Nissan Rogue (T33) 2021-Present Service Manual: Differential Side Oil Seal

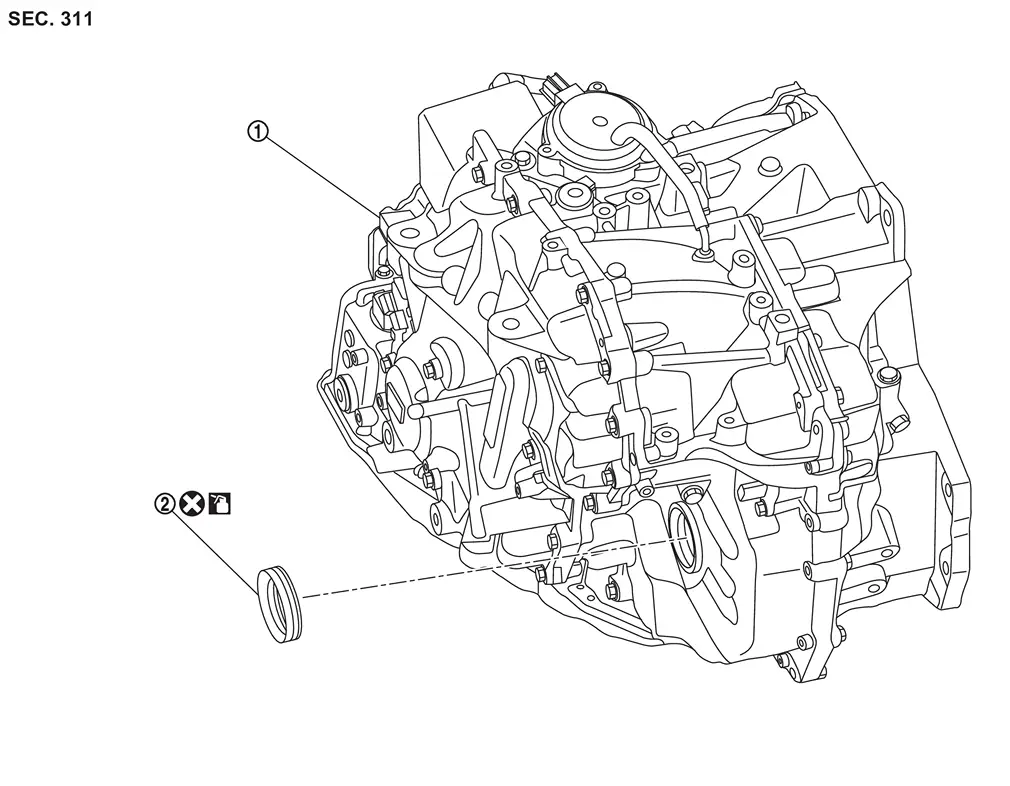

Exploded View

| 1. | Transaxle assembly | 2. | Differential side oil seal (left side) | 3. | Differential side oil seal (right side) |

: Always replace after every disassembly.

: Always replace after every disassembly.

: Apply CVT fluid.

: Apply CVT fluid.

| 1. | Transaxle assembly | 2. | Differential side oil seal (left side) |

: Always replace after every disassembly.

: Always replace after every disassembly.

: Apply CVT fluid.

: Apply CVT fluid.

Removal and Installation

REMOVAL

| Never Reuse These Parts | Part Code | For additional information: |

|---|---|---|

| Seal-O-ring, differential transmission case | 38342Q | Exploded View |

| Seal-O-ring, differential converter housing | 38342P | Exploded View |

Remove front drive shaft. Refer to Removal and Installation (2WD) or Removal and Installation (AWD).

Using a suitable tool remove the differential side oil seal.

CAUTION:

When removing the differential side oil seal, be careful not to scratch the oil seal mounting surfaces of the transaxle case and converter housing.

INSTALLATION

Note the following and install in the reverse order of removal.

CAUTION:

-

Never reuse differential side oil seal.

-

Apply CVT fluid to differential side oil seal.

-

When inserting the drive shaft, be sure to use protector on differential side oil seal. Refer to Removal and Installation(2WD) or Removal and Installation(AWD).

-

Install each differential side oil seal evenly using following Tools.

Tools to be used:

Location Special Service Tools Transaxle case side -

Output seal installer (case side) [SST: KV31500800(NI-52283)]

-

Universal driver handle [SST: ST35325000 (NI-8092)]

Converter housing side -

Output seal installer (torque converter side) [SST: KV31500900 (NI-52284)]

-

Universal driver handle [SST: ST35325000 (NI-8092)]

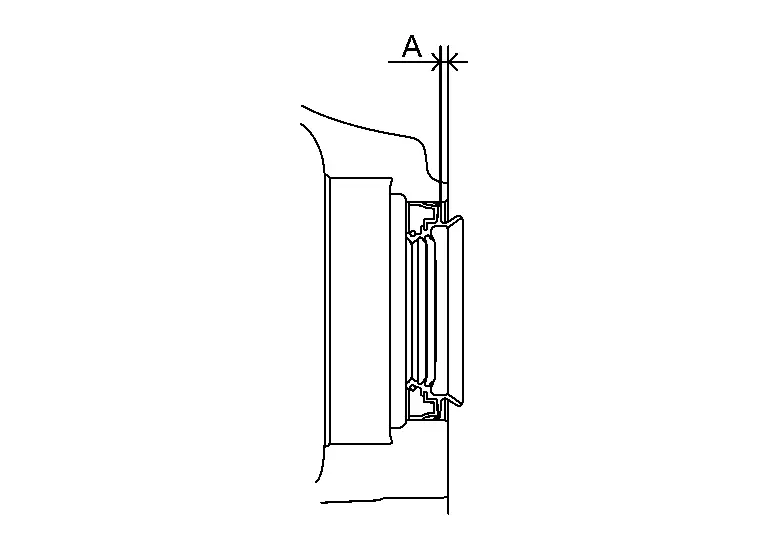

Install differential oil seal to the converter housing with seal installer (SST:NI-52283) until it is flush. Height or depth of differential oil seal from the surface (A):0±0.5mm (0 ± 0.020 mm)

-

Inspection and Adjustment

Check for CVT fluid leakage. Refer to Inspection.

Adjust CVT fluid level. Refer to Adjustment.

Other materials:

Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name Description

—

(NI-44372)

Pull gauge

Measuring steering wheel turning force and ball joint swinging force

KV40107300

(NI-51751)

Boot ban ...

Laser Branch Line Circuit

Diagnosis Procedure

CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors for damage, bend and loose connection (unit side and connector side).

Distance sensor

Harness connector B2 ...

C10b0-01 Parking Brake Actuator (rh)

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

C10B0

01

Parking brake actuator (RH)

[Parking brake actuator (right)]

Diagnosis condition

When parking brake is apply or release

Signal (terminal)

—

...