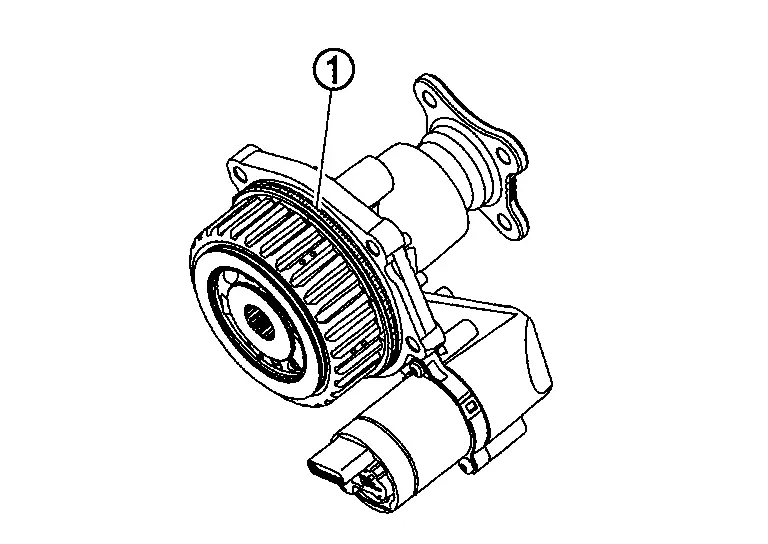

Nissan Rogue (T33) 2021-Present Service Manual: Rear Final Drive: R145 :: Removal and Installation

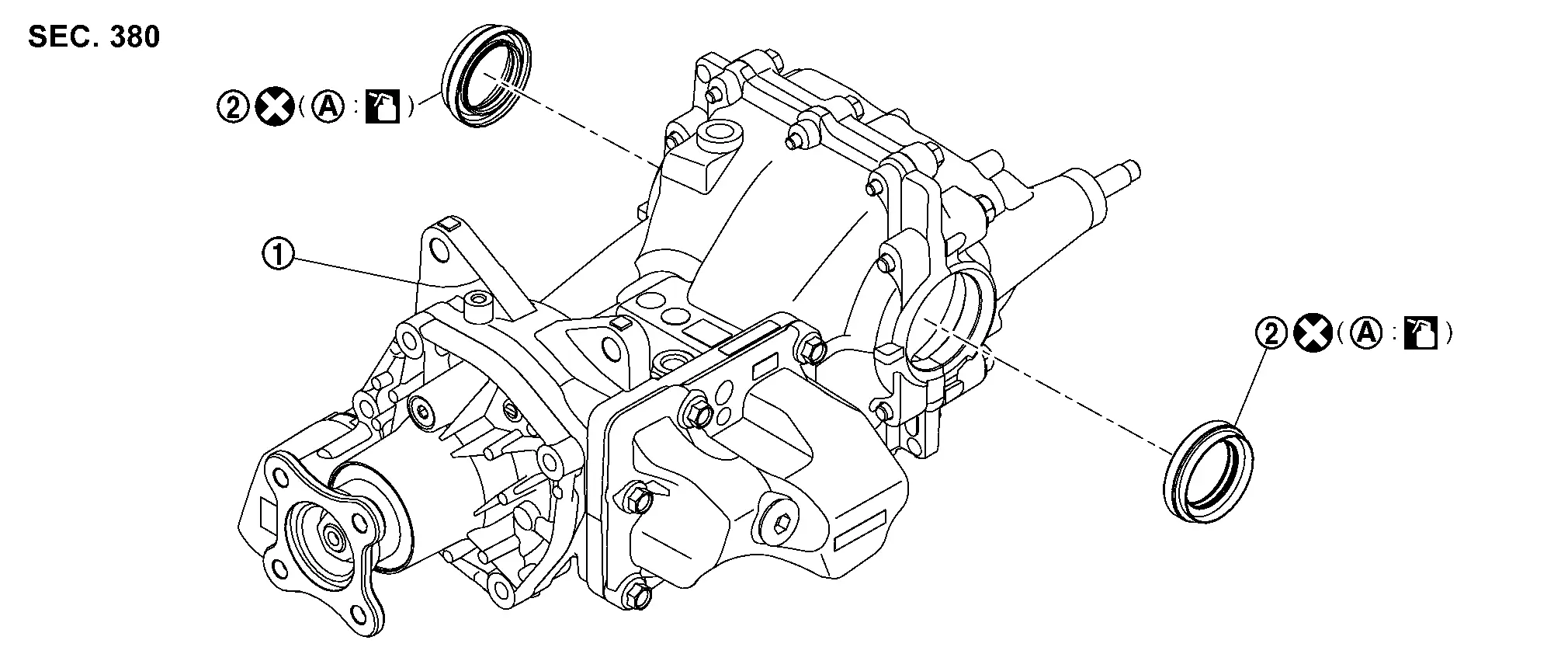

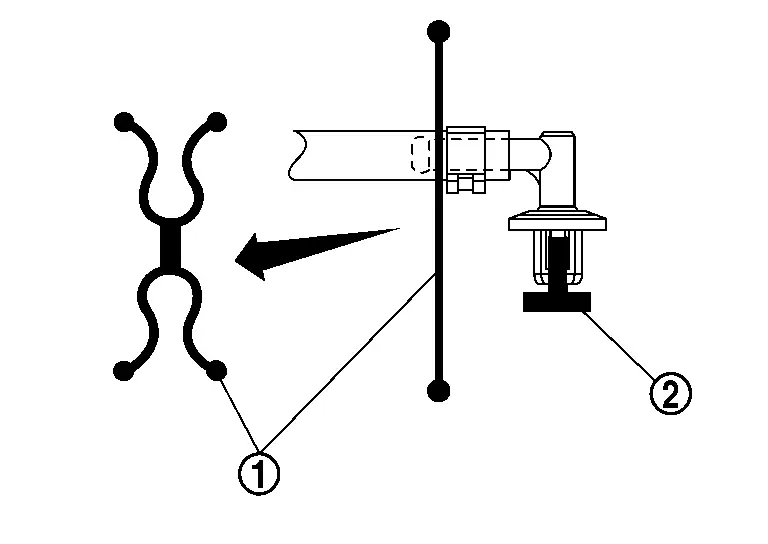

Side Oil Seal

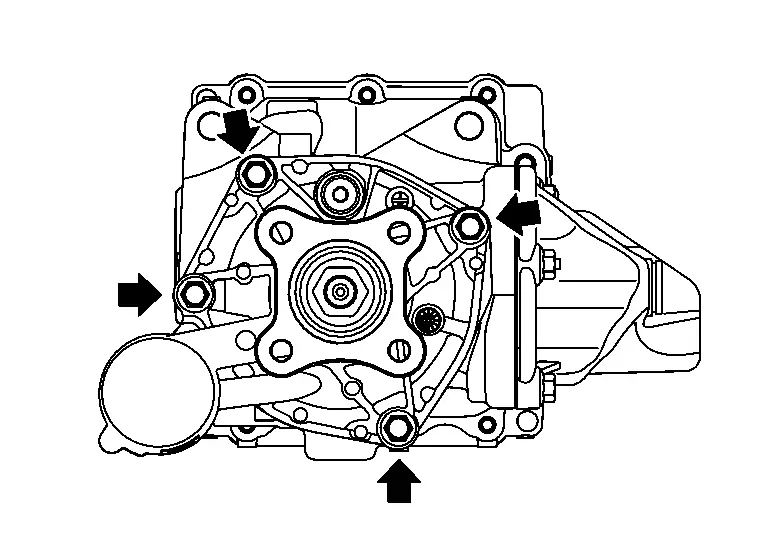

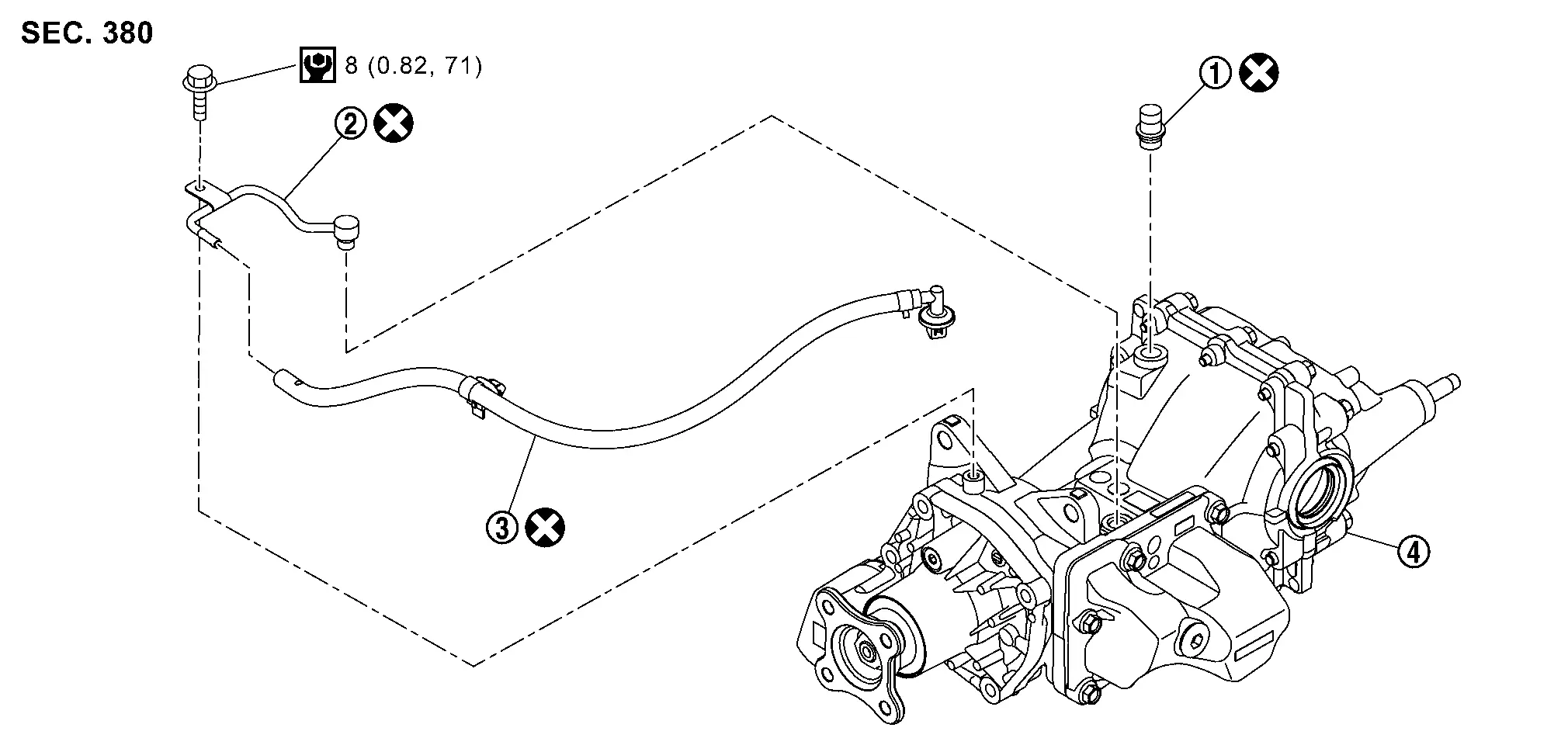

Exploded View

|

Rear final drive assembly |  |

Side oil seal | ||

|

Outer circumference | ||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

: Apply gear oil. : Apply gear oil. |

|||||

Removal and Installation

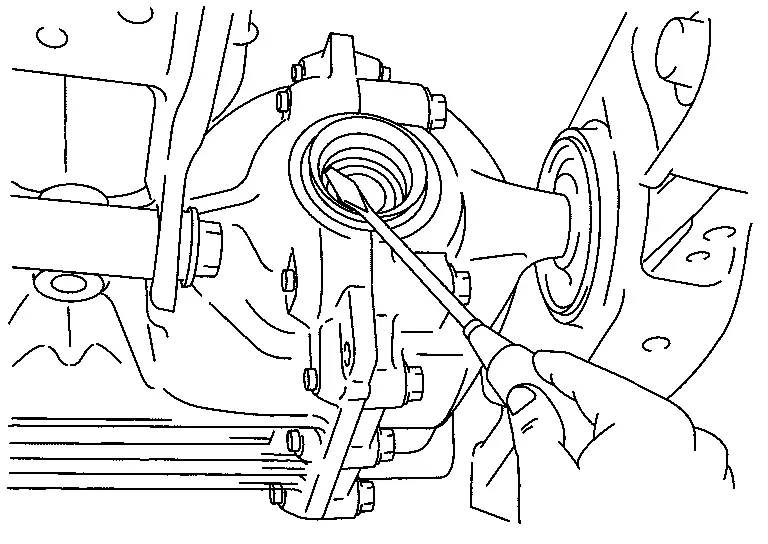

REMOVAL

Drain gear oil. Refer to Draining.

Remove rear drive shafts. Refer to Removal and Installation.

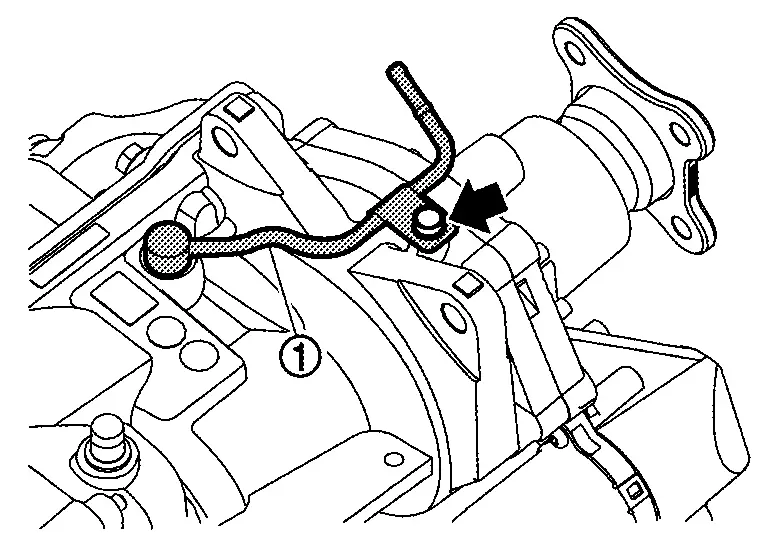

Remove side oil seal, using oil seal remover (commercial service tool).

CAUTION:

Never damage gear carrier and rear cover.

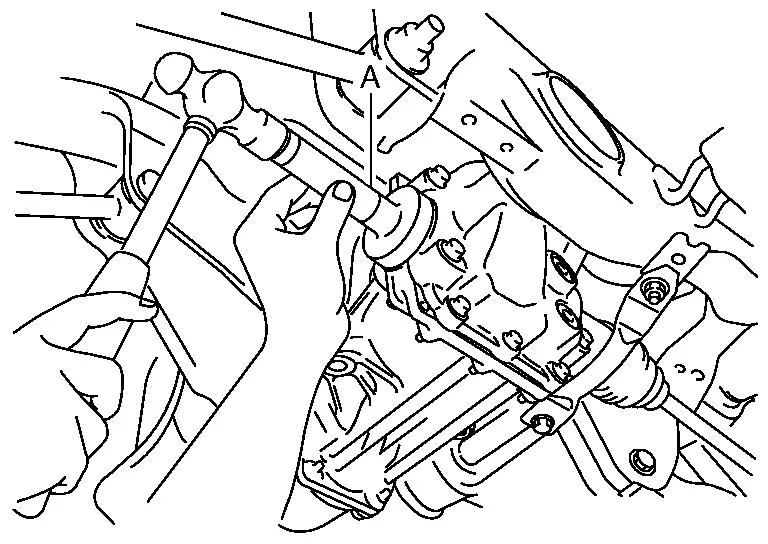

INSTALLATION

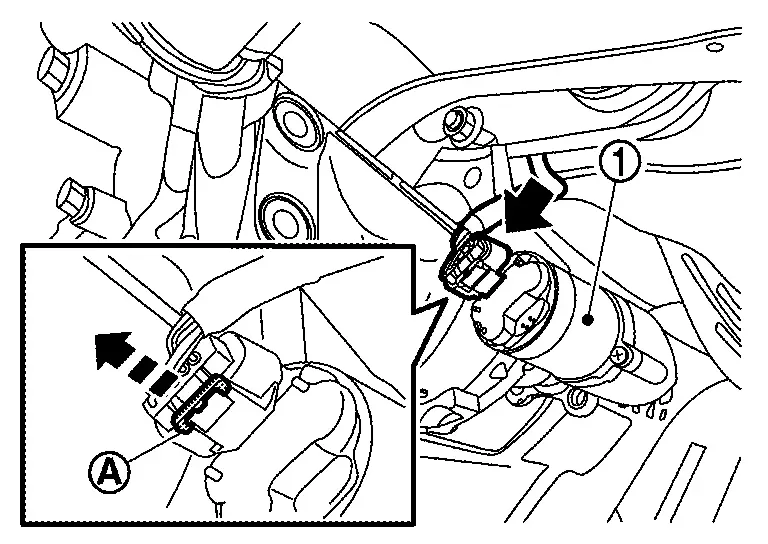

Using the drift (A) (commercial service tool), drive side oil seal until it becomes flush with the gear carrier end.

CAUTION:

-

Never reuse oil seal.

-

When installing, never incline oil seal.

-

Check that the oil seal lip is filled up with grease.

-

Apply gear oil lightly and evenly onto the outer circumference of oil seal.

Install rear drive shafts. Refer to Removal and Installation.

Refill gear oil to the final drive. Refer to Refilling.

Check the oil level and the oil leakage after installation. Refer to Inspection .

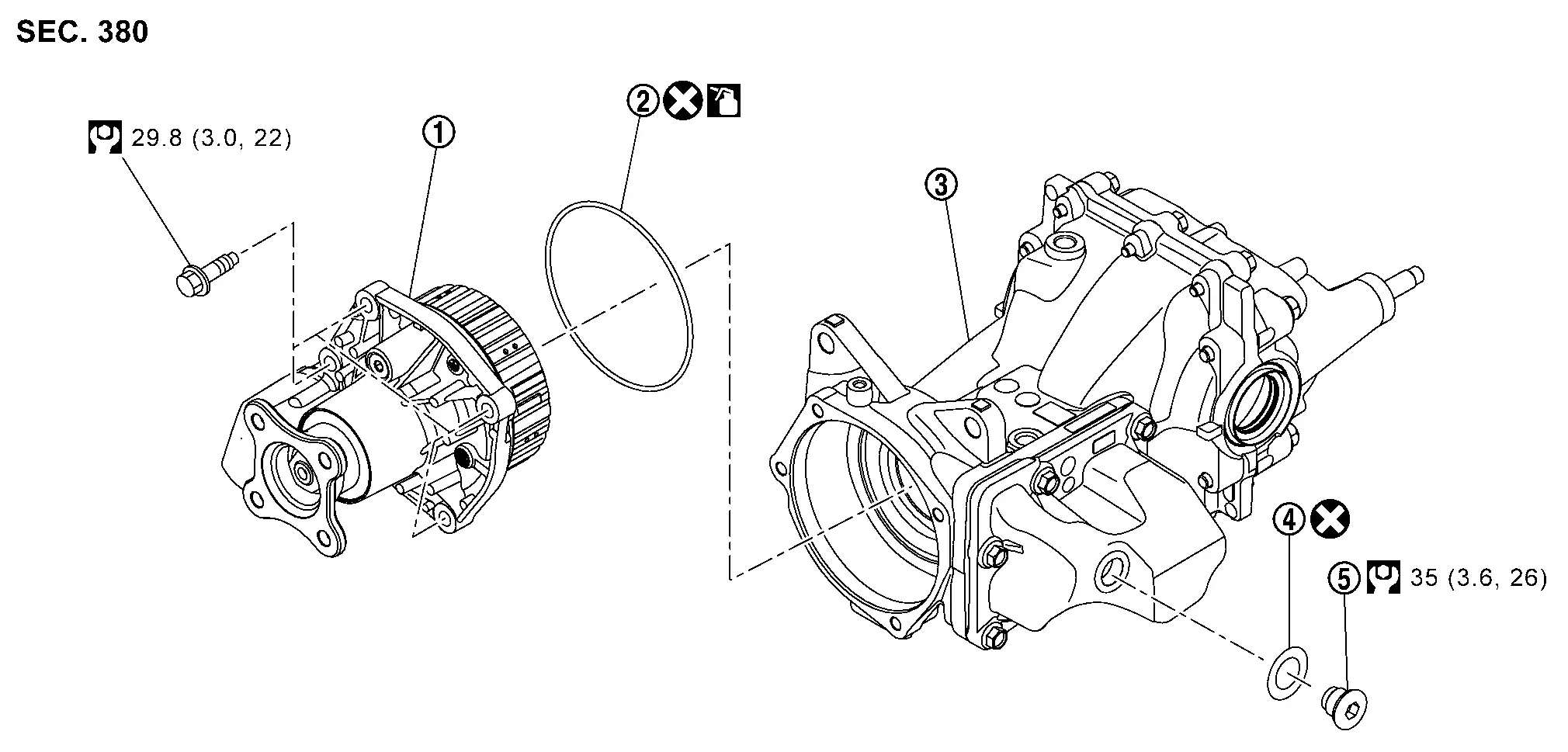

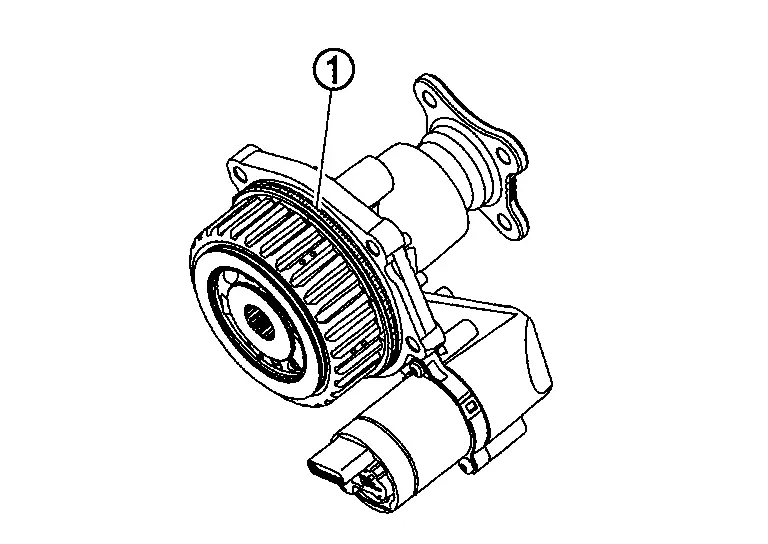

Electro-Hydraulic Coupling

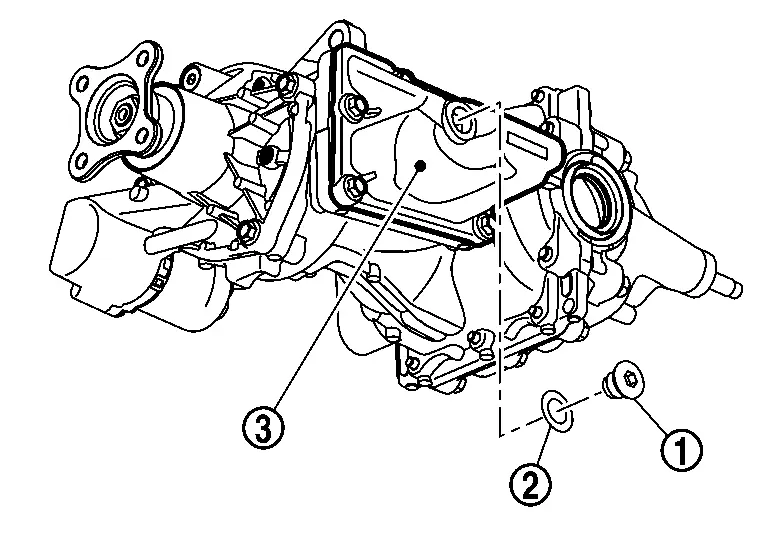

Exploded View

|

Electro-hydraulic coupling assembly |  |

O-ring |  |

Rear final drive assembly |

|

Gasket |  |

Filler plug | ||

: N·m (kg-m, ft-lb) : N·m (kg-m, ft-lb) |

|||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

: Apply electro-hydraulic coupling oil (Genuine part). : Apply electro-hydraulic coupling oil (Genuine part). |

|||||

Removal and Installation

REMOVAL

NOTE:

NOTE:

-

When replacing AWD control unit (integrated with actuator assembly of electro-hydraulic coupling assembly) or electro-hydraulic coupling assembly perform adjustment before removal. Refer to Adjustment.

-

Before replacing electro-hydraulic coupling due to vibration and/or noise when making low speed turns, refer to TSB to assist in proper diagnosis.

Remove propeller shaft from rear final drive companion flange. Refer to Removal and Installation (CVJ-CVJ-C).

NOTE:

NOTE:

Tie propeller shaft aside with a suitable strap.

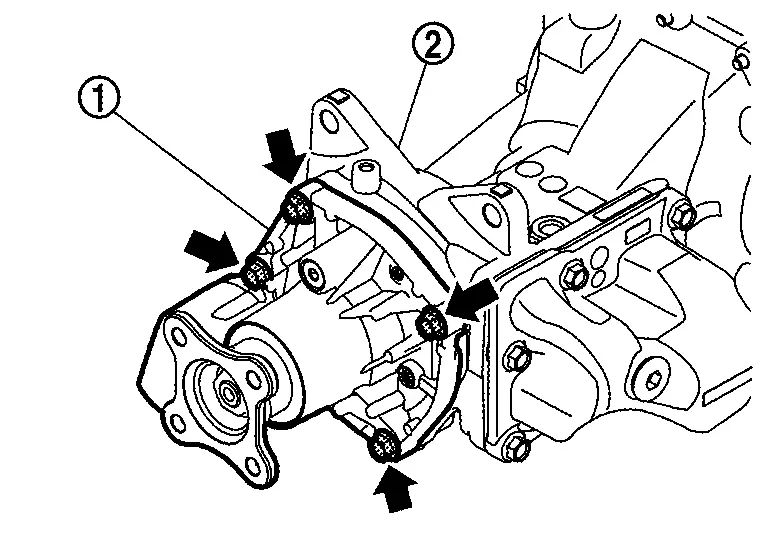

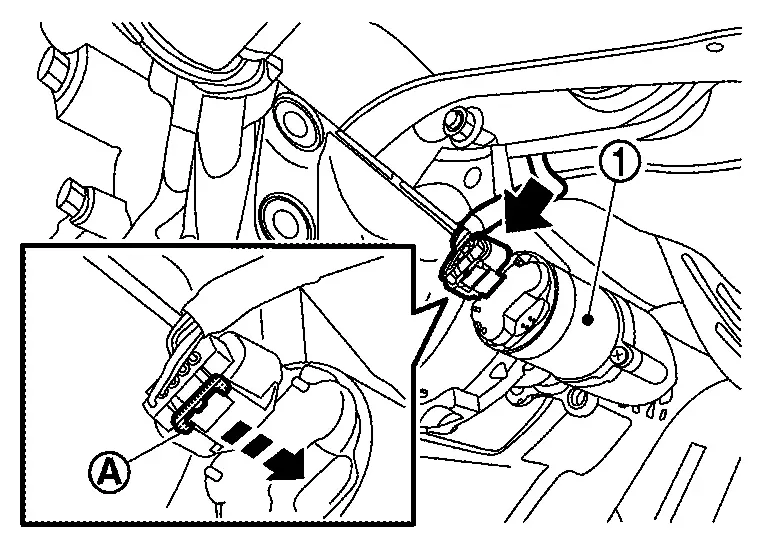

Disconnect harness connector of actuator assembly  .

.

-

To disconnect harness connector, the lock tab

must be pulled outward.

must be pulled outward.

Place a pan under electro-hydraulic coupling assembly mounting part.

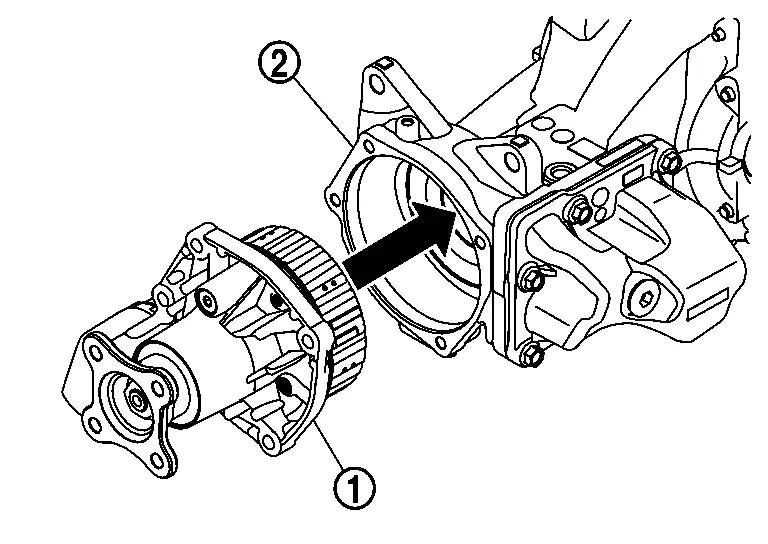

Remove electro-hydraulic coupling assembly  from final drive assembly

from final drive assembly  after removing electro-hydraulic coupling assembly mounting bolts.

after removing electro-hydraulic coupling assembly mounting bolts.

CAUTION:

Oil is drained from between electro-hydraulic coupling assembly and final drive assembly when removing.

-

If necessary, use cutout

to pry.

to pry.

Remove O-ring  from electro-hydraulic coupling assembly.

from electro-hydraulic coupling assembly.

CAUTION:

-

Never use a tool.

-

Never damage electro-hydraulic coupling assembly.

INSTALLATION

CAUTION:

Be careful to place each part so that the contamination never stick to the drum surface flange during work.

Install O-ring  to electro-hydraulic coupling assembly.

to electro-hydraulic coupling assembly.

CAUTION:

-

Never reuse O-ring.

-

Apply electro-hydraulic coupling oil lightly and evenly onto O-ring.

-

When installing O-ring, never use a tool.

-

Never damage O-ring.

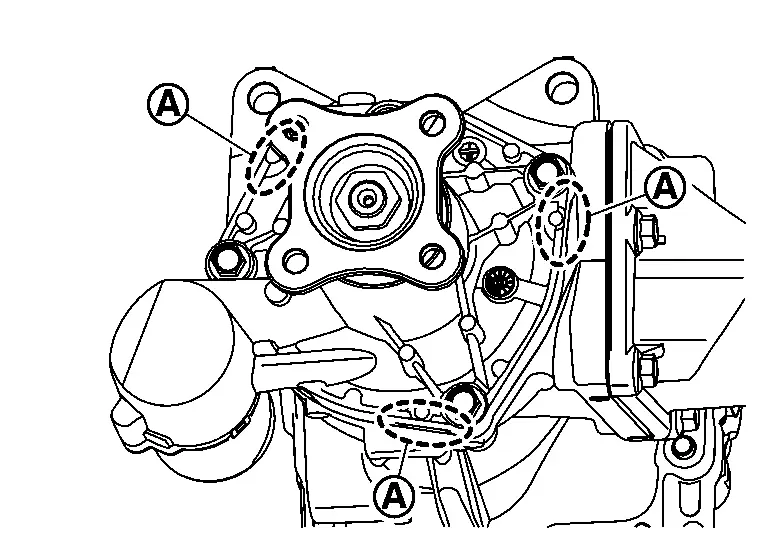

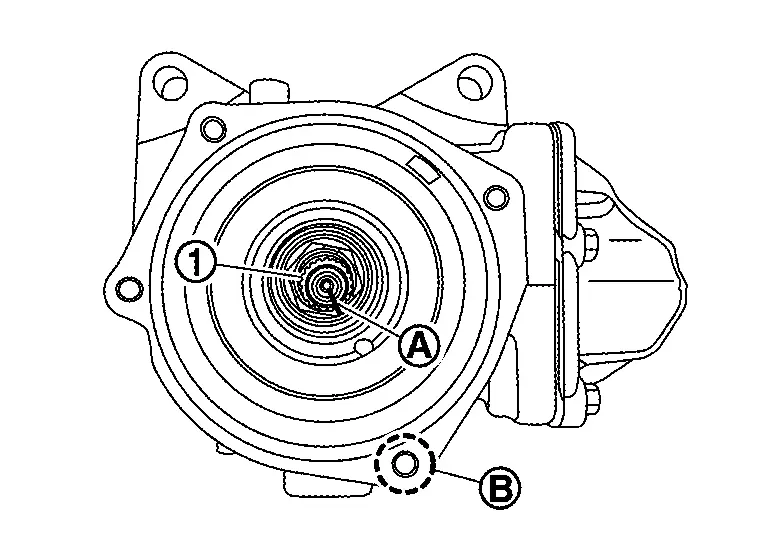

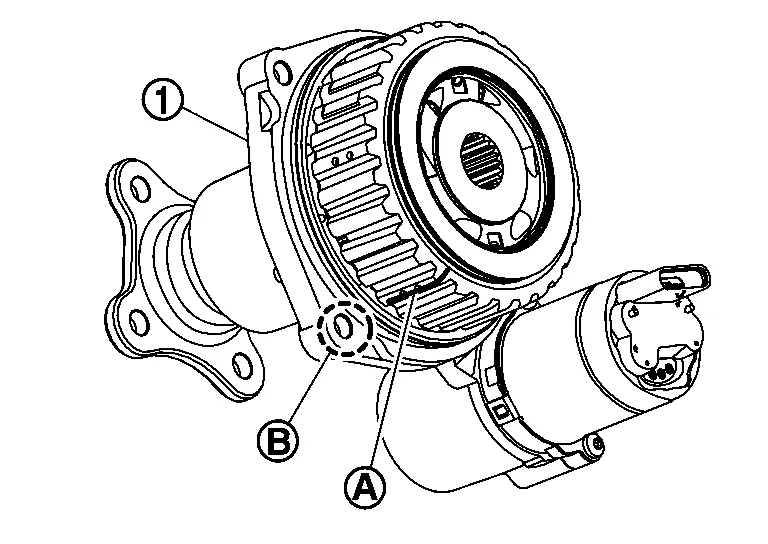

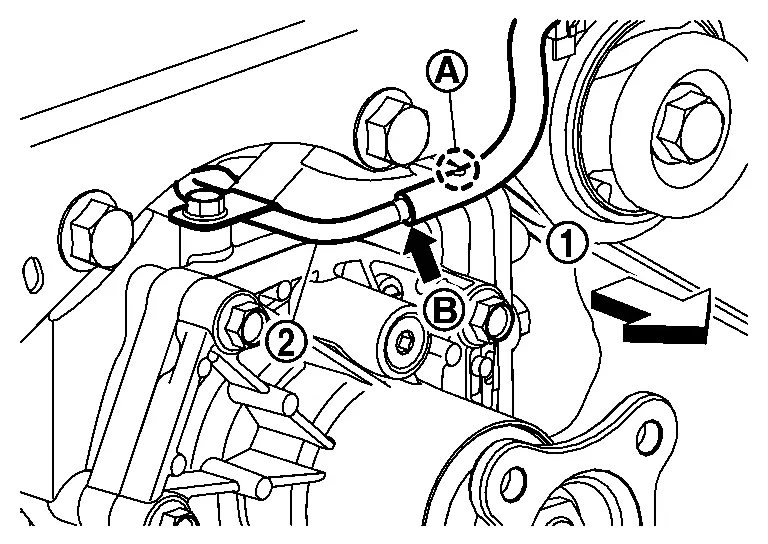

Locate aligning marking  on tip of drive pinion

on tip of drive pinion  . Rotate rear wheels until the aligning marking is aligned with the lower bolt hole

. Rotate rear wheels until the aligning marking is aligned with the lower bolt hole  , as shown in figure.

, as shown in figure.

Locate aligning marking  on drum of electro-hydraulic coupling assembly

on drum of electro-hydraulic coupling assembly  and align it marking with the lower bolt hole

and align it marking with the lower bolt hole  , as shown in figure.

, as shown in figure.

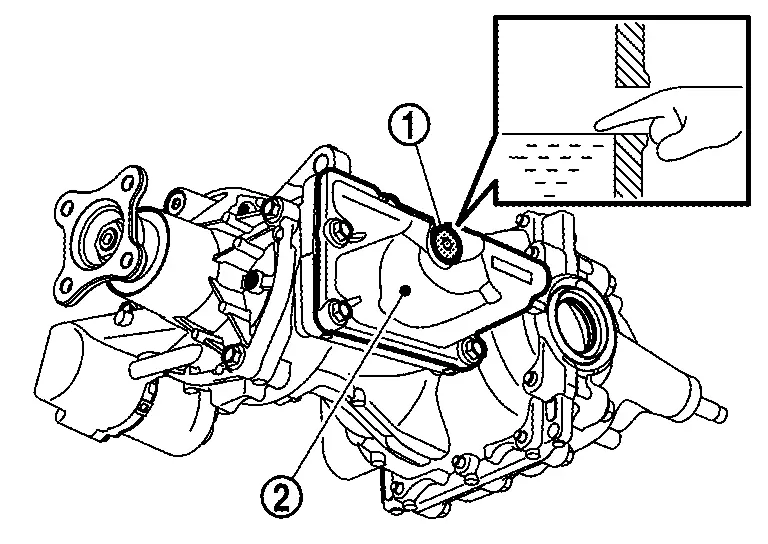

Install electro-hydraulic coupling assembly  to final drive assembly

to final drive assembly  .

.

CAUTION:

Aligning marking on drum of electro-hydraulic coupling assembly and marking on tip of drive pinion.

-

Keep the aligning marking aligned with the lower bolt hole, as close as possible, while installing electro-hydraulic coupling assembly.

-

It may be necessary to slightly rotate companion flange during installation, to align the splines.

Tighten electro-hydraulic coupling assembly mounting bolts to the specified torque diagonally.

-

For tightening torque, refer to Exploded View.

CAUTION:

Check that electro-hydraulic coupling assembly is seated fully on final drive assembly before installing mounting bolts.

Connect harness connector of actuator assembly  .

.

-

Push lock tab

inward to engage the connector.

inward to engage the connector.

Install propeller shaft to rear final drive companion flange. Refer to Removal and Installation (CVJ-CVJ-C).

Refill electro-hydraulic coupling oil. Refer to Adjustment.

When replacing AWD control unit (integrated with actuator assembly of electro-hydraulic coupling assembly) or electro-hydraulic coupling assembly perform adjustment after installation. Refer to Adjustment.

Adjustment

ADJUSTMENT BEFORE REMOVAL

AWD Control Unit Part Number Saving

When replacing AWD control unit (integrated with actuator assembly of electro-hydraulic coupling assembly) and electro-hydraulic coupling assembly, perform AWD control unit part number saving. Refer to Description.

ADJUSTMENT AFTER INSTALLATION

AWD Control Unit Programming

When replacing AWD control unit (integrated with actuator assembly of electro-hydraulic coupling assembly) and electro-hydraulic coupling assembly, perform programming to AWD control unit. Refer to Description.

Electro-Hydraulic Coupling Oil Filling, Air Bleeding and Initialize Oil Deterioration Level

When the electro-hydraulic coupling oil is drained, such as when replacing or removing/installing electro-hydraulic coupling component parts, the air bleeding and initialize oil deterioration level of electro-hydraulic coupling oil is required after fill with new electro-hydraulic coupling oil.

Fill with electro-hydraulic coupling oil following the instructions below.

Remove filler plug  and gasket

and gasket  from coupling oil tank cover

from coupling oil tank cover  .

.

Fill with new electro-hydraulic coupling oil to specified amount.

| Specified amount | : Approx. 0.6  (1-1/4 US pt, 1 lmp pt) (1-1/4 US pt, 1 lmp pt) |

CAUTION:

-

Use LSC Transmission Fluid 12-301 or equivalent for electro-hydraulic coupling oil.

-

When using oil, allow the additives to diffuse well before use.

-

Oil that has been stored for 12 months can not be used.

NOTE:

NOTE:

Oil level should be level with bottom of filler plug mounting hole.

Set the original gasket on filler plug, and install it to coupling oil tank cover.

NOTE:

NOTE:

The gasket will be replaced to new one at a later work.

Tighten filler plug to the specified torque. Refer to Exploded View.

Perform air bleeding and initialize oil deterioration level of electro-hydraulic coupling oil. Refer to Description.

Check oil level for electro-hydraulic coupling oil again.

NOTE:

NOTE:

The oil level may be reduced after air bleeding.

Check oil level from filler plug mounting hole as shown in the figure after removing filler plug and gasket from coupling oil tank cover

and gasket from coupling oil tank cover  .

.

CAUTION:

Turn the ignition switch OFF while checking oil level.

-

Oil level should be level with bottom of filler plug mounting hole. Add electro-hydraulic coupling oil if necessary.

CAUTION:

Never reuse gasket.

Tighten filler plug to the specified torque. Refer to Exploded View.Air Breather

Exploded View

|

Breather assembly (1-way) |  |

Coupling breather tube |  |

Coupling breather hose assembly |

|

Rear final drive assembly | ||||

: N·m (kg-m, in-lb) : N·m (kg-m, in-lb) |

|||||

: Always replace after every disassembly. : Always replace after every disassembly. |

|||||

Removal and Installation

REMOVAL

Final Drive Side

Remove breather assembly (1-way) from rear final drive assembly.

-

When removing/installing breather assembly (1-way), remove rear final drive assembly from the Nissan Ariya vehicle. Refer to Removal and Installation.

Electro-hydraulic Coupling Side

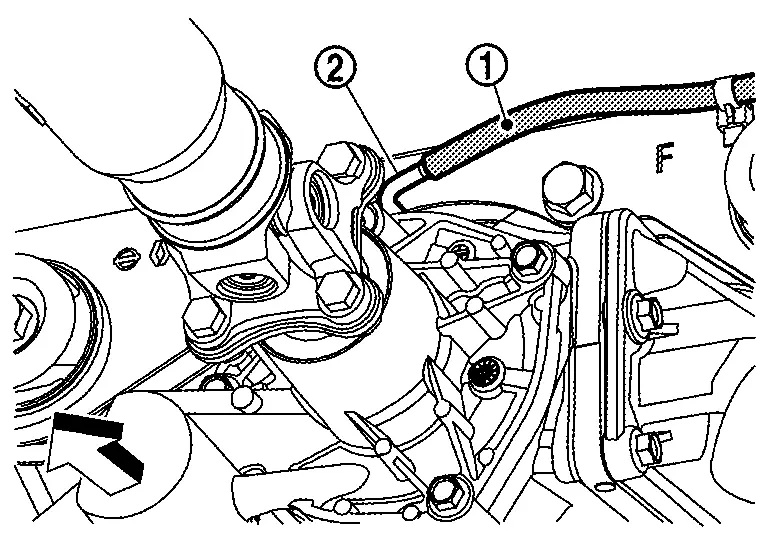

Remove coupling breather hose assembly  from coupling breather tube

from coupling breather tube  .

.

|

: Nissan Ariya Vehicle front |

Remove clip  of coupling breather hose assembly from final drive mounting bracket.

of coupling breather hose assembly from final drive mounting bracket.

|

: Nissan Ariya Vehicle front |

Remove left rear tire. Refer to Removal and Installation.

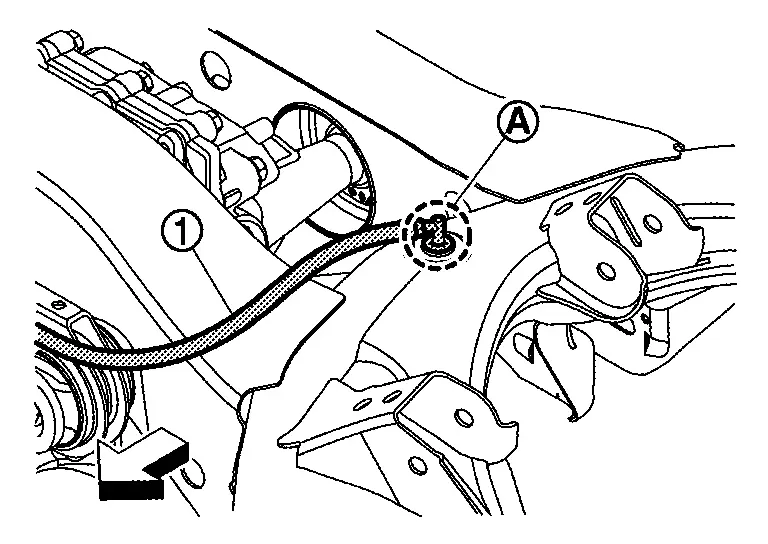

Remove breather connector part  from suspension member and remove coupling breather hose assembly

from suspension member and remove coupling breather hose assembly  .

.

|

: Nissan Ariya Vehicle front |

Remove rear final drive assembly from the vehicle. Refer to Removal and Installation.

Remove coupling breather tube mounting bolt and remove coupling breather tube  with O-ring.

with O-ring.

INSTALLATION

Note the following, and install in the reverse order of removal.

-

For non-reusable parts, refer to Exploded View.

-

When installing air breather hose, make sure there are no pinched or restricted areas on air breather hose caused by bending or winding.

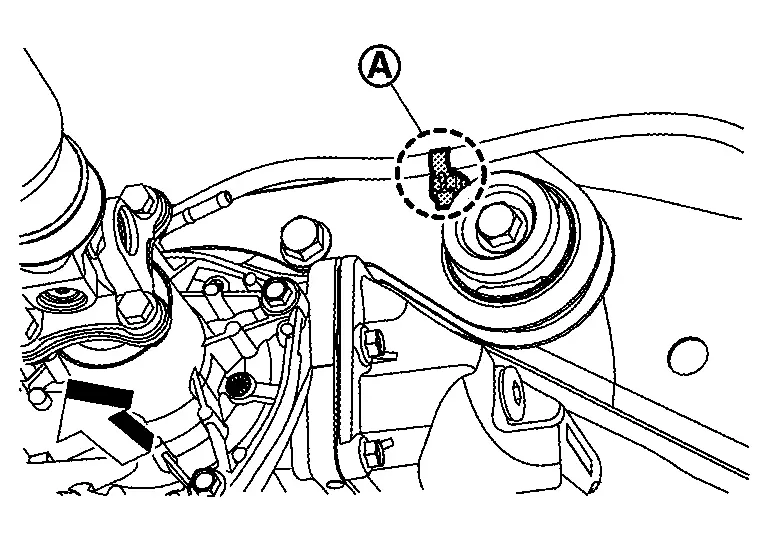

Final Drive Side

-

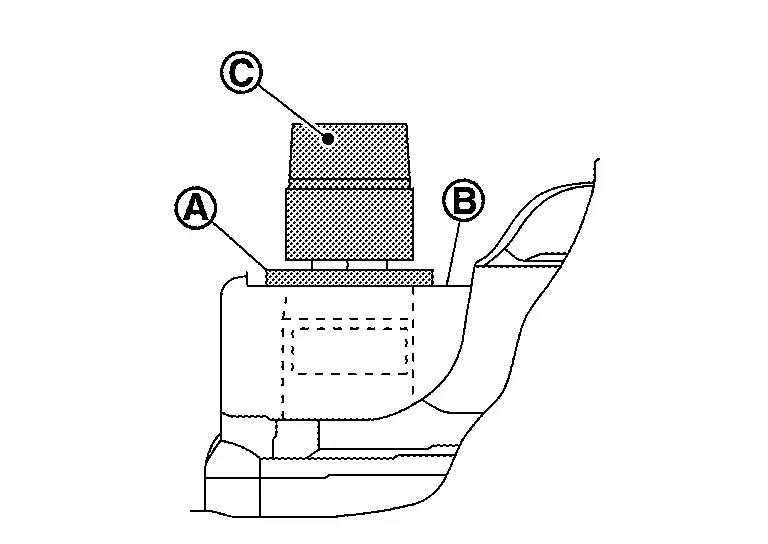

Breather assembly (1-way) must be press fitted until whole circumference of flange

reach the surface

reach the surface  of rear cover.

of rear cover.

CAUTION:

Never press the cap

.

.

Electro-hydraulic Coupling Side

-

When installing coupling breather tube, make sure there are no damage on O-ring.

NOTE:

NOTE:

In case of difficult insertion, apply electro-hydraulic coupling oil (genuine part) to O-ring.

-

When installing coupling breather hose assembly, loosely tighten bolt by hand. Secondly, tighten to the specified torque. Refer to Exploded View.

-

Securely install breather connector part

of coupling breather hose assembly to suspension member

of coupling breather hose assembly to suspension member  as shown in figure.

as shown in figure.

: Nissan Ariya Vehicle front -

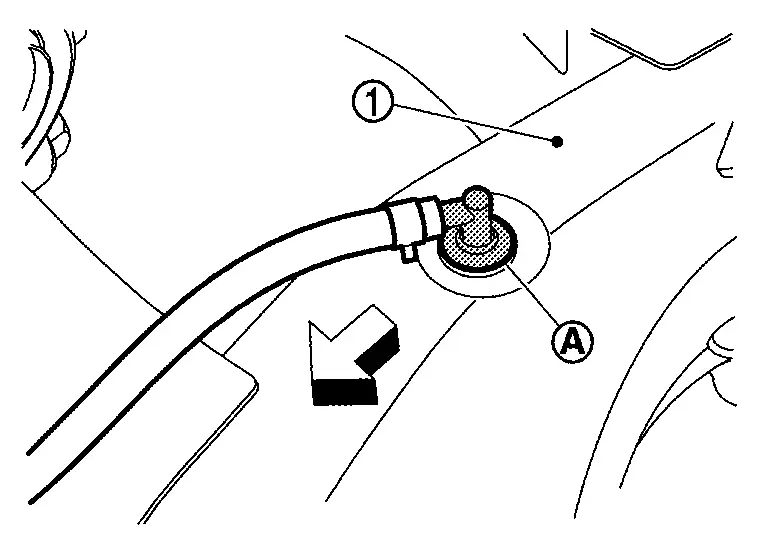

Set coupling breather hose assembly

with the paint mark

with the paint mark  facing upward, and install it to coupling breather tube

facing upward, and install it to coupling breather tube  all the way to the bulged part

all the way to the bulged part  .

.

: Nissan Ariya Vehicle front

NOTE:

NOTE:

If fastener  and rubber plug

and rubber plug  are attached, they are unnecessary and should be discarded.

are attached, they are unnecessary and should be discarded.

Other materials:

Dtc/circuit Diagnosis. B14e0-4a Wheel Sensor

DTC Description

DTC DETECTION LOGIC DTC No. CONSULT screen terms DTC detection condition

B14E0

4A

Wheel sensor

Diagnosis condition

Ignition switch is ON.

Signal (terminal)

Front left wheel sensor signal

Threshold

When front left wheel sensor is installed to wrong po ...

Dtc/circuit Diagnosis. B203d-14 Inside Antenna

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC detecting condition

B203D-14

Inside antenna

(Inside antenna)

Diagnosis condition

Work supports “Inside/outside antenna diagnosis”: activated

Signal (terminal)

Inside key an ...

B24f4-14 Heated Steering Wheel Relay

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

B24F4-14

Heated steering wheel relay

(Heated steering wheel relay)

Diagnosis condition

Ignition switch ON

Signal (Terminal)

Heated steering wheel relay cont ...