Nissan Rogue (T33) 2021-Present Service Manual: Heated Oxygen Sensor 2

Component Function Check

PERFORM COMPONENT FUNCTION CHECK-1

Without CONSULT

Without CONSULT

-

Start engine and warm it up to normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Check the voltage between ECM harness connector and ground as per the following condition.

ECM Condition Voltage Connector + ŌłÆ Terminal F71 92 97 Revving up to 4,000 rpm under no load at least 10 times The voltage should be above 0.71 V at least once during this procedure.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 2.

PERFORM COMPONENT FUNCTION CHECK-2

Check the voltage between ECM harness connector and ground as per the following condition.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | ŌłÆ | ||

| Terminal | ||||

| F71 | 92 | 97 | Keeping engine speed at idle for 10 minutes | The voltage should be above 0.71 V at least once during this procedure. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 3.

PERFORM COMPONENT FUNCTION CHECK-3

Check the voltage between ECM harness connector and ground as per the following condition.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | ŌłÆ | ||

| Terminal | ||||

| F71 | 92 | 97 | Coasting from 80 km/h (50 MPH) in D position | The voltage should be above 0.71 V at least once during this procedure. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>Refer to Component Inspection.

Component Inspection

INSPECTION START

Do you have CONSULT?

Do you have CONSULT?

YES>>GO TO 2.

NO>>GO TO 3.

CHECK HEATED OXYGEN SENSOR 2

With CONSULT

With CONSULT

-

Turn ignition switch ON and select ŌĆ£DATA MONITORŌĆØ mode of ŌĆ£ENGINEŌĆØ using CONSULT.

-

Start engine and warm it up to normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Select ŌĆ£FUEL INJECTIONŌĆØ in ŌĆ£ACTIVE TESTŌĆØ mode of ŌĆ£ENGINEŌĆØ using CONSULT, and select ŌĆ£HO2S2 (B1)ŌĆØ as the monitor item with CONSULT.

-

Check ŌĆ£HO2S2 (B1)ŌĆØ at idle speed when adjusting ŌĆ£FUEL INJECTIONŌĆØ to ┬▒ 25%.

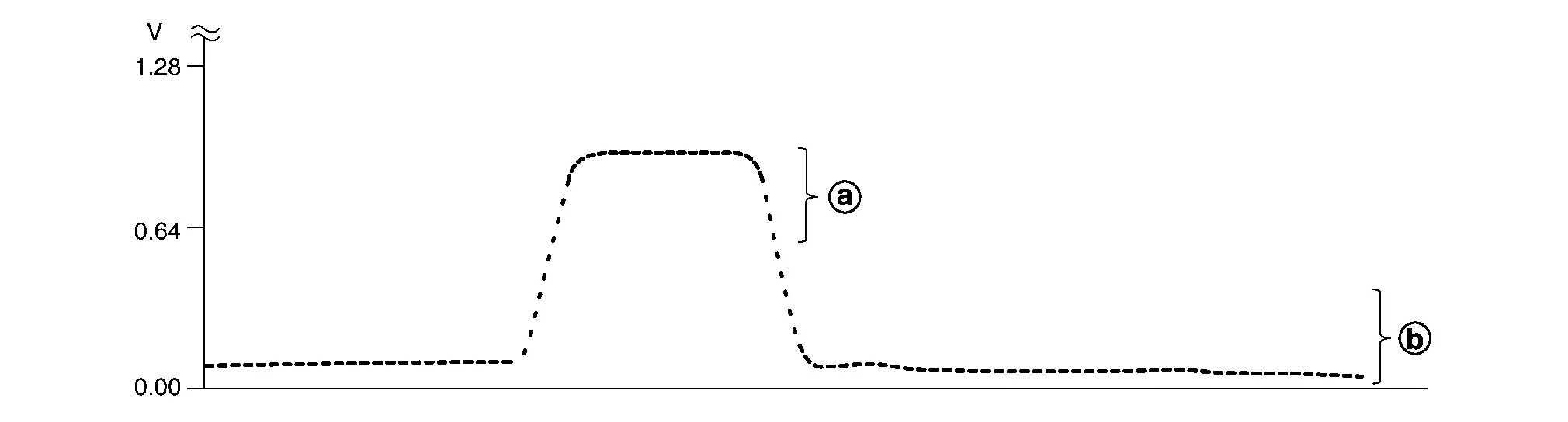

ŌĆ£HO2S2 (B1)ŌĆØ should be above

0.71 V at least once when the ŌĆ£FUEL INJECTIONŌĆØ is + 25%.

0.71 V at least once when the ŌĆ£FUEL INJECTIONŌĆØ is + 25%.ŌĆ£HO2S2 (B1)ŌĆØ should be below

0.18 V at least once when the ŌĆ£FUEL INJECTIONŌĆØ is ŌłÆ 25%.

0.18 V at least once when the ŌĆ£FUEL INJECTIONŌĆØ is ŌłÆ 25%.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 6.

CHECK HEATED OXYGEN SENSOR 2-1

Without CONSULT

Without CONSULT

-

Start engine and warm it up to normal operating temperature.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

-

Let engine idle for 1 minute.

-

Check the voltage between ECM harness connector and ground as per the following condition.

ECM Condition Voltage Connector + ŌłÆ Terminal F71 92 97 Revving up to 4,000 rpm under no load at least 10 times The voltage should be above 0.71 V at least once during this procedure.

The voltage should be below 0.18 V at least once during this procedure.

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 4.

CHECK HEATED OXYGEN SENSOR 2-2

Check the voltage between ECM harness connector and ground as per the following condition.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | ŌłÆ | ||

| Terminal | ||||

| F71 | 92 | 97 | Keeping engine speed at idle for 10 minutes |

The voltage should be above 0.71 V at least once during this procedure. The voltage should be below 0.18 V at least once during this procedure. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 5.

CHECK HEATED OXYGEN SENSOR 2-3

Check the voltage between ECM harness connector and ground as per the following condition.

| ECM | Condition | Voltage | ||

|---|---|---|---|---|

| Connector | + | ŌłÆ | ||

| Terminal | ||||

| F71 | 92 | 97 | Coasting from 80 km/h (50 MPH) in D position |

The voltage should be above 0.71 V at least once during this procedure. The voltage should be below 0.18 V at least once during this procedure. |

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 6.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to Exploded View.

CAUTION:

-

Discard any sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard surface such as a concrete floor; use a new one.

-

Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner [commercial service tool (NI-43897-18 or NI-43897-12)] and approved Anti-seize Lubricant (commercial service tool).

>>

INSPECTION END

Other materials:

ProPILOT Assist displays and indicators

Models with full-screen display

Models with analog meter and color display

ProPILOT Assist, ProPILOT Assist 1.1

ProPILOT activationAppears once the ProPILOT Assist system in your Nissan Rogue is activated.

Vehicle ahead detection indicatorShows whether the system detects a vehicle ahead (only ...

Dtc/circuit Diagnosis. B2043-4a Electric Shift Id Discord

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC detecting condition

B2043ŌĆō4A

Electric shift ID discord

(Electric shift identification discord)

Diagnosis condition

When registering electric shift control module

Signal (termina ...

P34ac Electric Intake Valve Timing Control Actuator

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P34AC

00

A camshaft posi actuator posi sens B1

(A Camshaft Position Actuator Position Sensor A Circuit Bank 1)

Diagnosis condition

ŌĆö

Signal (terminal)

...