Nissan Rogue (T33) 2021-Present Service Manual: Removal and Installation :: Windshield Glass

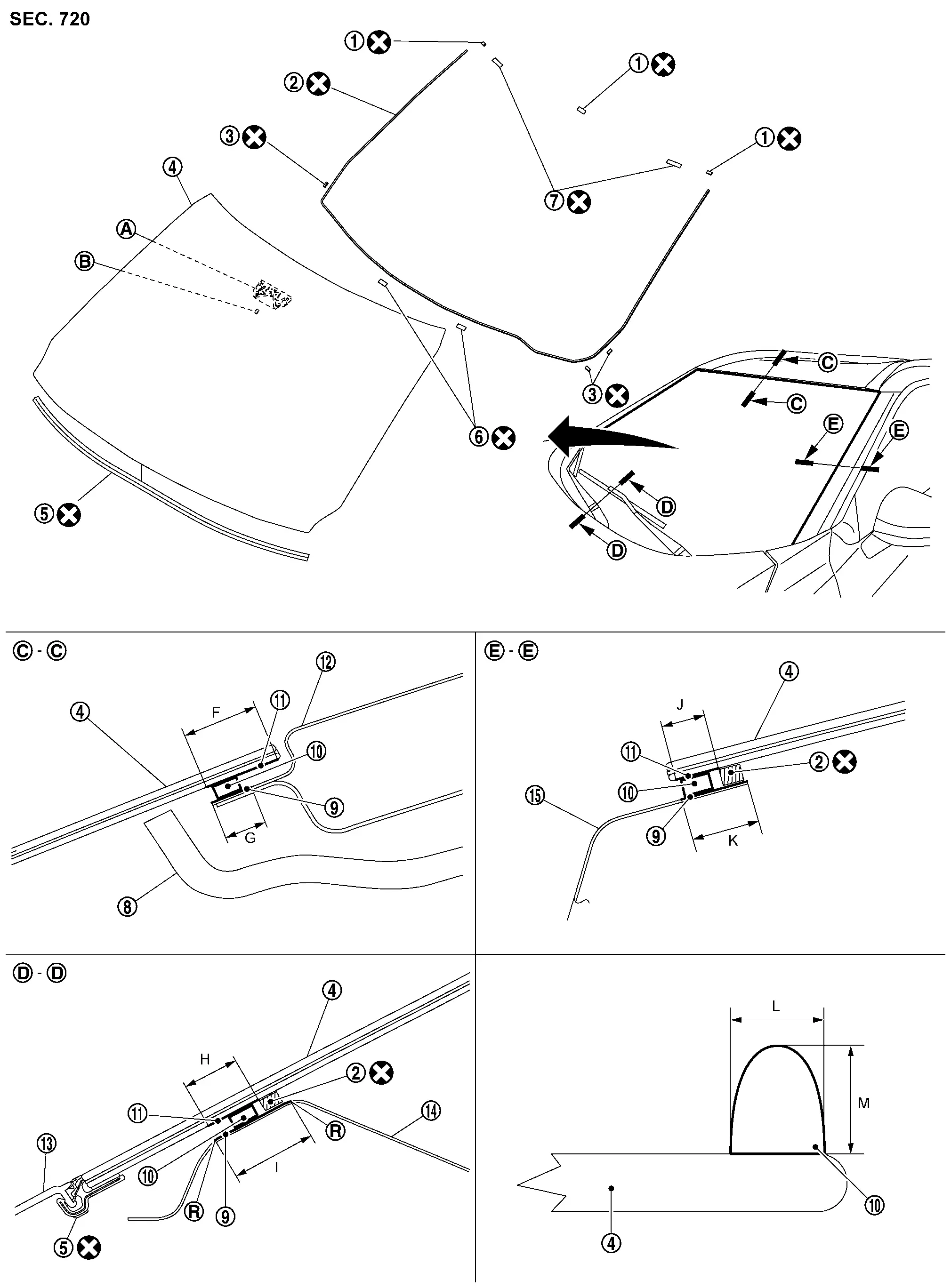

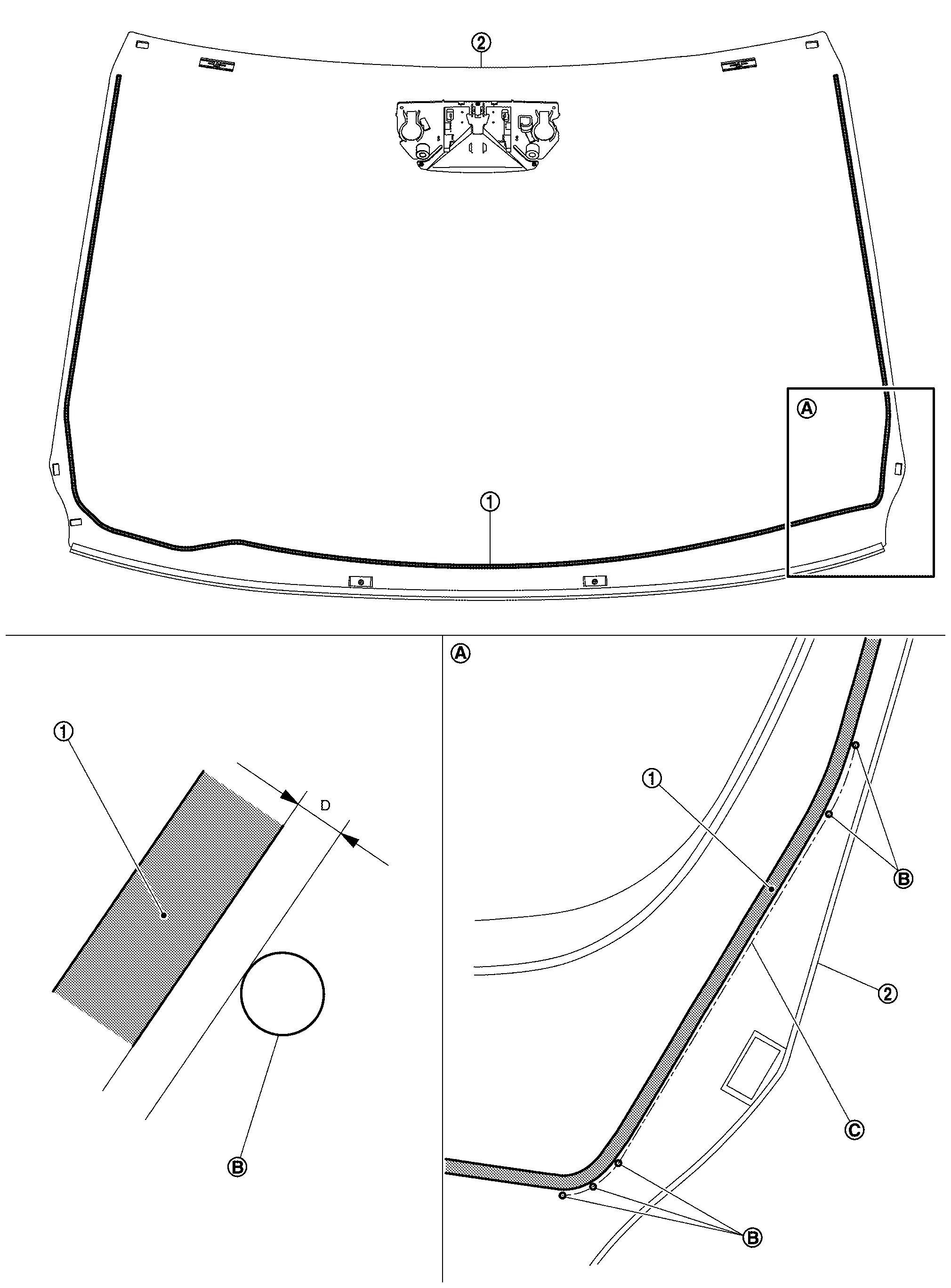

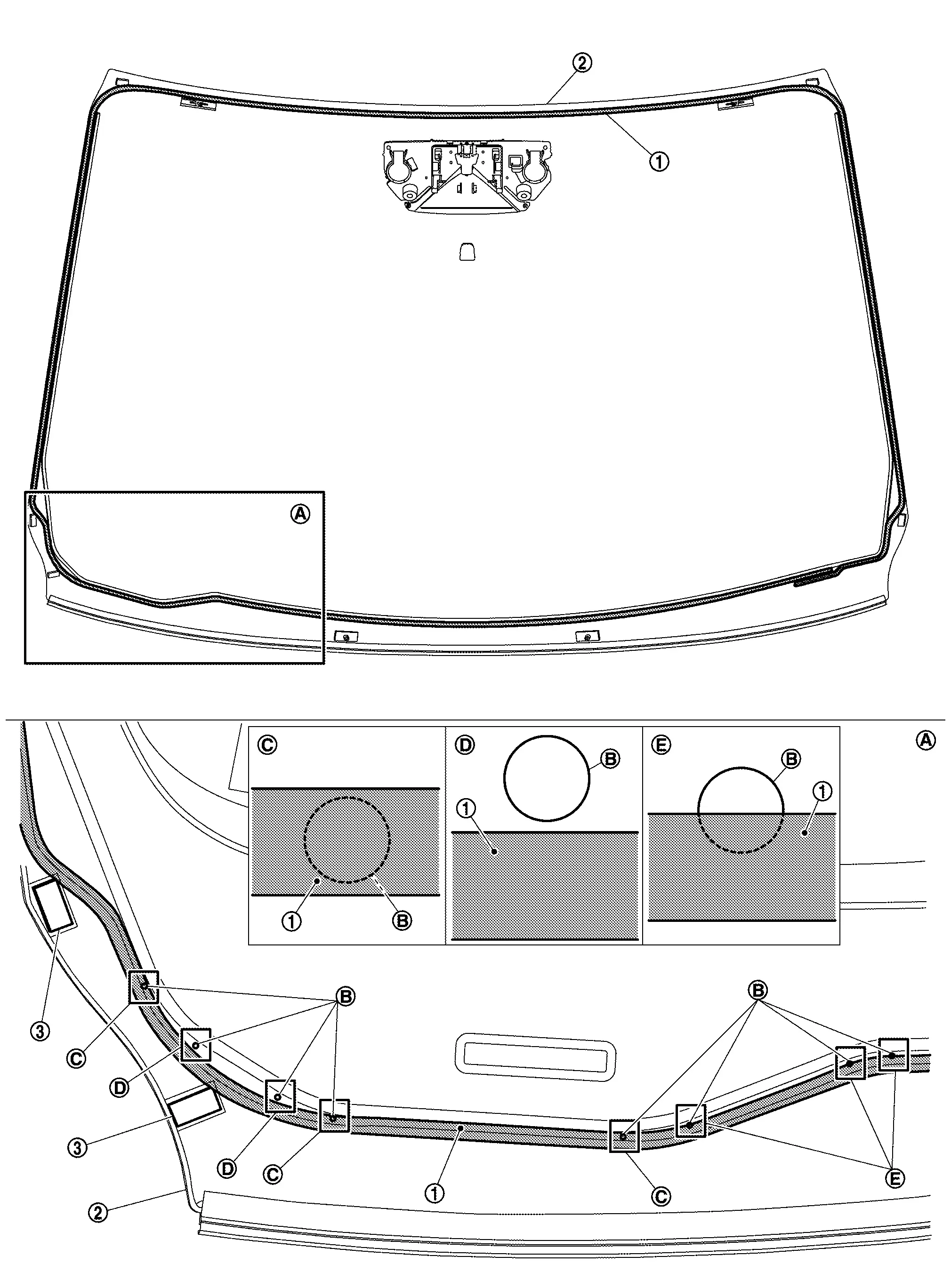

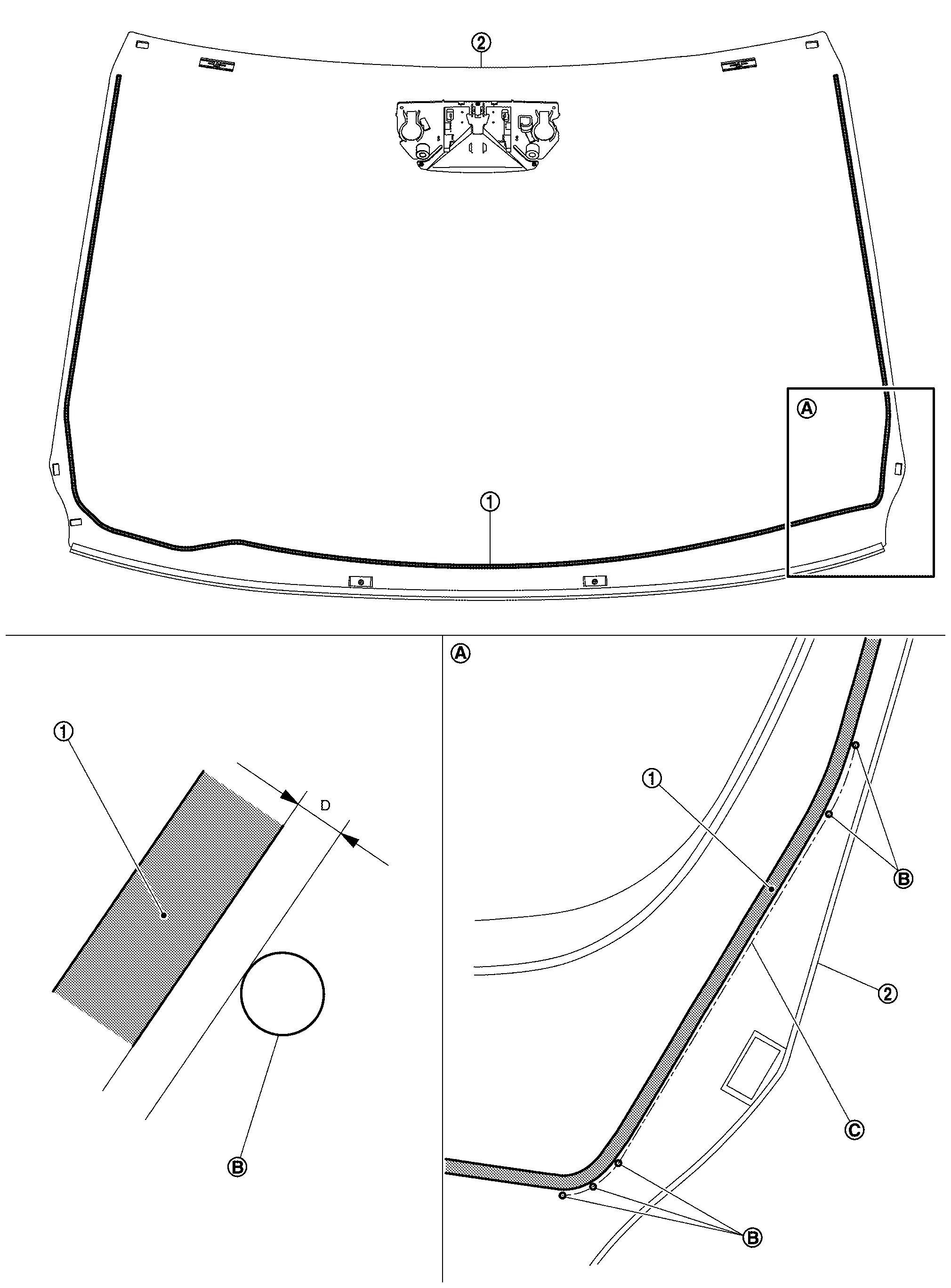

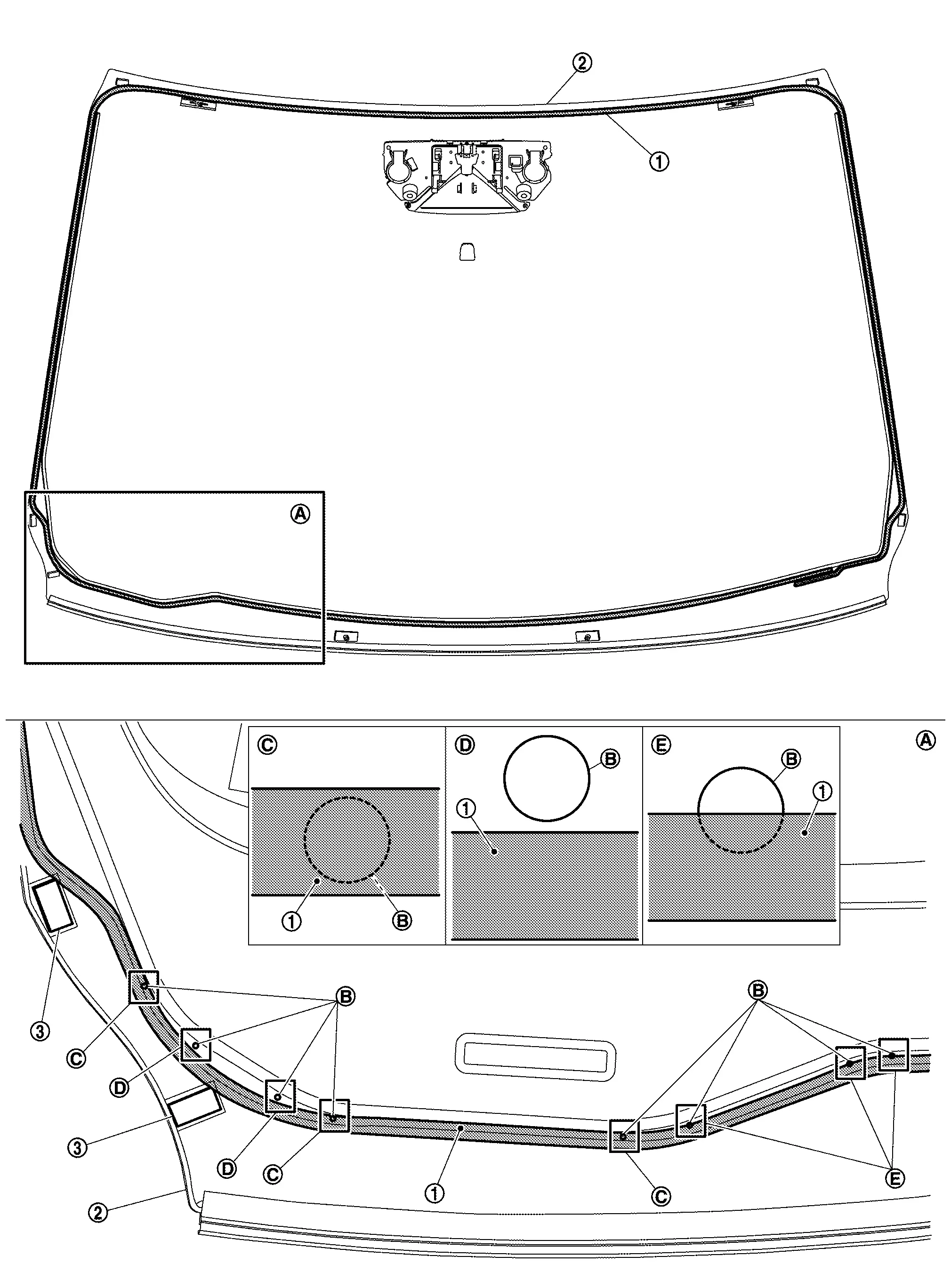

Exploded View

NMK Production

|

Spacer (upper) |  |

Dam sealant rubber |  |

Spacer (lower) |

|

Windshield glass |  |

Windshield glass molding |  |

Clip (lower) |

|

Clip (upper) |  |

Headlining assembly |  |

Painted surface primer |

|

Adhesive |  |

Glass primer |  |

Roof panel |

|

Cowl top cover |  |

Dash upper |  |

body side outer panel |

|

: Front camera unit and cover bracket (with front camera unit) | ||||

|

: inside mirror base | ||||

|

: R end | ||||

|

: Always replace after every disassembly. | ||||

Unit: mm (in)

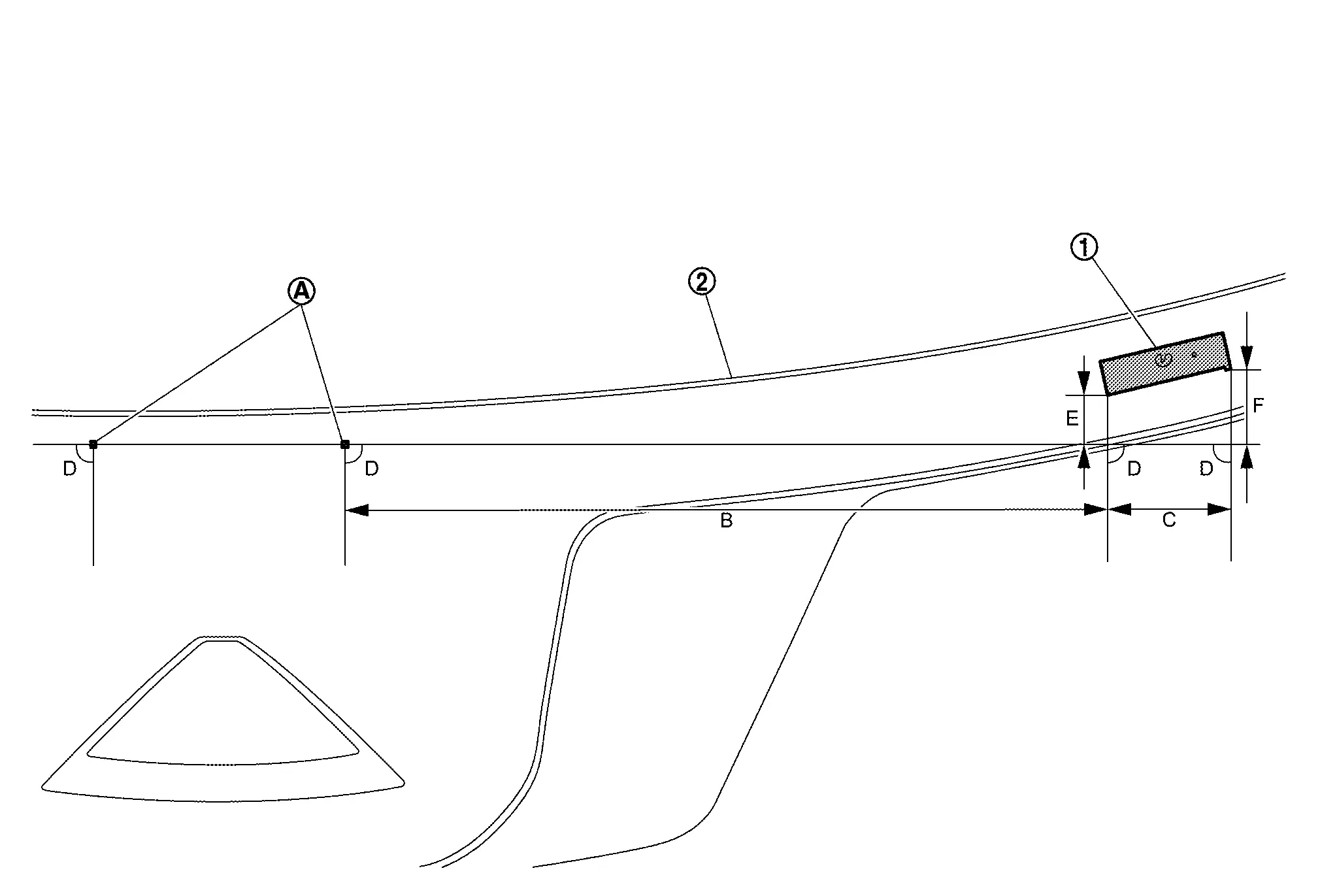

| Portion | Primer range | Adhesive range | |||

|---|---|---|---|---|---|

| L | M | ||||

| Windshield glass – Roof panel |  – – |

F |

21.7 (0.854) |

7.0 (0.276) |

12.0 (0.47) |

| G |

15.0 (0.59) |

||||

| Windshield glass – Dash upper |  – – |

H |

13.0 (0.512) |

||

| I |

R end to R end |

||||

| Windshield glass – Body side outer panel |  – – |

J |

12.0 (0.47) |

||

| K |

18.0 (0.71) |

||||

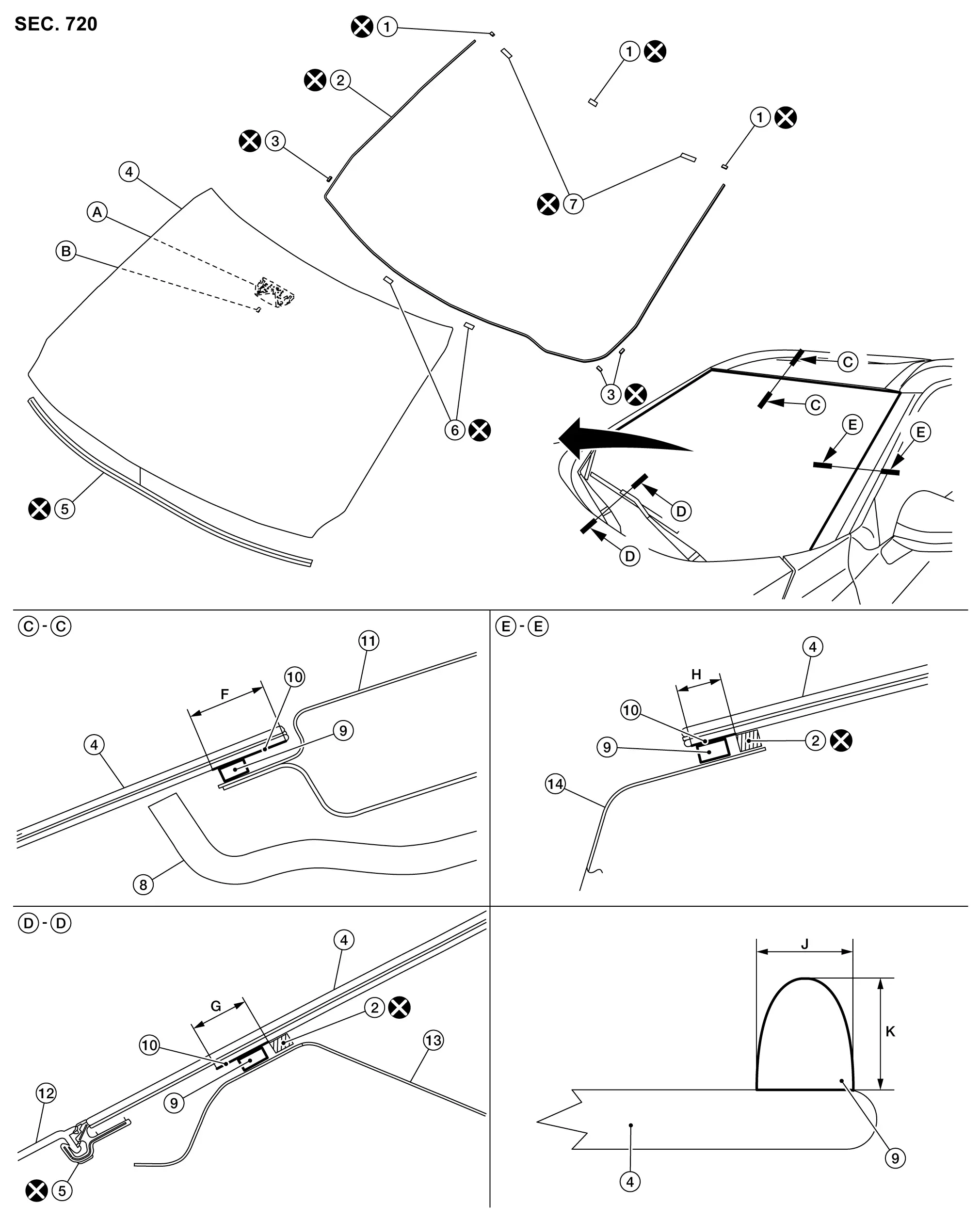

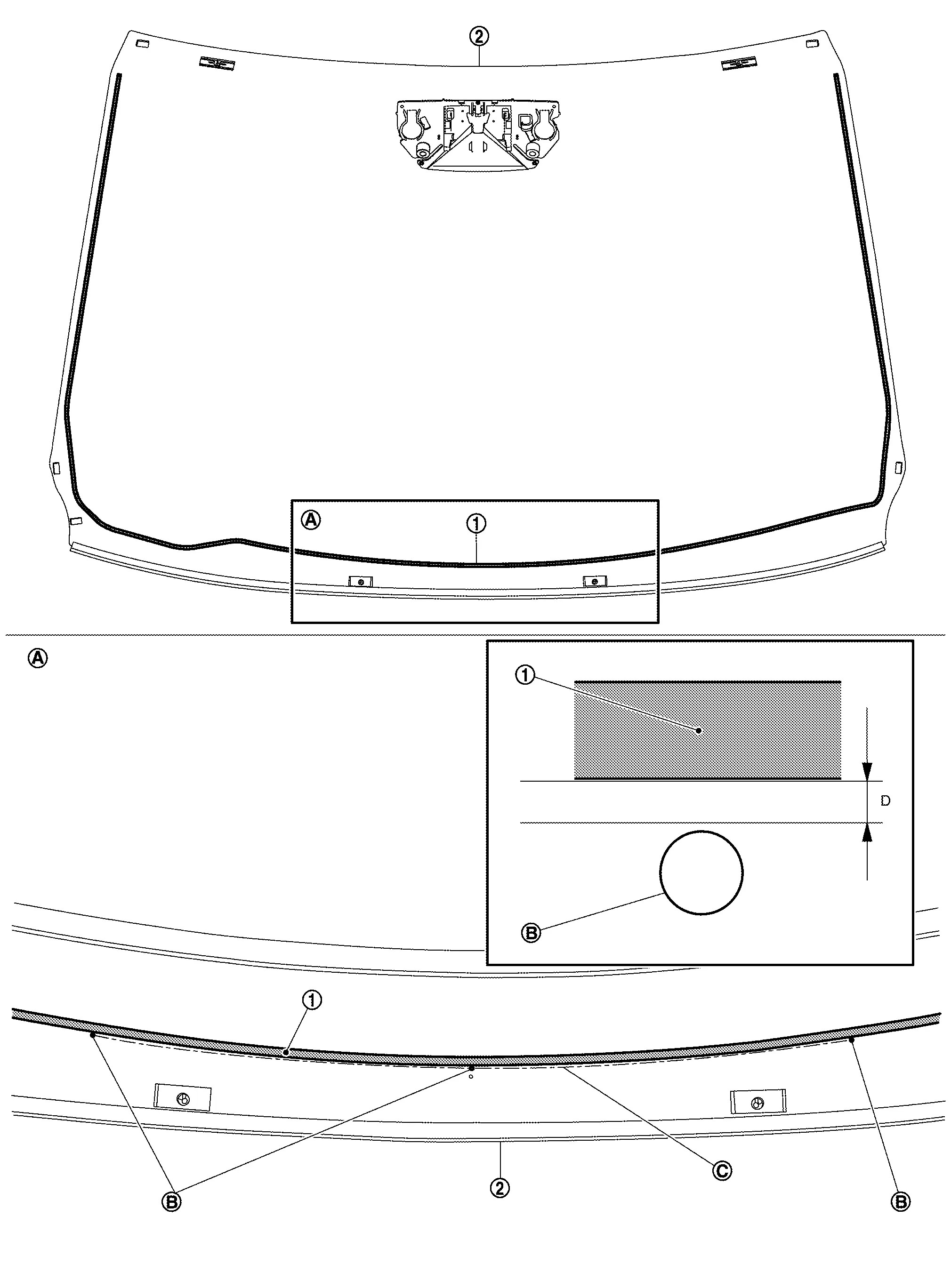

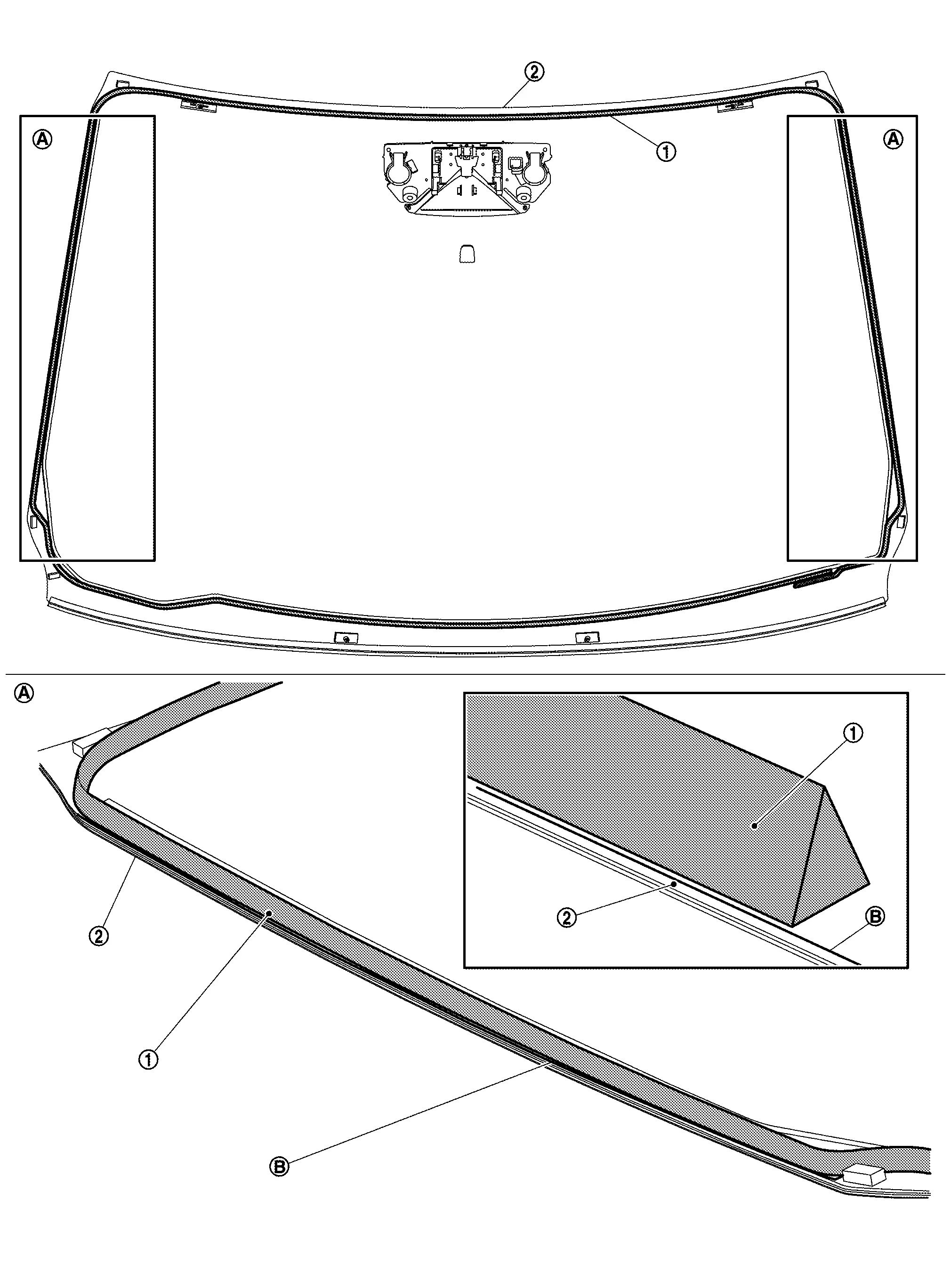

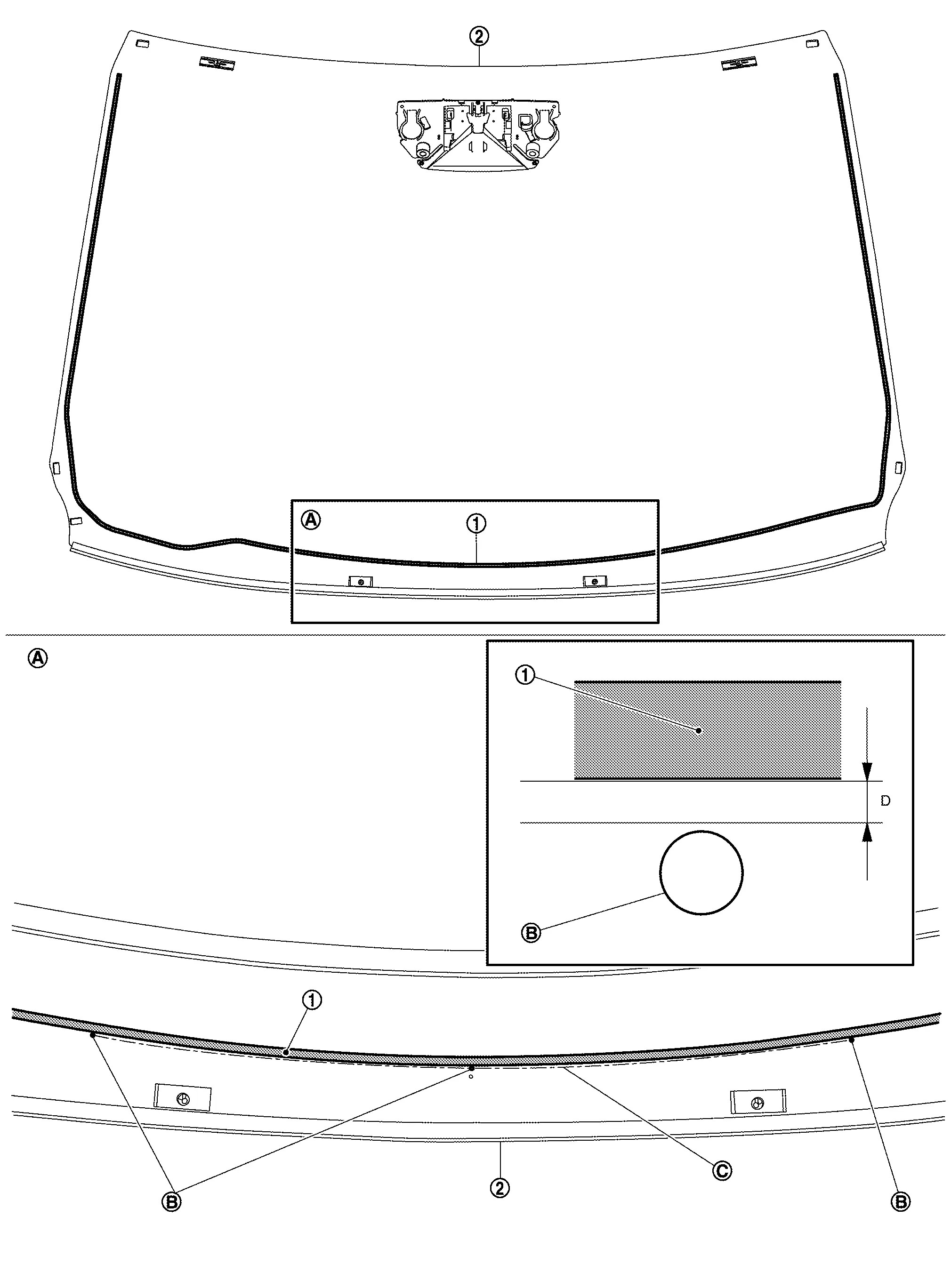

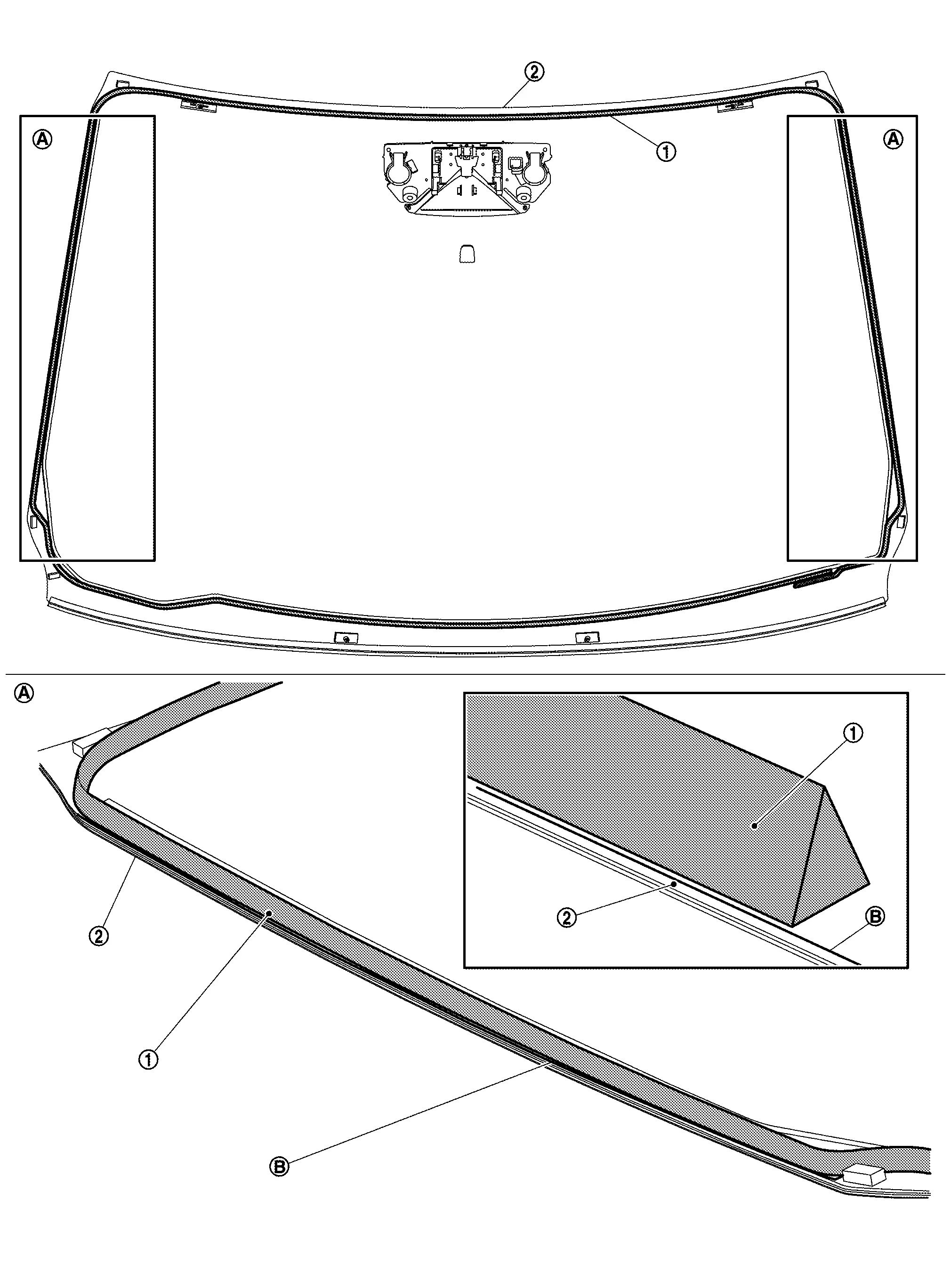

USA Production

|

Spacer (upper) |  |

Dam sealant rubber |  |

Spacer (lower) |

|

Windshield glass |  |

Windshield glass molding |  |

Clip (lower) |

|

Clip (upper) |  |

Headlining assembly |  |

Adhesive |

|

Glass primer |  |

Roof panel |  |

Cowl top cover |

|

Dash upper |  |

body side outer panel | ||

|

: Front camera unit and cover bracket (with front camera unit) | ||||

|

: inside mirror base | ||||

|

: Always replace after every disassembly. | ||||

| Portion | Primer range | Adhesive range | |||

|---|---|---|---|---|---|

| J | K | ||||

| Windshield glass – Roof panel |  – – |

F |

21.7 (0.854) |

7.0 (0.276) |

12.0 (0.47) |

| Windshield glass – Dash upper |  – – |

G |

13.0 (0.512) |

||

| Windshield glass – Body side outer panel |  – – |

H |

12.0 (0.47) |

||

Removal and Installation

REMOVAL

Replacement Windshield Glass

CAUTION:

Never damage body panel.

Remove headlining assembly. Refer to Removal and Installation.

Remove inside mirror. Refer to Removal and Installation.

Remove front camera unit. Refer to Removal and Installation (with front camera unit).

Remove cowl top cover. Refer to Removal and Installation.

Remove pillar finisher. Refer to Removal and Installation.

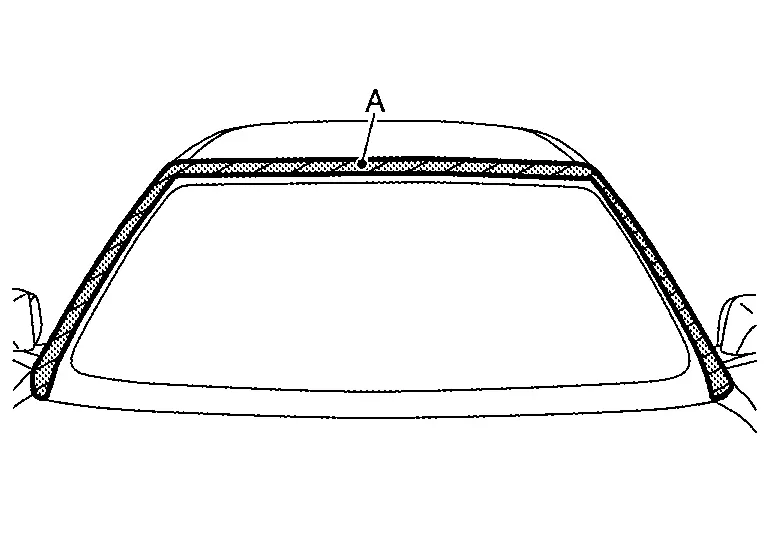

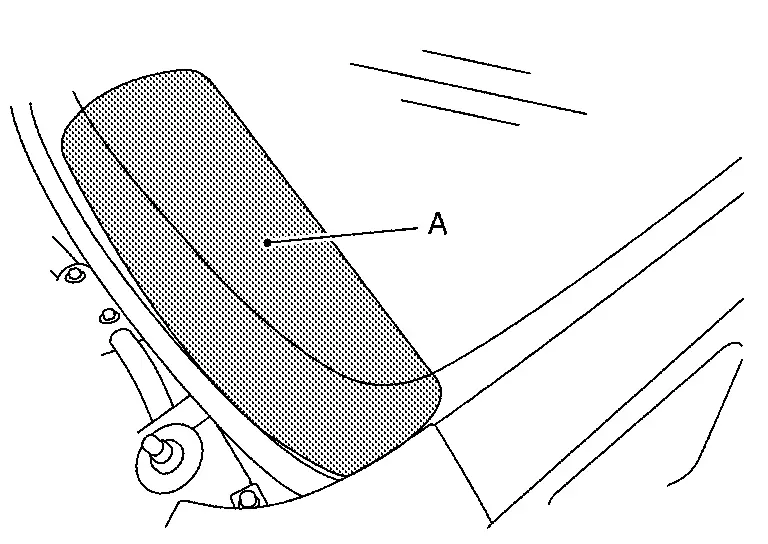

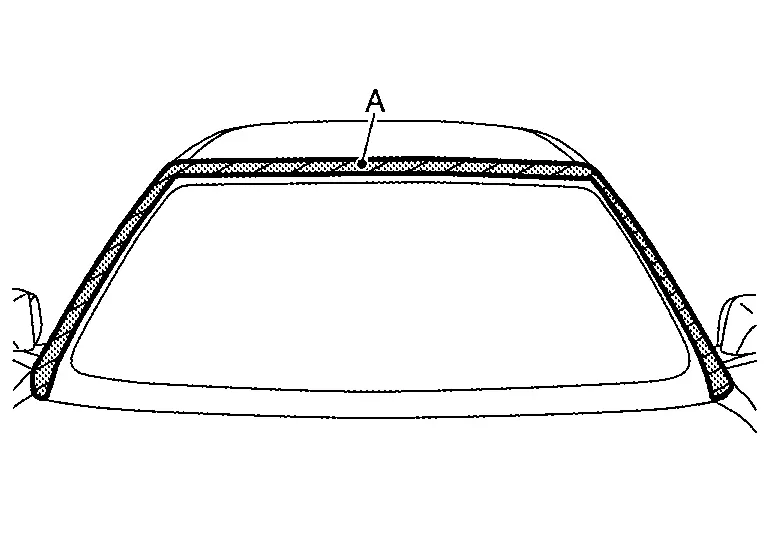

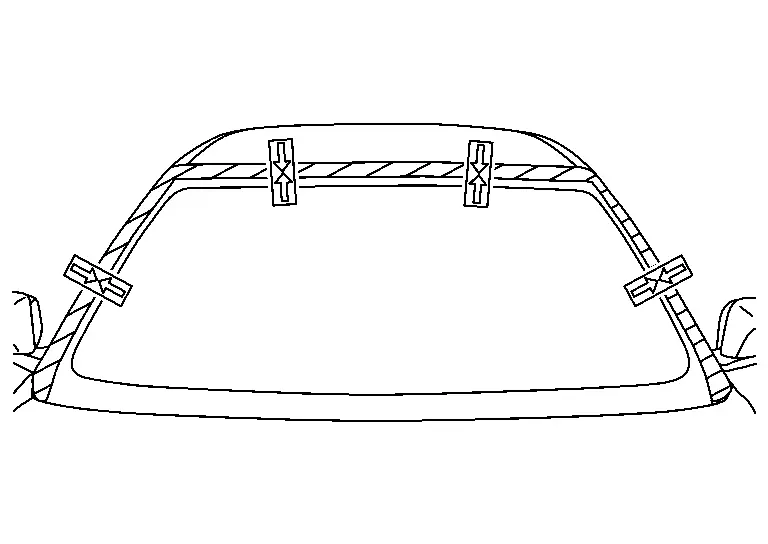

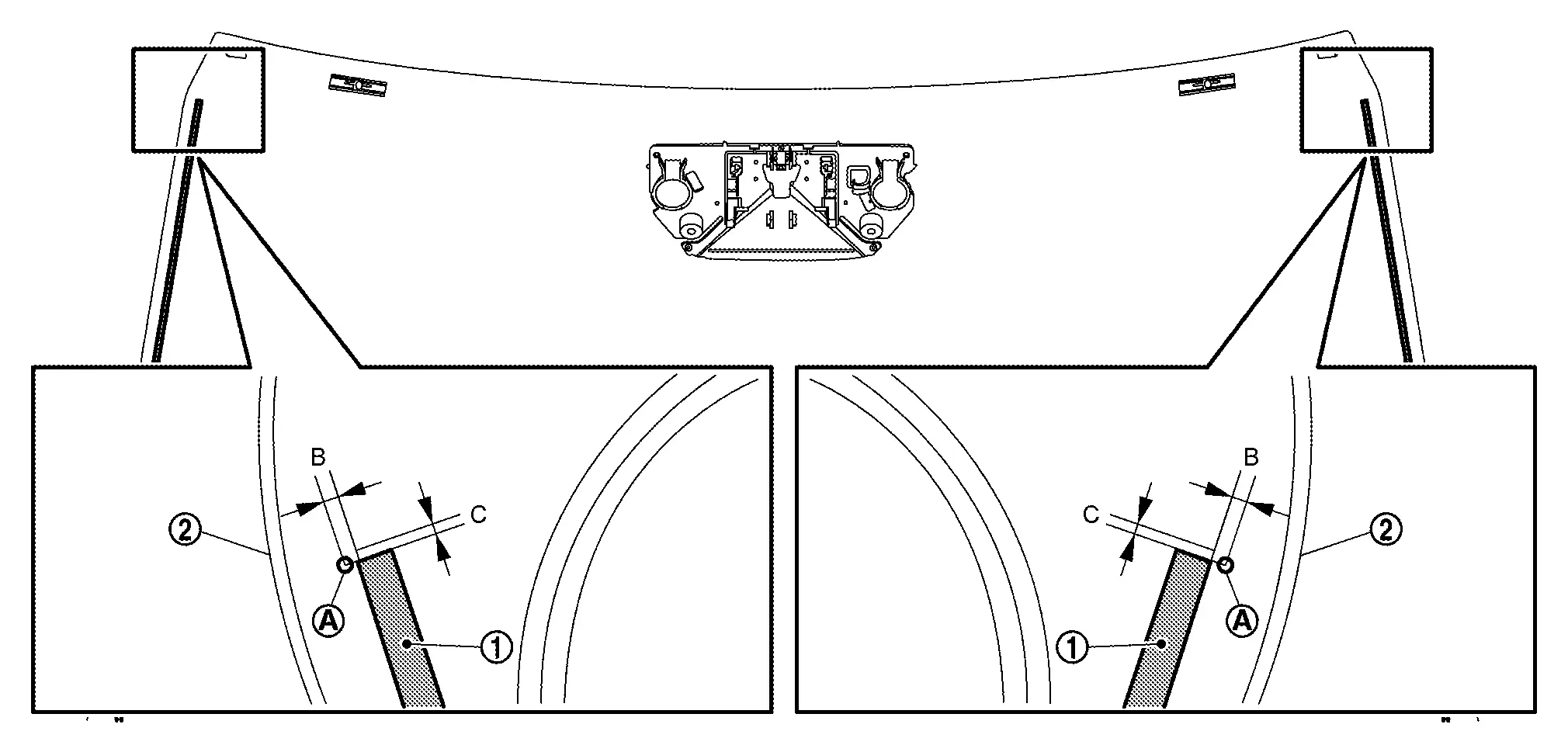

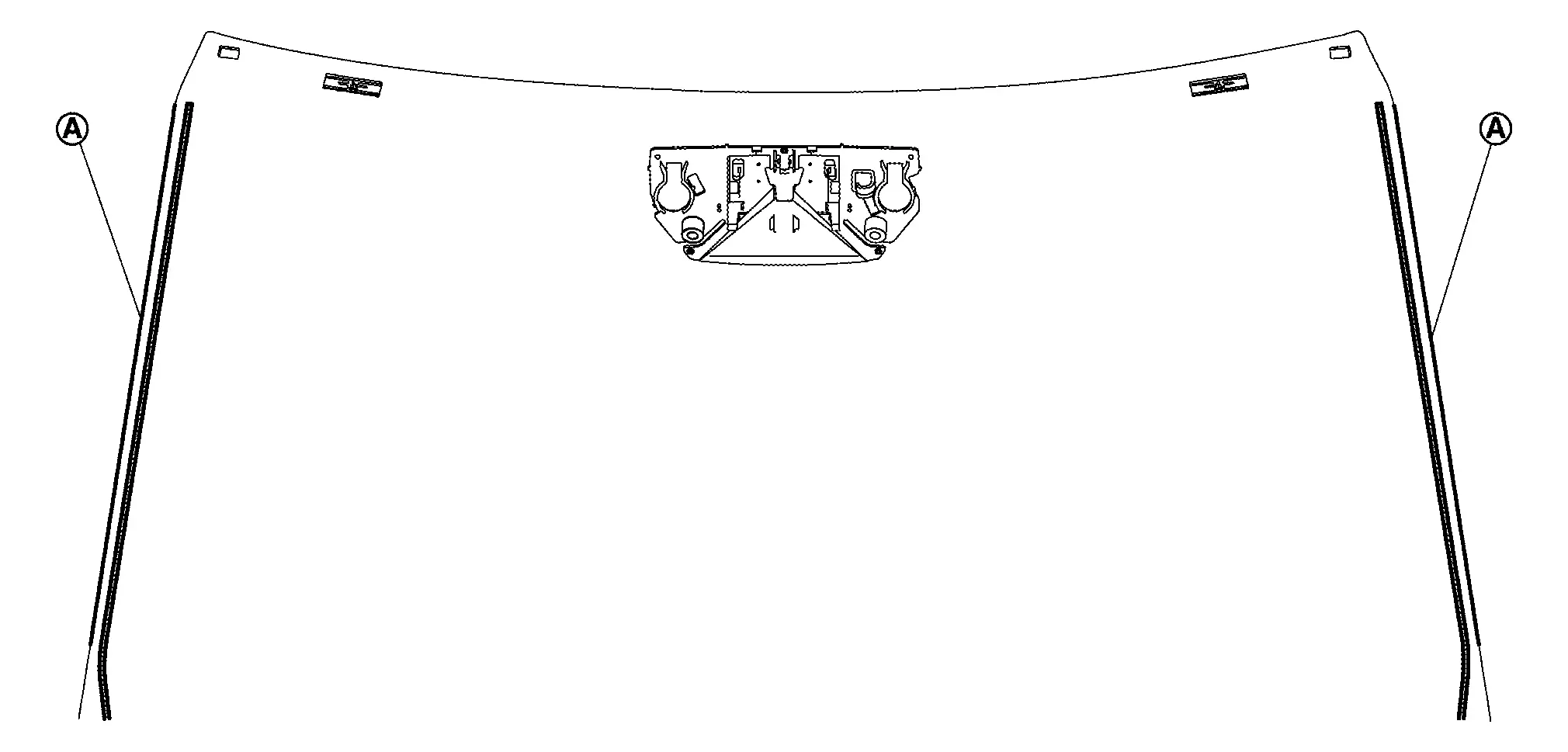

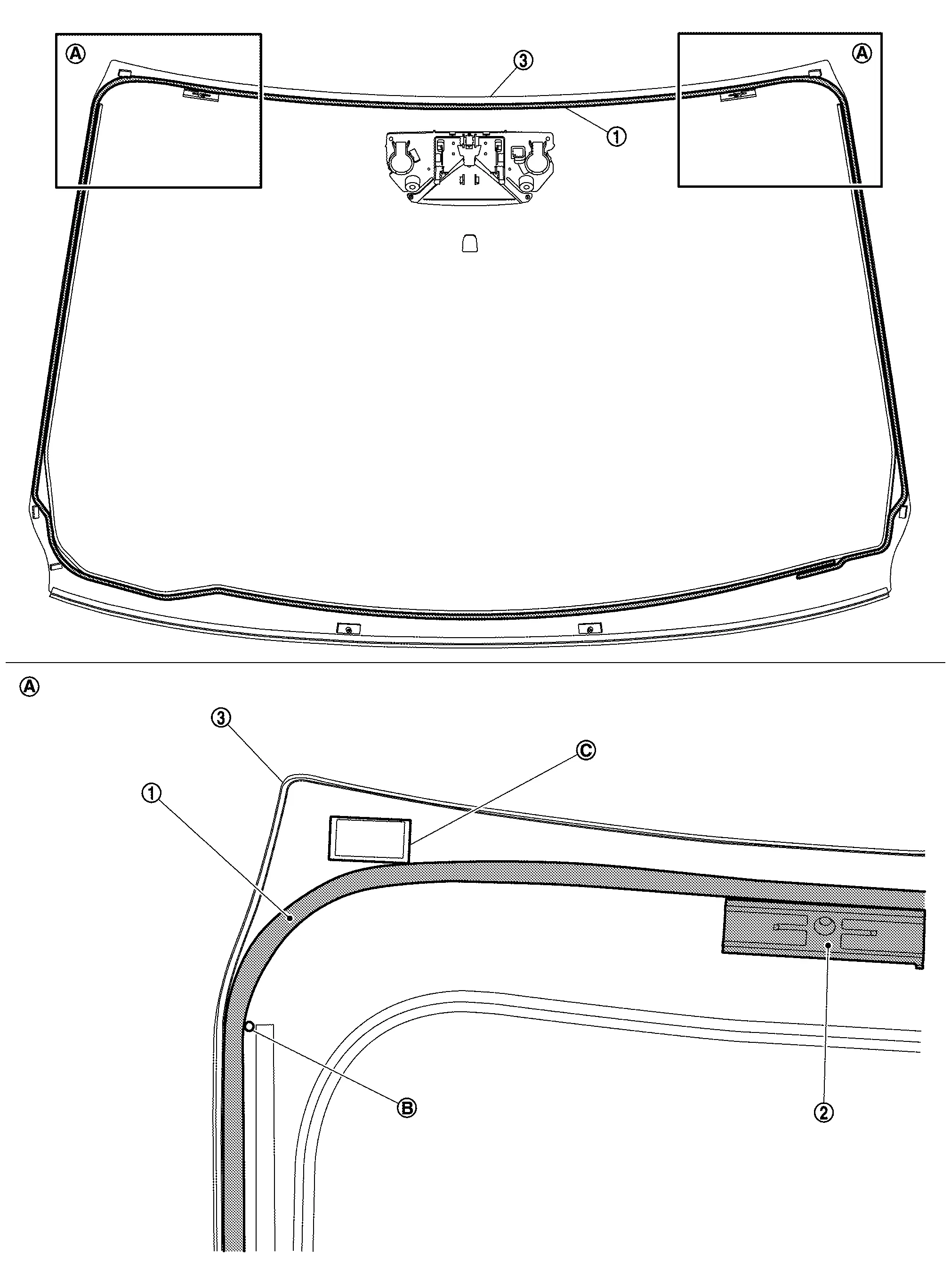

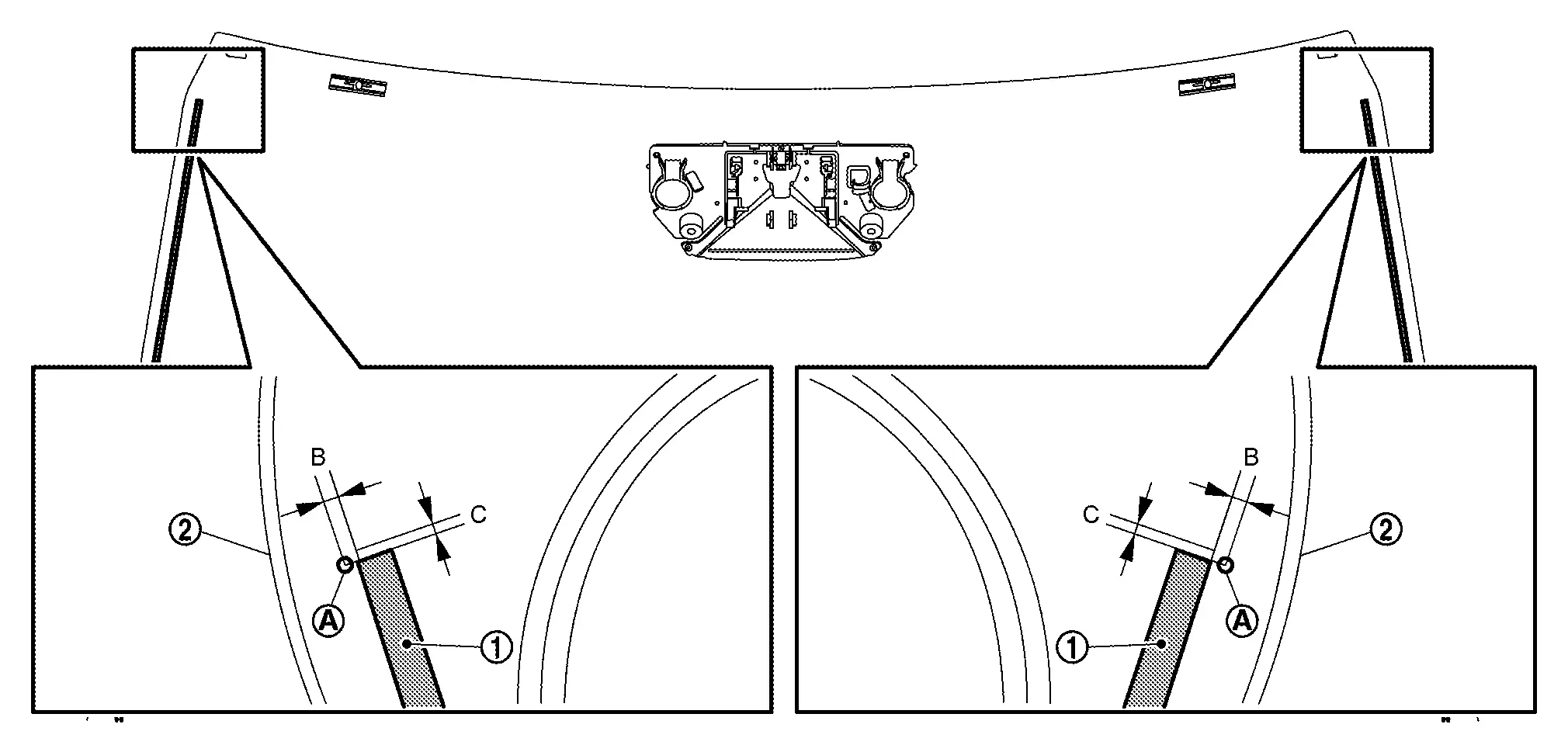

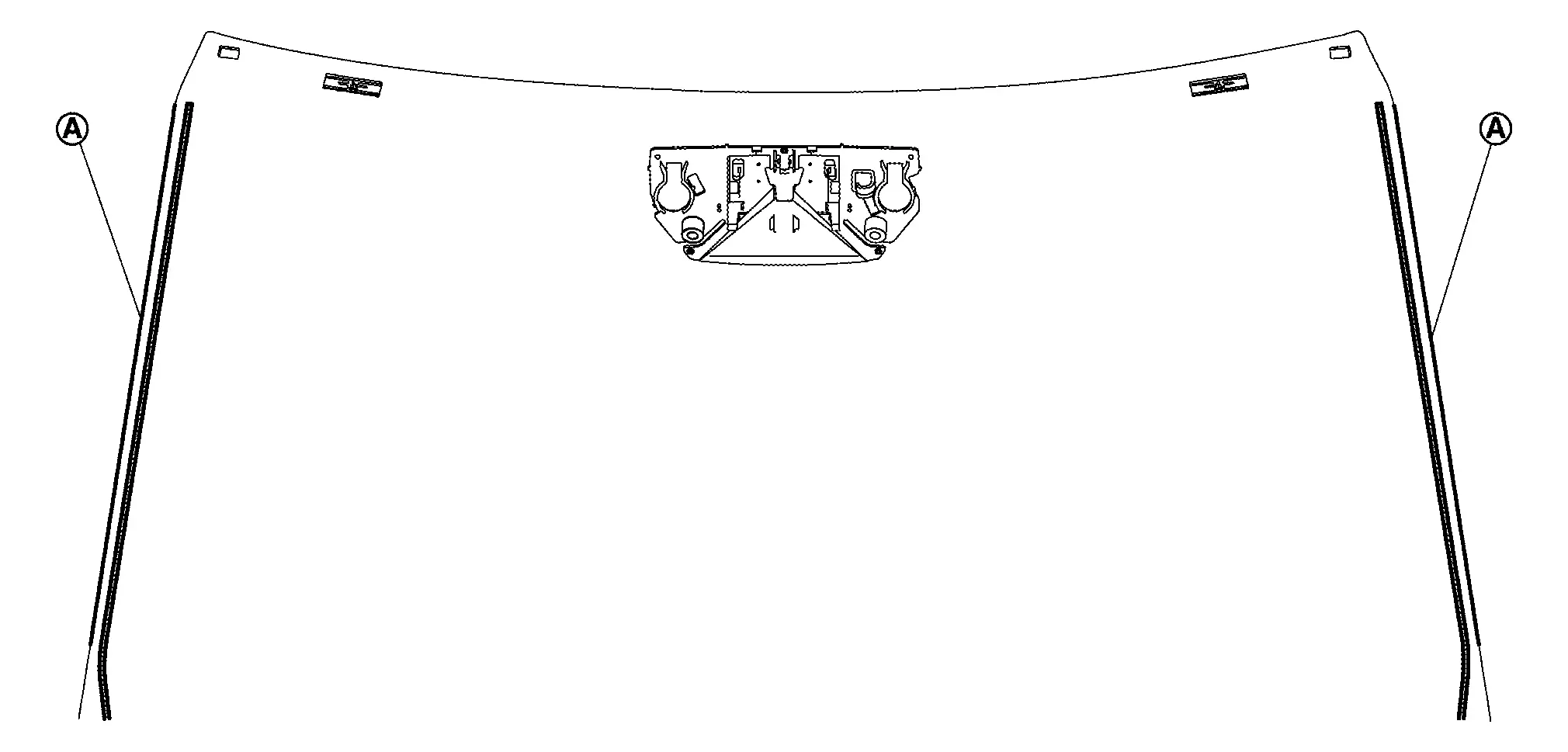

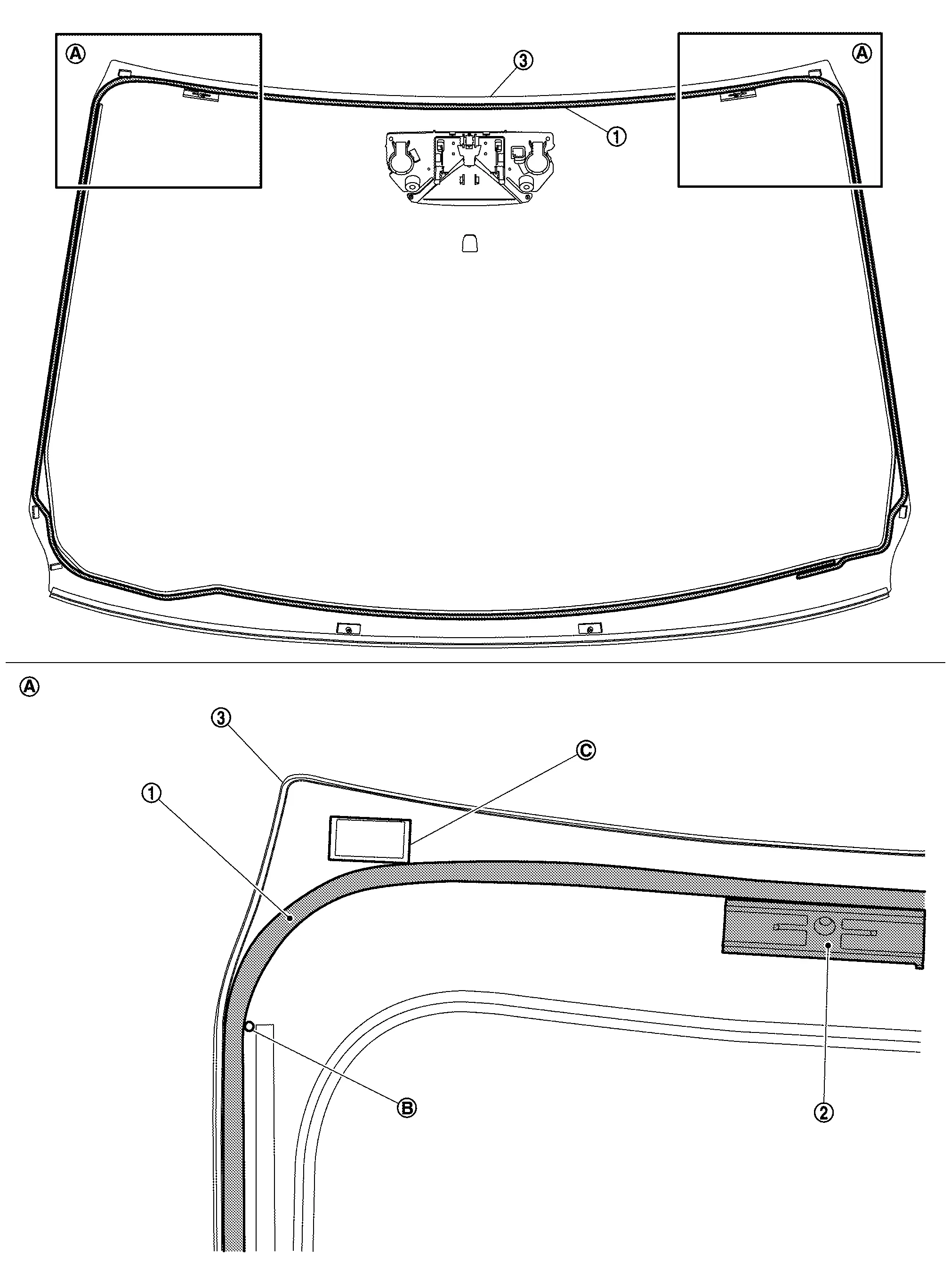

Apply protective tape (A) on roof panel and body side outer panel around windshield glass to protect painted surface from damage.

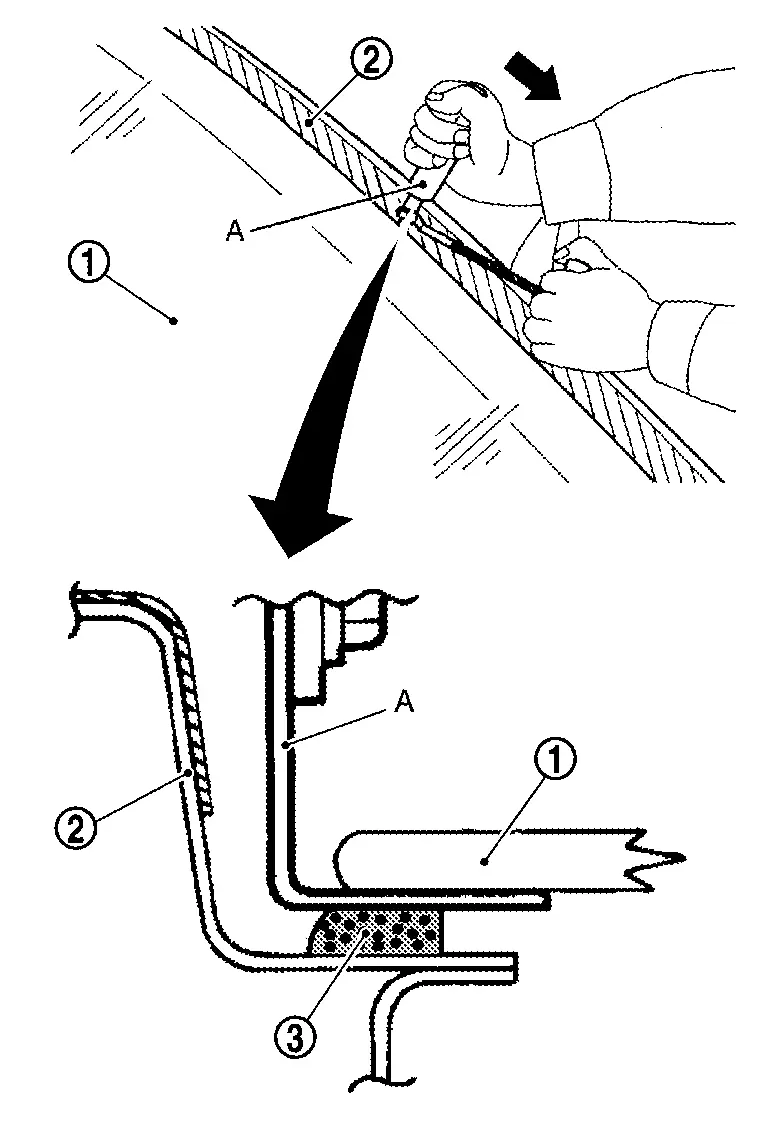

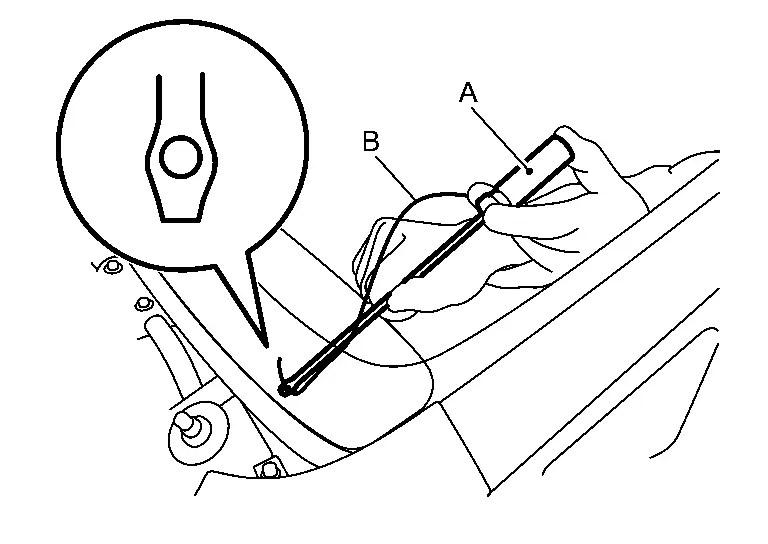

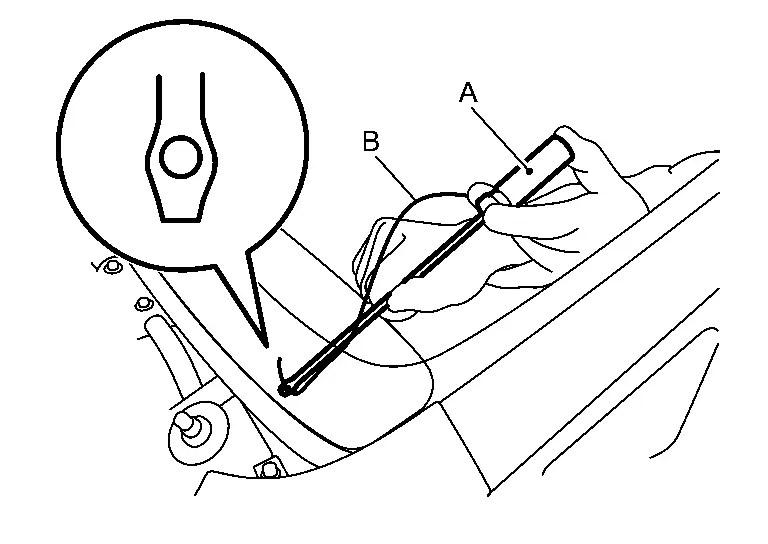

Insert a windshield cutter (A) between windshield glass  and body panel

and body panel  . Cut the adhesive

. Cut the adhesive  by pulling the windshield cutter, keeping the tip parallel to the edge of windshield glass.

by pulling the windshield cutter, keeping the tip parallel to the edge of windshield glass.

CAUTION:

Use piano wire to cut sealant if its difficult to use windshield cutter.

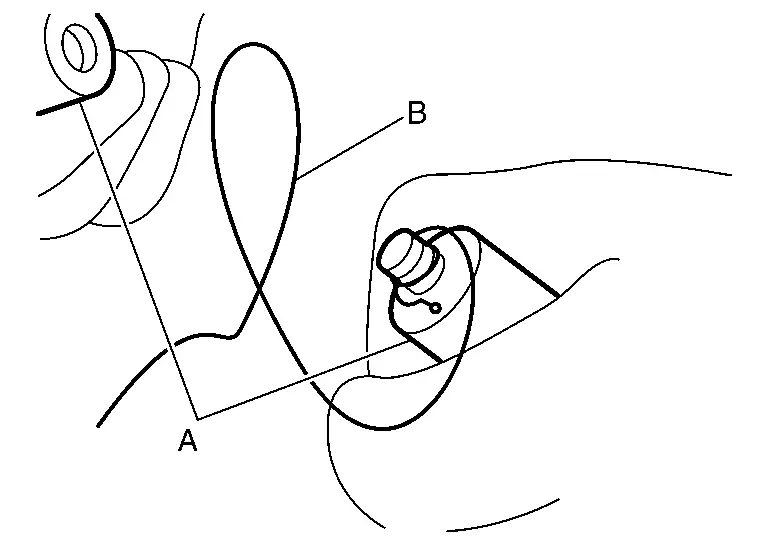

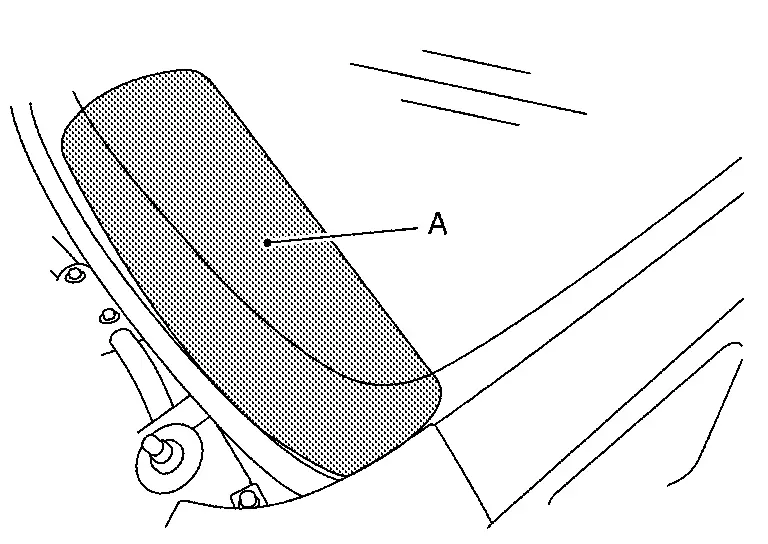

Apply protective standish cover (A) on instrument panel to protect it from damage.

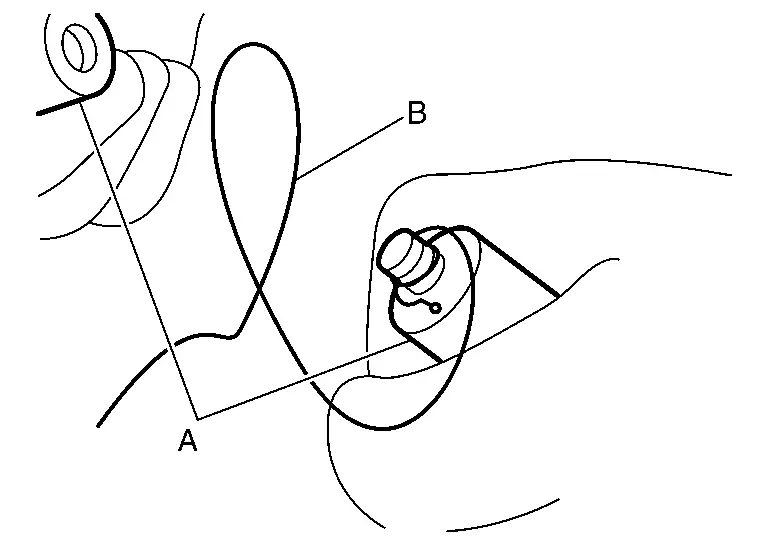

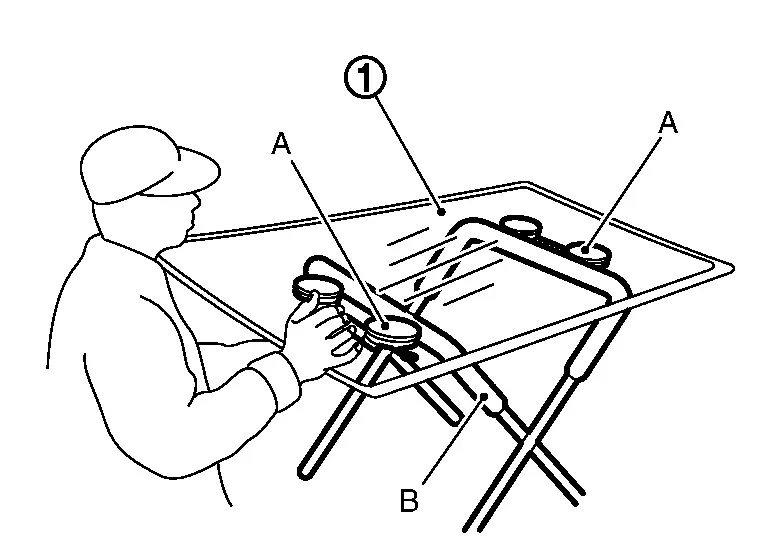

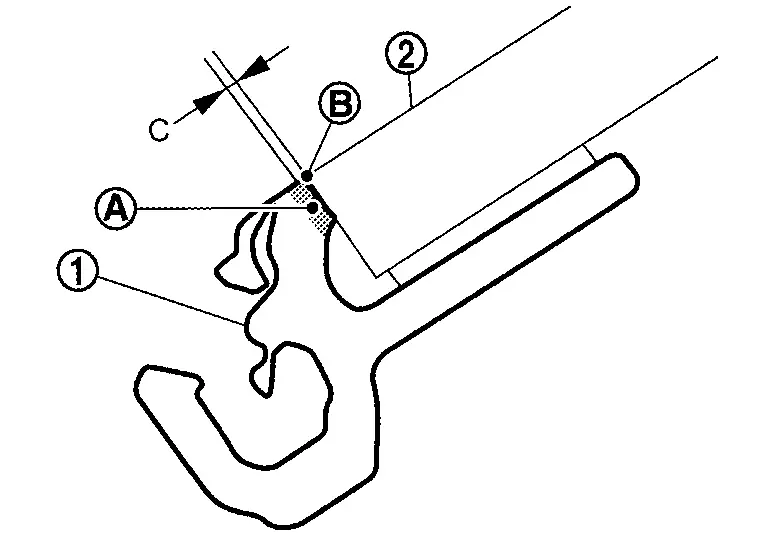

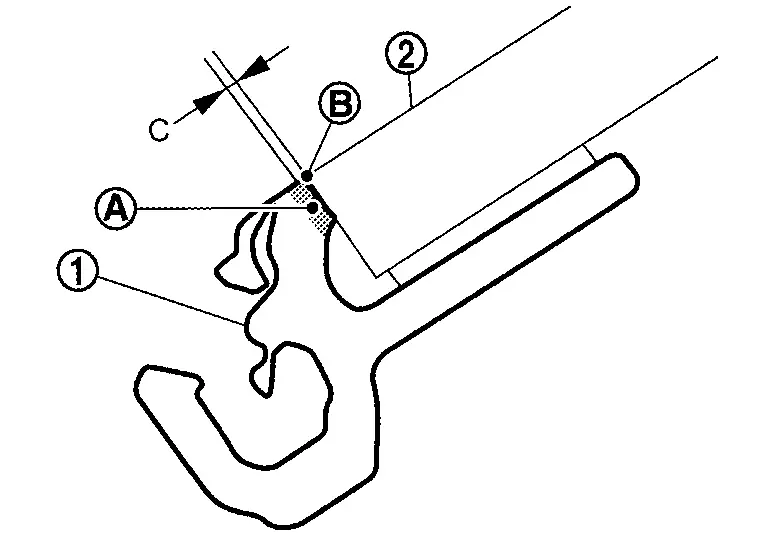

Cut the adhesive using a piano wire.Pass the piano wire (B) from passenger room to bonded area of glass using a wire pierce (A).

CAUTION:

-

Never use plane surface of wire pierce tip vertically.

-

Never press piano wire excessively against edge of glass.

-

Never damage surrounding parts.

CAUTION:

-

Never press piano wire excessively against edge of glass.

-

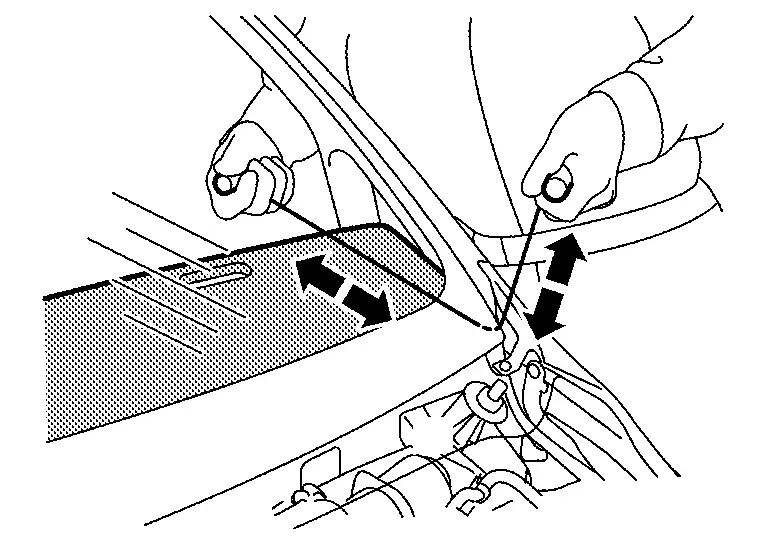

To cut adhesive, 2 workers are required by all means.

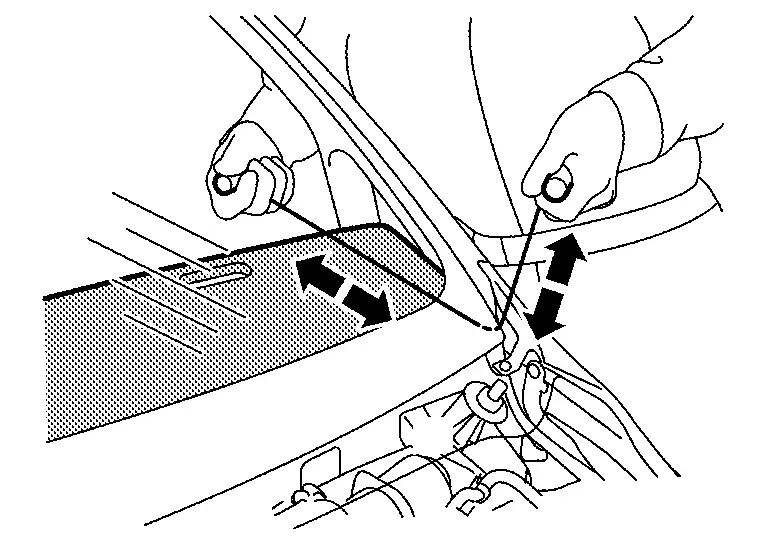

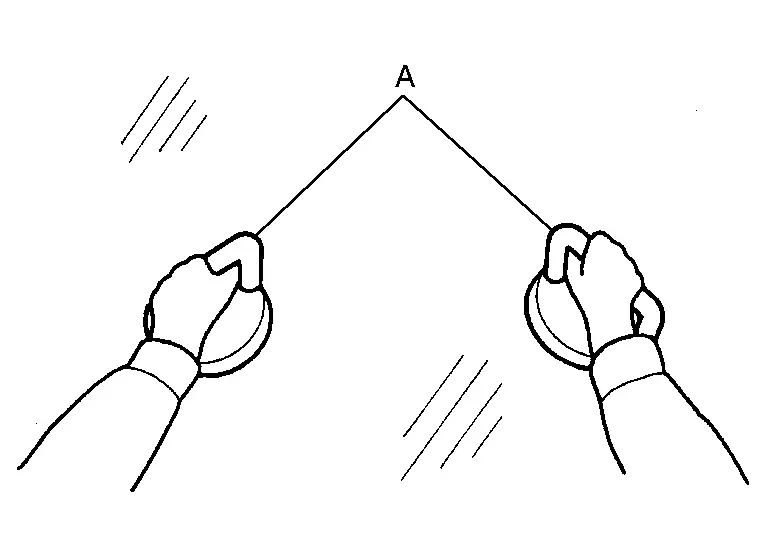

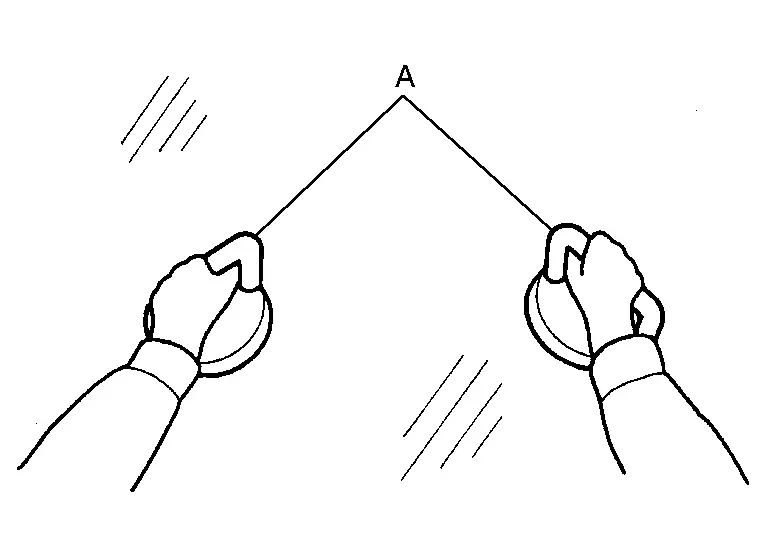

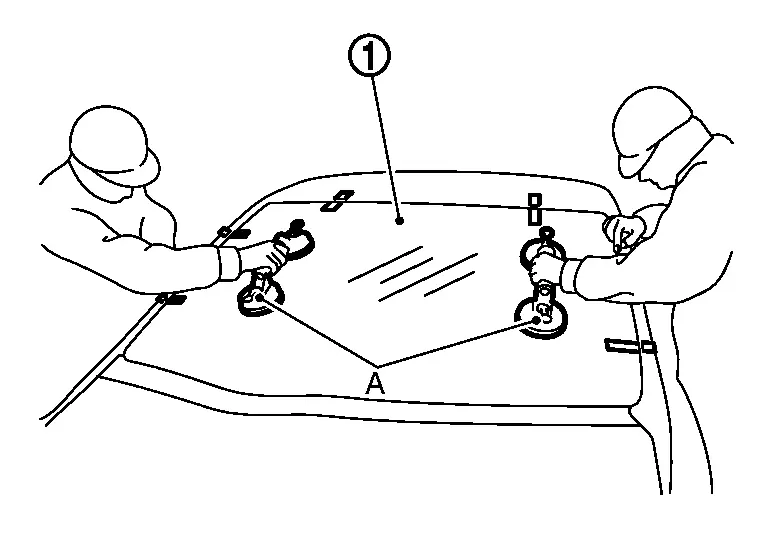

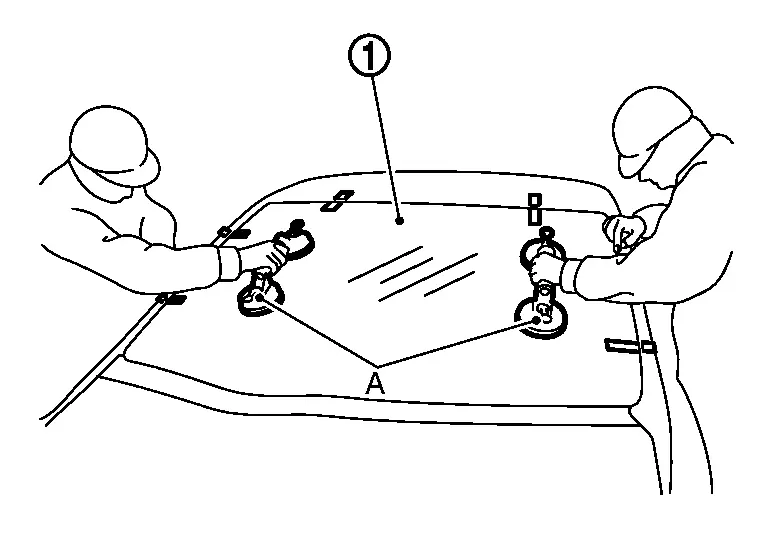

Use rubber suction cups or suction lifter (A), etc. to remove windshield glass from the Nissan Ariya vehicle.

CAUTION:

Due to weight of windshield glass, 2 workers are required by all means.

Reuse Windshield Glass

CAUTION:

-

Never use a windshield cutter if the windshield glass is reused. (It may scratch the glass surface)

-

Never damage windshield glass and body panel.

Remove headlining assembly. Refer to Removal and Installation.

Remove inside mirror. Refer to Removal and Installation.

Remove front camera unit. Refer to Removal and Installation (with front camera unit).

Remove cowl top cover. Refer to Removal and Installation.

Remove pillar finisher. Refer to Removal and Installation.

Apply protective tape (A) on roof panel and body side outer panel around windshield glass to protect painted surface from damage.

Apply matching marks to windshield glass, roof panel and both side of body side outer panel.

CAUTION:

To prevent the gap when install windshield glass put on matching marks by all means.

Apply protective standish cover (A) on instrument panel to protect it from damage.

Cut the adhesive using a piano wire.Pass the piano wire (B) from passenger room to bonded area of glass using a wire pierce (A).

CAUTION:

-

Never use plane surface of wire pierce tip vertically.

-

Never press piano wire excessively against edge of glass.

-

Never damage surrounding parts.

CAUTION:

-

Never press piano wire excessively against edge of glass.

-

To cut adhesive, 2 workers are required by all means.

Use rubber suction cups or suction lifter (A), etc. to remove windshield glass from the Nissan Ariya vehicle.

CAUTION:

Due to weight of windshield glass, 2 workers are required by all means.

INSTALLATION

CAUTION:

Before installing, check the painted surface is not have scratched.

If it has scratched, touch up the same color by touch up pen etc.

Replacement Windshield Glass

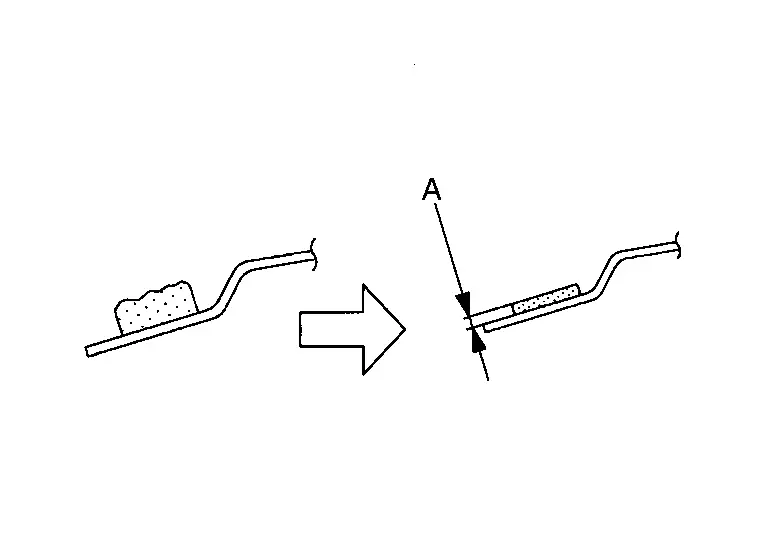

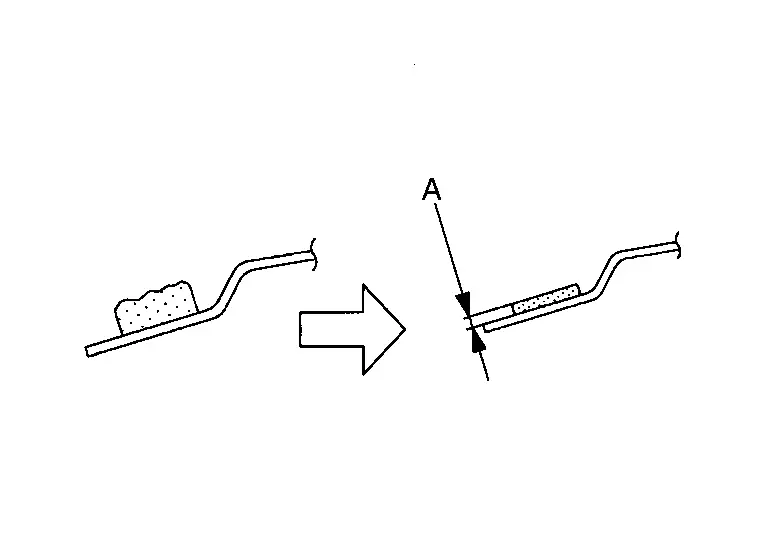

Use a cutter knife or scraper, and leave the of adhesive and sealant on the body side approximately 2 mm (0.079 in) (A) to make adhesive and sealant surface smooth.

CAUTION:

-

If the bonded area on the body is scratched, repair it using a 2 liquid type urethane paint. Never use lacquer type paint.

-

Smooth out adhesive and sealant surface.

Place new windshield glass on the Nissan Ariya vehicle temporarily, put on matching marks on windshield glass, roof panel and both side of body side outer panel.

CAUTION:

To prevent the gap when install new windshield glass put on matching marks by all means.

Use suction lifter (A) to set windshield glass  on glass stand (B).

on glass stand (B).

Clean the bonded area on windshield glass and body panel side using a white gasoline or degreasing agent.

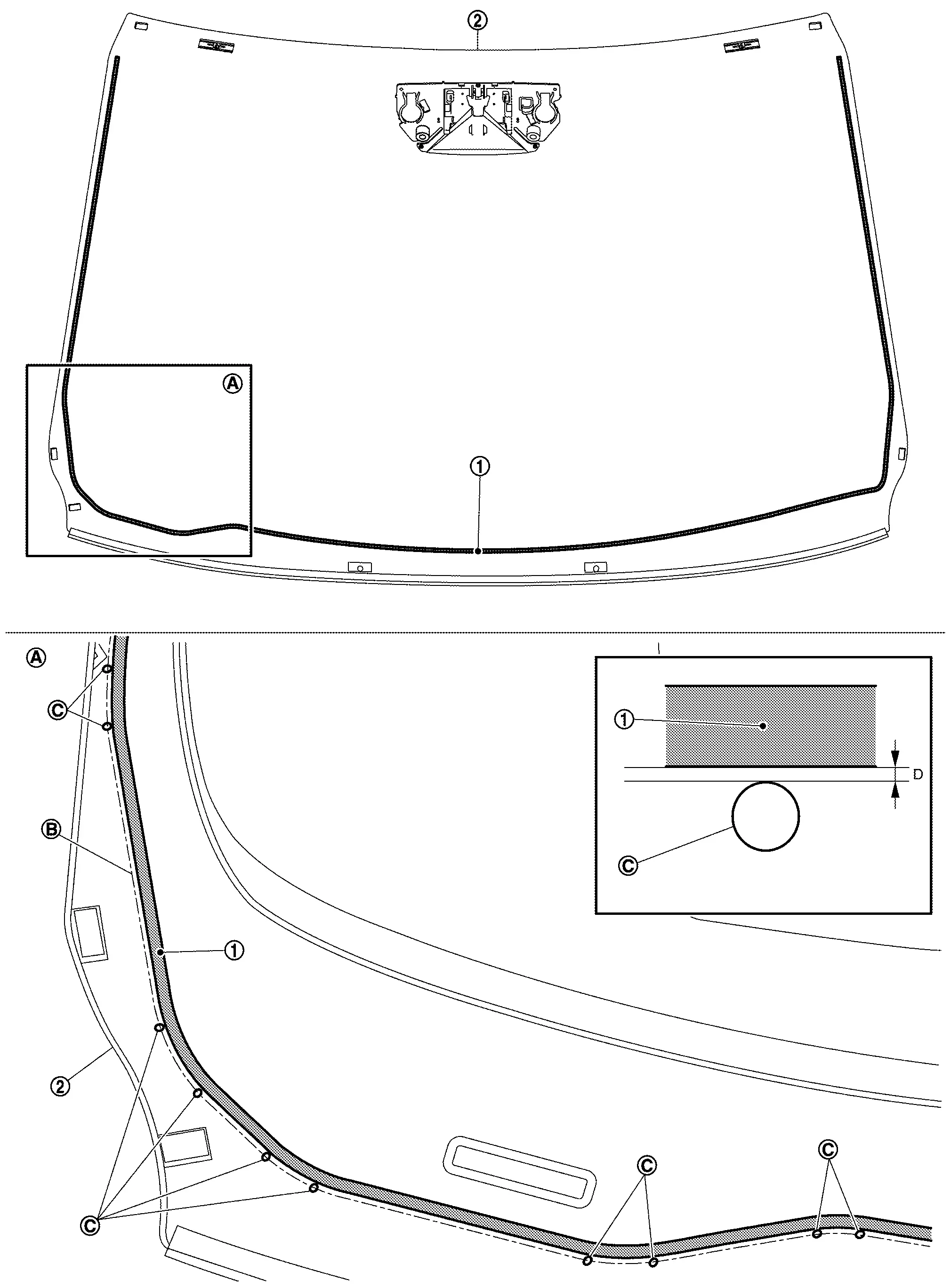

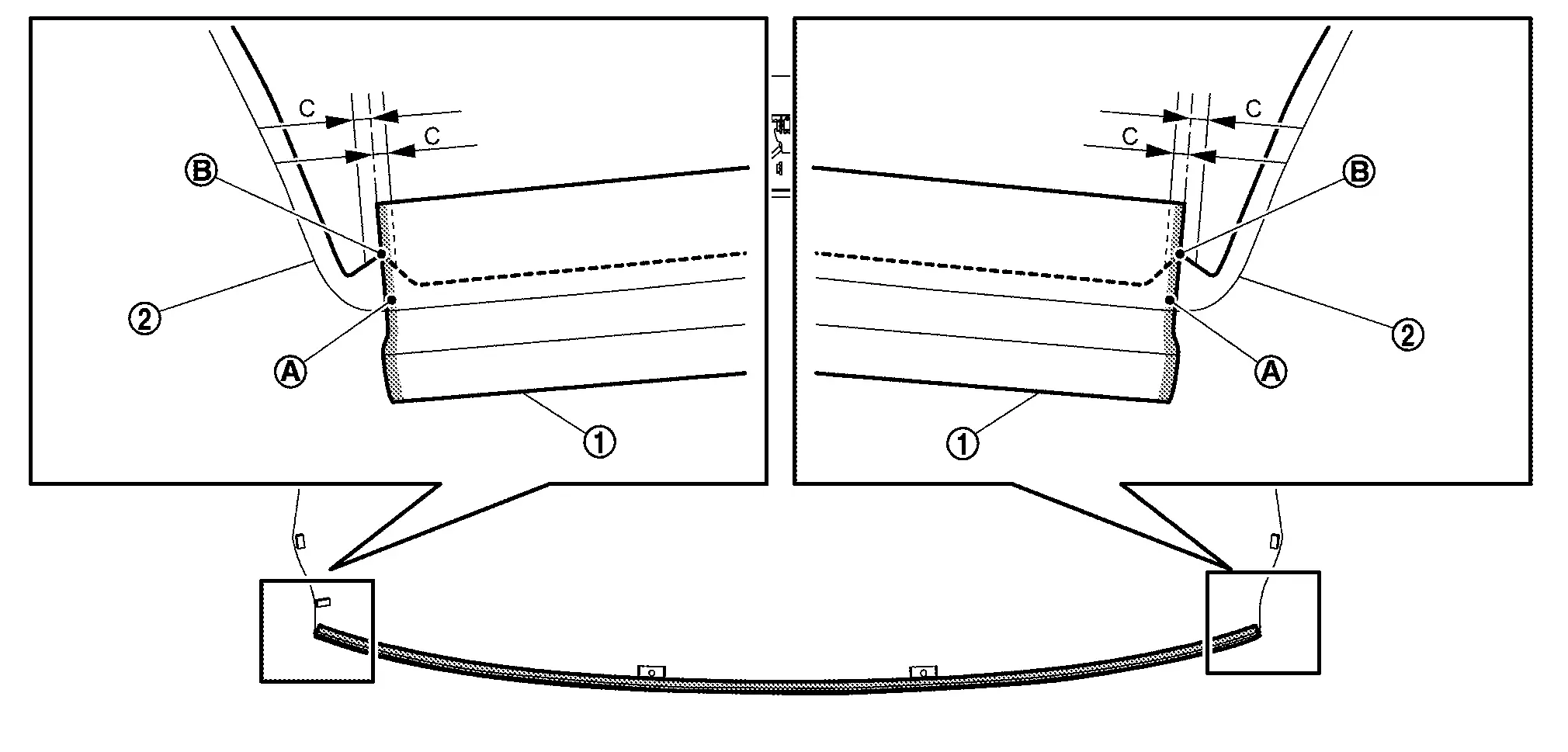

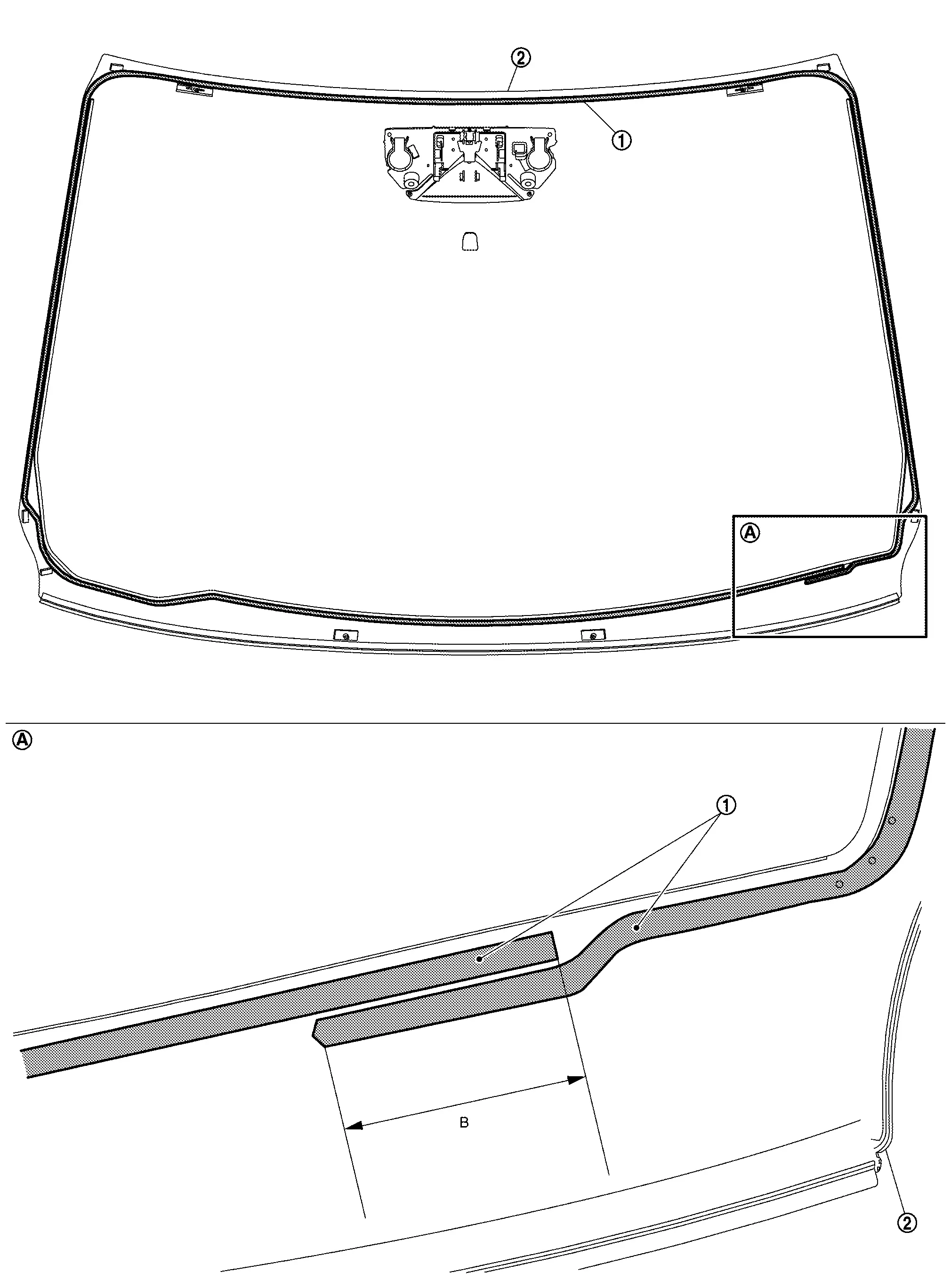

Install windshield glass molding.Temporarily install new windshield

glass molding on windshield glass to check for apply glass primer

position. Clean windshield glass to applying position of glass primer by

using white gasoline or degreasing agent. Apply glass primer on

windshield glass of windshield glass instal position. Remove release

liner of double sided tape for installing windshield glass molding.

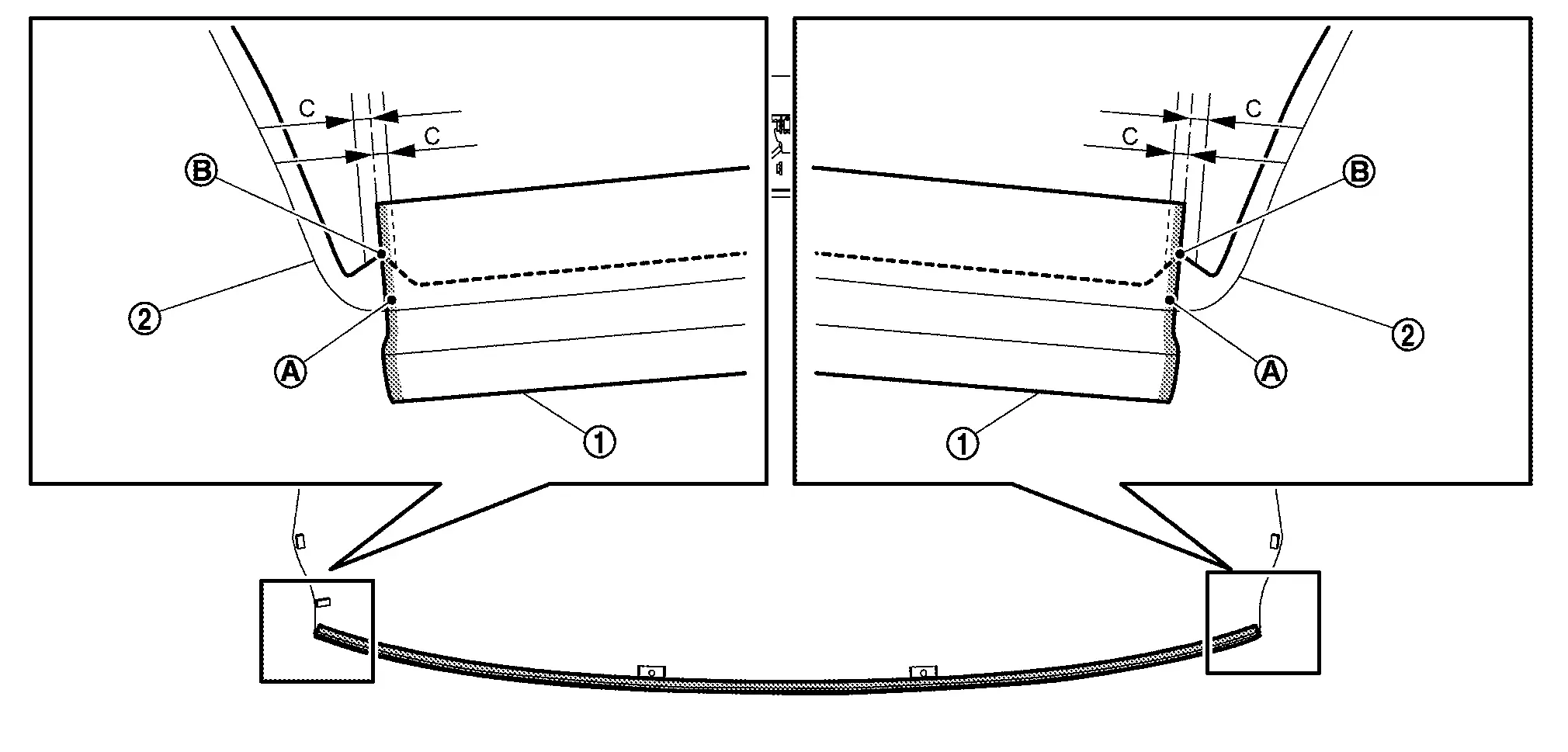

Install windshield glass molding  on windshield glass

on windshield glass  as shown in figure.

as shown in figure.

|

: The ends of windshield glass molding |

|

: Black print matching mark |

| C | : 2.5 mm (0.098 in) |

CAUTION:

When installing, the lip  of windshield glass molding

of windshield glass molding  is touch on the edge

is touch on the edge  of windshield glass

of windshield glass  as shown in figure. (Never press lip to edge.)

as shown in figure. (Never press lip to edge.)

| C | : 0 – 0.75 mm (0 – 0.0295 in) |

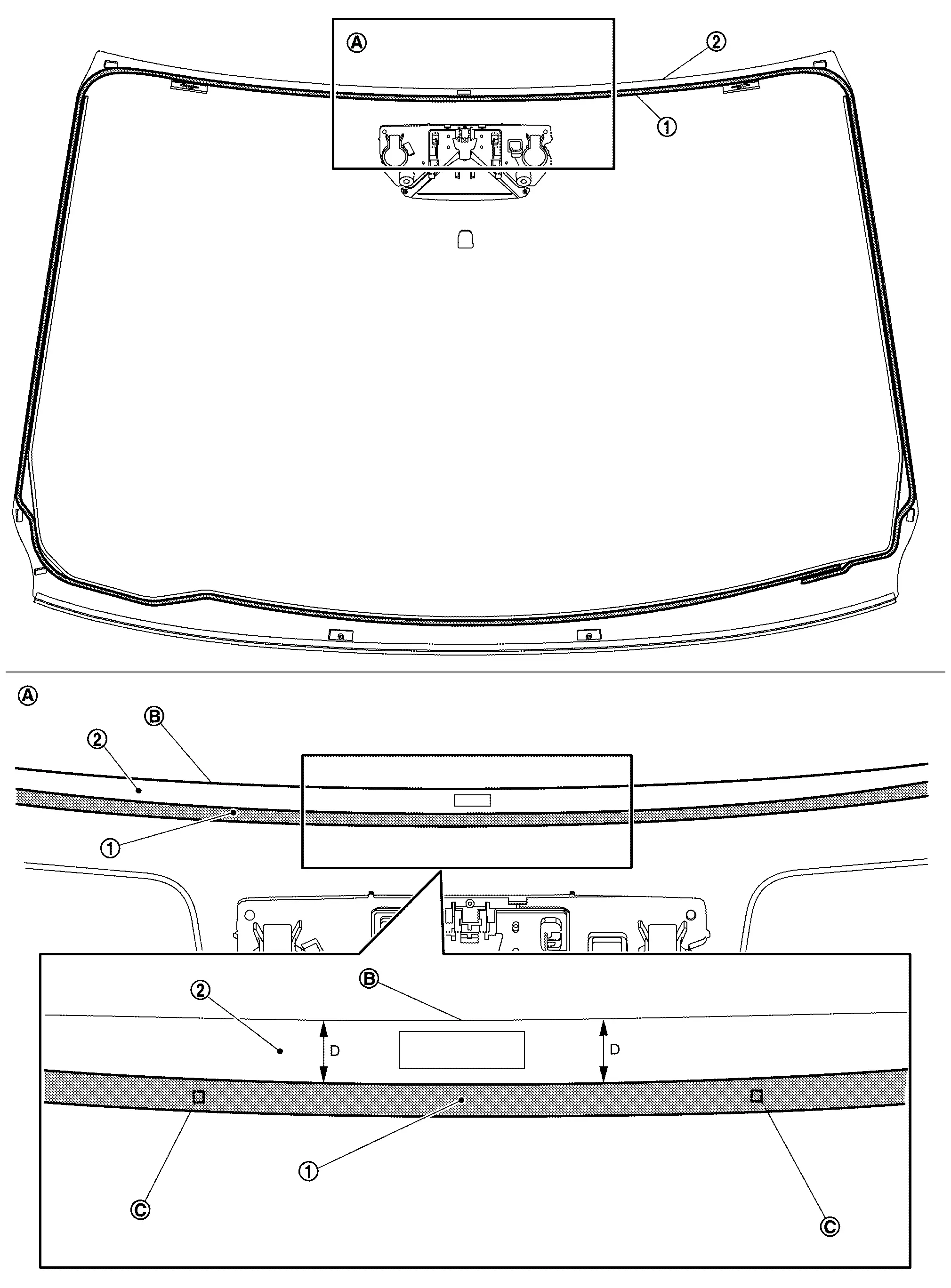

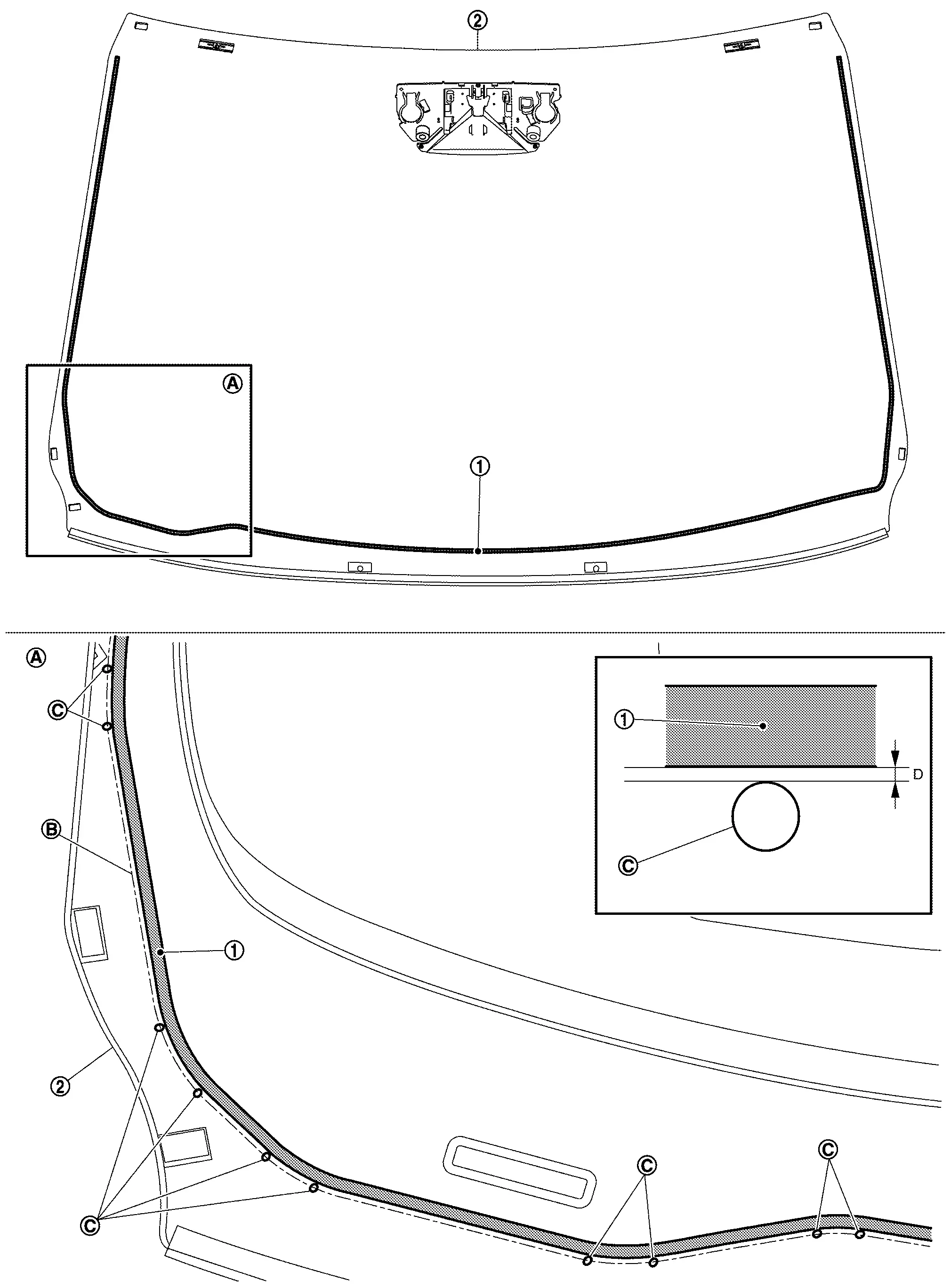

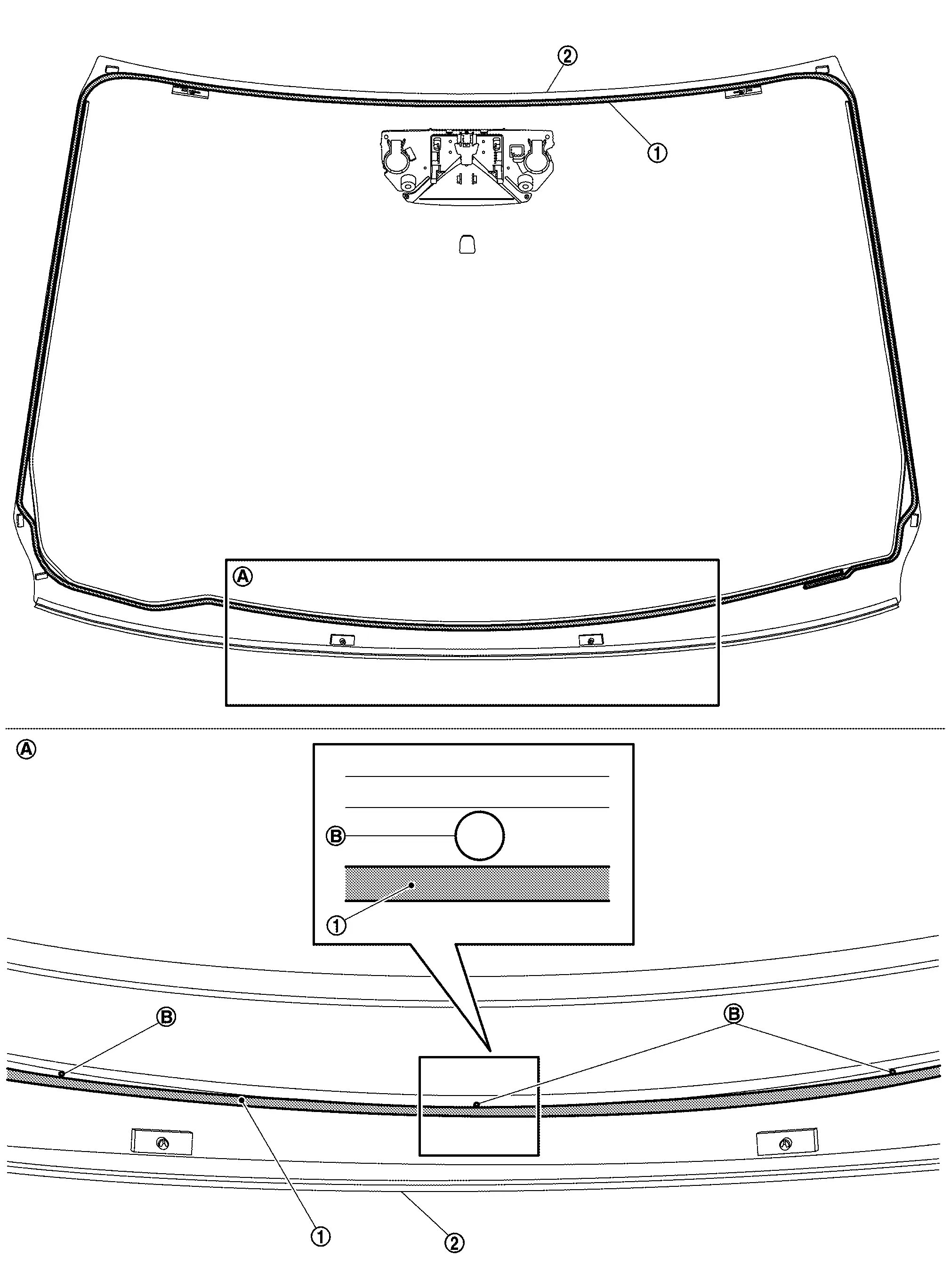

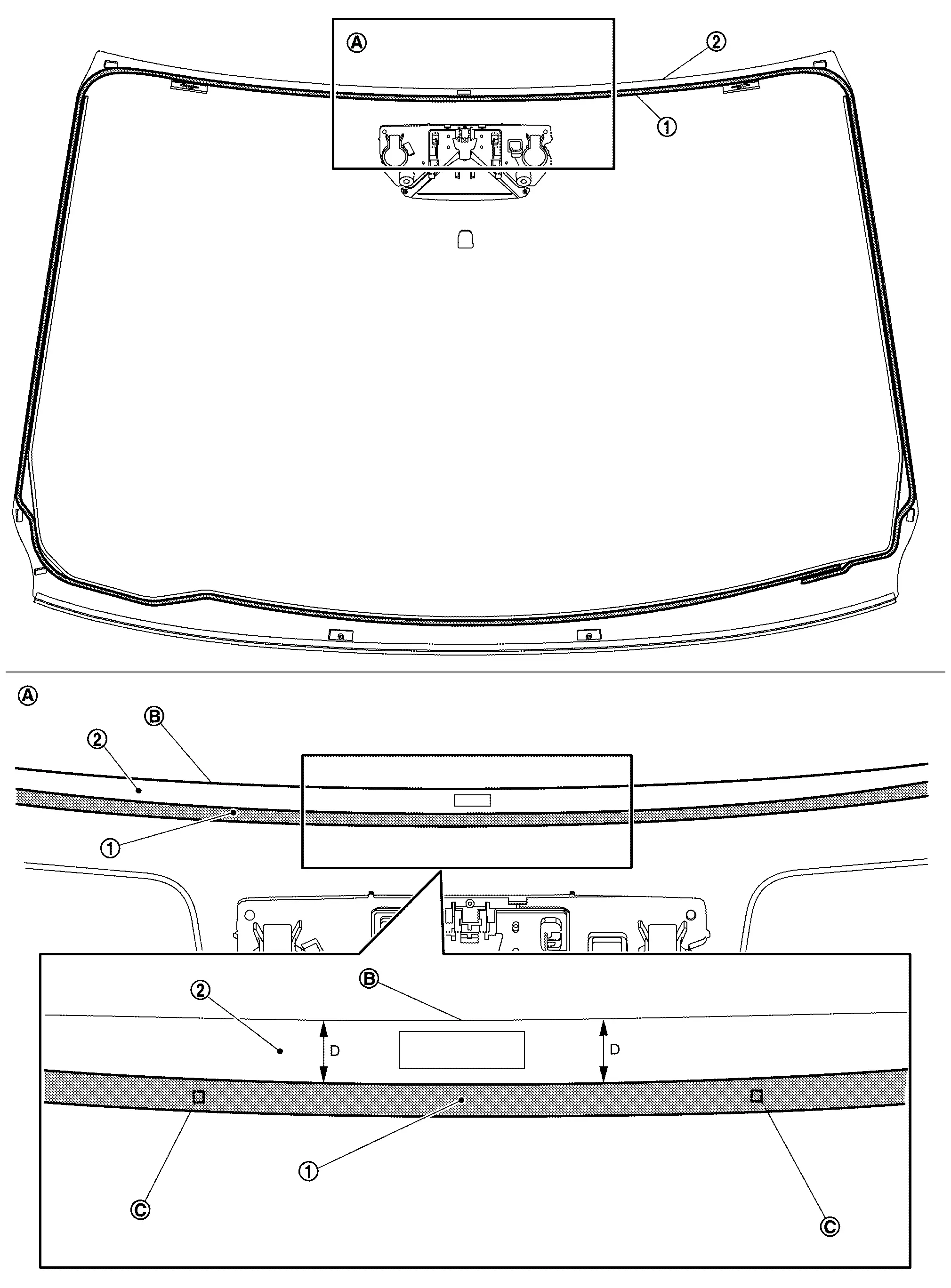

Install dam sealant rubber.Clean windshield glass to applying position for dam sealant rubber by using white gasoline or degreasing agent. Remove release liner of double sided tape for installing dam sealant rubber. Install dam sealant rubber on windshield glass.

CAUTION:

-

The stop/start position is as shown in figure.

: Dam sealant rubber

: Windshield glass

: Black print matching mark B : 1.0 mm (0.039 in) C : 0 mm – 5.0 mm (0 – 0.20 in) -

The left/right side are along with edge

of windshield glass edge as shown in figure.

of windshield glass edge as shown in figure.

-

The lower left

to installing dam sealant rubber are as shown in figure.

to installing dam sealant rubber are as shown in figure.

: Dam sealant rubber

: Windshield glass

: Connected line of black print matching marks

: Black print matching mark D : 1.0 mm (0.039 in) -

The lower right position

as shown in figure.

as shown in figure.

: Dam sealant rubber

: Windshield glass

: Black print matching mark

: Connected line of black print matching marks D : 1.0 mm (0.039 in) -

The lower middle

is as shown in figure.

is as shown in figure.

: Dam sealant rubber

: Windshield glass

: Black print matching mark

: Connected line of black print matching marks D : 1.0 mm (0.039 in)

Apply glass primer along the entire circumference of windshield glass. The range of glass primer refer to Exploded View.

For NMK production only, apply painted surface primer to the body side bonding surface. The range of painted surface primer refer to Exploded View.

Apply adhesive to windshield glass by using a sealant gun. The volume of adhesive refer to Exploded View.

CAUTION:

-

The stop/start position to applying adhesive

are locate

are locate  on windshield glass

on windshield glass  as shown in figure.

as shown in figure. -

When finish to applying adhesive, its should be overlap from start position as shown in figure.

B : 68 mm (2.68 in) -

When applying adhesive

onto lower middle position

onto lower middle position  , never cover windshield glass

, never cover windshield glass  black print matching marks

black print matching marks  as shown in figure.

as shown in figure.

-

The lower left

to applying adhesive as shown in figure.

to applying adhesive as shown in figure.

: Adhesive

: Windshield glass

: Spacer (lower)

: Black print matching mark

: Fully cover

: Not cover  and touch spacer (lower)

and touch spacer (lower)

: Only half cover

-

The left/right side

to applying adhesive

to applying adhesive  along windshield glass

along windshield glass  black print edge

black print edge  as shown in figure.

as shown in figure.

-

The upper left/right

to applying adhesive are as shown in figure.

to applying adhesive are as shown in figure.

: Adhesive

: Clip (upper)

: Windshield glass

: Black print matching mark

: Black print matching mark [for spacer (upper)] -

The upper middle

to applying adhesive as shown in figure.

to applying adhesive as shown in figure.

: Adhesive

: Windshield glass

: The edge bend of windshield glass

: Black print matching mark D : 12.8 mm (0.504 in)

Use suction lifter (A) that is installed in advance, align the

matching marks between the holder and roof panel hole and between the

body panel and windshield glass  to install them on the Nissan Ariya vehicle.

to install them on the Nissan Ariya vehicle.

CAUTION:

Due to weight of windshield glass, 2 workers are required by all means.

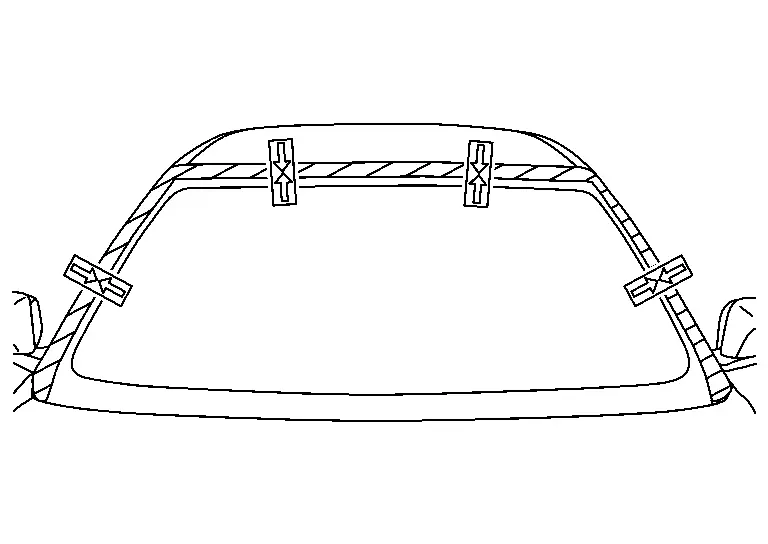

Press entire surface of windshield glass lightly to fit it completely.

Correct any adhesive overflow or shortage using a spatula to make the surface smooth.

CAUTION:

-

Dry the adhesive according to the specification of adhesive kit.

-

After installing windshield glass, keep the all door glass open until the adhesive is completely cured.

-

Never drive the Nissan Ariya vehicle before the adhesive is completely cured.

Remove protective tape.

Install removed parts.

CAUTION:

-

Perform additional service after removing front camera unit (with front camera unit). Refer to Work Procedure.

-

Adjust the front wiper arms auto stop position. Refer to Adjustment.

-

Check the matching with surrounding parts. Adjust if necessary.

-

After installing, perform the inspection. Refer to Inspection.

Reuse Windshield Glass

CAUTION:

Never reuse if it has damage, crack etc..

Use a cutter knife or scraper, and leave the of adhesive and sealant on the body side approximately 2 mm (0.079 in) (A) to make adhesive and sealant surface smooth.

CAUTION:

-

If the bonded area on the body is scratched, repair it using a 2 liquid types urethane paint. Never use lacquer type paint.

-

Smooth out adhesive and sealant surface.

Remove remaining adhesive, dam sealant rubber, spacers and clips from windshield glass surface.

Clean the bonded area on windshield glass and body panel side using a white gasoline or degreasing agent.

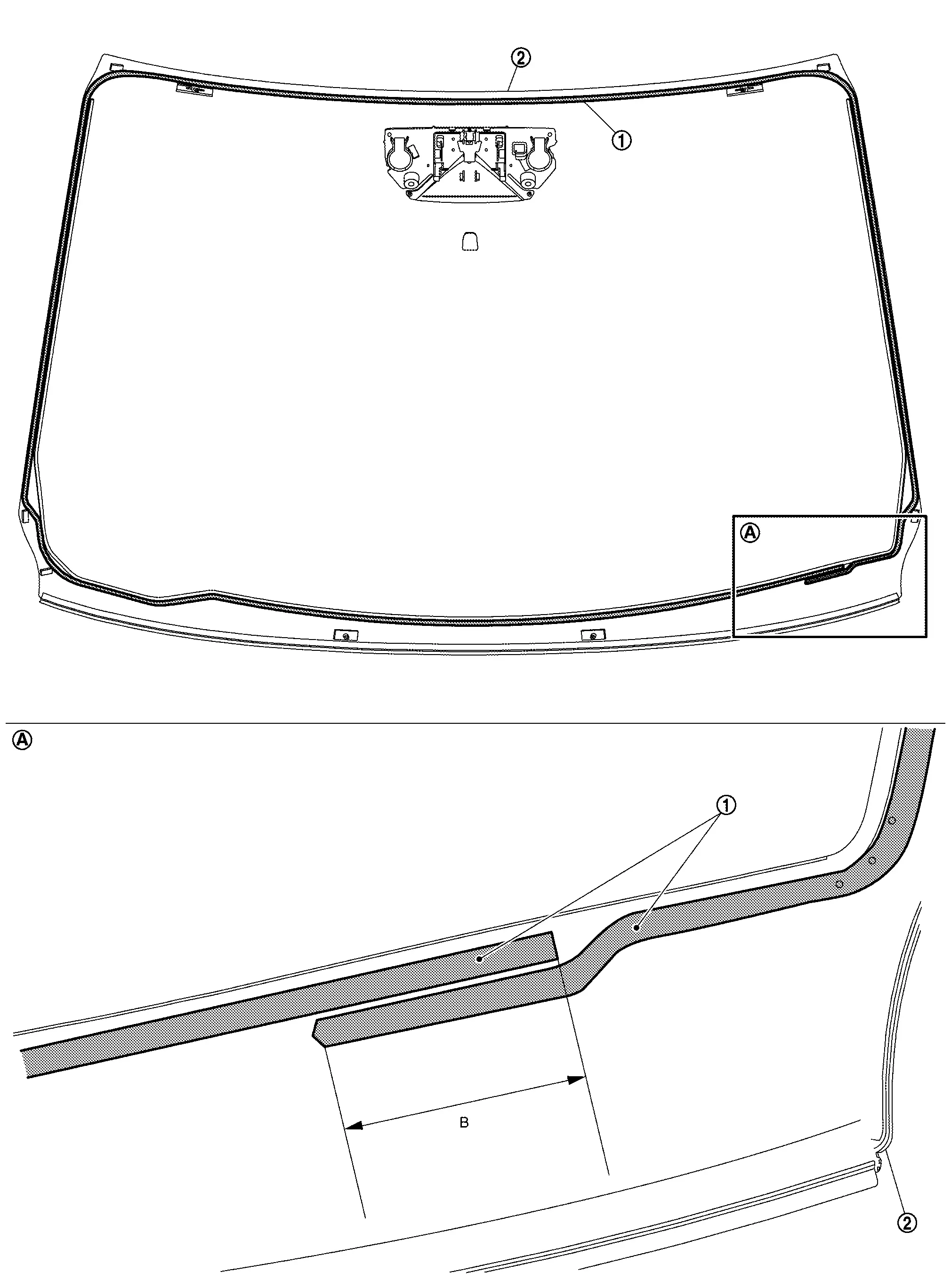

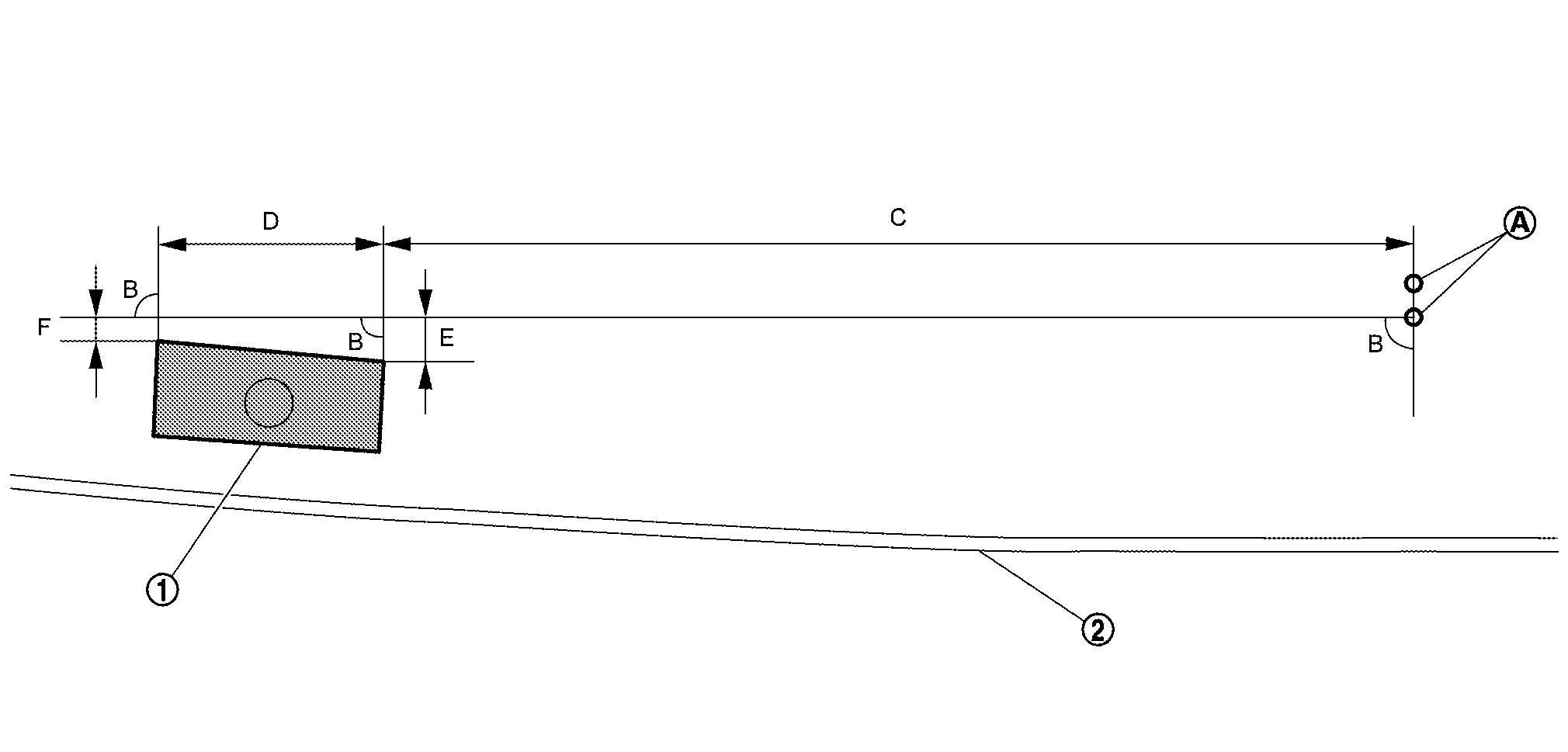

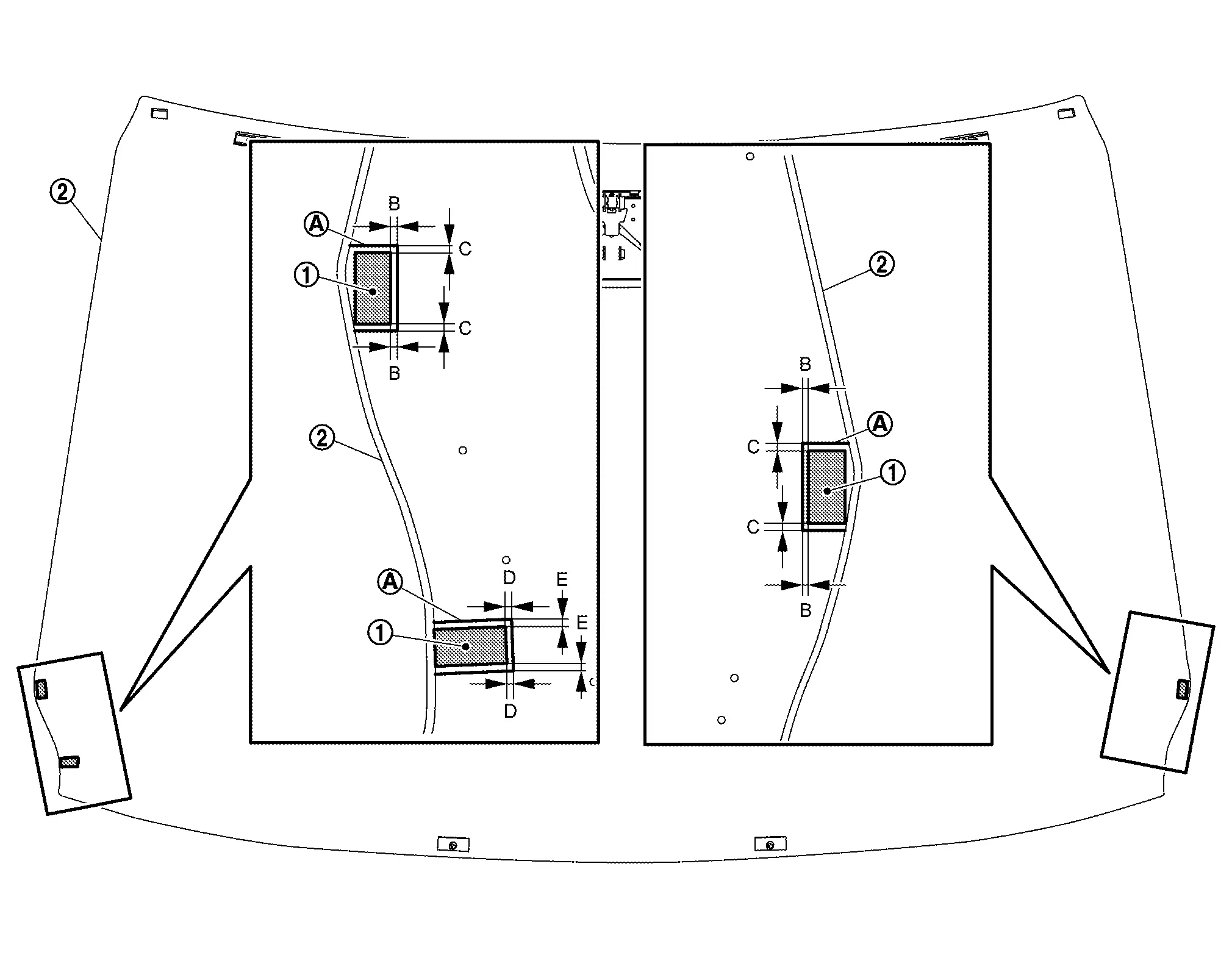

Install clip (upper).Clean windshield glass to install position of

clip (upper) by using white gasoline or degreasing agent. Apply glass

primer on windshield glass of clip (upper) install position. Remove

release liner of double sided tape for installing clip (upper). Install

clip (upper)  on windshield glass

on windshield glass  .

.

CAUTION:

Install on the position correctly as shown in figure.

|

: Windshield glass black print matching mark |

| B | : 365.7 mm (14.40 in) |

| C | : 59.0 mm (2.32 in) |

| D | : 90° |

| E | : 29.8 mm (1.173 in) |

| F | : 46.1 mm (1.815 in) |

Install clip (lower).Clean windshield glass to install position of

clip (lower) by using white gasoline or degreasing agent. Apply glass

primer on windshield glass of clip (lower) install position. Remove

release liner of double sided tape for installing clip (lower). Install

clip (lower)  on windshield glass

on windshield glass  .

.

CAUTION:

Install on the position correctly as shown in figure.

|

: Windshield glass black print matching mark |

| B | : 90° |

| C | : 183.3 mm (7.22 in) |

| D | : 39.9 mm (1.571 in) |

| E | : 5.0 mm (0.20 in) |

| F | : 0.25 mm (0.0098 in) |

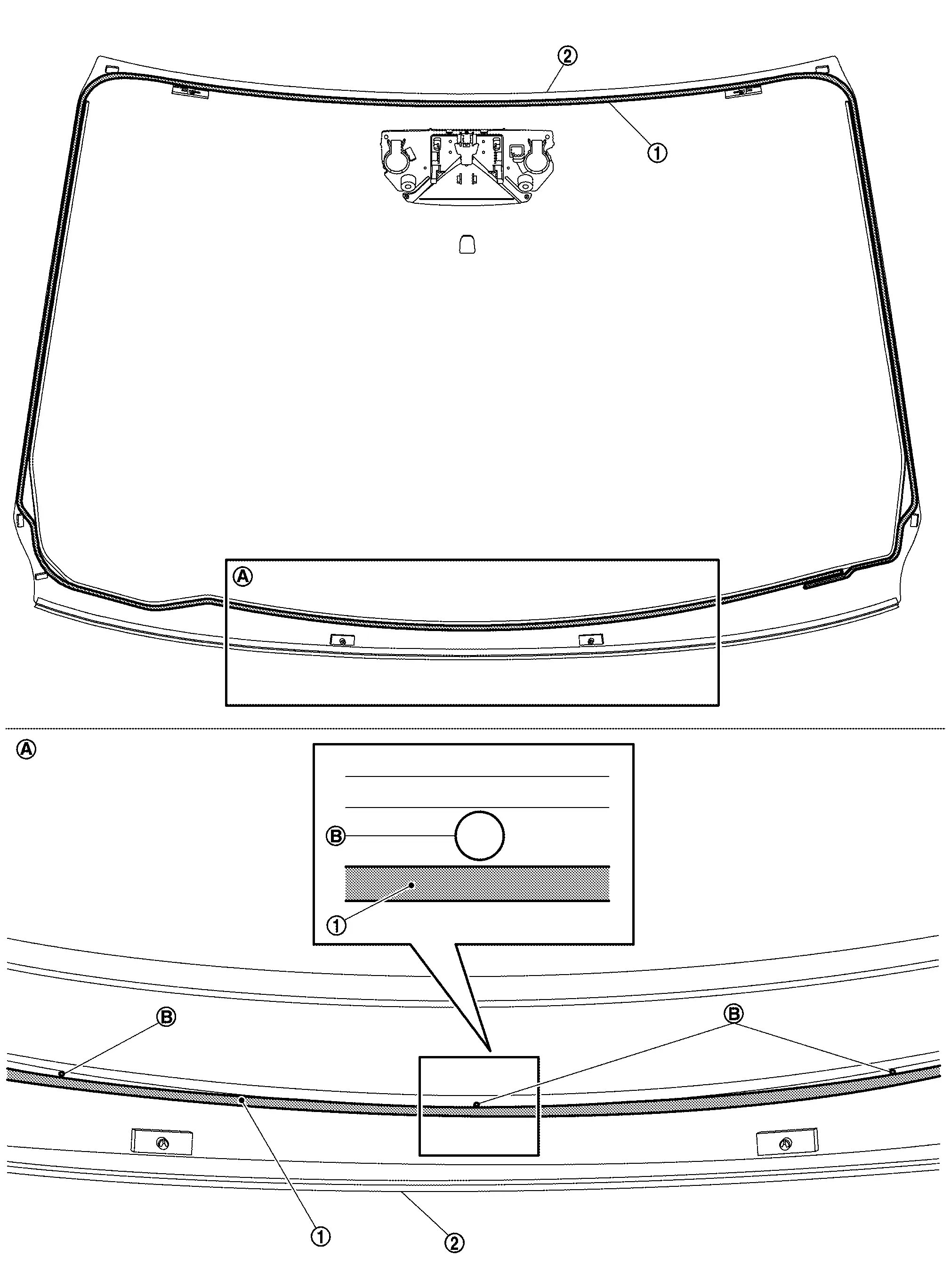

Install spacer (upper).Clean windshield glass to install position of

spacer (upper) by using white gasoline or degreasing agent. Apply glass

primer on windshield glass of spacer (upper) install position. Remove

release liner of double sided tape for installing spacer (upper).

Install spacer (upper)  on windshield glass

on windshield glass  .

.

CAUTION:

Install on the position correctly as shown in figure.

-

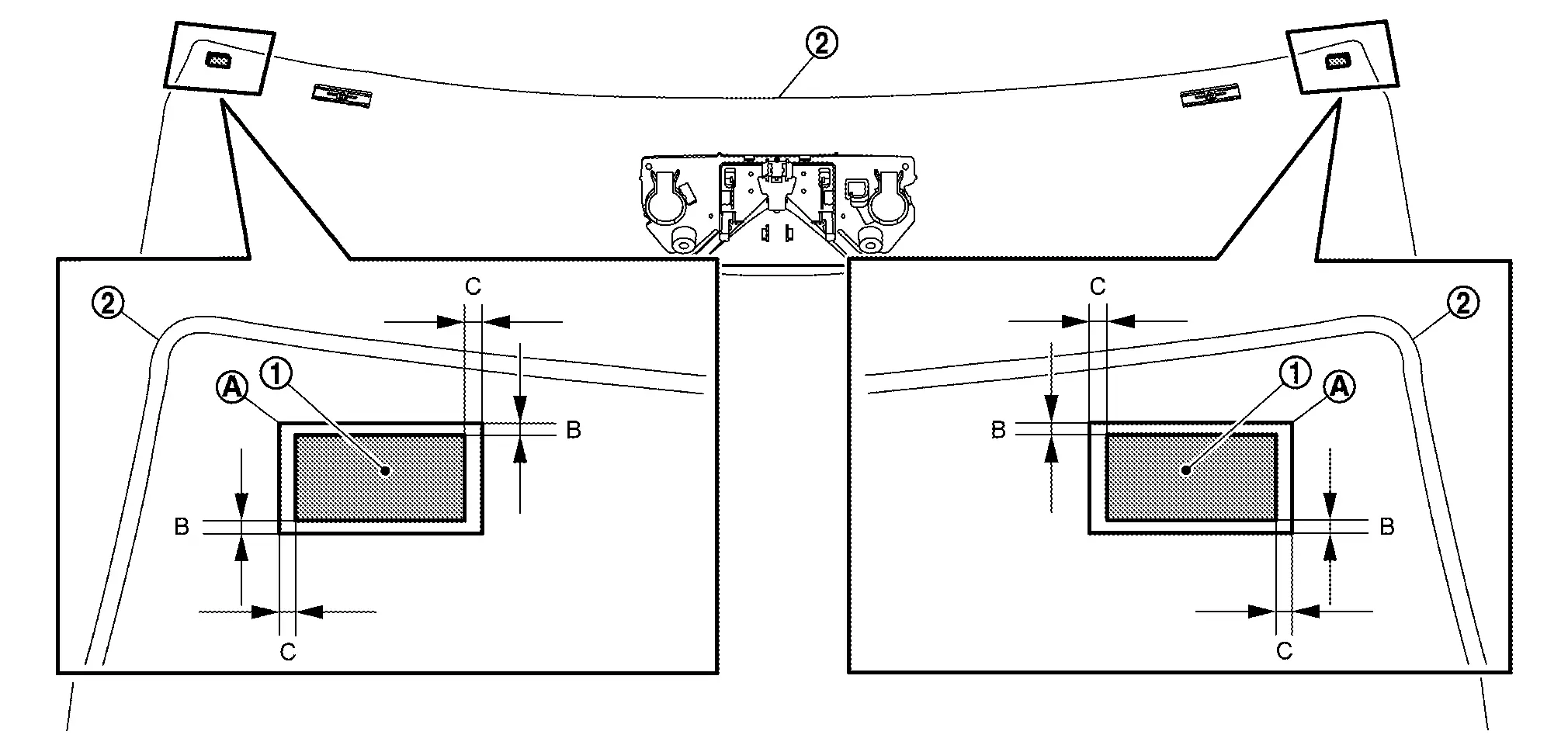

LH and RH side

: Windshield glass black print matching mark B : 1.5 mm (0.059 in) C : 2.0 mm (0.079 in) -

Center

: Windshield glass black print matching mark B : 50.0 mm (1.97 in) C : 90° D : 7.2 mm (0.283 in)

Install spacer (lower).Clean windshield glass to install position of

spacer (lower) by using white gasoline or degreasing agent. Apply glass

primer on windshield glass of spacer (lower) install position. Remove

release liner of double sided tape for installing spacer (lower).

Install spacer (lower)  on windshield glass

on windshield glass  .

.

CAUTION:

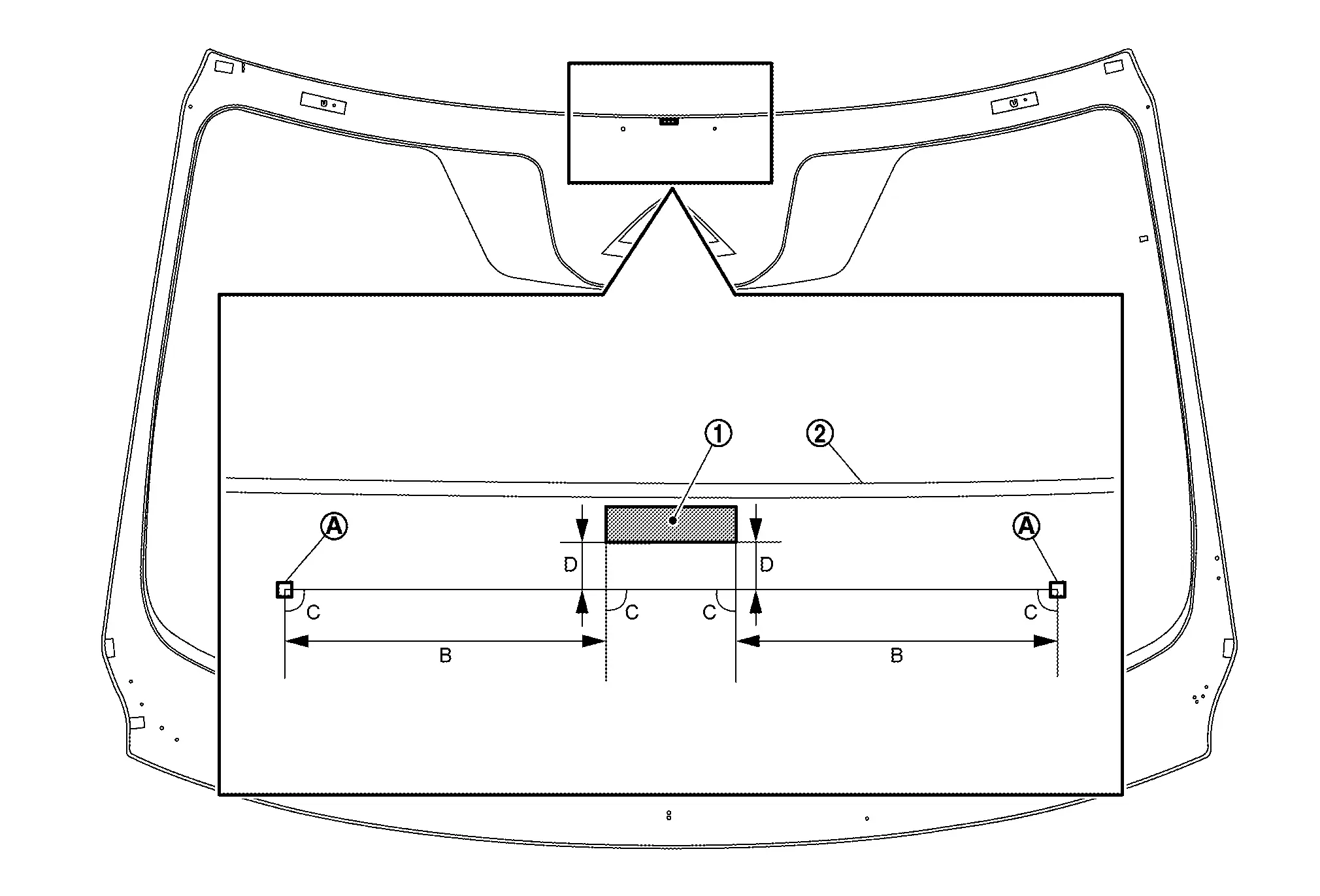

Install on the position correctly as shown in figure.

|

: Windshield glass black print matching mark |

| B | : 1.5 mm (0.059 in) |

| C | : 2.0 mm (0.079 in) |

| D | : 1.5 mm (0.059 in) |

| E | : 2.0 mm (0.079 in) |

Install windshield glass molding.Temporarily install new windshield

glass molding on windshield glass to check for apply glass primer

position. Clean windshield glass to applying position of glass primer by

using white gasoline or degreasing agent. Apply glass primer on

windshield glass of windshield glass instal position. Remove release

liner of double sided tape for installing windshield glass molding.

Install windshield glass molding  on windshield glass

on windshield glass  as shown in figure.

as shown in figure.

|

: The ends of windshield glass molding |

|

: Black print matching mark |

| C | : 2.5 mm (0.098 in) |

CAUTION:

When installing, the lip  of windshield glass molding

of windshield glass molding  is touch on the edge

is touch on the edge  of windshield glass

of windshield glass  as shown in figure. (Never press lip to edge.)

as shown in figure. (Never press lip to edge.)

| C | : 0 – 0.75 mm (0 – 0.0295 in) |

Install dam sealant rubber.Clean windshield glass to applying position for dam sealant rubber by using white gasoline or degreasing agent. Remove release liner of double sided tape for installing dam sealant rubber. Install dam sealant rubber on windshield glass.

CAUTION:

-

The stop/start position is as shown in figure.

: Dam sealant rubber

: Windshield glass

: Black print matching mark B : 1.0 mm (0.039 in) C : 0 mm – 5.0 mm (0 – 0.20 in) -

The left/right side are along with edge

of windshield glass edge as shown in figure.

of windshield glass edge as shown in figure.

-

The lower left

to installing dam sealant rubber are as shown in figure.

to installing dam sealant rubber are as shown in figure.

: Dam sealant rubber

: Windshield glass

: Connected line of black print matching marks

: Black print matching mark D : 1.0 mm (0.039 in) -

The lower right position

as shown in figure.

as shown in figure.

: Dam sealant rubber

: Windshield glass

: Black print matching mark

: Connected line of black print matching marks D : 1.0 mm (0.039 in) -

The lower middle

is as shown in figure.

is as shown in figure.

: Dam sealant rubber

: Windshield glass

: Black print matching mark

: Connected line of black print matching marks D : 1.0 mm (0.039 in)

Apply glass primer along the entire circumference of windshield glass. The range of glass primer refer to Exploded View.

For NMK production only, apply painted surface primer to the body side bonding surface. The range of painted surface primer refer to Exploded View.

Apply adhesive to windshield glass by using a sealant gun. The volume of adhesive refer to Exploded View.

CAUTION:

-

The stop/start position to applying adhesive

are locate

are locate  on windshield glass

on windshield glass  as shown in figure.

as shown in figure. -

When finish to applying adhesive, its should be overlap from start position as shown in figure.

B : 68 mm (2.68 in) -

When applying adhesive

onto lower middle position

onto lower middle position  , never cover windshield glass

, never cover windshield glass  black print matching marks

black print matching marks  as shown in figure.

as shown in figure.

-

The lower left

to applying adhesive as shown in figure.

to applying adhesive as shown in figure.

: Adhesive

: Windshield glass

: Spacer (lower)

: Black print matching mark

: Fully cover

: Not cover  and touch spacer (lower)

and touch spacer (lower)

: Only half cover

-

The left/right side

to applying adhesive

to applying adhesive  along windshield glass

along windshield glass  black print edge

black print edge  as shown in figure.

as shown in figure.

-

The upper left/right

to applying adhesive are as shown in figure.

to applying adhesive are as shown in figure.

: Adhesive

: Clip (upper)

: Windshield glass

: Black print matching mark

: Black print matching mark [for spacer (upper)] -

The upper middle

to applying adhesive as shown in figure.

to applying adhesive as shown in figure.

: Adhesive

: Windshield glass

: The edge bend of windshield glass

: Black print matching mark D : 12.8 mm (0.504 in)

Use suction lifter (A) that is installed in advance, align the

matching marks between the holder and roof panel hole and between the

body panel and windshield glass  to install them on the Nissan Ariya vehicle.

to install them on the Nissan Ariya vehicle.

CAUTION:

Due to weight of windshield glass, 2 workers are required by all means.

Press entire surface of windshield glass lightly to fit it completely.

Correct any adhesive overflow or shortage using a spatula to make the surface smooth.

CAUTION:

-

Dry the adhesive according to the specification of adhesive kit.

-

After installing windshield glass, keep the all door glass open until the adhesive is completely cured.

-

Never drive the Nissan Ariya vehicle before the adhesive is completely cured.

Remove protective tape.

Install removed parts.

CAUTION:

-

Perform additional service after removing front camera unit (with front camera unit). Refer to Work Procedure.

-

Adjust the front wiper arms auto stop position. Refer to Adjustment.

-

Check the matching with surrounding parts. Adjust if necessary.

-

After installing, perform the inspection. Refer to Inspection.

Inspection

WATER LEAKAGE INSPECTION

CAUTION:

-

Dry adhesive according to the specification of adhesive kit, do the leaking check when adhesive is stiffen.

-

If leakage was found, start over from the beginning as windshield glass removal, install and leaking check.

Other materials:

Removal and Installation. Door Lock/unlock Switch Rh

Removal and Installation

CAUTION:

Never bend the pawl of power window switch finisher.

REMOVAL

Remove power window switch finisher RH. Refer to Removal and Installation.

Release pawl using a suitable tool and remove the door lock/unlock switch RH from the power window switch finisher RH ...

P01f0 Engine Coolant Temperature

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P01F0

00

Coolant temperature

(Coolant temperature relapsed below diagnostic monitoring temperature)

Diagnosis condition

After engine warmed up

Nissan ...

Diagnosis System (driver Monitor Camera Control Unit)

CONSULT Function (Driver Monitor Camera)

APPLICATION ITEMSCONSULT performs the following functions via CAN communication using driver monitor camera control unit. Diagnosis mode Description

Self Diagnostic Result

Retrieve DTC from ECU and display diagnostic items

Data Monitor

Monitor ...