Nissan Rogue (T33) 2021-Present Service Manual: Steering Switch Signal B Circuit

Component Function Check

CHECK COMBINATION METER INPUT SIGNAL

CONSULT

CONSULT

-

Ignition switch ON.

-

Select “Steering switch input” in “Data monitor” mode of “M&A”.

-

Check that the function operates normally according to the following conditions:

| Condition | Value |

|---|---|

| CONTROL switch is pressed | SW1 |

| Jog dial is rotated to upward | SW2 |

| Jog dial is rotated to downward | SW3 |

| OK switch is pressed | SW4 |

| LEFT/BACK switch is pressed | SW5 |

| RIGHT switch is pressed | SW6 |

| VOL DOWN switch is pressed | SW7 |

| VOL UP switch is pressed | SW8 |

| TEL END switch is pressed | SW9 |

| VR/TEL switch is pressed | SW10 |

| SEEK DOWN switch is pressed | SW11 |

| SEEK UP switch is pressed | SW12 |

| Other than above | NO INPUT |

Is the inspection result normal?

YES>>Inspection End.

NO>>Refer to Diagnosis Procedure.

Diagnosis Procedure

CHECK STEERING SWITCH SIGNAL B CIRCUIT

-

Disconnect combination meter harness connector and spiral cable harness connector.

-

Check continuity between combination meter harness connector and spiral cable harness connector.

Combination meter Spiral cable Continuity Connector Terminal Connector Terminal M76 23 M30 9 Yes -

Check continuity between combination meter harness connector and ground.

Combination meter Ground Continuity Connector Terminal M76 23 No

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair harness or connector.

CHECK STEERING SWITCH SIGNAL GROUND CIRCUIT

-

Check continuity between combination meter harness connector and spiral cable harness connector.

Combination meter Spiral cable Continuity Connector Terminal Connector Terminal M76 34 M30 11 Yes -

Check continuity between combination meter harness connector and ground.

Combination meter Ground Continuity Connector Terminal M76 34 No

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair harness or connector.

CHECK SPIRAL CABLE

-

Disconnect spiral cable harness connectors.

-

Check continuity between spiral cable harness connectors.

Spiral cable Continuity Connector Terminal Connector Terminal M154 23 M30 9 Yes 25 11

Is the inspection result normal?

YES>>GO TO 4.

NO>>Replace spiral cable. Refer to Removal and Installation.

CHECK STEERING SWITCH

Check steering switch. Refer to Component Inspection.

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace steering switches. Refer to Removal and Installation.

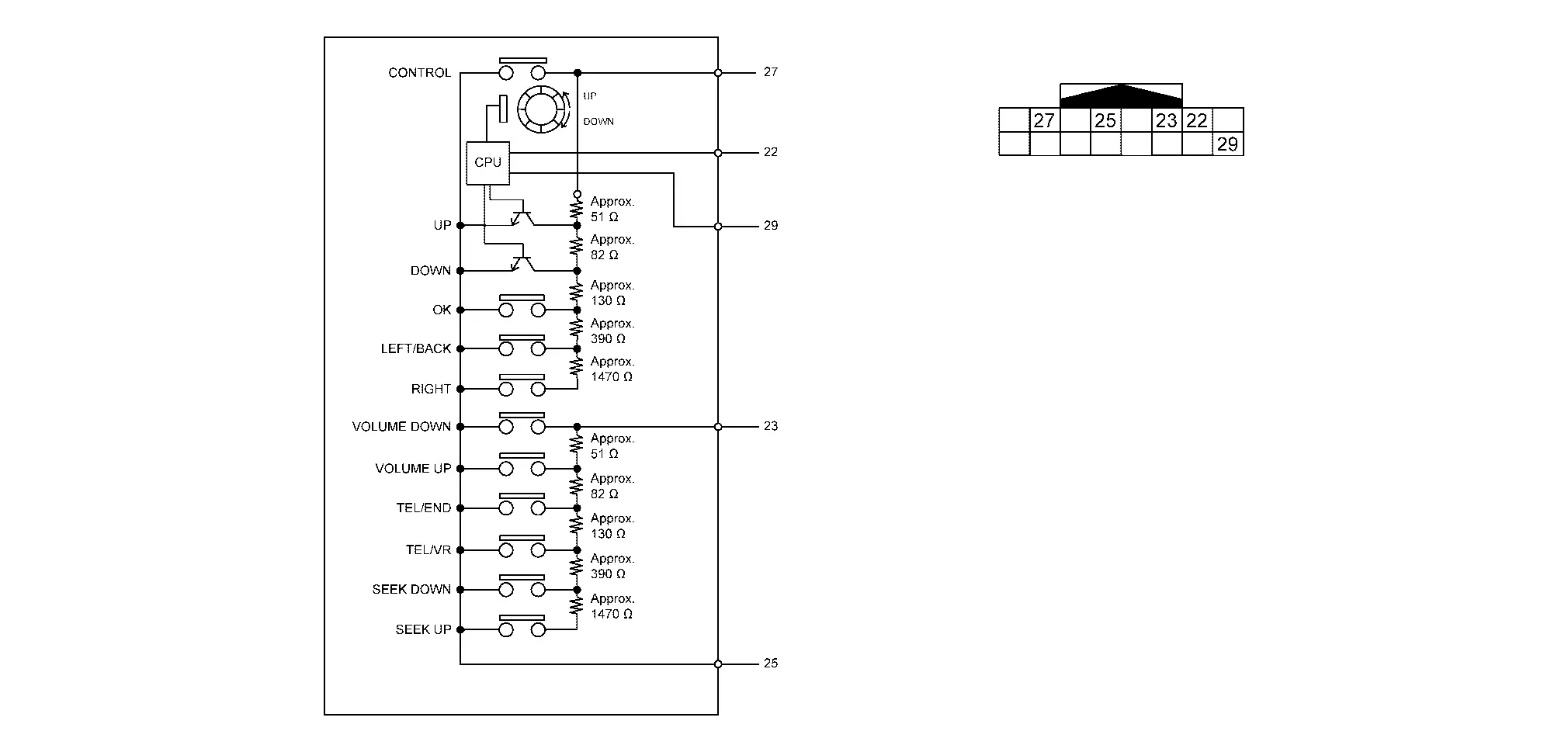

Component Inspection

CHECK STEERING SWITCH

-

Remove steering switch. Refer to Removal and Installation.

-

Measure the resistance between the steering switch connector.

Steering switch Condition Resistance

(Approx.) ΩTerminal 23 25 SEEK UP switch is pressed 2080.54 – 2165.46 SEEK DOWN switch is pressed 639.94 – 666.06 TEL/VR switch is pressed 257.74 – 268.26 TEL END switch is pressed 130.34 – 135.66 VOL UP switch is pressed 49.98 – 52.02 VOL DOWN switch is pressed 1 or less

Is the inspection result normal?

YES>>Inspection End.

NO>>Replace steering switch. Refer to Removal and Installation.

Other materials:

Basic Inspection. Additional Service When Replacing Power Steering Control Module Control Unit

Work Procedure

DESCRIPTIONWhen replacing the power steering control

module, the procedures of BEFORE REPLACEMENT and AFTER REPLACEMENT must

be performed. For work procedure, refer to the following:

Before power steering control module replacement.

After power steering control module rep ...

Removal and Installation. Front Bumper

Exploded View

1.

Front bumper side bracket RH

2.

Front bumper reinforcement

3.

Front bumper reinforcement bracket LH

4.

Front bumper reinforcement bracket RH

5.

Front bumper reinforcement lower

6.

Front bumper energy absorber

7.

Front bumper energy absorb ...

Three-point type seat belt with retractor

Basic information

WARNING

Every person riding in the Nissan Rogue must wear a seat belt at all times. Children should always ride in the rear in an appropriate restraint.

Do not ride in the vehicle when the seatback is reclined.

This is dangerous because the shoulder belt will not rest prope ...