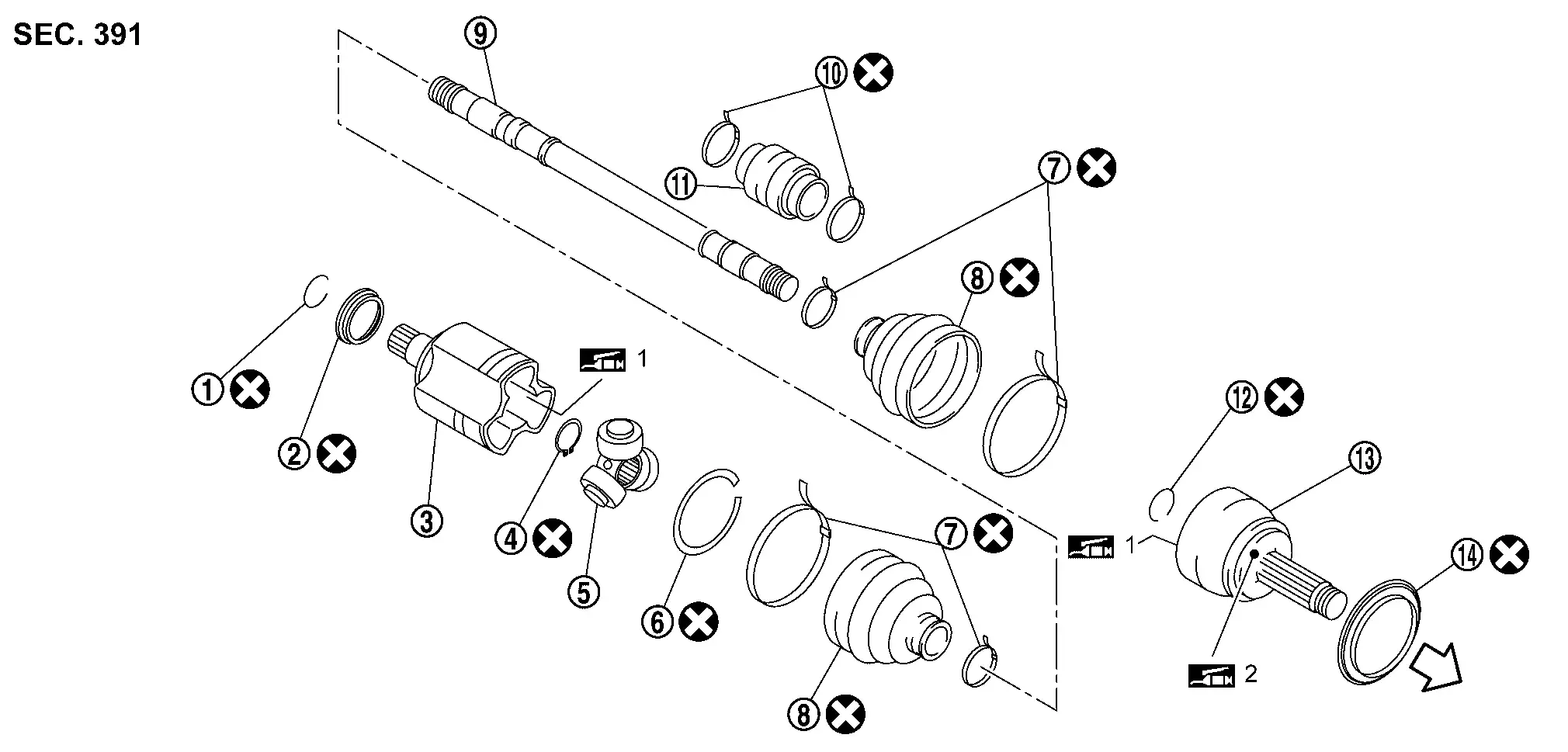

Nissan Rogue (T33) 2021-Present Service Manual: Front Drive Shaft Boot (kr15ddt)

Exploded View

LEFT SIDE

|

Circular clip |  |

Dust shield |  |

Housing |

|

Snap ring  |

|

Spider assembly |  |

Stopper ring |

|

Boot band |  |

Boot |  |

Shaft |

|

Damper band |  |

Dynamic damper |  |

Circular clip |

|

Joint sub-assembly |  |

Dust shield | ||

|

: Wheel side | ||||

|

1: Fill NISSAN Genuine grease or equivalent. | ||||

|

2: Apply paste [service parts (440037S000)] | ||||

|

: Always replace after every disassembly. | ||||

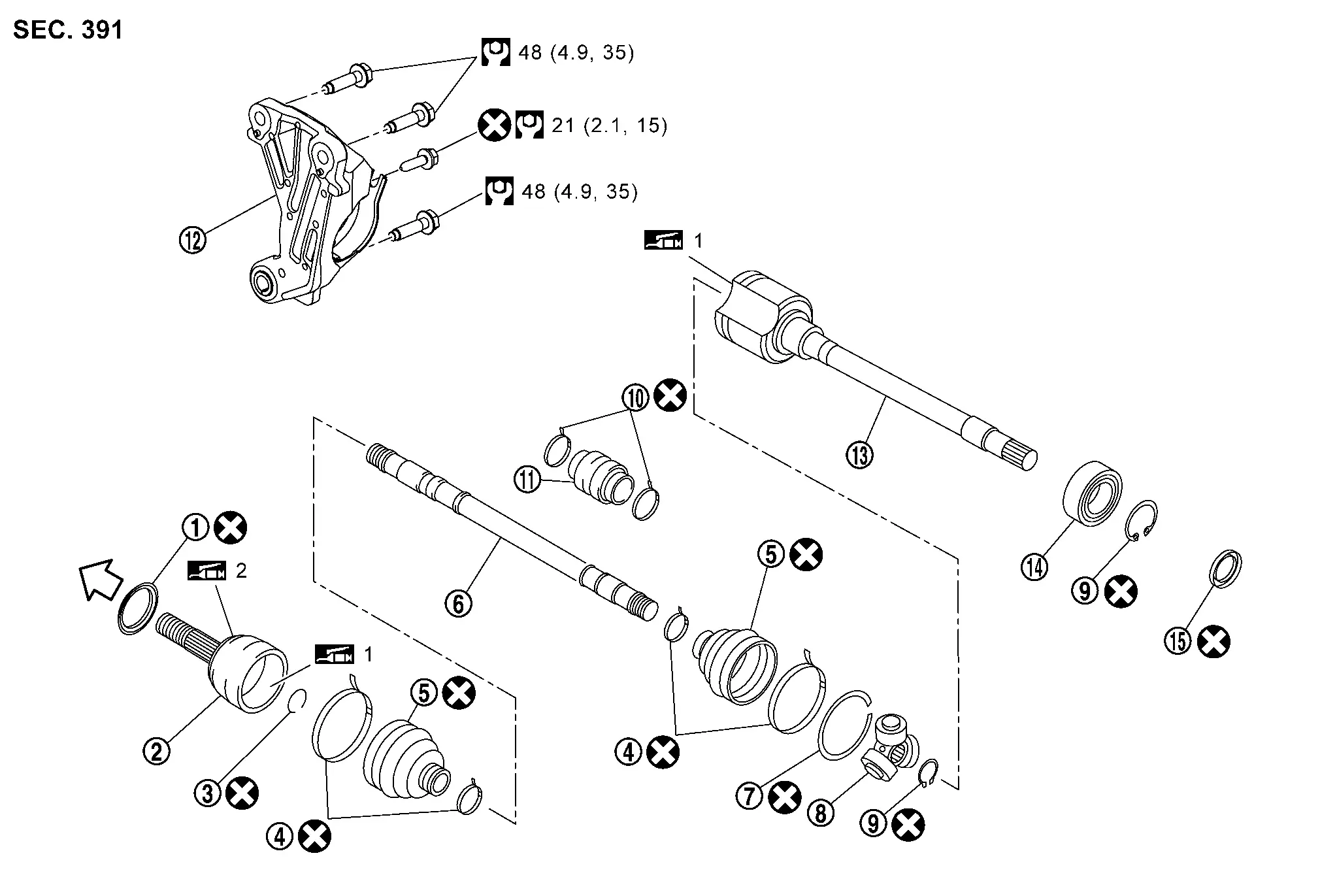

RIGHT SIDE

|

Dust shield |  |

Joint sub-assembly |  |

Circular clip |

|

Boot band |  |

Boot |  |

Shaft |

|

Stopper ring |  |

Spider assembly |  |

Snap ring |

|

Damper band |  |

Dynamic damper |  |

Support bearing bracket |

|

Housing |  |

Support bearing |  |

Dust shield |

|

: Wheel side | ||||

|

1: Fill NISSAN Genuine grease or equivalent. | ||||

|

2: Apply paste [service parts (440037S000)] | ||||

|

: Always replace after every disassembly. | ||||

Removal and Installation

REMOVAL

Wheel Side

Remove tires. Refer to Removal & Installation.

Remove wheel sensor from steering knuckle. Refer to Removal and Installation.

Remove lock plate from strut assembly. Refer to Exploded View.

Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to Removal and Installation.

CAUTION:

Never depress brake pedal while brake caliper is removed.

Remove disc rotor. Refer to Removal and Installation.

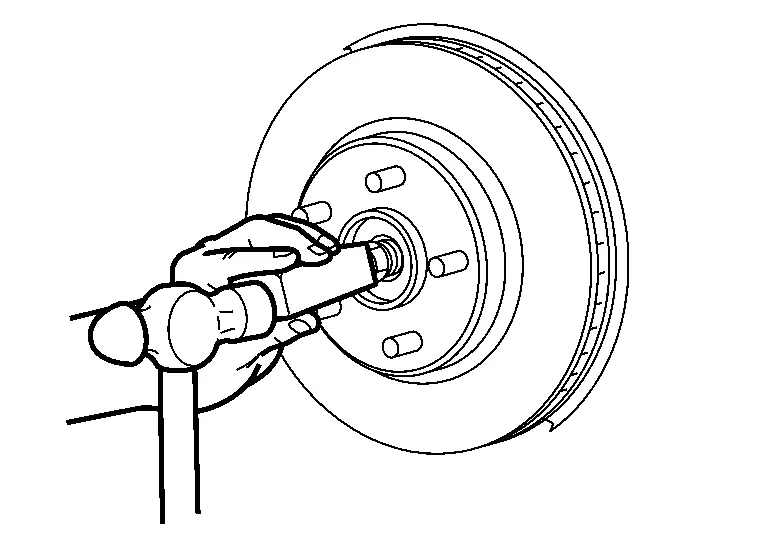

Release stacked area of wheel hub lock nut. Refer to Removal and Installation.

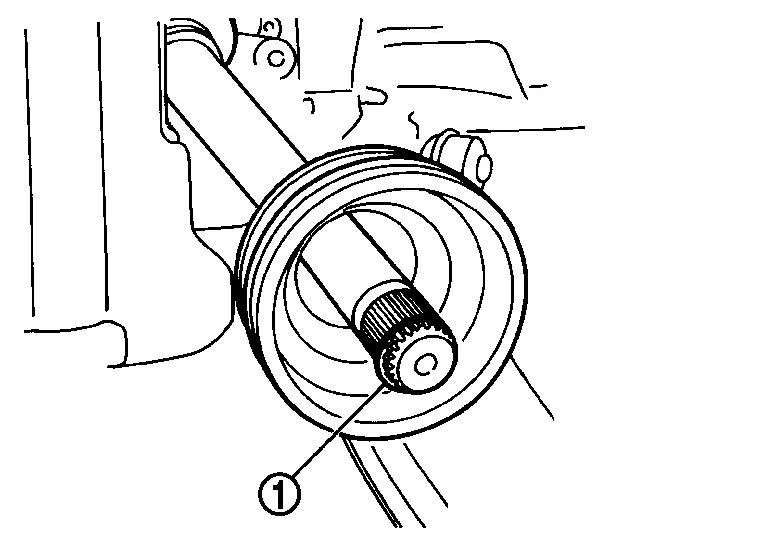

Loosen wheel hub lock nut using a hub lock nut wrench (A) (SST: KV40104000). Refer to Removal and Installation.

Patch wheel hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub from drive shaft.

CAUTION:

-

Never place drive shaft joint at an extreme angle.

-

Also be careful not to overextend slide joint.

-

Never allow drive shaft to hang down without support for joint sub-assembly, shaft and the other parts.

NOTE:

NOTE:

Use suitable puller, if wheel hub and drive shaft cannot be separated even after performing the above procedure.

Remove wheel hub lock nut.

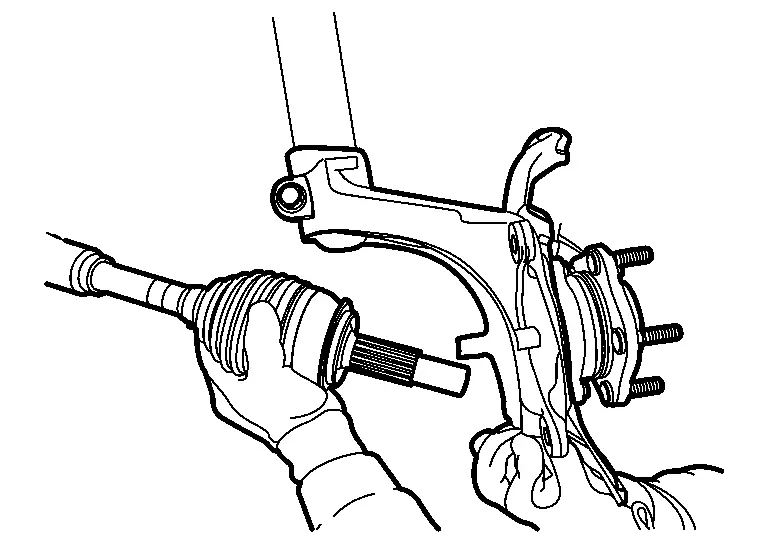

Separate transverse link from steering knuckle (lower side). Refer to Removal and Installation.

Separate steering outer socket from steering knuckle. Refer to Removal and Installation.

Remove drive shaft from wheel hub and bearing assembly.

CAUTION:

-

Never place drive shaft joint at an extreme angle.

-

Be careful not to overextend slide joint.

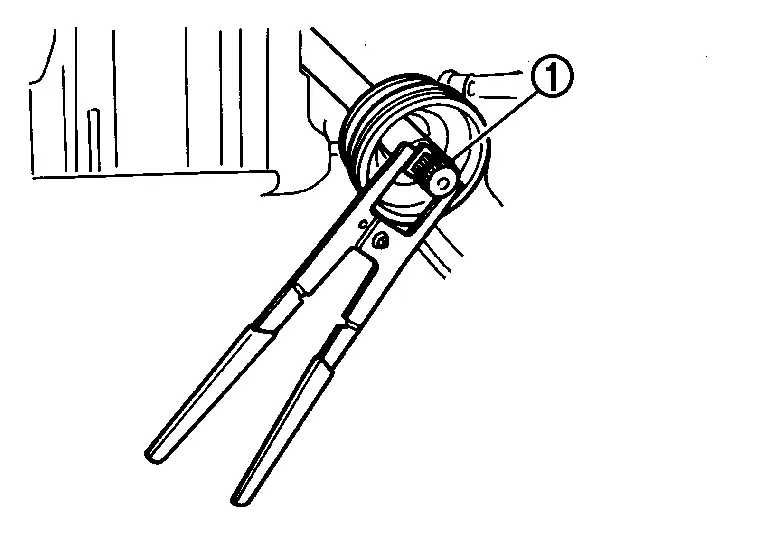

Remove boot bands, and then separate boot from joint sub-assembly.

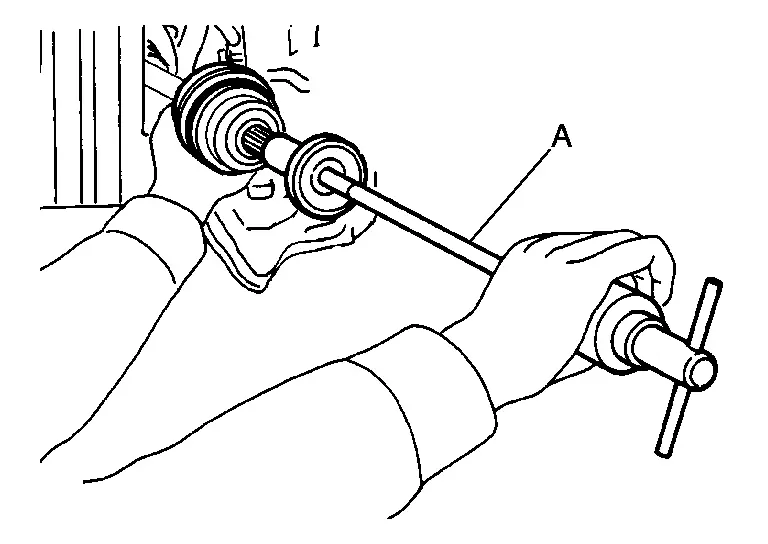

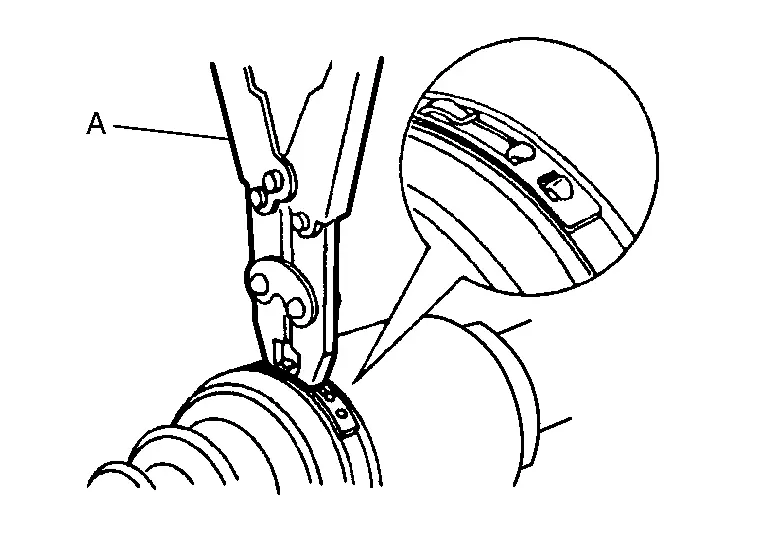

Screw suitable tool (A) into joint sub-assembly screw part to a length of 30 mm (1.18 in) or more. Support drive shaft with one hand and pull out joint sub-assembly from shaft.

CAUTION:

-

Align sliding hammer and drive shaft and remove them by pulling directory.

-

If joint sub-assembly cannot be pulled out, try after removing drive shaft from Nissan Ariya vehicle. Refer to Disassembly and Assembly.

Remove circular clip  from shaft.

from shaft.

Remove boot from shaft.

Transaxle Side

Remove boot after removing drive shaft.

-

Remove: Refer to Removal and Installation.

-

Disassembly: Refer to Disassembly and Assembly.

INSTALLATION

Wheel Side

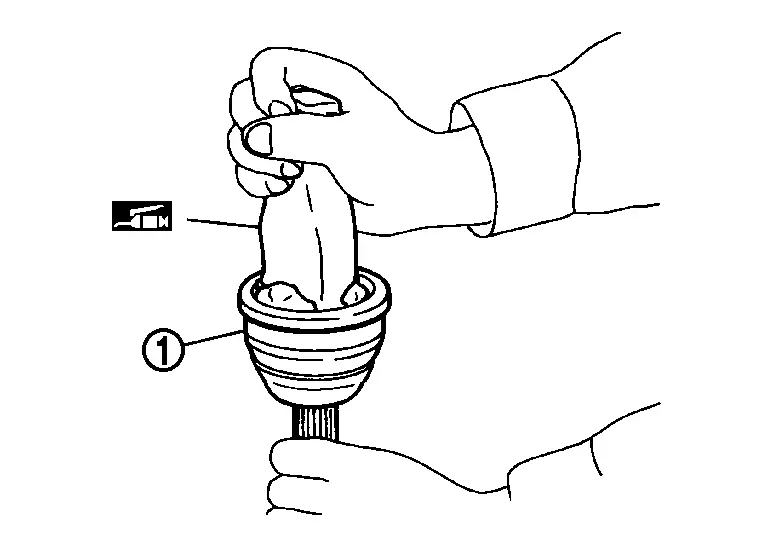

Clean the old grease on joint sub-assembly with paper waste.

Fill serration slot joint sub-assembly  with NISSAN genuine grease or equivalent until the serration slot and ball groove become full to the brim.

with NISSAN genuine grease or equivalent until the serration slot and ball groove become full to the brim.

CAUTION:

After applying grease, use a shop cloth to wipe off old grease that has oozed out.

Install boot and boot bands to shaft.

CAUTION:

-

Never reuse boot and boot band.

-

Wrap serration on shaft with tape

to protect the boot from damage.

to protect the boot from damage.

Remove the tape wrapped around the serration on shaft.

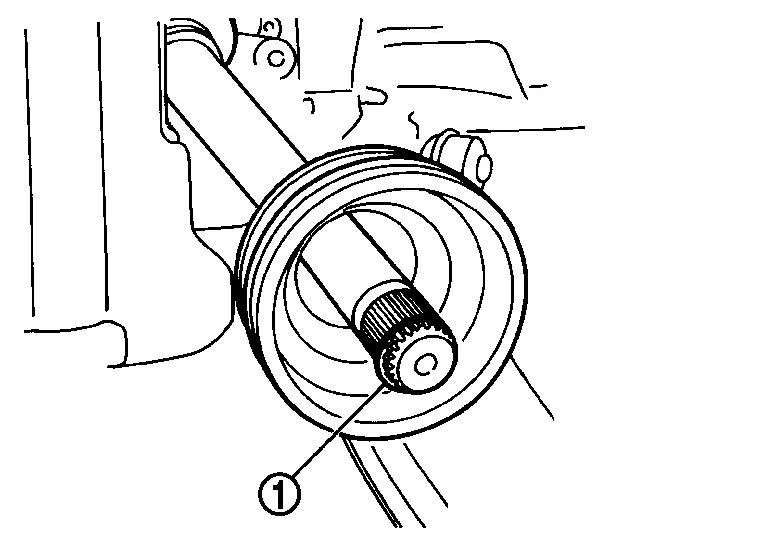

Position the circular clip  on groove at the shaft edge.

on groove at the shaft edge.

CAUTION:

Never reuse circular clip.

NOTE:

NOTE:

Drive joint inserter is recommended when installing circular clip  .

.

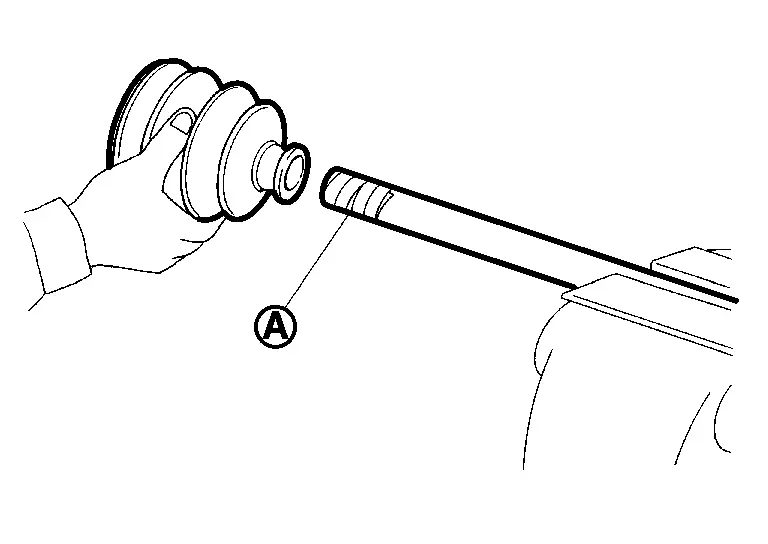

Align both center axles of the shaft edge and joint sub-assembly. Then assemble shaft with joint sub-assembly holding circular clip.

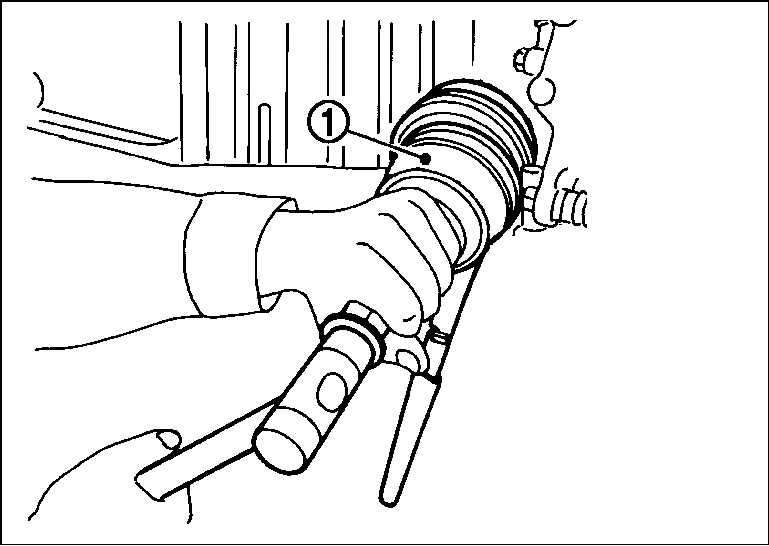

Install joint sub-assembly  to shaft using plastic hammer.

to shaft using plastic hammer.

WARNING:

Ensure that circular clip is properly engaged, otherwise the joint sub-assembly could pull away from transaxle during Nissan Ariya vehicle operation resulting in loss of drive force and possible drive shaft damage, which may cause a crash and serious injury or damage the drive shaft.

Pull the joint sub-assembly in the axial direction away from transaxle assembly. Confirm that the joint sub assembly cannot be pulled out.

Fill into the boot inside with the specified amount of grease from large diameter side of boot.

| Grease amount | : Refer to Drive Shaft (KR15DDT). |

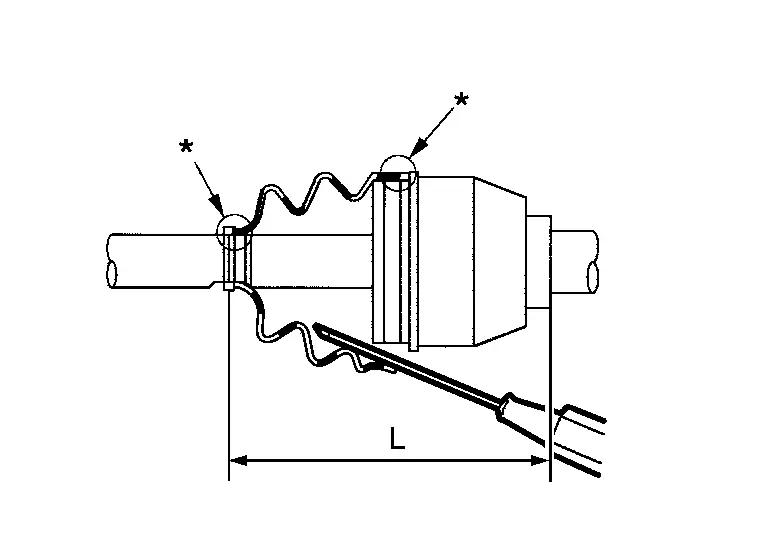

Install the boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated by “*” mark) on the shaft or joint subassembly. boot may be removed. Remove all grease from the boot mounting surface.

To prevent the deformation of the boot, adjust the boot installation length (L) to the specified value shown below by inserting the suitable tool into the inside of the boot from the large diameter side of the boot and discharging the inside air.

| L | : Refer to Drive Shaft (KR15DDT). |

CAUTION:

-

If the boot mounting length exceeds the standard, it may cause breakage in the boot.

-

Be careful not to touch the inside of the boot with a tip of tool.

Secure the large and small ends of the boot with boot bands using the boot band crimping tool (A) (SST: KV40107300).

CAUTION:

Never reuse boot band.

NOTE:

NOTE:

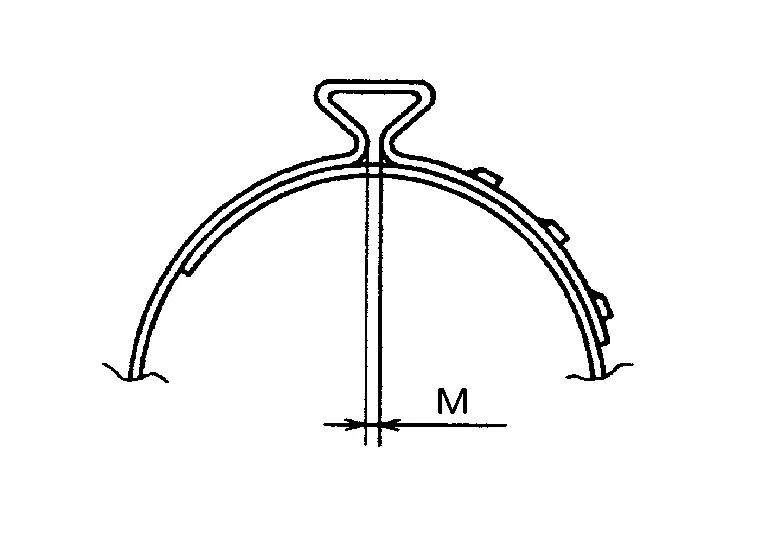

Secure boot band so that dimension (M) meets the specification as shown in the figure.

| M | : 1.0 – 4.0 mm (0.039 – 0.157 in) |

Check that displacement does not occur when boot is rotated with the joint sub-assembly and shaft fixed.

CAUTION:

-

Reinstall them using boot bands when boot installation positions become incorrect.

-

Never reuse boot band.

Clean the matching surface of wheel hub lock nut and wheel hub and bearing assembly.

CAUTION:

Never apply lubricating oil to these matching surface.

Clean the matching surface of drive shaft and wheel hub and bearing

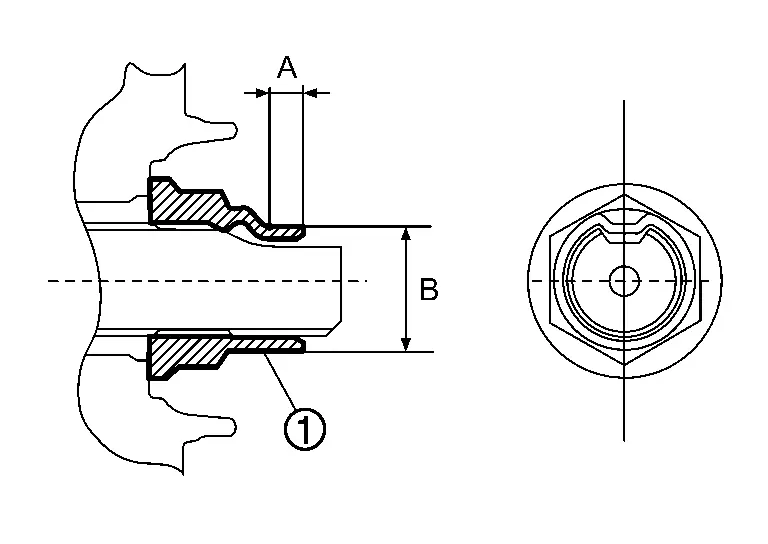

assembly. And then apply paste [service parts (440037S000)] to surface  of joint sub-assembly of drive shaft.

of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly of drive shaft.

| Amount paste | : 1.0 – 3.0 g (0.04 – 0.10 oz) |

Insert drive shaft to wheel hub, and then temporarily tighten hub lock nut.

CAUTION:

Never overlap drive shaft stacked area  and wheel hub bolts

and wheel hub bolts  .

.

Install transverse link to steering knuckle (lower side). Refer to Removal and Installation.

Install steering outer socket to steering knuckle. Refer to Removal and Installation.

Install disc rotor. Refer to Removal and Installation.

Install brake caliper assembly to steering knuckle. Refer to Removal and Installation.

Install lock plate to strut assembly. Refer to Exploded View.

Tighten the wheel hub lock nut to the specified torque.

|

: 255 N·m (26 kg-m, 188 ft-lb) |

CAUTION:

-

Since the drive shaft is assembled by press-fitting, use the tightening torque range for the wheel hub lock nut.

-

Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

-

Never reuse wheel hub lock nut.

NOTE:

NOTE:

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than torque for avoiding looseness.

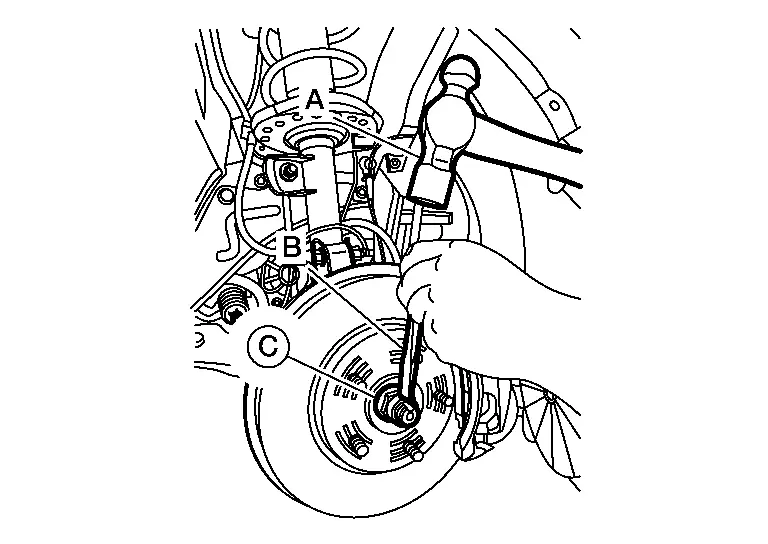

Using suitable tool (A) and cold chisel (B) stake the wheel hub lock nut (C) as shown.

NOTE:

NOTE:

Use the following range for stacking the wheel hub lock nut.

| A | : 6.2 mm (0.244 in) |

| B | : 26.4 – 27.8 mm (1.039 – 1.094 in) |

Install front wheel sensor to steering knuckle. Refer to Removal and Installation.

Install tires to Nissan Ariya vehicle. Refer to Removal and Installation.

Perform inspection after installation. Refer to Inspection.

Transaxle Side

-

Installation: Refer to Removal and Installation.

-

Assembly: Refer to Disassembly and Assembly.

Inspection

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

-

Check components for deformation, cracks, and other damage.

-

Check boots of transverse link and steering outer socket ball joint for breakage, axial end play, and swing torque.

-

Transverse link: Refer to Inspection.

-

Steering outer socket: Refer to Inspection.

-

INSPECTION AFTER INSTALLATION

Check wheel sensor harness for proper connection. Refer to Exploded View.

Check the wheel alignment. Refer to Inspection.

Adjust neutral position of steering angle sensor. Refer to Work Procedure.

Other materials:

Diagnosis System (side Radar Front Lh)

CONSULT Function [Side radar (Front left)]

APPLICATION ITEMSCONSULT performs the following functions via CAN communication using side radar front LH. Diagnosis mode Description

Self Diagnostic Result

Retrieve DTC from ECU and display diagnostic items

Data Monitor

Monitor the input/ou ...

Adjustment of Steering Angle Sensor Neutral Position

Description

Always adjust the neutral position of steering angle sensor before

driving when the following operation is performed. Refer to Work

Procedure.×: Required —: Not required Procedure Adjust the neutral position of steering angle sensor

Removing/ installing ABS actuator and elect ...

Electrical Load Signal

Component Function Check

CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

With CONSULT

Turn ignition switch ON.

Select “DATA MONITOR” of “ENGINE” with CONSULT.

Select “LOAD SIGNAL” and check indication under the following conditions.

Monitor item Condition Indication

LO ...