Nissan Rogue (T33) 2021-Present Service Manual: Removal and Installation :: Transverse Link

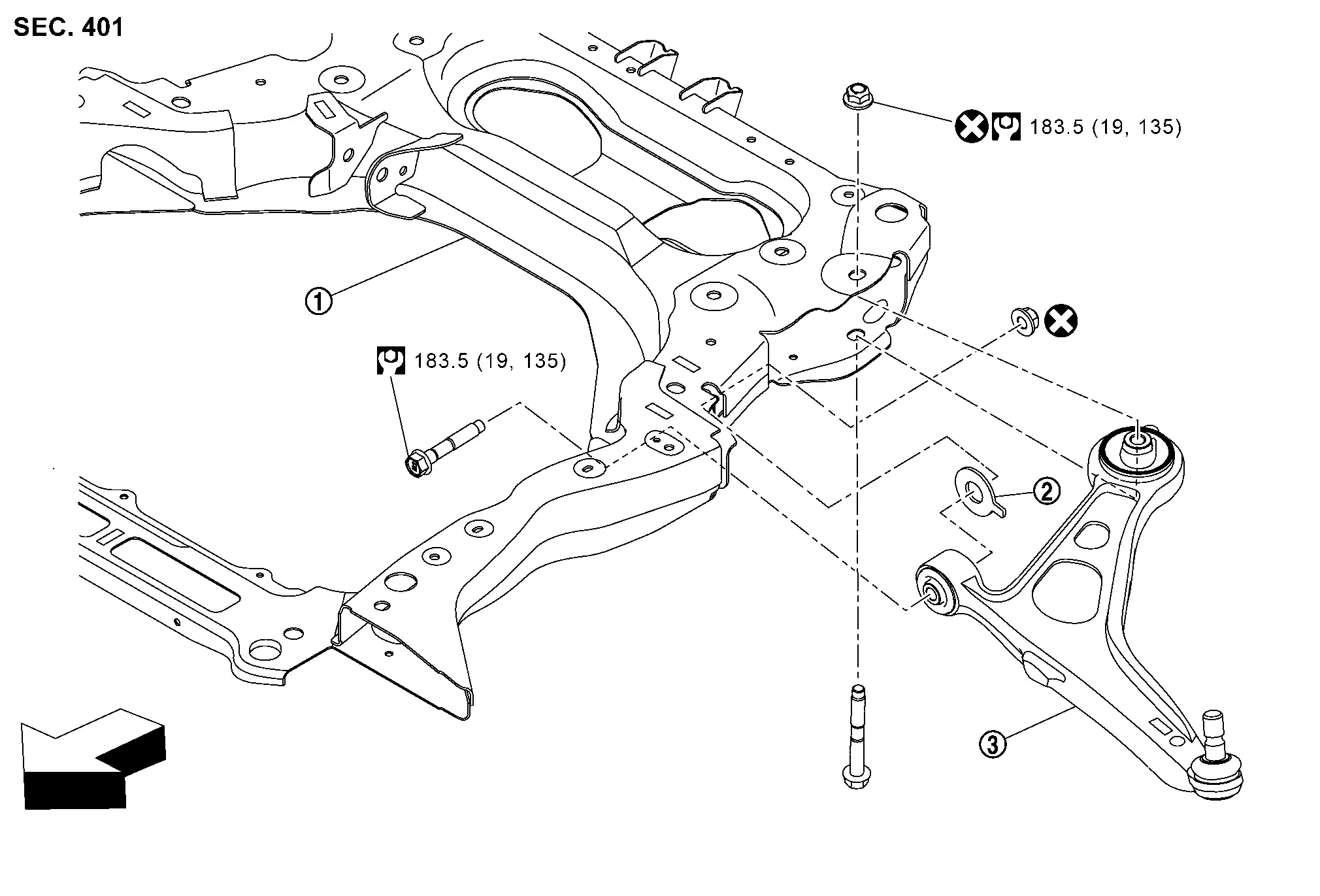

Exploded View

JAPAN PRODUCTION MODELS

| 1. | Front suspension member | 2. | Bush | 3. | Transverse link |

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Always replace after every disassembly. | ||||

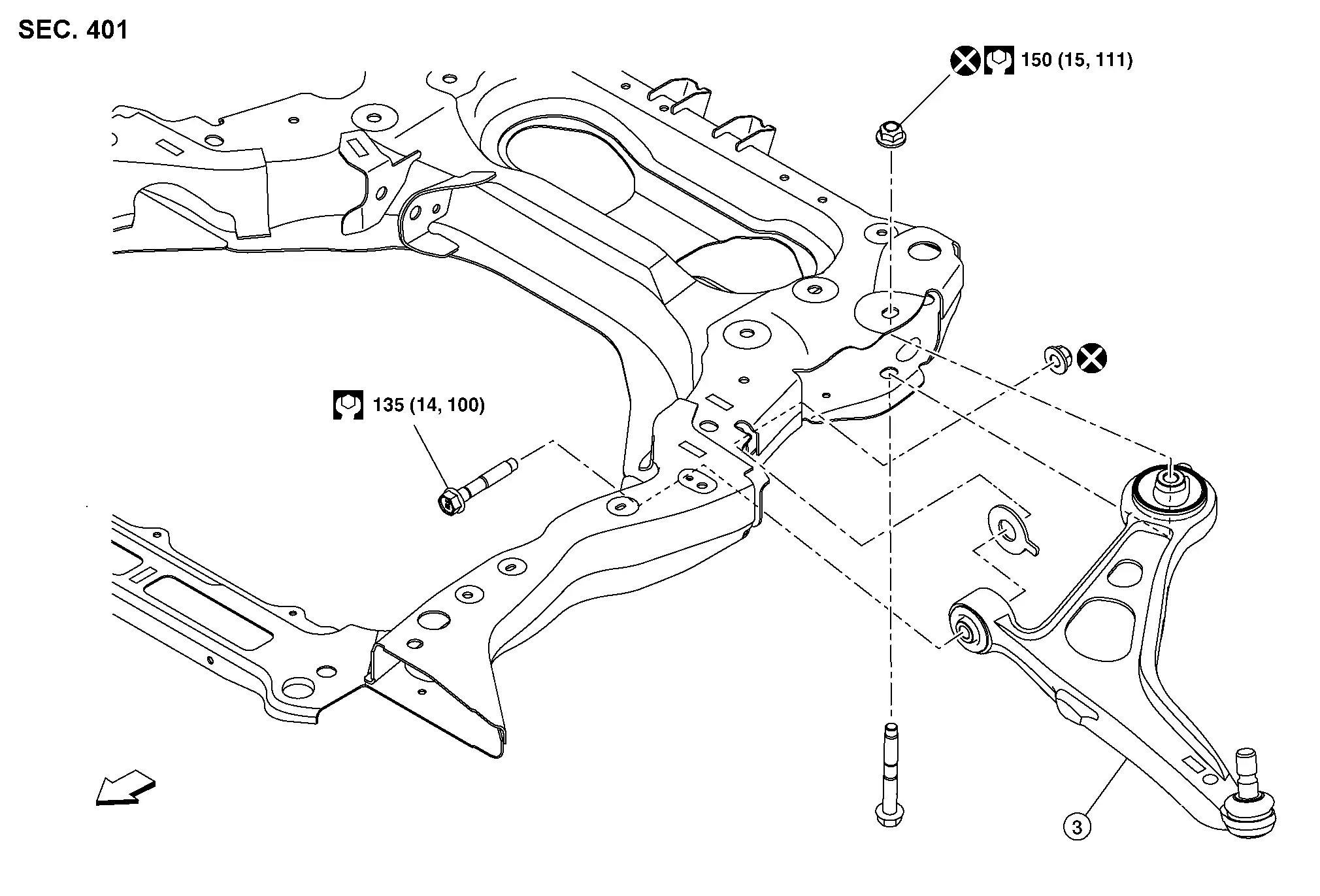

NORTH AMERICA PRODUCTION MODELS

| 1. | Front suspension member | 2. | Bush | 3. | Transverse link |

|

: Nissan Ariya Vehicle front | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Always replace after every disassembly. | ||||

Removal and Installation

REMOVAL

Remove front suspension member. Refer to Removal and Installation.

Remove transverse link mounting bolts  and nuts

and nuts  , and then remove transverse link

, and then remove transverse link  from suspension member.

from suspension member.

Perform inspection after removal. Refer to Inspection.

INSTALLATION

Note the following, and install in the reverse order of removal.

-

Never reuse transverse link mounting nut.

-

Perform final tightening of bolts and nuts at the Nissan Ariya vehicle installation position (rubber bushing), under unladen conditions with tires on level ground.

-

Perform inspection after installation. Refer to Inspection.

Inspection

INSPECTION AFTER REMOVAL

Check the following items, and replace the parts if necessary.

Transverse Link

-

Transverse link for deformation, cracks or damage.

-

Check the bushing for complete separation. (If completely separated, inner metal can be pulled out fromtransverse link.)

-

Ball joint boot for cracks or other damage, and also for grease leakage.

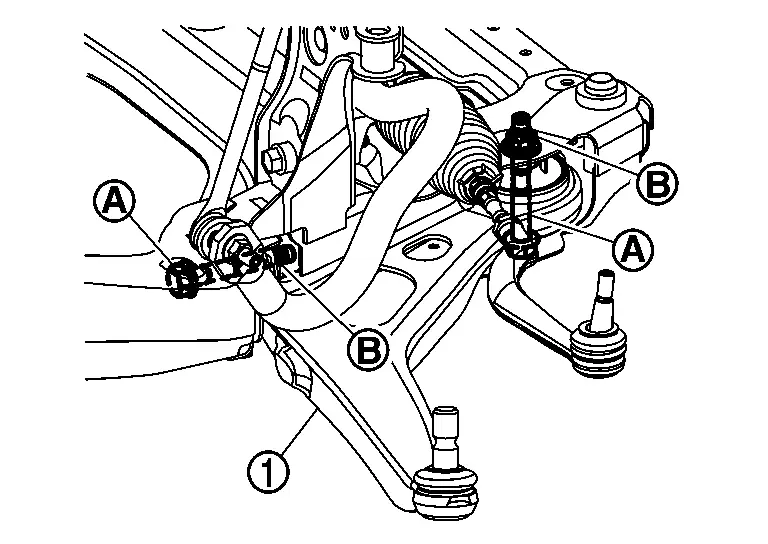

Swing Torque

Manually move ball stud to confirm it moves smoothly with no binding.

Move ball stud at least ten times by hand to check for smooth movement.

Hook a spring balance (A) at cutout on ball stud  . Confirm spring balance measurement value is within specifications when ball stud begins moving.

. Confirm spring balance measurement value is within specifications when ball stud begins moving.

| Swing torque | : Refer to Ball Joint. |

| Measurement on spring balance | : Refer to Ball Joint. |

-

If swing torque exceeds standard range, replace transverse link assembly.

Axial End Play

Move ball stud at least ten times by hand to check for smooth movement.

Move tip of ball stud in axial direction to check for looseness.

-

If there is axial end play, replace transverse link assembly.

INSPECTION AFTER INSTALLATION

Check wheel alignment. Refer to Inspection.

Adjust neutral position of steering angle sensor. Refer to Description.

Other materials:

Modes de fonctionnement des essuie-glaces

Type A (selon Ă©quipement)

Type B (selon Ă©quipement)

Les commandes de visibilité de votre Nissan Rogue s'activent lorsque le contact est sur "ON" :

Mode AUTO / Intermittent :

- Type A (Automatique) : Le Nissan Rogue ajuste seul la vitesse selon l'intensité de la pluie ...

P0112 Iat Sensor

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

P0112

00

IAT SEN/CIRCUIT-B1

(Intake air temperature sensor 1 circuit low bank 1)

Diagnosis condition

—

Signal (terminal)

Intake air temperature sensor sign ...

Main Line Between Anc and Pwbd Circuit

Diagnosis Procedure

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Disconnect the following harness connectors.

BCM

Active noise control unit

Automatic back door control unit

Check ...