Nissan Rogue (T33) 2021-Present Service Manual: Fuel Pressure Check

Work Procedure

FUEL PRESSURE RELEASE

FUEL PRESSURE RELEASE

With CONSULT

With CONSULT

-

Turn ignition switch ON.

-

Perform ŌĆ£ENGINEŌĆØ in ŌĆ£WORK SUPPORTŌĆØ mode with CONSULT.

-

Start the engine.

-

After engine stalls, crank it two or three times to release all fuel pressure.

-

Turn ignition switch OFF.

Without CONSULT

Without CONSULT

-

Remove fuel pump fuse located in IPDM E/R.

-

Start the engine.

-

After engine stalls, crank it two or three times to release all fuel pressure.

-

Turn ignition switch OFF.

-

Reinstall fuel pump fuse after servicing fuel system.

>>

INSPECTION END

FUEL PRESSURE CHECK

FUEL PRESSURE CHECK

-

Release fuel pressure.

-

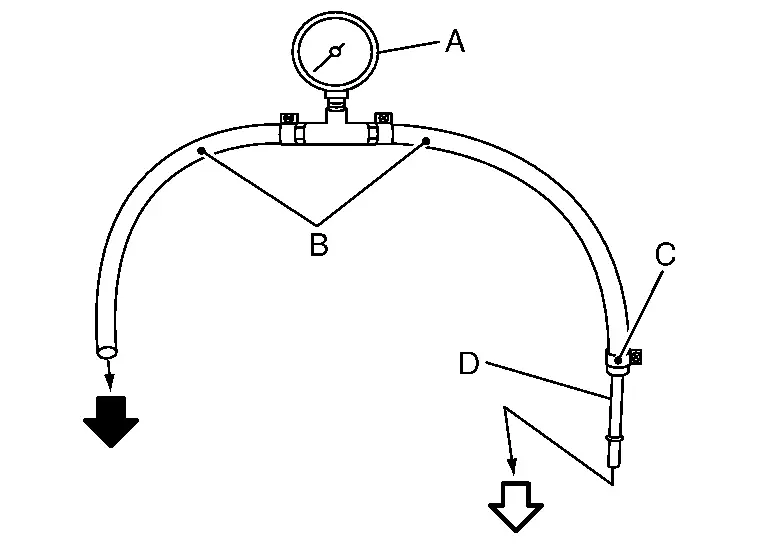

Connect fuel hose for fuel pressure check (B) to fuel pressure gauge (A). Then, connect fuel hose for fuel pressure check to fuel tube adapter (SST: KV10120000) (D) with hose clamp (C).

: To high pressure fuel pump

: To quick connector CAUTION:

-

Use suitable fuel hose for fuel pressure check (genuine NISSAN fuel hose)

-

To avoid unnecessary force or tension to hose, use moderately long fuel hose for fuel pressure check.

-

Wipe off oil or dirt from hose insertion part using cloth moistened with gasoline.

-

Apply proper amount of gasoline on the hose insertion part.

-

Use NISSAN genuine hose clamp (part number: 16439 N4710 or 16439 N4710)

-

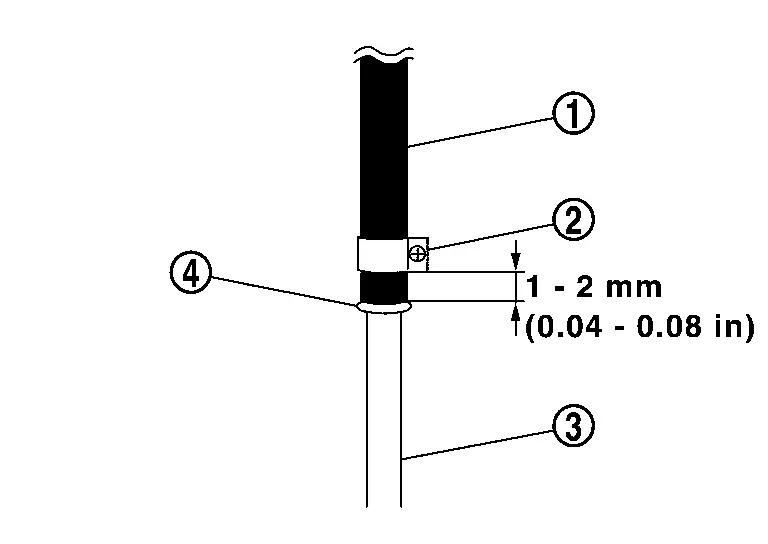

Install hose clamp to the hose end position within 1- 2 mm (0.04 - 0.08 in) and tighten hose clamp to the specified torque.

Tightening torque: 1 - 1.5 N┬Ęm (0.1 - 0.15 kgŌłÆm) -

-

Disconnect quick connector and disconnect fuel feed hose from high pressure fuel pump. Refer to Exploded View.

CAUTION:

-

Make sure to release fuel pressure before removal of fuel line.

-

Do the following procedure in the place where ventilation is good without the combustible.

NOTE:

NOTE:

-

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pressure cannot be completely released because this models do not have fuel return system.

-

Use fuel tube adapter (SST: KV10120000) and fuel pressure gauge to check fuel pressure.

-

-

Install fuel hose for fuel pressure check to high pressure fuel pump with hose clamp.

CAUTION:

-

Wipe off oil or dirt from hose insertion part using cloth moistened with gasoline.

-

Apply proper amount of gasoline on the hose insertion part.

-

Insert fuel hose for fuel pressure check

until it touchesthe spool

until it touchesthe spool  on high pressure fuel pump

on high pressure fuel pump  .

. -

Use NISSAN genuine hose clamp

(part number: 16439ŌĆéN4710 or 16439ŌĆé40U00).

(part number: 16439ŌĆéN4710 or 16439ŌĆé40U00). -

Install hose clamp to the hose end position within 1- 2 mm (0.04 - 0.08 in) and tighten hose clamp to the specified torque.

Tightening torque: 1 - 1.5 N┬Ęm (0.1 - 0.15 kgŌłÆm) -

After connecting fuel hose for fuel pressure check, pull the hose with a force of approximately 100 N (approximately 10 kg, 22 lb) to confirm fuel sub tube does not come off.

-

-

Install fuel pressure check adapter to quick connector of fuel feed hose.

-

Turn ignition switch ON and check for fuel leakage.

-

Start engine and check for fuel leakage.

-

Stop the engine.

-

Turn ignition switch ON and read the indication of fuel pressure gauge.

At ignition switch ON : Approximately 450 kPa (4.5 bar, 4.59 kg/ŃÄĀ, 65.25 psi)

Is the inspection result normal?

YES>>INSPECTION END

NO>>GO TO 2.

CHECK FUEL HOSE

Check fuel hose for clogging.

Is the inspection result normal?

YES>>Repair or replace the malfunctioning part.

NO>>Replace fuel filter and fuel pump assembly. Refer to Removal and Installation.

Other materials:

Basic Inspection. Diagnosis and Repair Work Flow

Work Flow

DETAILED FLOWINTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform

an interview utilizing reproduce symptoms as well as fully understand

it. Ask customer about his/her complaints carefully. Check symptoms by

driving Nissan Ariya vehicle wi ...

Radio Antenna

The antenna on the Nissan Rogue is located on the rear part of the vehicle roof and is designed to provide stable radio reception during everyday driving.

CAUTION

A build-up of ice on the antenna can affect radio performance.

Remove the ice to restore proper radio reception on your Nissan Rogue.

...

Fuel Injector

Component Function Check

INSPECTION START

Turn ignition switch to START.

Are any cylinders ignited?

YES>>

GO TO 2.

NO>>

Refer to Diagnosis Procedure.

CHECK FUEL INJECTOR FUNCTION

With CONSULT

Start engine.

Perform ŌĆ£POWER BALANCEŌĆØ in ŌĆ£ACTIVE TESTŌĆØ mode of ŌĆ£E ...