Nissan Rogue (T33) 2021-Present Service Manual: Kr15ddt :: Periodic Maintenance

Idle Speed

IDLE SPEED : Periodic Maintenance

With CONSULT

With CONSULT

Check idle speed in ÔÇťDATA MONITORÔÇŁ mode of ÔÇťENGINEÔÇŁ using CONSULT.

Without CONSULT

Without CONSULT

Check idle speed with Service $01 of GST.

| Idle speed: | IDLE SPEED : Service Data |

Ignition Timing

IGNITION TIMING : Periodic Maintenance

With CONSULT

With CONSULT

Check Ignition timing in ÔÇťDATA MONITORÔÇŁ mode of ÔÇťENGINEÔÇŁ using CONSULT.

| Ignition timing : | IGNITION TIMING : Service Data |

Evaporative Emission System

EVAPORATIVE EMISSION SYSTEM : Inspection

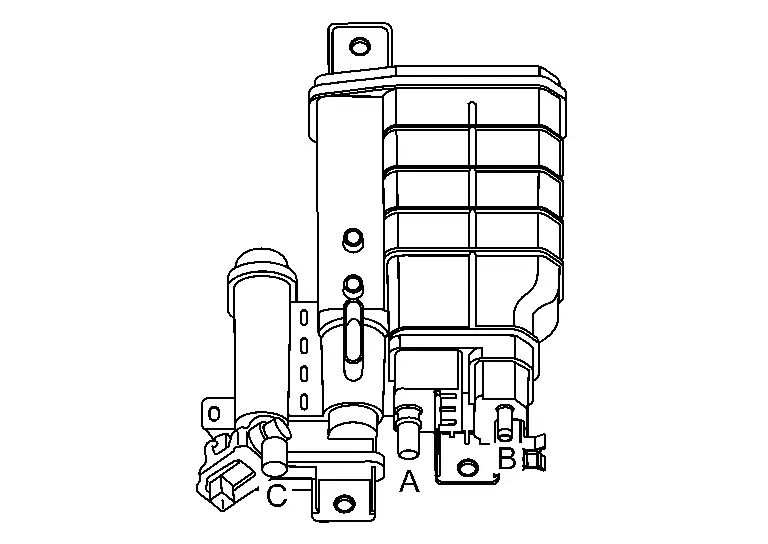

CHECK EVAP CANISTER

-

Block port (B).

-

Blow air into port (A) and check that it flows freely out of port (C).

-

Release blocked port (B).

-

Apply vacuum pressure to port (B) and check that vacuum pressure exists at the ports (A) and (C).

-

Block port (A) and (B).

-

Apply pressure to port (C) and check that there is no leakage.

INSPECTION END

Evap Leak Check

EVAP CANISTER : Periodic Maintenance

CAUTION:

-

Do not use compressed air or a high pressure pump.

-

Do not exceed 4.12 kPa (0.042 kg/cm2, 0.6 psi) of pressure in EVAP system.

NOTE:

NOTE:

-

Do not start engine.

-

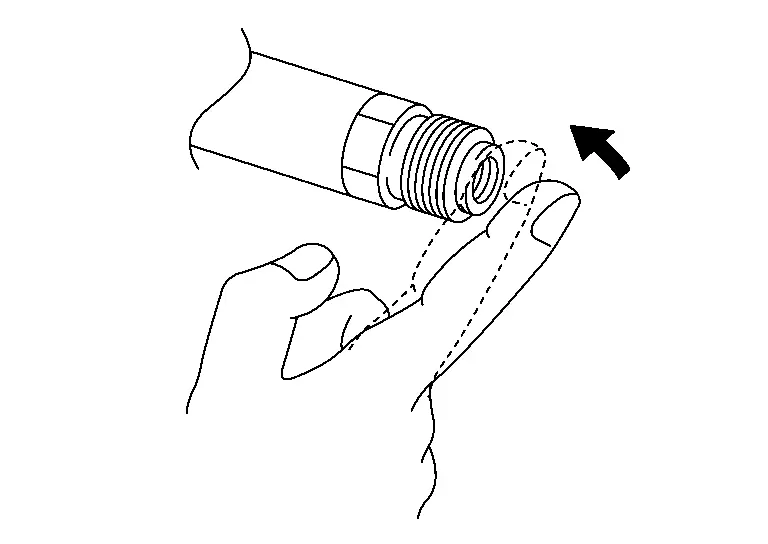

Improper installation of EVAP service port adapter [commercial service tool: (NI-41413-OBD)] to the EVAP service port may cause a leak.

WITH CONSULT

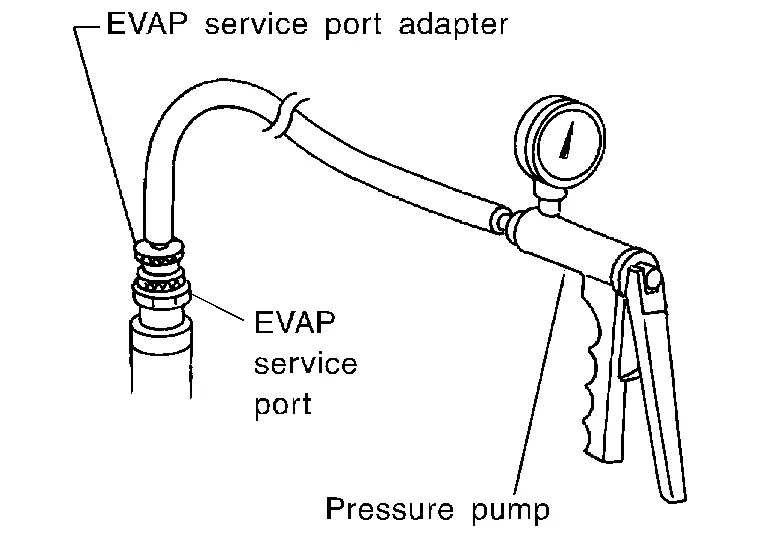

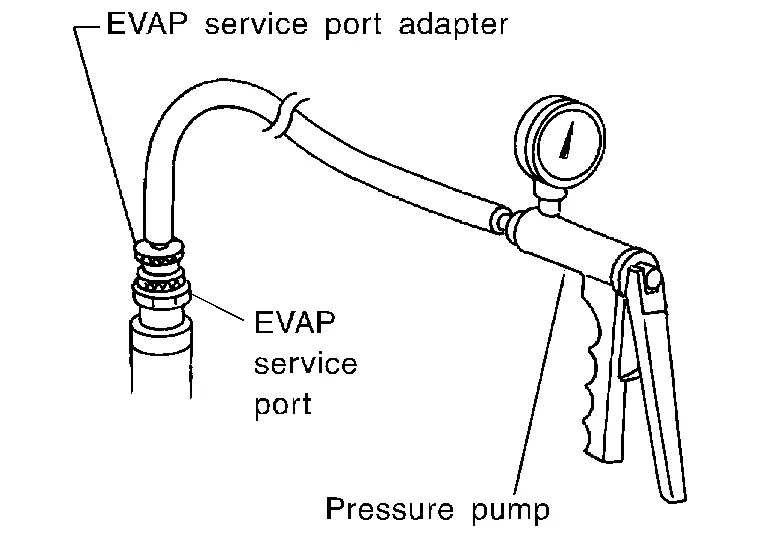

Install EVAP service port adapter [commercial service tool: (NI-41413-OBD)] and pressure pump to EVAP service port.

NOTE:

NOTE:

If vacuum delay valve does not have EVAP service port, remove vacuum delay valve and install EVAP service port [commercial service tool: (Part No. 149393S500)] instead.

Turn ignition switch ON.

Select the ÔÇťEVAP SYSTEM CLOSEÔÇŁ of ÔÇťWORK SUPPORTÔÇŁ mode with CONSULT.

Touch ÔÇťSTARTÔÇŁ. A bar graph (Pressure indicating display) will appear on the screen.

Apply positive pressure to the EVAP system until the pressure indicator reaches the middle of the bar graph.

Remove EVAP service port adapter [commercial service tool: (NI-41413-OBD)] and hose with pressure pump.

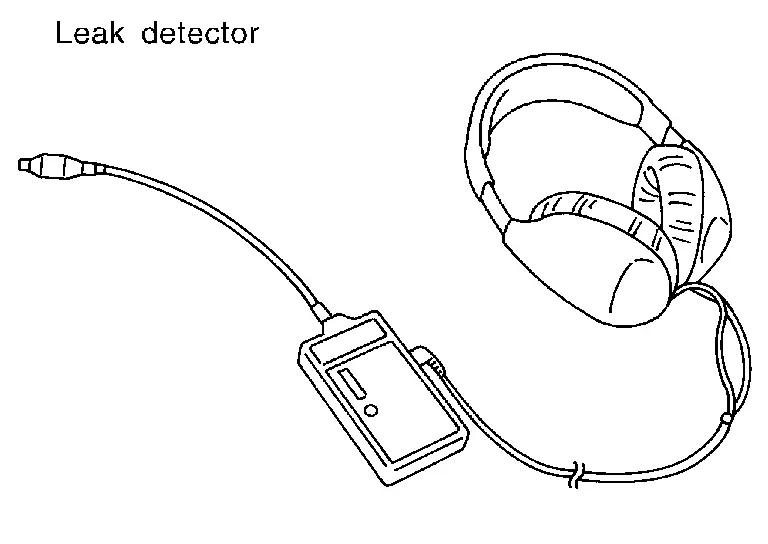

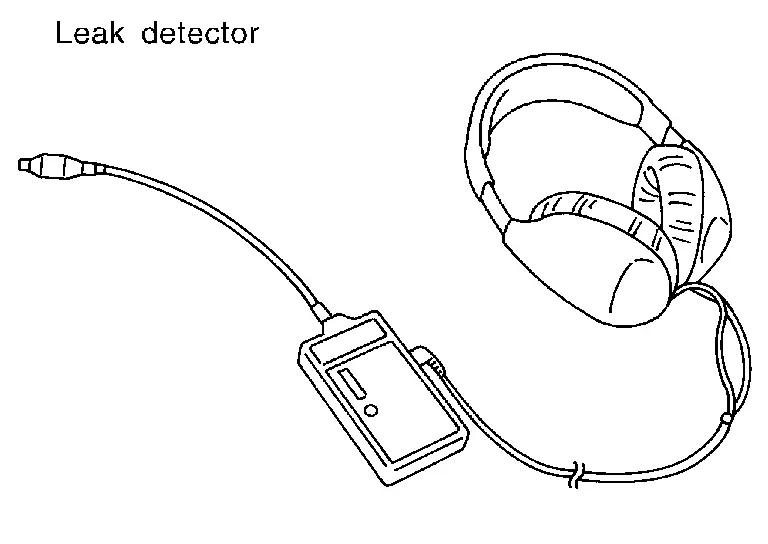

Locate the leak using a leak detector (commercial service tool). Refer to System Description.

WITHOUT CONSULT

Install EVAP service port adapter [commercial service tool: (NI-41413-OBD)] and pressure pump to EVAP service port.

NOTE:

NOTE:

If vacuum delay valve does not have EVAP service port, remove vacuum delay valve and install EVAP service port [commercial service tool: (Part No. 149393S500)] instead.

Apply battery voltage between the terminals of EVAP canister vent control valve to make a closed EVAP system.

To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to 2.76 kPa (0.014 to 0.028 kg/cm2, 0.2 to 0.4 psi).

Remove EVAP service port adapter [commercial service tool: (NI-41413-OBD)] and hose with pressure pump.

Locate the leak using a leak detector (commercial service tool). Refer to System Description.

Positive Crankcase Ventilation

POSITIVE CRANKCASE VENTILATION : Periodic Maintenance

Start engine and let it idle.

Replace PCV valve from the rocker cover. Refer to Removal and Installation.

Connect PCV valve to PCV hose.

Block and unblock the air hole of PCV valve and check if a hissing noise can be heard from the air hole.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace PCV valve. Refer to Removal and Installation.

Other materials:

P1a10 Ecm Initial Learning Incomplete

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P1A10

00

ECM initial learning Incomplete

(ECM initial learning Incomplete)

Diagnosis condition

Ignition switch ON

Signal (terminal)

ÔÇö

Threshold ...

Power Supply and Ground Circuit

Diagnosis Procedure

CHECK CHASSIS CONTROL MODULE ACCESSORY POWER SUPPLY

Ignition switch OFF.

Disconnect the chassis control module harness connector.

Check the voltage between chassis control module harness connector and ground.

+ ÔÇö Voltage

Chassis control module

Connecto ...

P0046 Wastegate Control Motor

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

P0046

00

TC/SC BOOST CONTROL A

(Turbocharger/supercharger boost control A circuit range/performance)

Diagnosis condition

ÔÇö

Signal (terminal)

ÔÇö

Thres ...