Nissan Rogue (T33) 2021-Present Service Manual: P04db Crankcase Ventilation System

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P04DB | 00 |

Crankcase Ventilation System Hose Disconnection (Crankcase Ventilation System Disconnected) |

Diagnosis condition | The intake system failuer ratio exceeds specified value. |

| Signal | ŌĆö | |||

| Threshold | The intake system failuer ratio exceeds specified value. | |||

| Diagnosis delay time | 10 seconds | |||

POSSIBLE CAUSE

-

PCV hose failure

-

PCV valve failure

-

Intake air leaks

-

Intake system failure

(Mass air flow sensor, electric throttle control actuator, intake manifold)

-

Fuel system failure

[Incorrect fuel pressure, fuel injector, air fuel ratio (A/F) sensor 1]

FAIL-SAFE

Engine Control System

Not applicable

Stop/Start System

Not applicable

DTC CONFIRMATION PROCEDURE

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

-

Ignition switch OFF and wait at least 10 seconds.

-

Ignition switch ON.

-

Ignition switch OFF and wait at least 10 seconds.

>>

GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE

-

Start engine and warm it up to the normal operating temperature.

-

Let engine idle.

-

Check DTC.

Is DTC detected?

YES>>Proceed to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

CHECK FOR INTAKE AIR LEAK

-

Listen for an intake air leak after the mass air flow sensor.

-

Check the following.

-

Air leak from intake pipe or intake hose

-

Incorrect PCV hose connection

-

Air leak from electric throttle control actuator

-

Air leak from intake manifold

-

Is intake air leak detected?

YES>>GO TO 2.

NO>>Repair or replace malfunctioning part.

CHECK OIL LEVEL GAUGE

Check installation condition of oil level gauge.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace error-detected parts.

CHECK BLOW-BY HOSE

Check blow-by hose (fresh air hose and PCV valve hose) for disconnected or damege.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace error-detected parts.

CHECK CRANKCASE, ROCKER COVER, AND FRONT COVER

Visually check crankcase, rocker cover, and front cover for damege.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Replace the error-detected parts.

CHECK PCV VALVE

Check the PCV valve. Refer to POSITIVE CRANKCASE VENTILATION : Periodic Maintenance.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Replace PCV valve. Refer to Exploded View.

CHECK CRANKCASE VENTILATION VALVE

Check crankcase ventilation valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 7.

NO>>Repair or replace error-detected parts.

CHECK CRANKCASE PRESSURE SENSOR

Check the crankcase pressure sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Replace crankcase pressure sensor. Refer to Exploded View.

CHECK AIR FUEL RATIO (A/F) SENSOR 1

Check air fuel ratio (A/F) sensor 1. Refer to

Is the inspection result normal?

YES>>GO TO 9.

NO>>Repair or replace error-detected parts.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Check air fuel ratio (A/F) sensor 1 heater. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 10.

NO>>Repair or replace error-detected parts.

CHECK MASS AIR FLOW SENSOR

Check mass air flow sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 11.

NO>>Repair or replace error-detected parts.

CHECK FUEL PRESSURE

Check fuel pressure. Refer to Work Procedure.

Is the inspection result normal?

YES>>GO TO 12.

NO>>GO TO 13.

DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES>>Replace ŌĆ£fuel level sensor unit and fuel pumpŌĆØ. Refer to Removal and Installation.

NO>>Repair or replace error-detected parts.

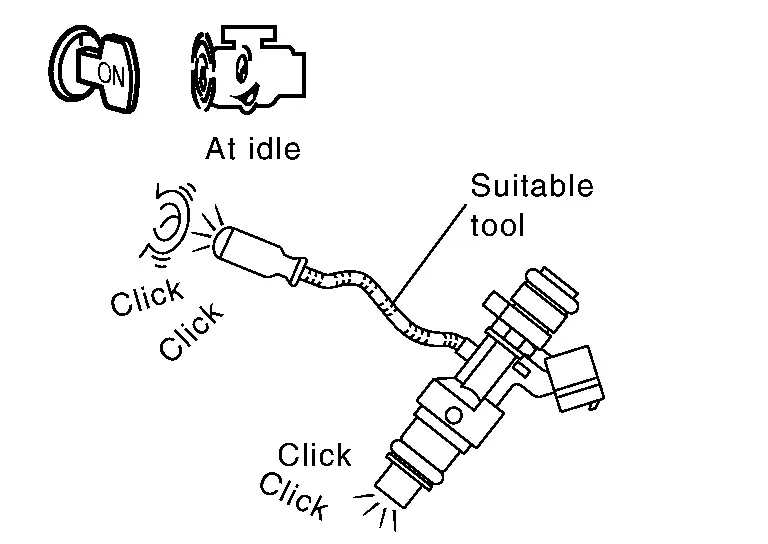

CHECK FUNCTION OF FUEL INJECTOR

With CONSULT

With CONSULT

-

Start engine.

-

Perform ŌĆ£POWER BALANCEŌĆØ in ŌĆ£Active testŌĆØ mode of ŌĆ£ECMŌĆØ.

-

Make sure that each circuit produces a momentary engine speed drop.

Clicking sound should be heard.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Perform trouble diagnosis for FUEL INJECTOR, Refer to Diagnosis Procedure.

Other materials:

Dtc/circuit Diagnosis. C1731-68 Tire Pressure Sensor Fl

DTC Description

NOTE:

The Signal Tech II Tool [ŌĆō (NI-50190)] can be used to

perform the following functions: Refer to the Signal Tech II User Guide

for additional information.

Activate and display TPMS sensor IDs

Display tire pressure reported by the TPMS sensor

Read TPMS DTCs ...

Manual operation

Fan speed control:

Press to increase or decrease fan speed manually.

Air intake control:

Each press of toggles between:

Recirculated air (indicator ON)

Outside air (indicator OFF)

Press and hold for 2 seconds to return to AUTO intake control

Air flow control:

Press to select:

ŌĆō Center ...

Usb Charge Port. System Description. Component Parts

Component Parts

Usb Charge Port

Component Parts Location

A -1

TYPE 1

A -2

TYPE 2

A -3

TYPE 3

No.Component

1.

Rear USB charge port

USB Charge Port

USB Charge PortSupply DC 5V from the (USB) port.Specification Rated voltage

’╝łV’╝ē

5

Maximum electric capacity

’╝łW’╝ē ...