Nissan Rogue (T33) 2021-Present Service Manual: Led Headlamp :: Basic Inspection

Diagnosis and Repair Work Flow

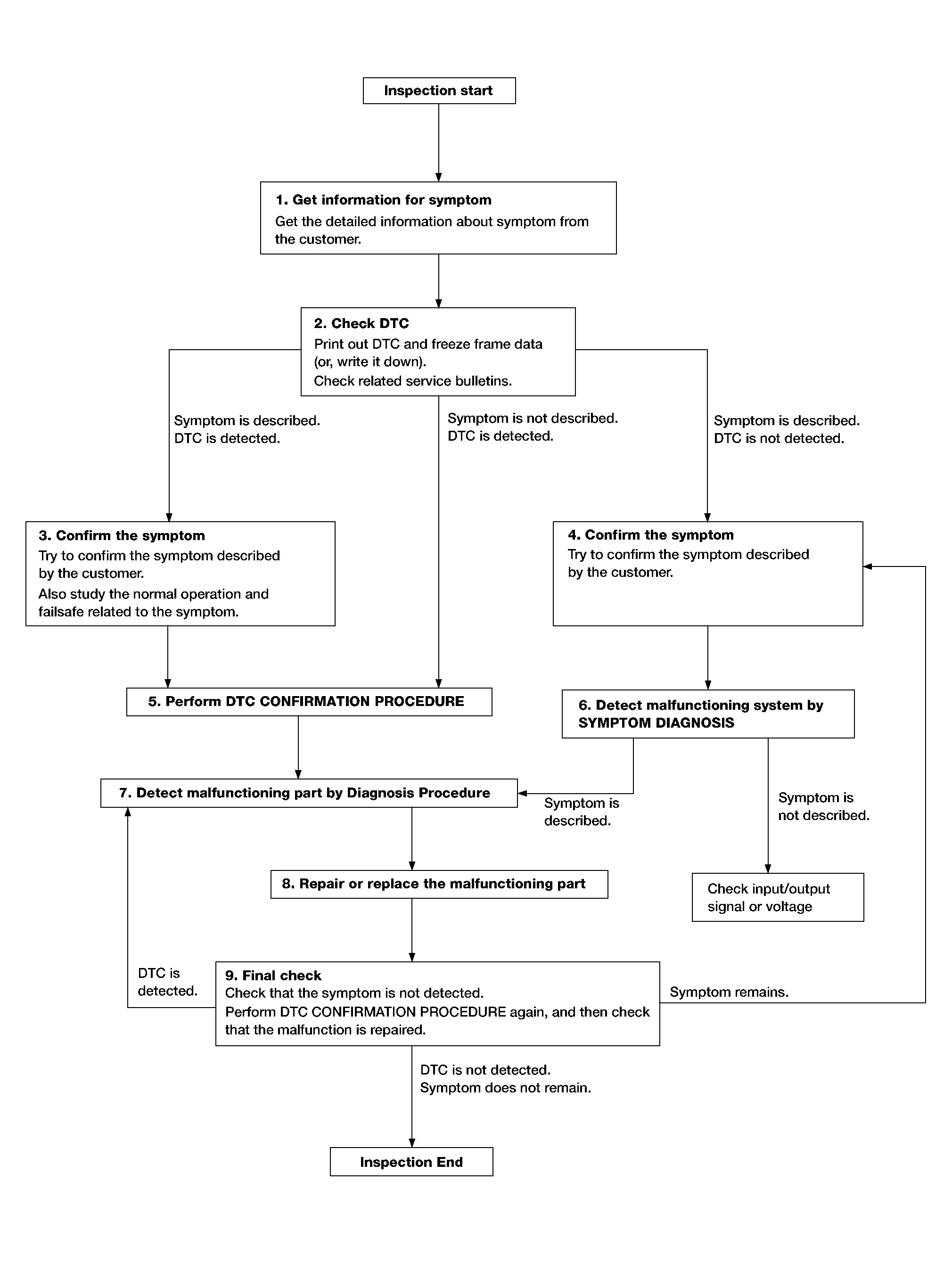

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

GET INFORMATION FOR SYMPTOM

-

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurs).

-

Check operation condition of the function that is malfunctioning.

>>

GO TO 2.

CHECK DTC

CONSULT

CONSULT

-

Check DTC.

-

Perform the following procedure if DTC is detected:

-

Record DTC and freeze frame data (print them out).

-

Erase DTC.

-

Study the relationship between the cause detected by DTC and the symptom described by the customer.

-

Are any symptoms described and any DTC detected?

Symptom is described, DTC is detected>>GO TO 3.

Symptom is described, DTC is not detected>>GO TO 4.

Symptom is not described, DTC is detected>>GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Also study the normal operation and fail-safe related to the symptom.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 5.

CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Verify relation between the symptom and the condition when the symptom is detected.

>>

GO TO 6.

PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC CONFIRMATION PROCEDURE for the detected DTC, and then check that DTC is detected again. At this time, always connect CONSULT to the Nissan Ariya vehicle, and check self diagnosis result in real time.

If two or more DTCs are detected, refer to DTC INSPECTION PRIORITY CHART, and determine trouble diagnosis order.

NOTE:

NOTE:

-

Freeze frame data is useful if the DTC is not detected.

-

Perform Component Function Check if DTC CONFIRMATION PROCEDURE is not included on Service Manual. This simplified check procedure is an effective alternative though DTC cannot be detected during this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC CONFIRMATION PROCEDURE.

Is DTC detected?

YES>>GO TO 7.

NO>>Check according to Intermittent Incident.

DETECT MALFUNCTIONING SYSTEM BY SYMPTOM DIAGNOSIS

CONSULT

CONSULT

Detect malfunctioning system according to SYMPTOM DIAGNOSIS based on the confirmed symptom in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

Is the symptom described?

YES>>GO TO 7.

NO>>Monitor input data from related sensors or check voltage of related module terminals.

DETECT MALFUNCTIONING PART BY DIAGNOSIS PROCEDURE

Inspect according to Diagnosis Procedure of the system.

Is malfunctioning part detected?

YES>>GO TO 8.

NO>>Check according to Intermittent Incident.

REPAIR OR REPLACE THE MALFUNCTIONING PART

-

Repair or replace the malfunctioning part.

-

Reconnect parts or connectors disconnected during Diagnosis Procedure again after repair and replacement.

-

Check DTC. If DTC is detected, erase it.

>>

GO TO 9.

FINAL CHECK

When DTC is detected in step 2, perform DTC CONFIRMATION PROCEDURE again, and then check that the malfunction is repaired securely.

When symptom is described by the customer, refer to confirmed symptom in step 3 or 4, and check that the symptom is not detected.

Is DTC detected and does symptom remain?

YES-1>>DTC is detected: GO TO 7.

YES-2>>Symptom remains: GO TO 4.

NO>>Before returning the Nissan Ariya vehicle to the customer, always erase DTC.

Led Headlamp Operation Inspection

Work Procedure

CHECK START

-

In the cool LED status (wait for more than 10 minutes after turning headlamp OFF), turn ON and turn OFF headlamp for the several times. Check that headlamp operates normally each time.

-

In the cool LED status, turn headlamp ON, wait until headlamp enters to the stable status (approximately 5 minutes after turning headlamp ON), and then check that headlamp operates normally without blinking or flickering.

-

In the warm LED status (turn headlamp ON for more than 15 minutes and wait for 1 minute after turning OFF), turn ON and turn OFF headlamp for the several times. Check that headlamp operates normally each time.

-

Turn headlamp ON for approximately 30 minutes, and then check that headlamp operates normally without difference in brightness between LH and RH, blinking or flickering.

Is the inspection result normal?

YES>>Inspection End.

NO>>Refer to Symptom Table.

Other materials:

U0402 Can Communication

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

U0402

00

Invalid data (TCM)

(Invalid Data Received From TCM)

Diagnosis condition

Ignition switch ON

Signal (terminal)

—

Threshold

When ECM is ...

Informations de base

Dans le Nissan Rogue, la sécurité enfant repose sur le bon choix du dispositif de retenue et sur une installation rigoureuse. Les recommandations ci-dessous complètent les consignes générales du manuel : elles visent à aider l’adulte à obtenir un montage stable, adapté à l’âge, au ...

Limites du système de sonar

AVERTISSEMENT

Les limites du système de sonar sont décrites ci-dessous. Le non-respect de ces limites lors de la conduite du Nissan Rogue peut entraîner des blessures graves, voire mortelles.

Lisez attentivement toutes les informations relatives aux limites du système de sonar présentées ...