Nissan Rogue (T33) 2021-Present Service Manual: Removal and Installation :: Brake Pedal

Without Propilot Assist 2.1

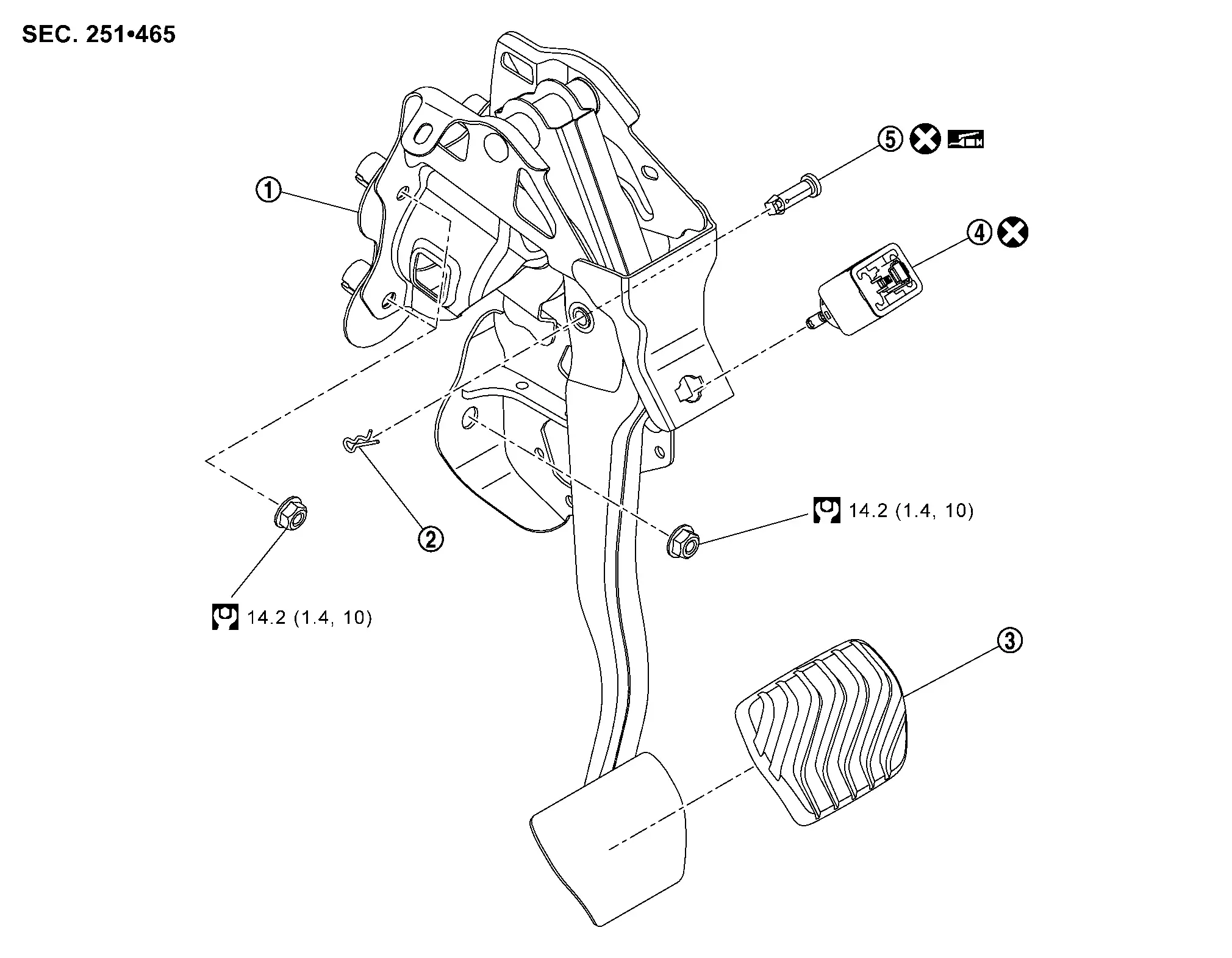

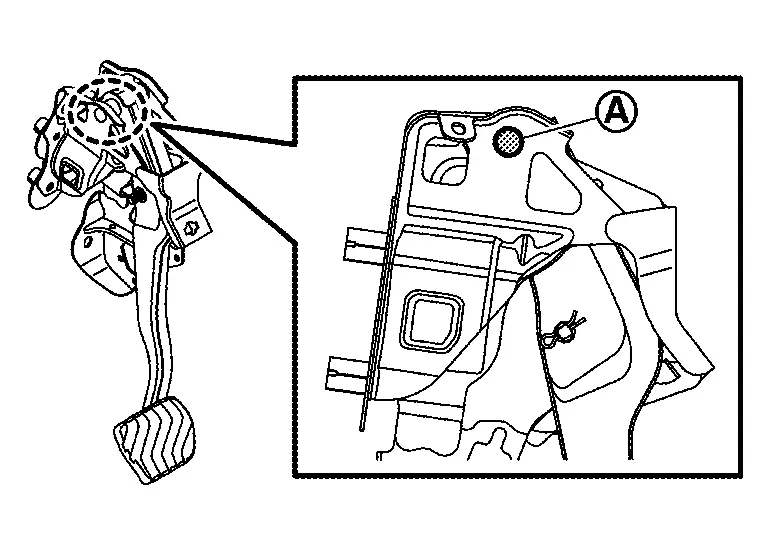

Exploded View

|

Brake pedal assembly |  |

Snap pin |  |

Brake pedal pad |

|

Stop lamp switch |  |

Clevis pin | ||

|

: N·m (kg-m, ft-lb) | ||||

|

: Apply multi-purpose grease. | ||||

|

: Always replace after every disassembly. | ||||

Removal and Installation

REMOVAL

Remove instrument lower panel LH. Refer to Removal and Installation.

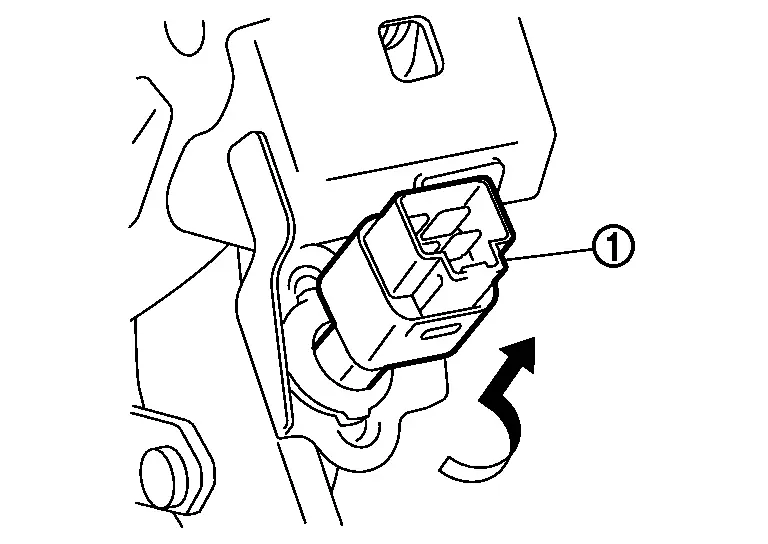

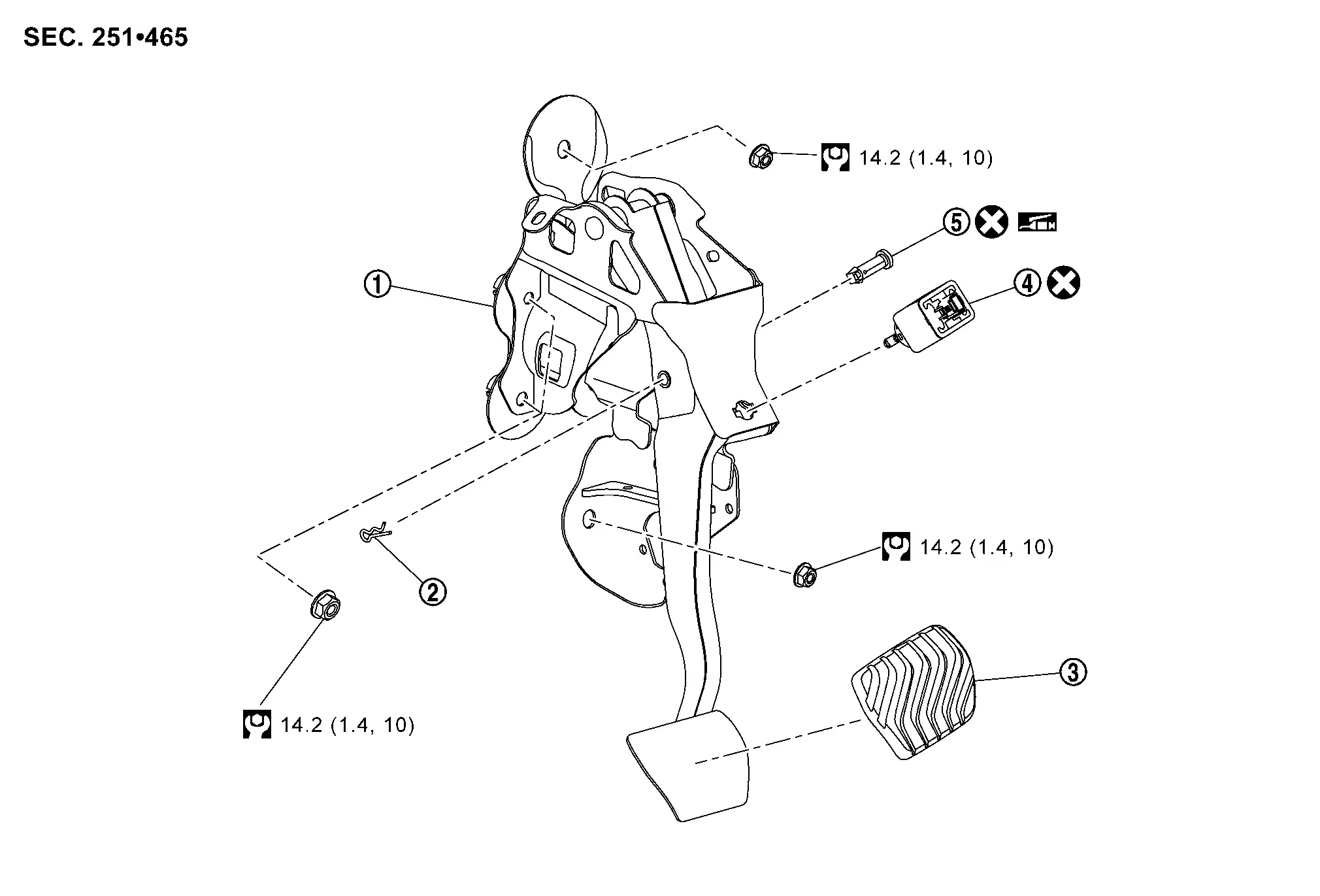

Disconnect the stop lamp switch harness connectors.

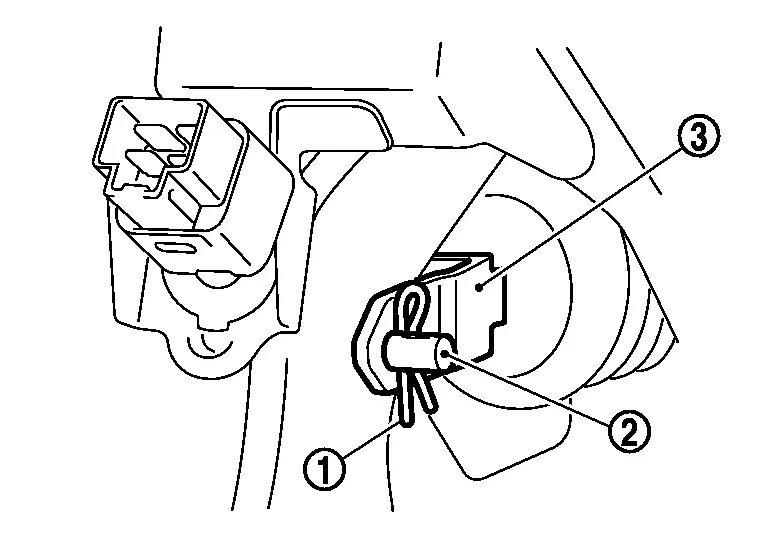

Rotate the stop lamp switch (1) counterclockwise to remove.

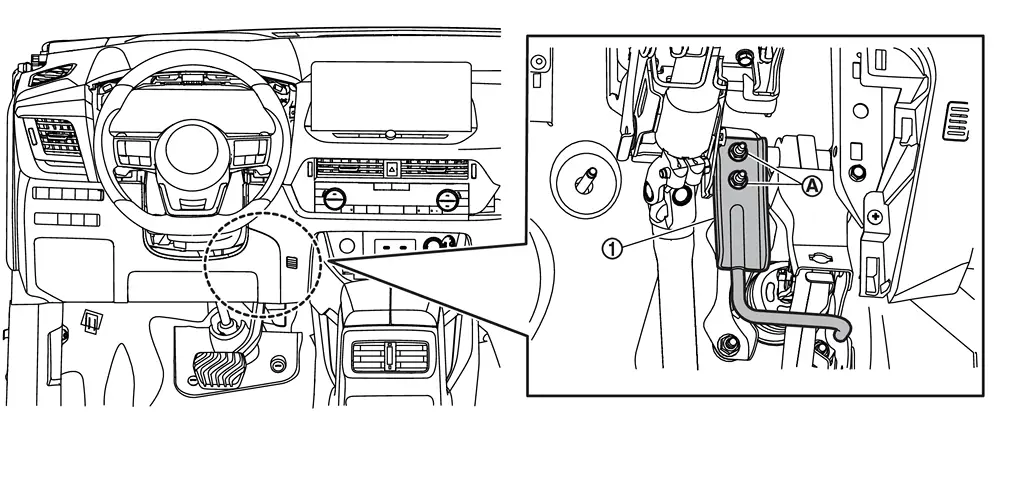

Disconnect the accelerator pedal harness connector.

Remove the accelerator pedal from the brake pedal assembly. Refer to Removal and Installation.

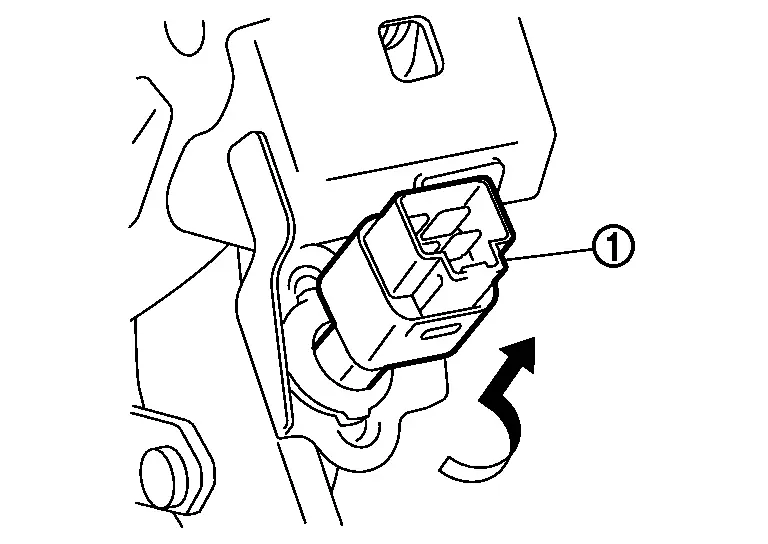

Remove nuts (A), and then remove bracket (1).

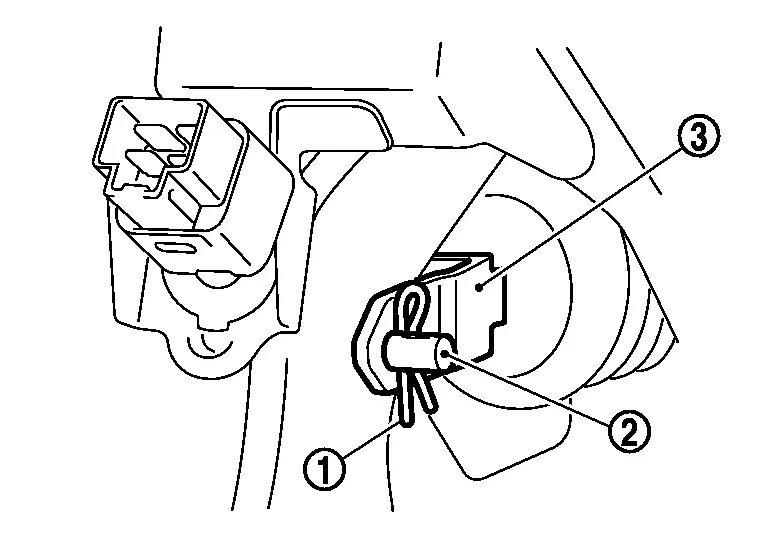

Remove snap pin (1) and clevis pin (2) from clevis of brake booster (3).

Remove harness clip from brake pedal.

Remove the brake pedal assembly.

CAUTION:

Hold the brake booster and master cylinder assembly so as not to drop out or contact them other parts.

Perform inspection after removal. Refer to Inspection and Adjustment.

INSTALLATION

Installation is in the reverse order of removal.

-

Never reuse the clevis pin.

-

Apply the multi-purpose grease to the clevis pin and the mating faces. (Not necessary if grease has been already applied)

NOTE:

NOTE:

The clevis pin may be inserted in either direction.

-

Never impact brake pedal such as drop and interference with tools and parts.

-

Replace brake pedal when impacting brake pedal.

-

Perform adjustment after installation. Refer to Inspection and Adjustment.

Inspection and Adjustment

INSPECTION AFTER REMOVAL

Check for the following items and replace the brake pedal assembly if necessary.

-

Check rivet

for deformation, crack, and damage.

for deformation, crack, and damage.

-

Check the brake pedal for bend, damage, and cracks on the welded parts.

ADJUSTMENT AFTER INSTALLATION

-

Adjust each item of brake pedal after installing the brake pedal assembly to the vehicle. Refer to Inspection and Adjustment.

-

Perform the release position learning of the accelerator pedal. Refer to Description.

With Propilot Assist 2.1

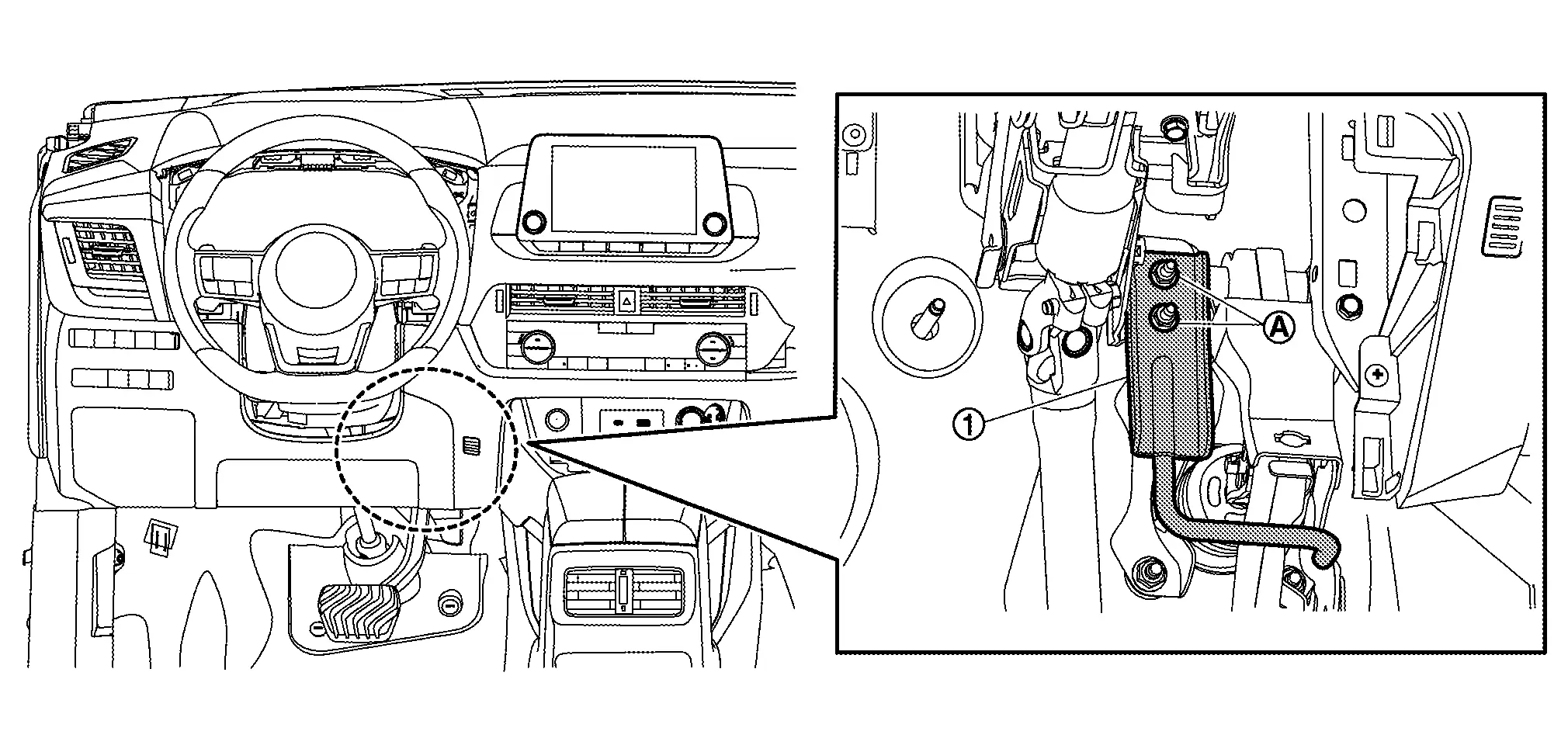

Exploded View

|

Brake pedal assembly |  |

Snap pin |  |

Brake pedal pad |

|

Stop lamp switch |  |

Clevis pin | ||

|

: N·m (kg-m, ft-lb) | ||||

|

: Apply Nissan multi-purpose Special Grease. | ||||

|

: Always replace after every disassembly. | ||||

Removal and Installation

REMOVAL

Remove driver knee air bag module. Refer to Removal and Installation.

Disconnect the stop lamp switch harness connectors.

Rotate the stop lamp switch  counterclockwise to remove.

counterclockwise to remove.

Disconnect the accelerator pedal harness connector.

Separate the accelerator pedal from the brake pedal assembly. Refer to Removal and Installation.

Remove nuts  , and then remove bracket

, and then remove bracket  .

.

Remove snap pin  and clevis pin

and clevis pin  from clevis of brake booster

from clevis of brake booster  .

.

Remove harness clip from brake pedal.

Remove the brake pedal assembly.

CAUTION:

Hold the brake booster and master cylinder assembly so as not to drop out or contact them other parts.

Perform inspection after removal. Refer to Inspection and Adjustment.

INSTALLATION

Note the following, and install in the reverse order of removal:

-

Never reuse the clevis pin and snap pin.

-

Apply the multi-purpose grease to the clevis pin and the mating faces (Not necessary if grease has been already applied).

NOTE:

NOTE:

The clevis pin may be inserted in either direction.

-

Never impact brake pedal such as drop and interference with tools and parts.

-

Replace brake pedal when impacting brake pedal.

-

Perform adjustment after installation. Refer to Inspection and Adjustment.

Inspection and Adjustment

INSPECTION AFTER REMOVAL

Check for the following items and replace the brake pedal assembly if necessary:

-

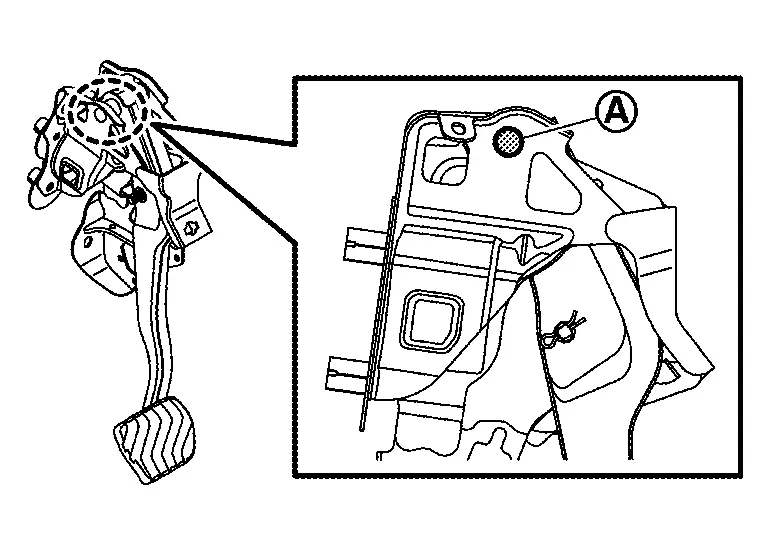

Check rivet (A) for deformation, crack, and damage.

-

Check the brake pedal for bend, damage, and cracks on the welded parts.

ADJUSTMENT AFTER INSTALLATION

-

Adjust each item of brake pedal after installing the brake pedal assembly to the vehicle. Refer to Inspection and Adjustment.

-

Perform the release position learning of the accelerator pedal. Refer to Description.

Other materials:

P10c9 Internal Control Module Fuel Injector

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P10C9

00

Internal control module fuel injector

(Internal control module fuel injector)

Diagnosis condition

—

Signal (terminal)

—

Threshold

...

Ascd. Removal and Installation. Ascd Steering Switch

Ascd Steering Switch

Removal and Installation

REMOVALFor servicing the Japan production ASCD steering

switch, service the Japan production steering wheel. Refer to Removal

and Installation.NOTE:

The Japan production ASCD steering switch is serviced as

an assembly with the Japan production s ...

Ceinture de sécurité à trois points d'ancrage avec enrouleur

Informations de base

Sur le Nissan Rogue, la ceinture de sécurité à trois points d’ancrage avec enrouleur est conçue pour maintenir efficacement le conducteur et les passagers tout en permettant une liberté de mouvement normale. Correctement portée et bien ajustée, elle contribue forteme ...