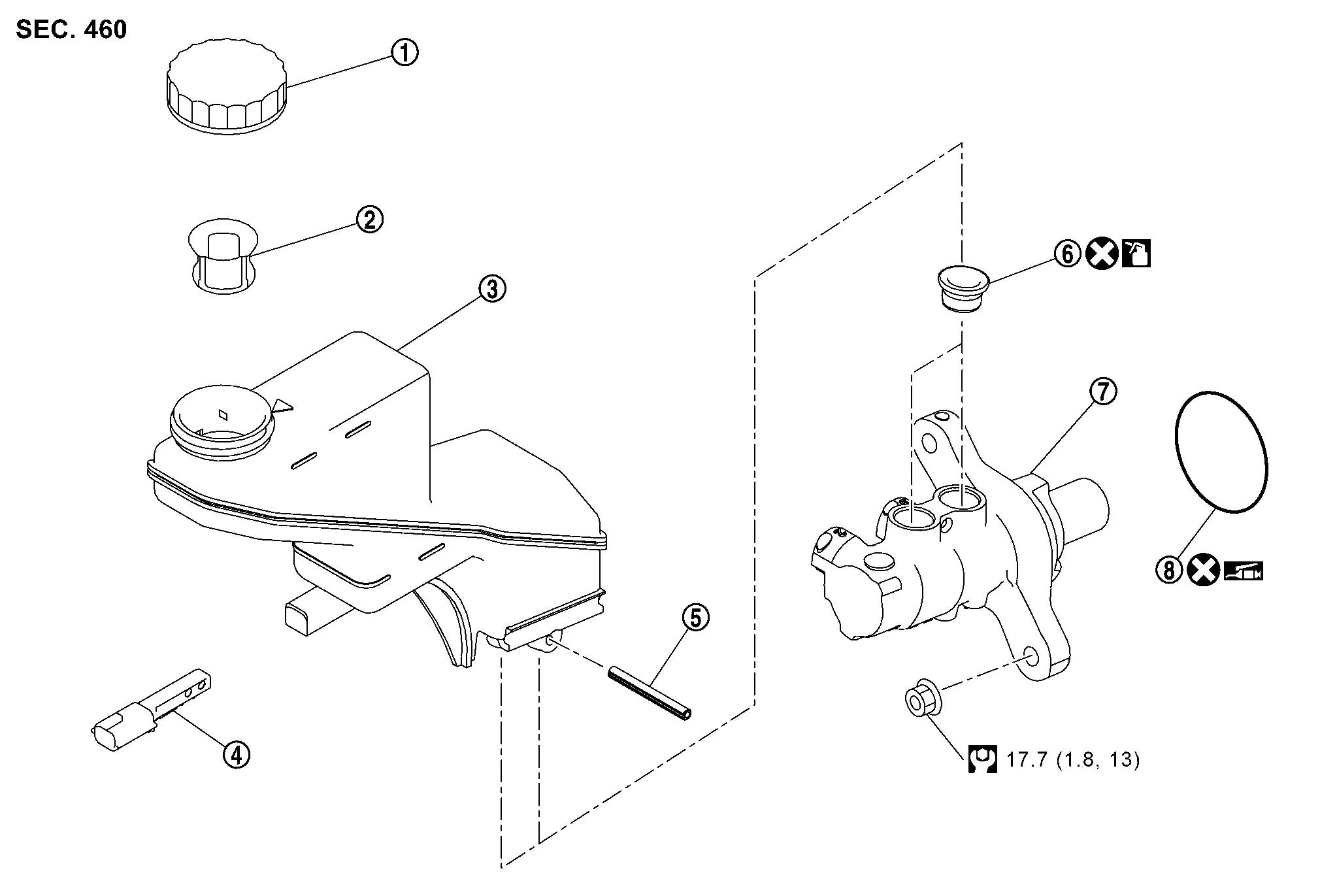

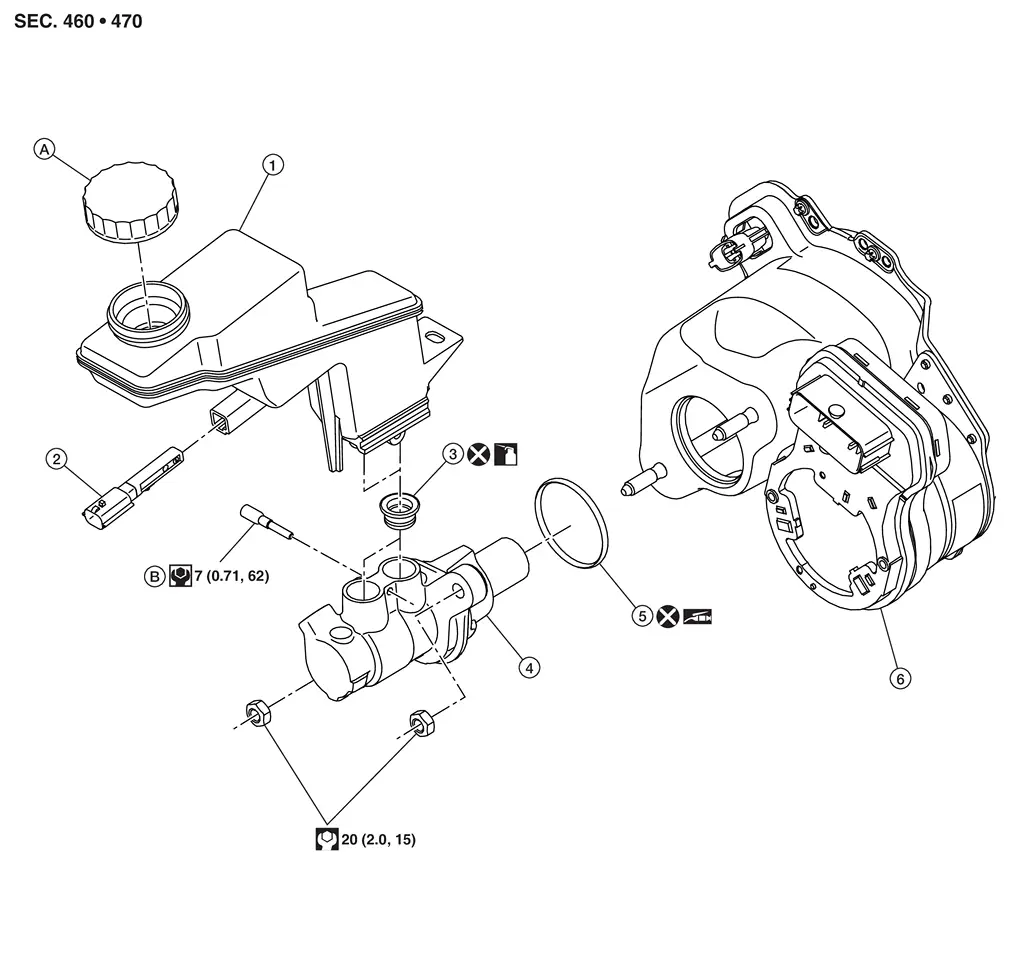

Exploded View

|

Reservoir cap |  |

Oil strainer |  |

Reservoir tank |

|

Brake fluid level switch |  |

Pin |  |

Grommet |

|

Cylinder body |  |

O-ring | ||

|

: N·m (kg-m, ft-lb) | ||||

|

: Apply brake fluid. | ||||

|

: Apply polyglycol ether based lubricant. | ||||

|

: Always replace after every disassembly. | ||||

Removal and Installation

REMOVAL

CAUTION:

-

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

-

Depress the brake pedal several times to release the vacuum pressure from the brake booster. Then remove the master cylinder assembly.

-

Never depress the brake pedal while removing the brake tube. If this is not complied with, brake fluid may splash.

Perform inspection before removal. Refer to Inspection.

Drain brake fluid. Refer to Draining.

Remove the 12V battery. Refer to Removal and Installation.

Remove the engine cover (if so equipped). Refer to Removal and Installation.

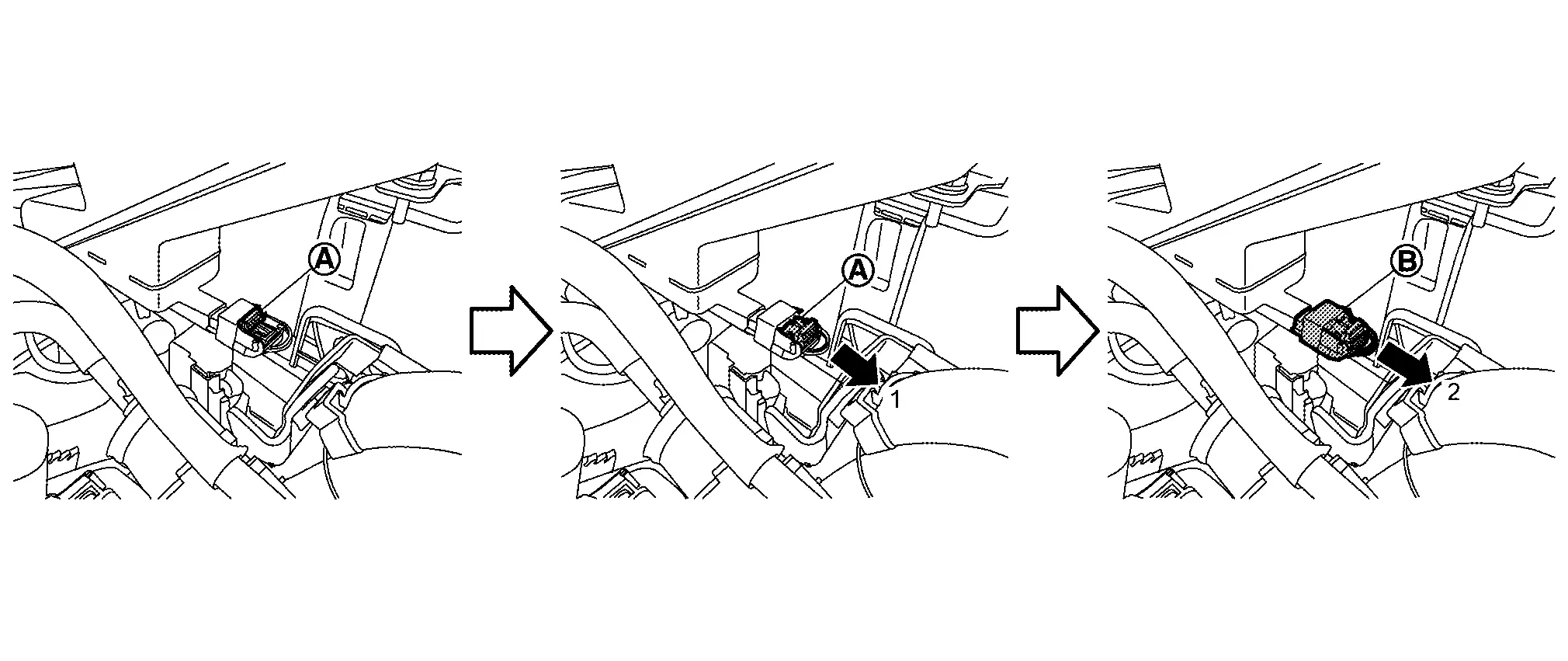

Disconnect the brake fluid level switch harness connector.

Secure the work space by fixing the fuel hose and canister hose with ropes.

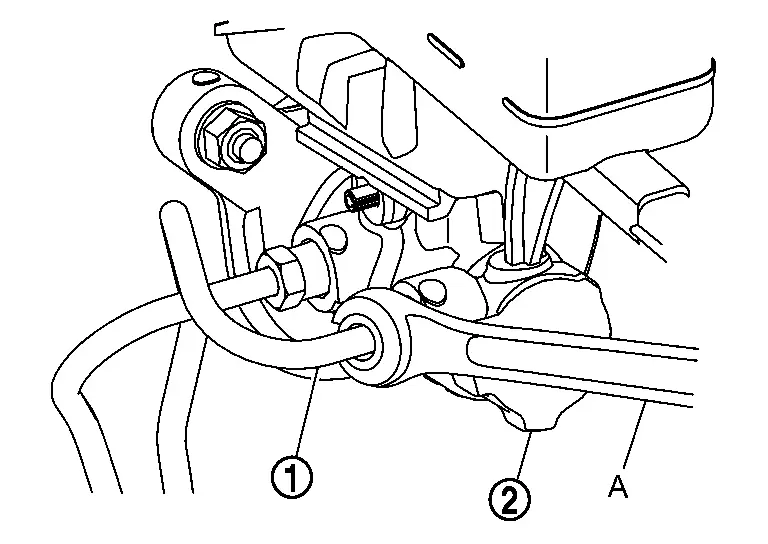

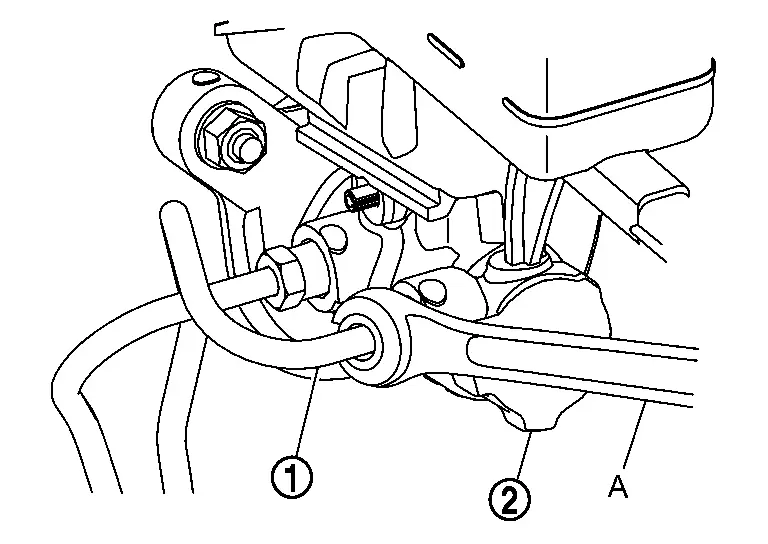

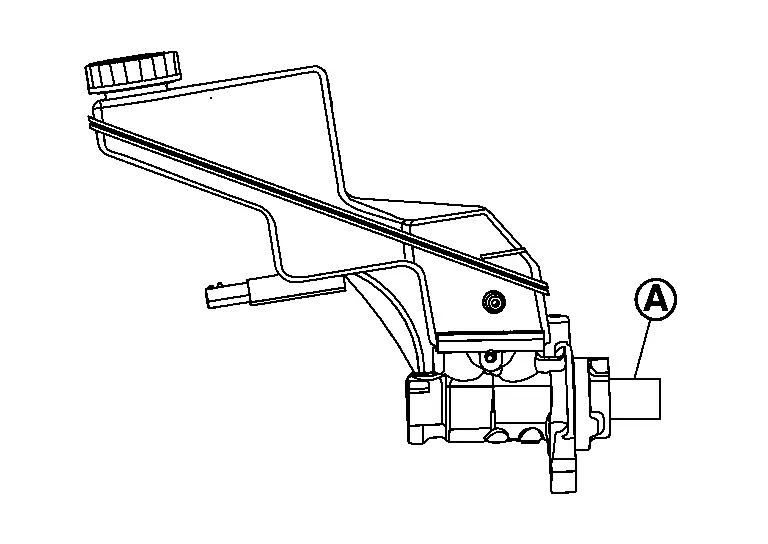

Separate the brake tube (1) from the master cylinder assembly (2) with a flare nut wrench (A).

CAUTION:

Never scratch the flare nut and the brake tube.

Remove the master cylinder assembly.

CAUTION:

-

Never deform or bend the brake tubes.

-

Never depress the brake pedal after the master cylinder assembly is removed.

-

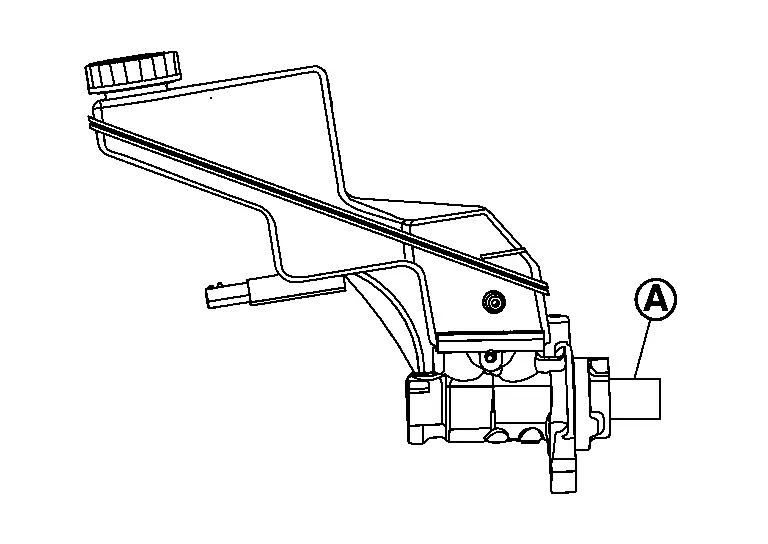

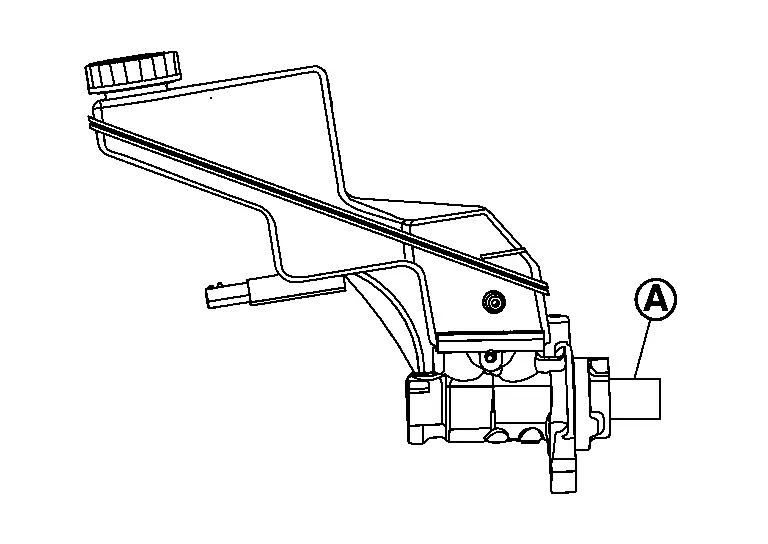

The piston (A) of the master cylinder assembly is exposed. Never damage it when removing the master cylinder.

-

The piston may drop off when pulled out strongly. Never hold the piston. Hold the cylinder body when handling the master cylinder assembly.

Remove the O-ring.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off immediately and wash with water if it gets on a painted surface. For brake component parts, never wash them with water.

Installation is in the reverse order of removal.

-

Never reuse the O-ring.

-

Never depress the brake pedal after the master cylinder assembly is removed.

-

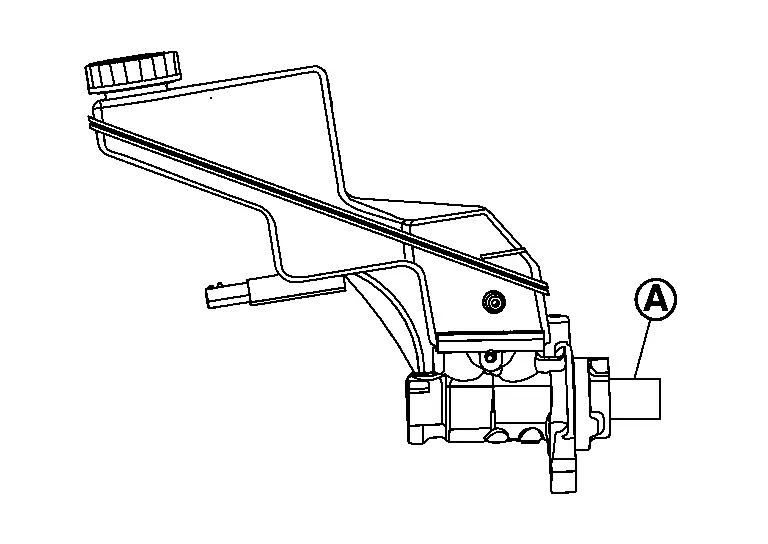

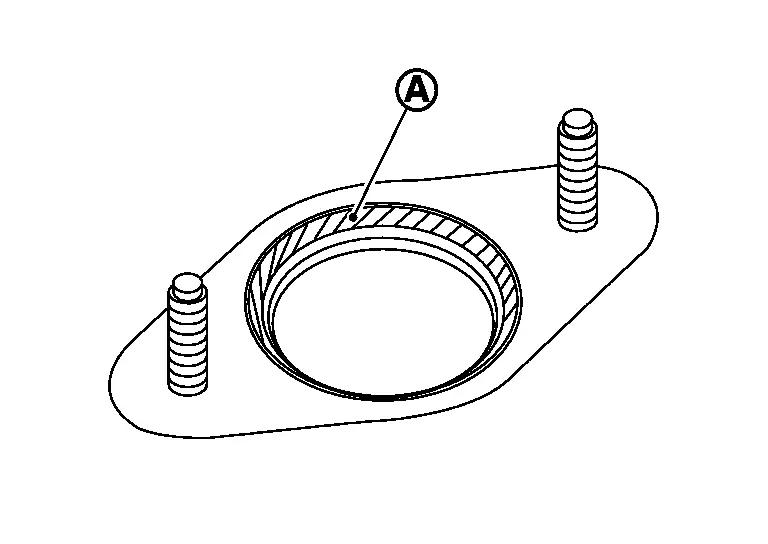

Apply polyglycol ether based lubricant to the brake booster [see (A) in the figure] when installing the master cylinder assembly to the brake booster.

-

The piston (A) of the master cylinder assembly is exposed. Never damage it when handling the master cylinder.

-

Check that no dirt and dust are present on the piston before installation. Clean it with new brake fluid if necessary.

-

The piston may drop off when pulled strongly. Never hold the piston. Hold the cylinder body when handling the master cylinder assembly.

-

Never deform or bend the brake tubes.

-

Temporarily tighten the brake tube (1) flare nut to the master cylinder assembly (2) by hand. Then tighten it to the specified torque with a flare nut torque wrench (A). Refer to Exploded View.

-

Perform the air bleeding. Refer to Bleeding Brake System.

-

Perform inspection after installation. Refer to Inspection.

Disassembly and Assembly

DISASSEMBLY

CAUTION:

-

Never disassemble the cylinder body.

-

Remove the reservoir tank only when necessary.

-

Never drop parts to remove. Replace new parts when dropping.

Fix the master cylinder assembly to a vise.

CAUTION:

-

Always set copper plates or cloth between vise grips when fixing the cylinder body to a vise.

-

Never overtighten the vise.

Remove the reservoir tank mounting screw.

Remove the reservoir tank and grommet from the cylinder body.

ASSEMBLY

CAUTION:

-

Never use mineral oils such as kerosene or gasoline and rubber grease during the cleaning and assembly process.

-

Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

-

Never drop when installing. The parts must not be reused if they are dropped.

Apply new brake fluid to the grommet and install it to the cylinder body.

CAUTION:

Never reuse grommets.

Install the reservoir tank to the cylinder body.

Fix the cylinder body to a vise.

CAUTION:

-

Place the reservoir tank with the chamfered screw hole (

) facing up.

) facing up.

-

Always set copper plates or cloth between vise grips when fixing the cylinder body to a vise.

-

Never overtighten the vise.

Tilt the reservoir tank so that a mounting screw can be fixed. Assemble with screw.

Inspection

INSPECTION BEFORE REMOVAL

Check the brake fluid level switch. Refer to Component Inspection.

INSPECTION AFTER INSTALLATION

Check the following items and replace if necessary.

-

Check the master cylinder for deformation, twist, contact with other parts or looseness of connection.

-

Check for fluid leakage from connection. Refer to Inspection.

CAUTION:

If the fluid leakage is present, retighten to the specified torque. Replace parts if necessary.

With Propilot Assist 2.1

Exploded View

| 1 | Reservoir tank | 2 | Brake fluid level switch | 3 | Grommet |

| 4 | Master cylinder | 5 | O-ring | 6 | Electrically-driven intelligent brake unit. Refer to Exploded View. |

| A | Reservoir cap | B | Screw | ||

: Apply polyglycol ether based lubricant. : Apply polyglycol ether based lubricant. |

|||||

: Apply brake fluid. : Apply brake fluid. |

|||||

Removal and Installation

REMOVAL

CAUTION:

-

Do not allow brake fluid to adhere to painted surfaces such as the body. If it adheres, it may damage the paint film. Wipe off quickly and wash with water. However, avoid washing the brake components with water.

-

During brake tube removal and installation work, do not depress the brake pedal, the brake fluid may splash.

Perform inspection before removal of brake master cylinder. Refer to Inspection.

Remove the battery tray 1. Refer to Removal and Installation.

Disconnect the brake fluid level switch harness connector.

If necessary, remove the brake fluid level switch as follows:

-

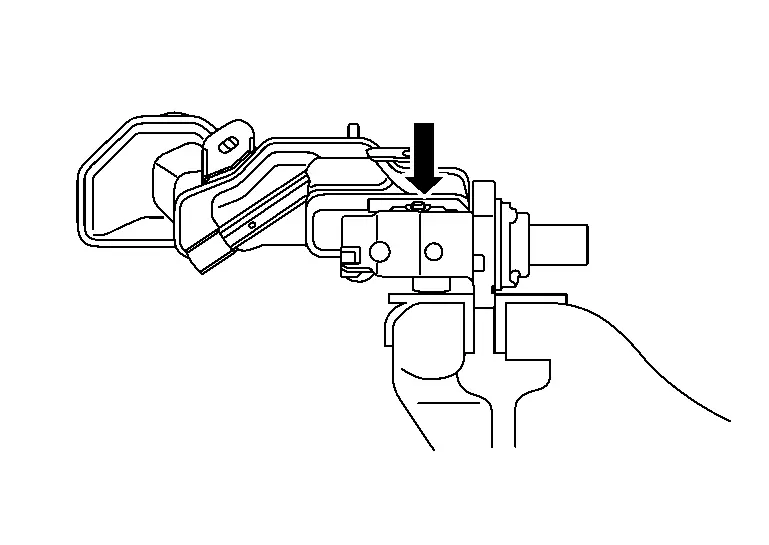

Pin punch hole on the reservoir tank bottom side (general purpose tool: pin punch a: 4 mm) using claw to push up, remove the brake fluid level switch from the reservoir tank.

CAUTION:

Never scratch the flare nut and the brake tube.

Separate the harness retainer from the reservoir tank.

Drain the brake fluid. Refer to Draining.

Using flare nut wrench, loosen the flare nut and remove the brake tube from the brake master cylinder assembly. Refer to Exploded View.

CAUTION:

-

Do not damage the flare nut and brake tube.

Remove the brake master cylinder assembly nuts and remove the brake master cylinder assembly from the electrically-driven intelligent brake unit.

CAUTION:

-

Do not deform or bend the brake tube when removing the brake master cylinder assembly.

-

Do not depress the brake pedal while the brake master cylinder assembly is removed.

-

The piston (A) of the master cylinder assembly is exposed. Never damage it when removing the master cylinder.

-

Hold the cylinder body when handling the brake master cylinder assembly, not the piston. Since the piston may detach from assembly if pulled strongly.

Remove the O-ring.

INSTALLATION

CAUTION:

-

Do not allow brake fluid to adhere to painted surfaces such as the body. If it adheres, it may damage the coating film, so quickly wipe it off and wash with water. However, avoid washing the brake components with water.

-

Do not depress the brake pedal while installing or removing the brake tube, as brake fluid may splash.

-

Do not depress the brake pedal while the brake master cylinder assembly is removed.

Pay attention to the following work and carry out the removal procedure in reverse order:

-

Do not reuse O-rings.

-

Install the brake fluid level switch if it was removed.

-

Do not scratch the piston part (A) since the piston of the brake master cylinder assembly is exposed.

-

The piston (A) of the master cylinder assembly is exposed. Never damage it when handling the master cylinder.

-

Confirm that there is no dirt or dust adhering to the piston. Also, when cleaning, use new brake fluid.

-

Hold the cylinder body when handling the brake master cylinder assembly, not the piston. Since the piston may detach from assembly if pulled strongly.

-

Do not deform or bend the brake tube when installing the brake master cylinder assembly.

-

Temporarily tighten the flare nut of the brake tube to the brake master cylinder assembly by hand. Then use the flare nut torque wrench (general-purpose tool). Tighten to the specified torque using flare nut wrench. Refer to Exploded View.

-

CAUTION:

Do not damage the flare nut and brake tube.

-

Refill with new brake fluid and perform the air bleeding. Refer to Bleeding Brake System.

-

Perform inspection after installation. Refer to Inspection.

-

Disassembly and Assembly

DISASSEMBLY

CAUTION:

-

Never disassemble the cylinder body.

-

Remove the reservoir tank only when necessary.

-

Never drop parts to remove. Replace new parts when dropping.

Fix the master cylinder assembly to a vise.

CAUTION:

-

Always set copper plates or cloth between vise grips when fixing the cylinder body to a vise.

-

Never overtighten the vise.

Remove the reservoir tank mounting screw.

Remove the reservoir tank and grommets from the cylinder body.

ASSEMBLY

CAUTION:

-

Never use mineral oils such as kerosene or gasoline and rubber grease during the cleaning and assembly process.

-

Never drop the when installing. The parts must not be reused if they are dropped.

-

Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

Apply new brake fluid to the grommets and install the grommets to the master cylinder body.

CAUTION:

Never reuse the grommets.

Install the reservoir tank to the master cylinder.

Fix the master cylinder to a vise.

CAUTION:

-

Place the reservoir tank with the chamfered pin hole facing up.

-

Always set copper plates or cloth between vise grips when fixing the master cylinder to a vise.

-

Never overtighten the vise.

Install the screw and tighten to the specification. Refer to Exploded View.

Inspection

INSPECTION BEFORE REMOVAL

Check the brake fluid level switch. Refer to Component Inspection.

INSPECTION AFTER INSTALLATION

Inspect the following items, and replace if any abnormality is found:

-

Check for scratches, twists, deformations, interference with other parts, and loose connections.

-

Check for fluid leakage from connection. Refer to Inspection.

CAUTION:

If fluid leakage occurs, re-tighten each part to the specified torque, and replace if any abnormality is found.

Other materials:

U214f Can Comm Circuit

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

U214F

57

CAN comm err (BCM)

[CAN comm err (BCM)]

Diagnosis condition

—

Signal (terminal)

—

Threshold

MAC communication error

Diagnosis ...

Anc (active Noise Control Unit)

B1a01-11 Front Door Speaker Lh

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

B1A01-11

FL-DOOR woofer OUT

(Front left door woofer)

Diagnosis condition

When ignition switch is ON

Signal (terminal)

Soun ...

Engine Can Communication Circuit

Diagnosis Procedure

CHECK CAN DIAGNOSIS

Check the CAN diagnosis results from CONSULT to see that the drivetrain CAN communication 2 circuit has no malfunction.

Is the drivetrain CAN communication circuit 2 normal?

YES>>

GO TO 2.

NO>>

Check and repair drivetrain CAN communication ...