Nissan Rogue (T33) 2021-Present Service Manual: Kr15ddt :: Removal and Installation

Fuel Level Sensor Unit, Fuel Filter and Fuel Pump Assembly

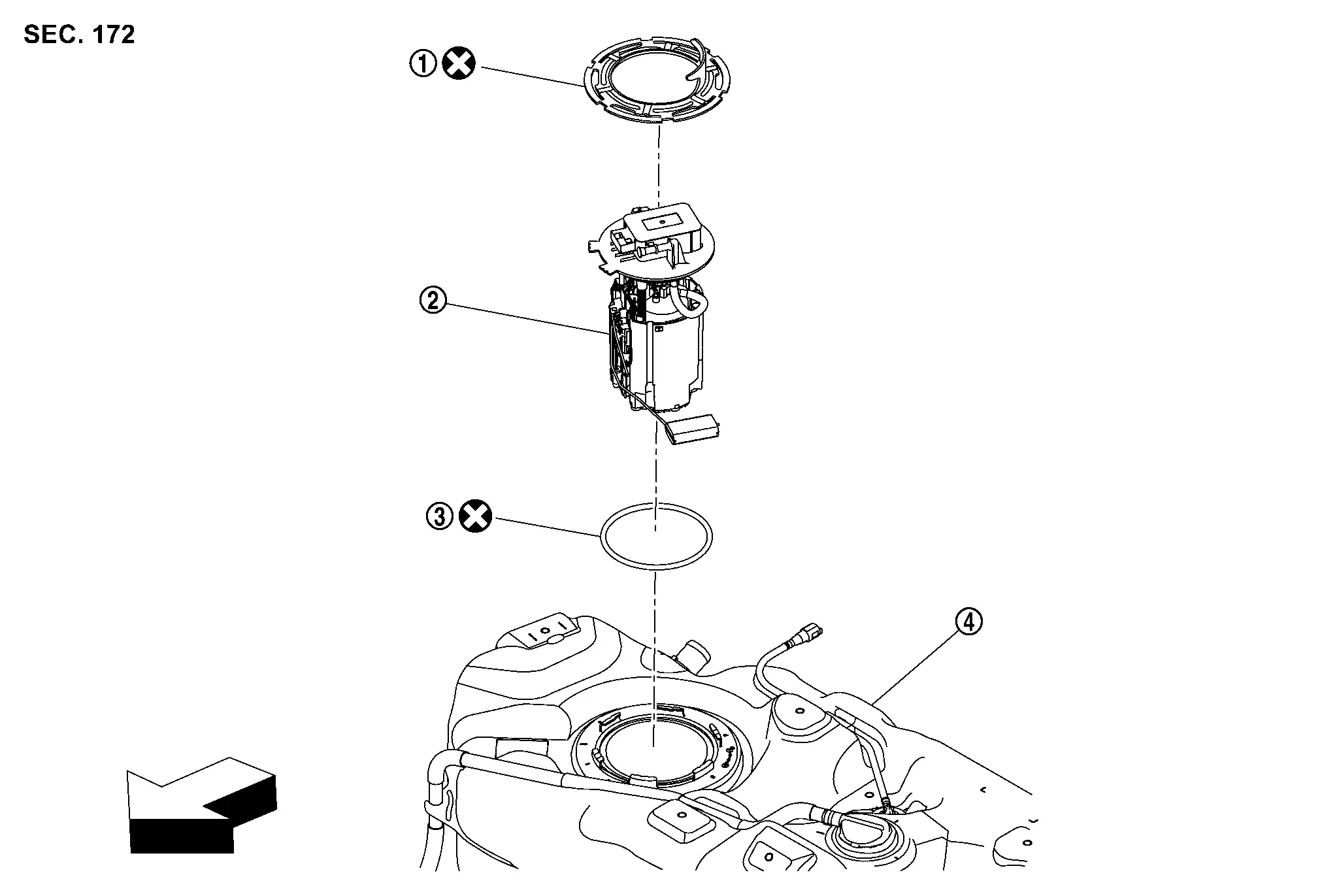

Exploded View

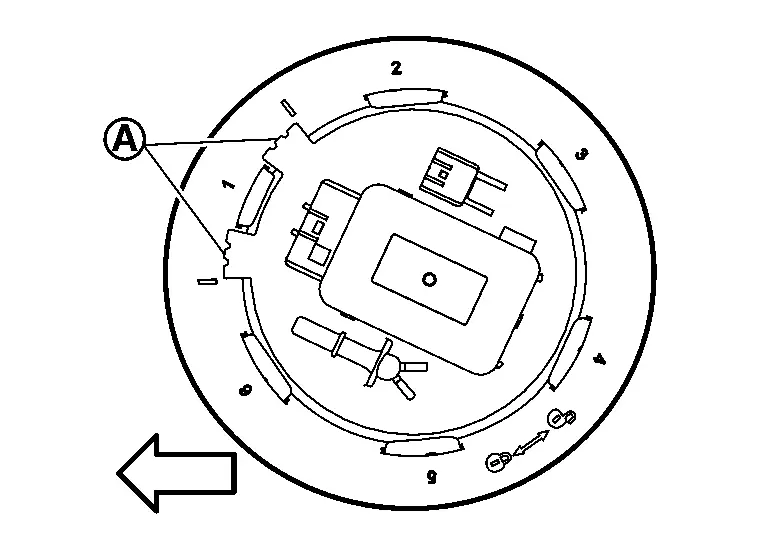

REMOVAL

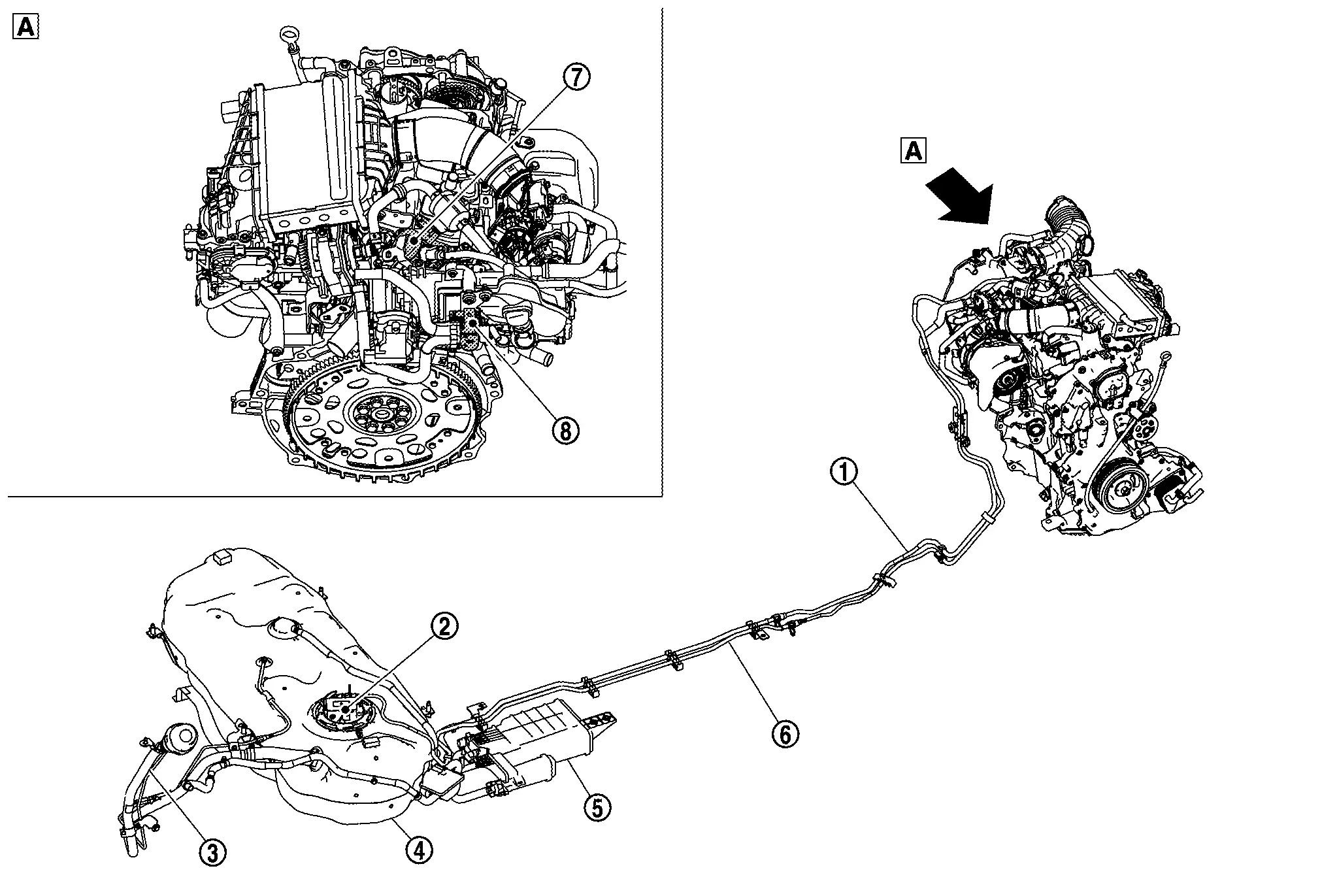

2WD

|

Lock ring |  |

Fuel level sensor unit, fuel filter and fuel pump assembly |  |

O-ring |

|

Fuel tank | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: Always replace after every disassembly. | ||||

CAUTION:

Never remove or disassemble parts unless instructed as shown in the figure.

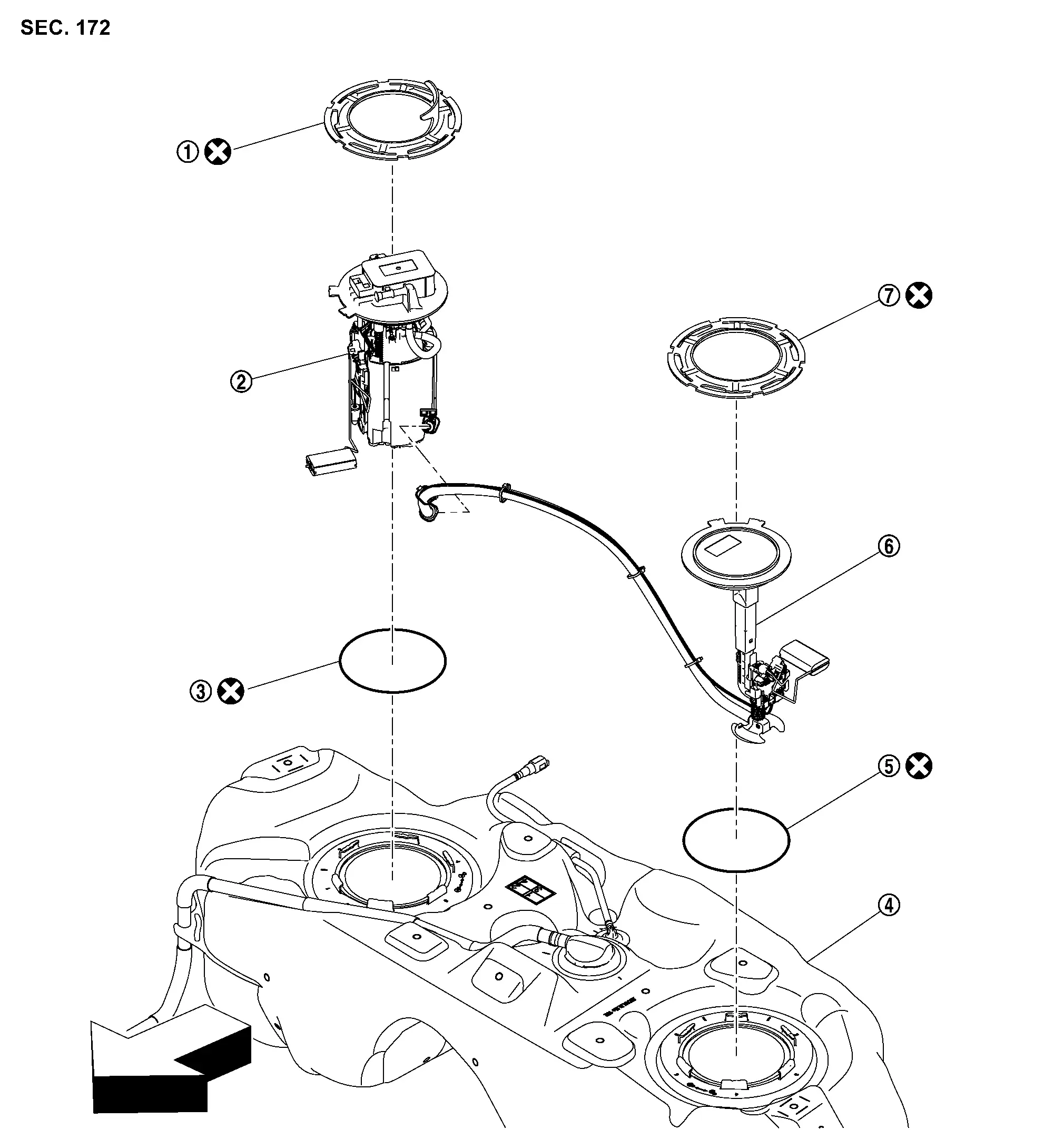

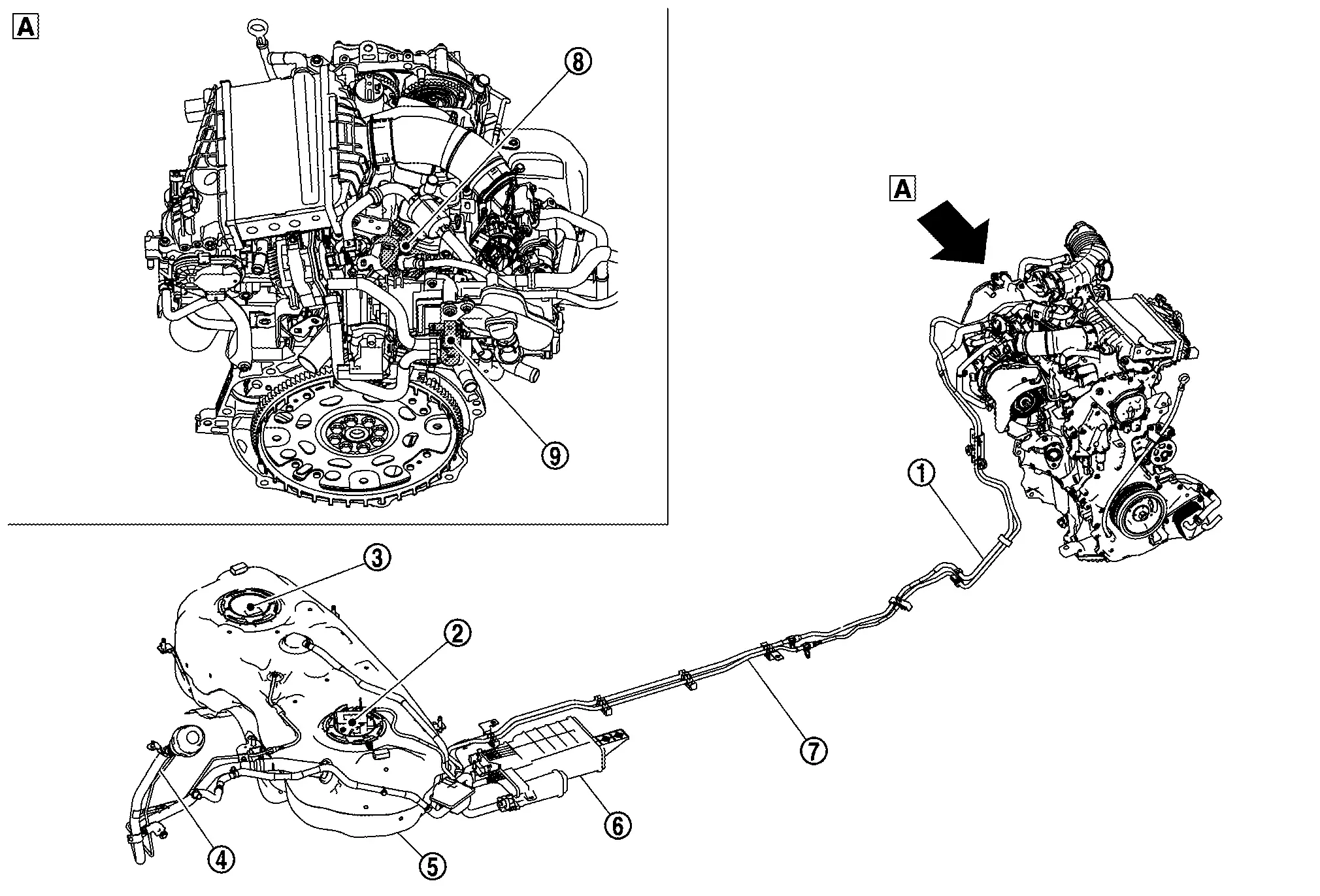

AWD

|

Lock ring |  |

Fuel level sensor unit, fuel filter and fuel pump assembly |  |

O-ring |

|

Fuel tank |  |

O-ring |  |

Sub fuel level sensor assembly |

|

Lock ring | ||||

|

: Nissan Ariya Vehicle front | ||||

|

: Always replace after every disassembly. | ||||

CAUTION:

Never remove or disassemble parts unless instructed as shown in the figure.

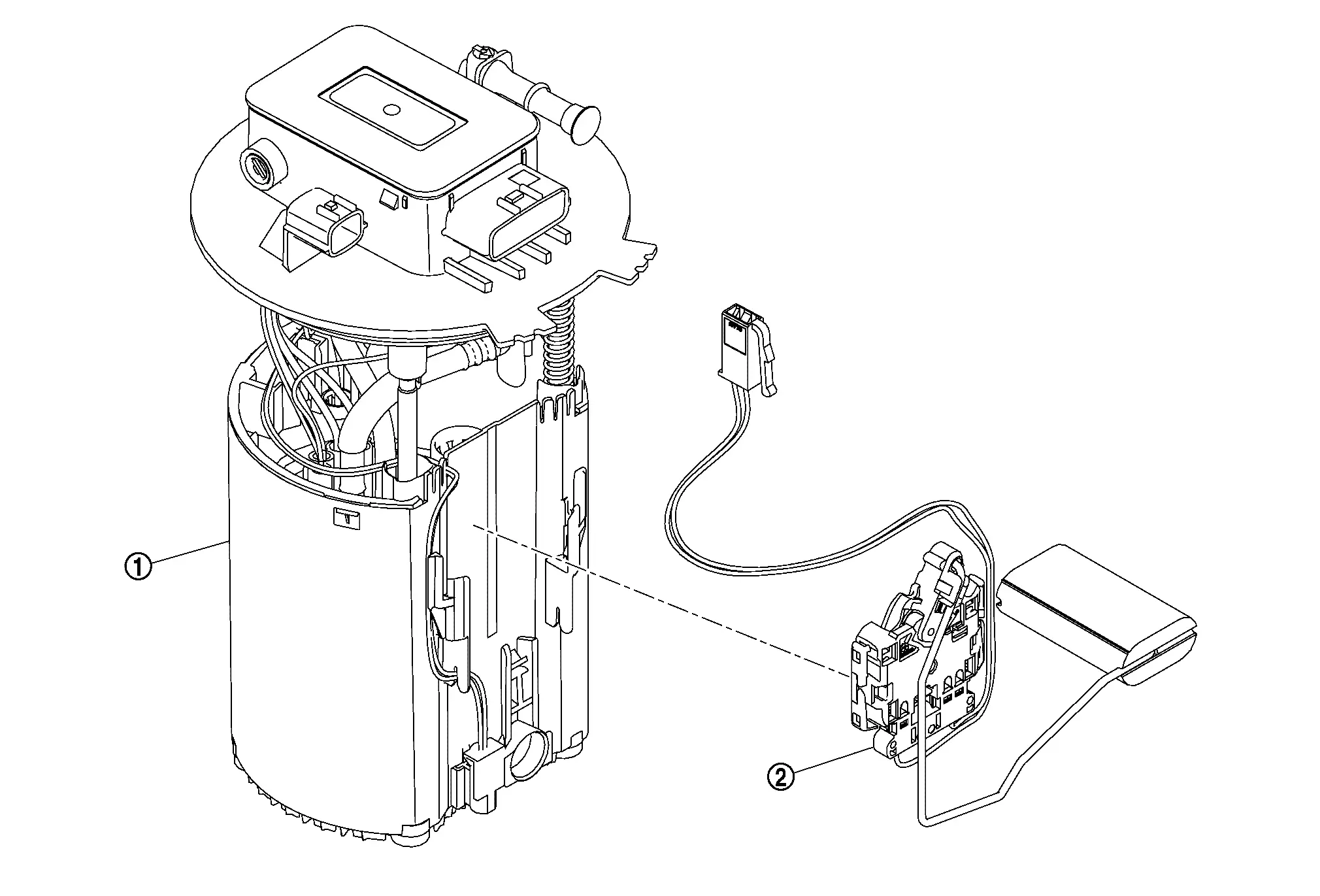

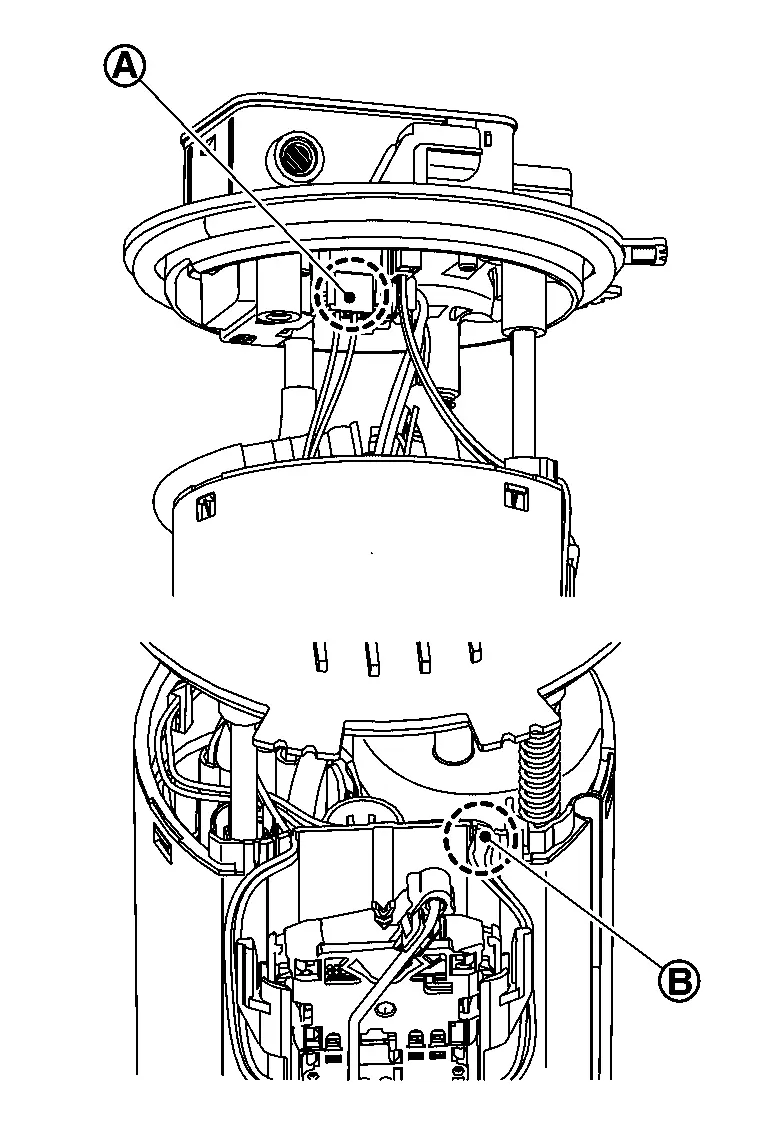

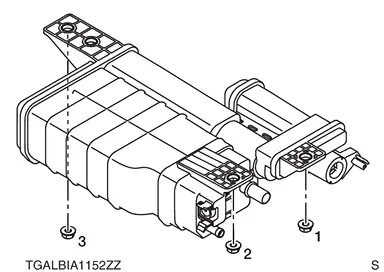

DISASSEMBLY

2WD

|

Fuel filter and fuel pump assembly |  |

Fuel level sensor unit |

AWD

NOTE:

NOTE:

Fuel level sensor unit cannot be disassembly from fuel level sensor unit, fuel filter and fuel pump assembly.

Removal and Installation

WARNING:

Read “General Precautions” when working on the fuel system. Refer to General Precautions.

REMOVAL

2WD

CAUTION:

Perform the operation with vehicle on level ground.

Release fuel pressure. Refer to Work Procedure.

Open fuel filler lid.

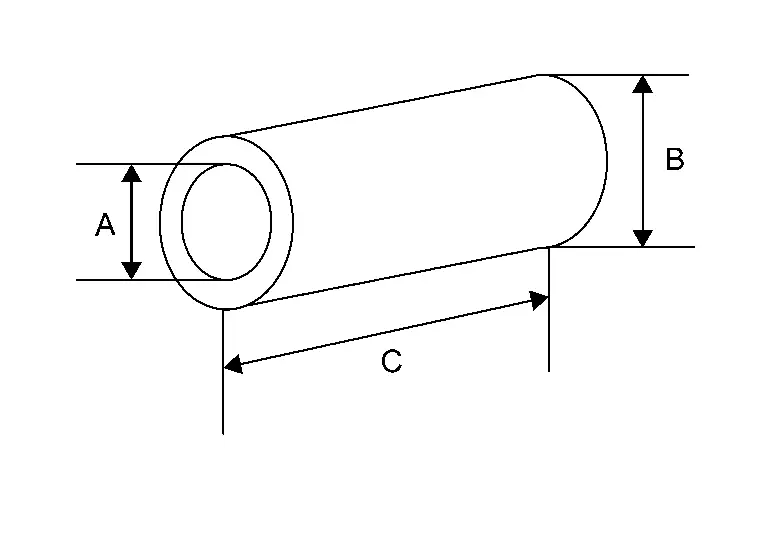

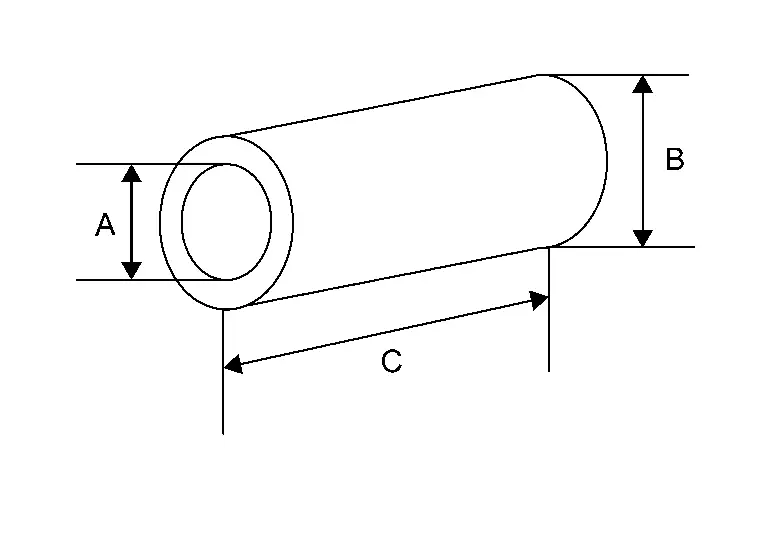

Insert a general purpose pipe with the dimensions shown in fuel filler cap less unit and release the pressure inside the fuel tank.

| A | : Over 16 mm (0.63 in) |

| B | : 21.0 mm (0.83 in) |

| C | : 150 mm (5.91 in) |

NOTE:

NOTE:

Insert and hold 80 mm (3.15 in) from the end of the general purpose pipe into the fuel filler port.

Check fuel level on a level ground. If the fuel level is 7/8 of the fuel tank (full or nearly full), draw appropriate amount of fuel from the fuel tank.

| Guideline | : Draw approximately 15 liters (4 US gal, 3-1/4 Imp gal) from a full-tank condition. |

In the event of malfunction in fuel pump, insert a hose measuring 16 mm (0.63 in) in diameter into the filler opening to draw approximately 15 liters (4 US gal, 3-1/4 Imp gal) fuel.

Remove rear seat cushion. Refer to Removal and Installation.

Remove inspection hole cover.

-

Using a screwdriver, remove it by turning clips clockwise by 90 degrees.

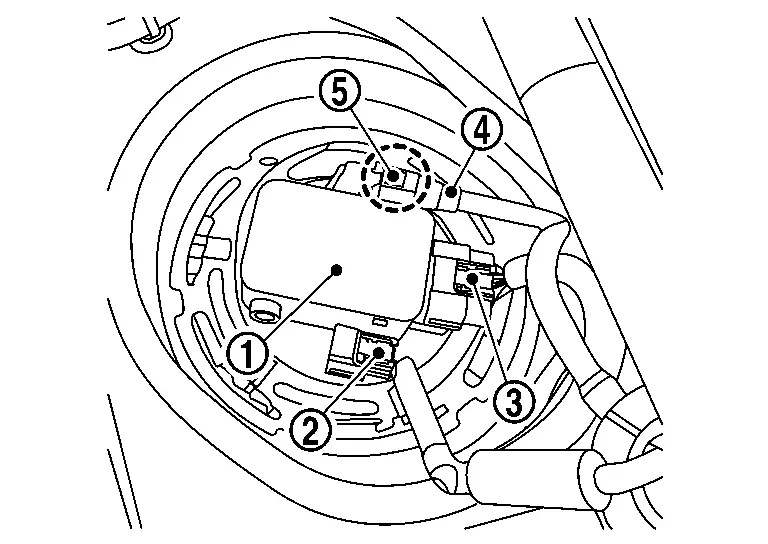

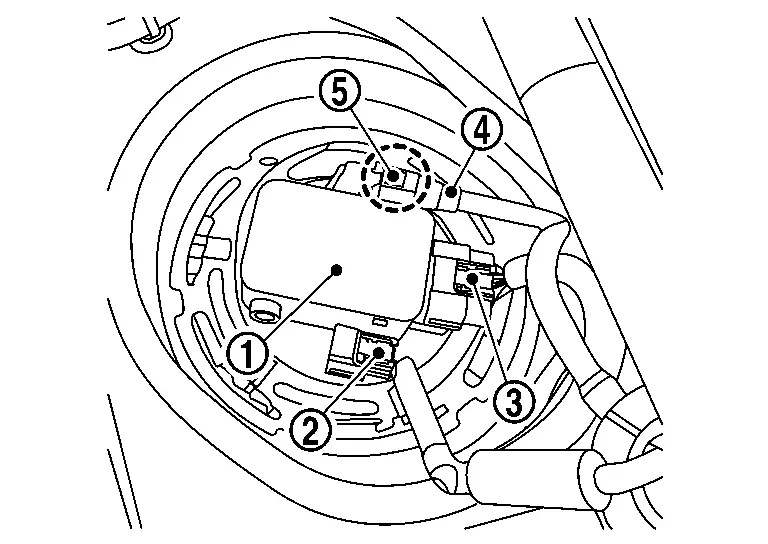

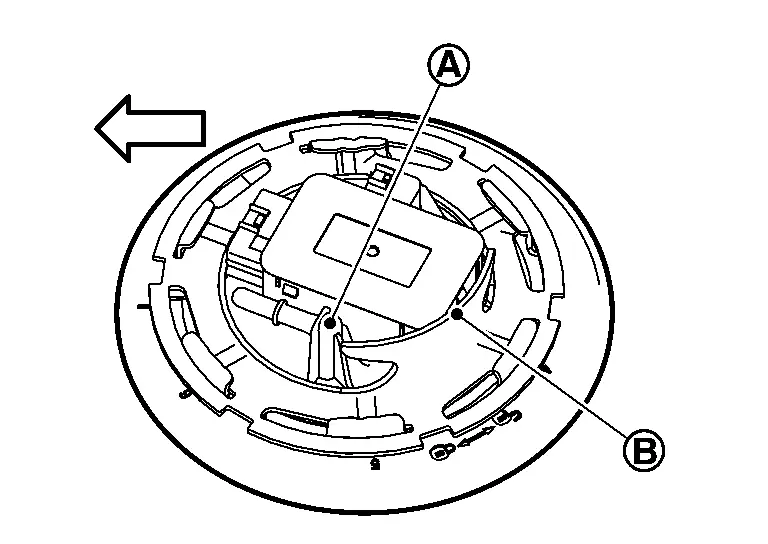

Disconnect harness connectors (2) and (3) and quick connector (5).

| 1. | : Fuel level sensor unit, fuel filter and fuel pump assembly |

| 4. | : Fuel feed tube |

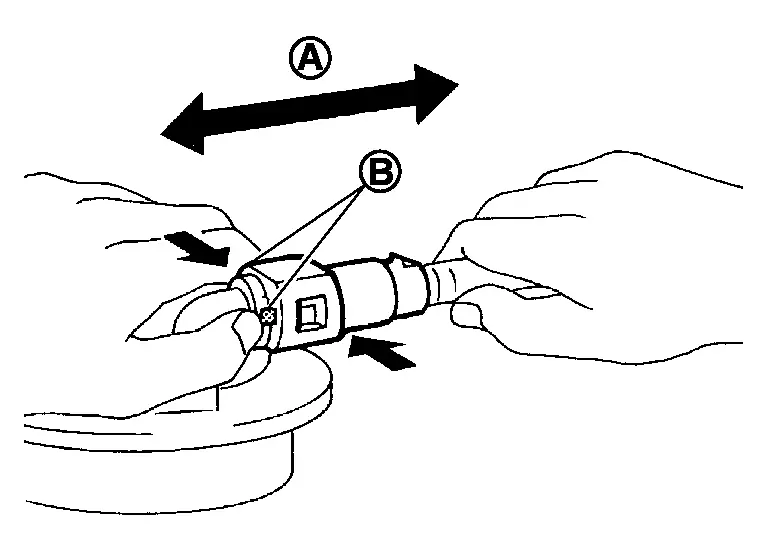

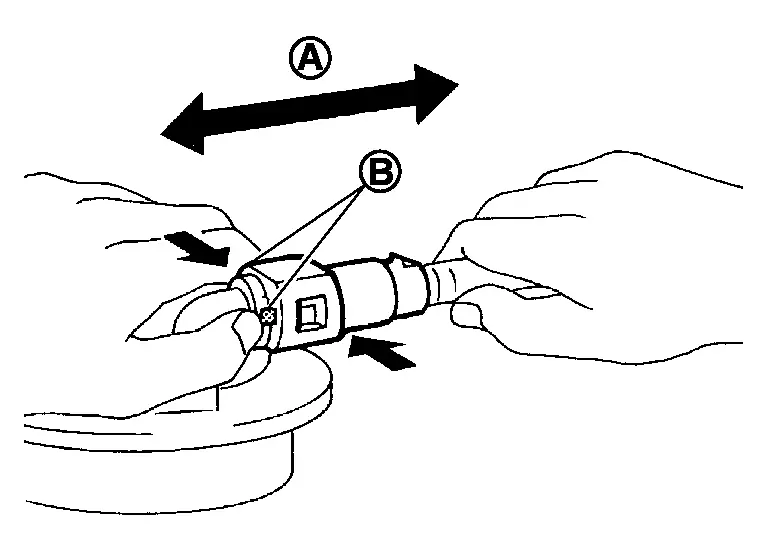

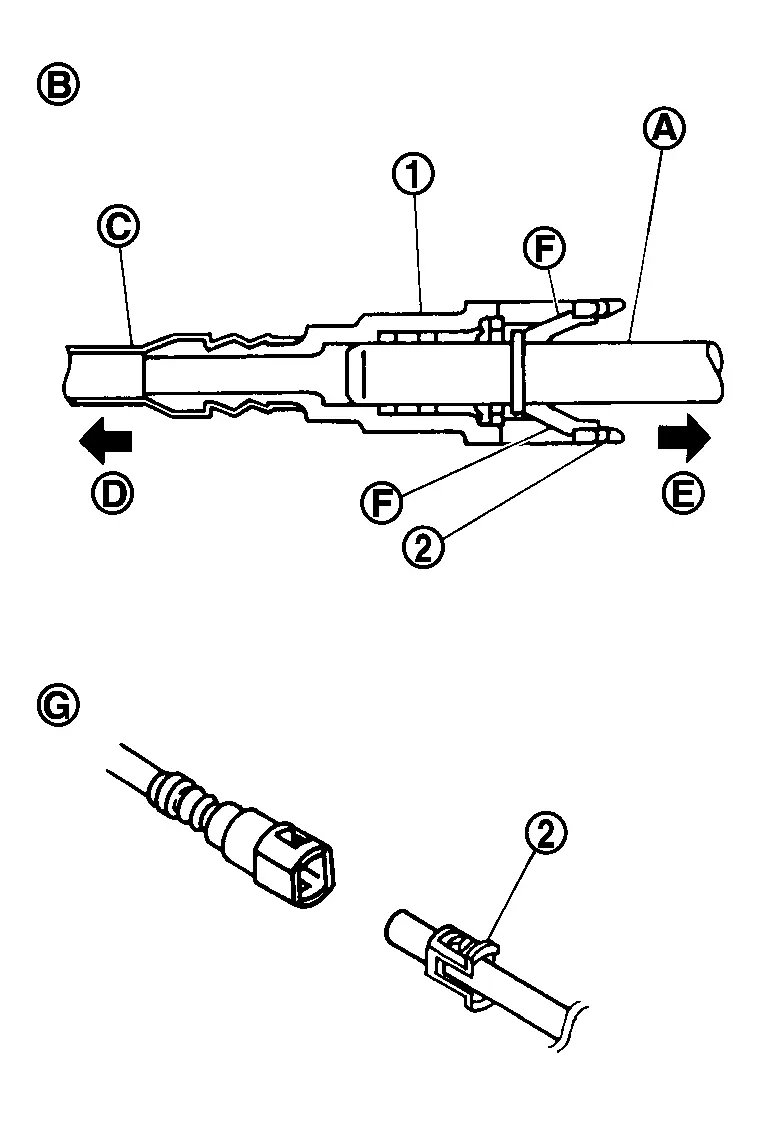

Disconnect quick connector as follows:

-

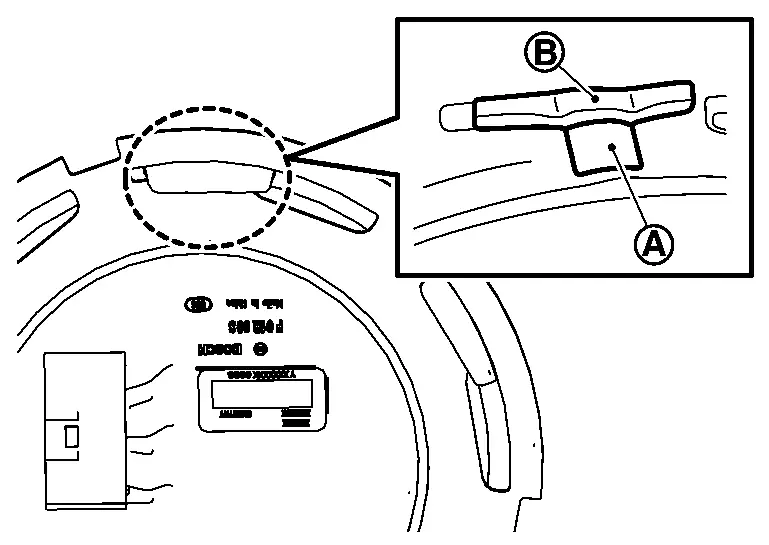

Hold the sides of connector, push in tabs (B) and pull out fuel feed tube.

A. : Pull -

If quick connector sticks to tube of fuel level sensor unit, fuel filter and fuel pump assembly, push and pull quick connector several times until they start to move. Then disconnect them by pulling.

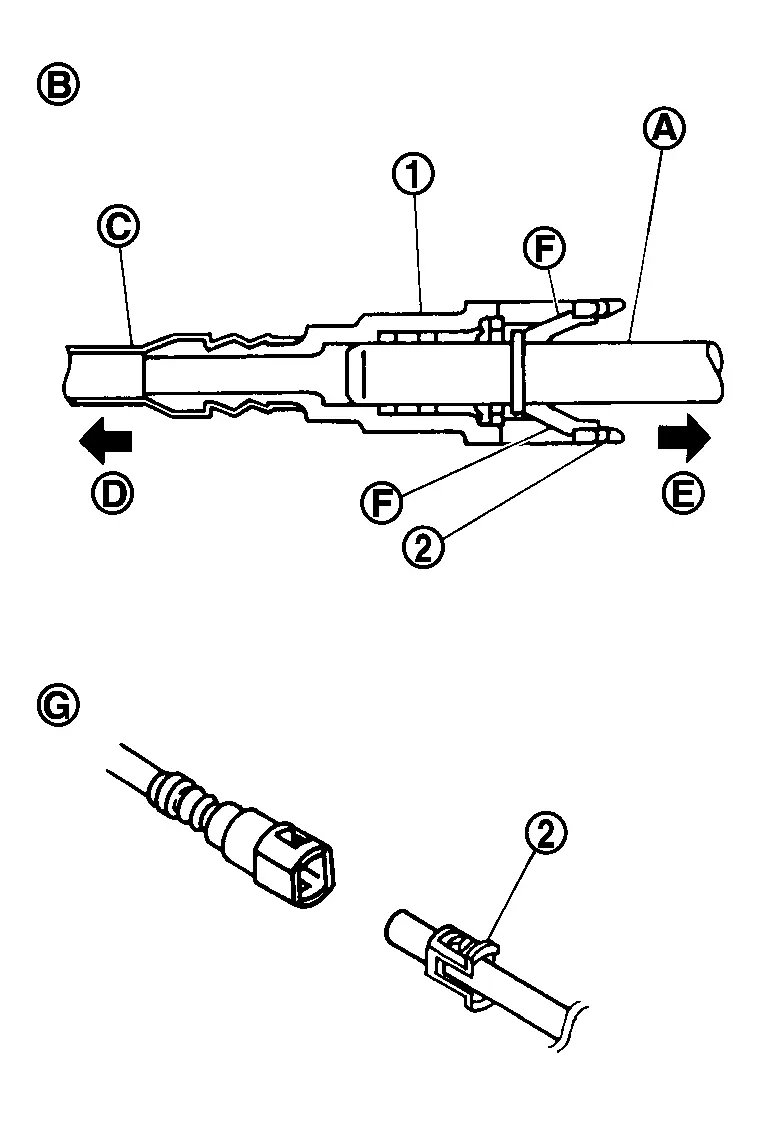

CAUTION:

-

Quick connector (1) can be disconnected when the tabs (F) are completely depressed. Never twist it more than necessary.

B. : Connection (cross-section) D. : To under floor fuel line E. : To fuel tank G. : Disconnection -

Never use any tools to disconnected quick connector.

-

Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

-

Prevent acid liquid such as battery electrolyte, etc. from getting on resin tube.

-

Never bend or twist resin tube during installation and disconnection.

-

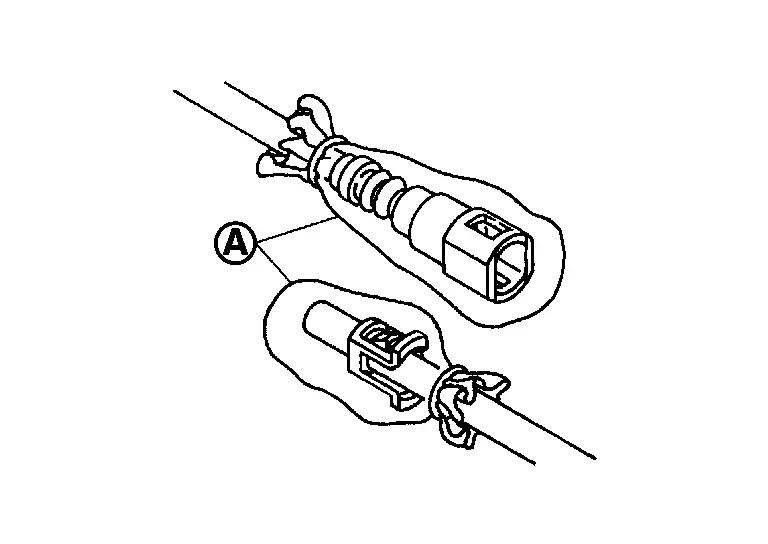

Never remove the remaining retainer (2) on hard tube (or the equivalent) (A) except when resin tube or retainer is replaced.

-

When resin tube or hard tube (or the equivalent) is replaced, also replace retainer with new one.

-

To keep the connecting portion clean and to avoid damage and foreign materials, cover them completely with plastic bags (A) or something similar.

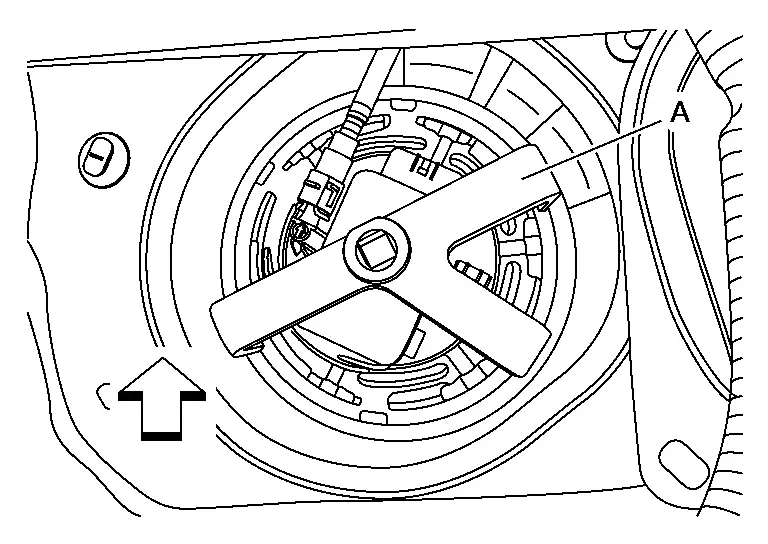

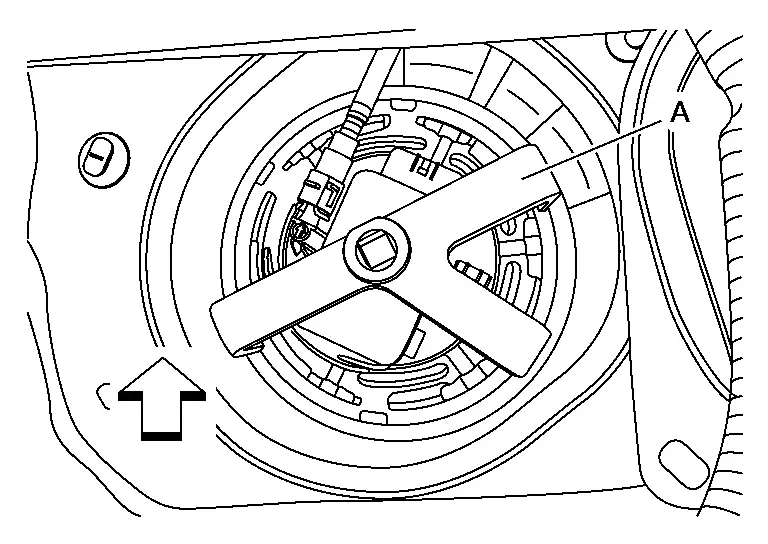

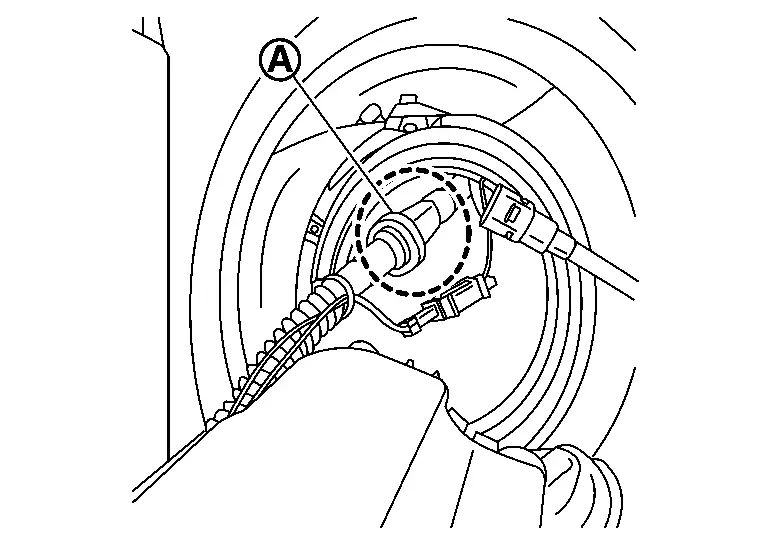

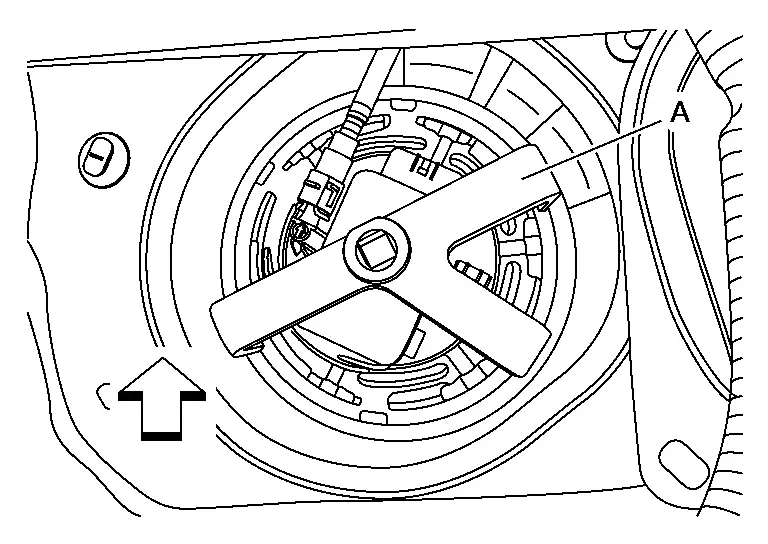

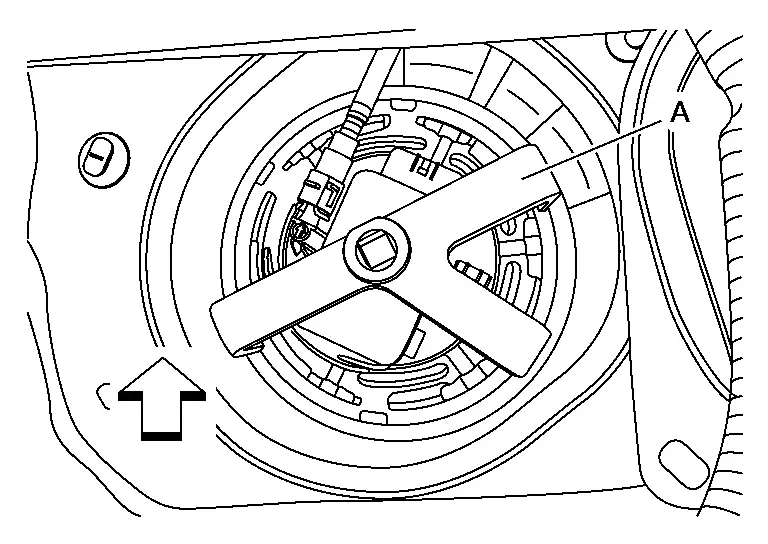

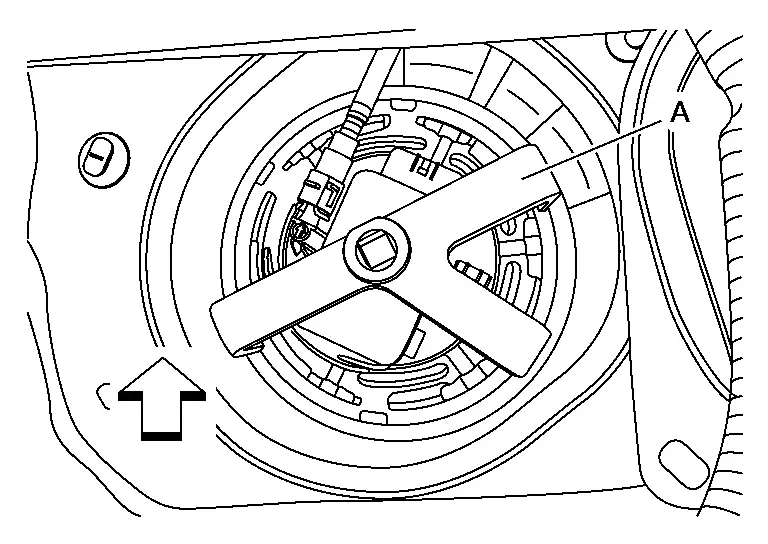

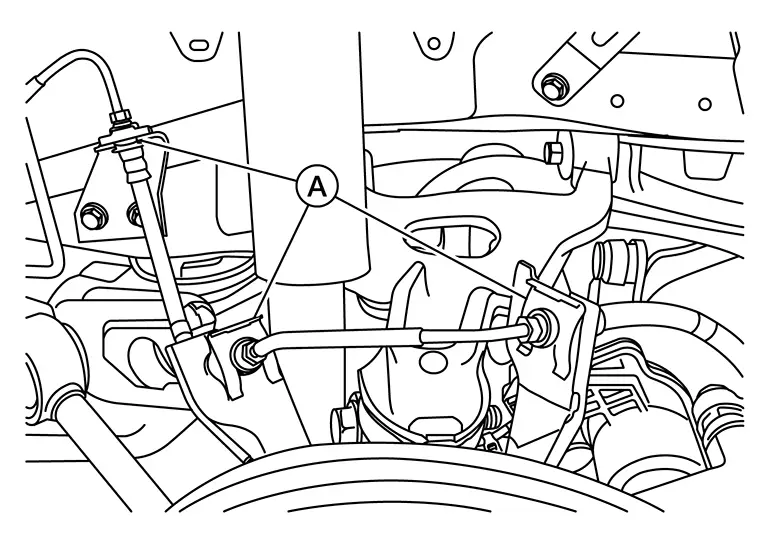

Remove lock ring from fuel level sensor, fuel filter, and fuel pump assembly using Tool (A).

| Tool number (A) |

: (NI-45747) (shown) : KV101207S0 |

|

: Front |

Remove fuel level sensor unit, fuel filter and fuel pump assembly.

AWD

CAUTION:

Perform the operation with vehicle on level ground.

Release fuel pressure. Refer to Work Procedure.

Open fuel filler lid.

Insert a general purpose pipe with the dimensions shown in fuel filler cap less unit and release the pressure inside the fuel tank.

| A. | : Over 16 mm (0.63 in) |

| B. | : 21.0 mm (0.83 in) |

| C. | : 150 mm (5.91 in) |

NOTE:

NOTE:

Insert and hold 80 mm (3.15 in) from the end of the general purpose pipe into the fuel filler port.

Check fuel level on a level ground. If the fuel level is 7/8 of the fuel tank (full or nearly full), draw appropriate amount of fuel from the fuel tank.

| Guideline | : Draw approximately 15 liters (4 US gal, 3-1/4 Imp gal) from a full-tank condition. |

In the event of malfunction in fuel pump, insert a hose measuring 16 mm (0.63 in) in diameter into the filler opening to draw approximately 15 liters (4 US gal, 3-1/4 Imp gal) fuel.

Remove rear seat cushion. Refer to Removal and Installation.

Remove inspection hole cover.

-

Using a screwdriver, remove it by turning clips clockwise by 90 degrees.

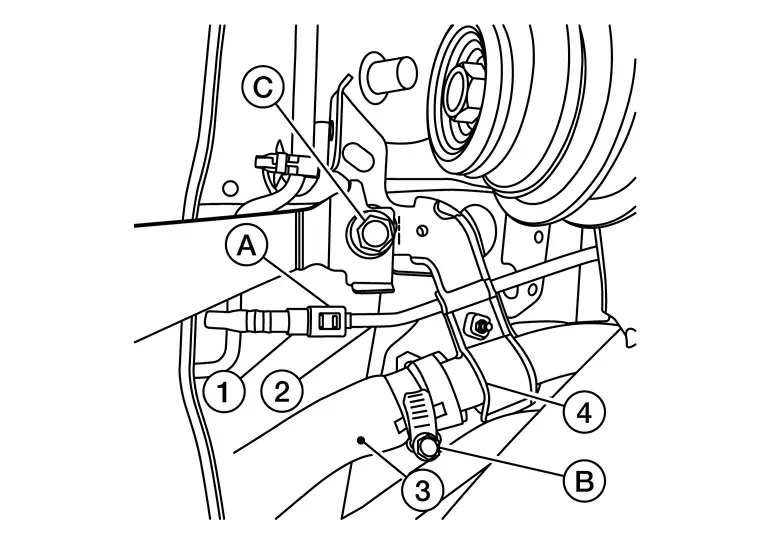

Disconnect harness connectors (2) and (3) and quick connector (5).

| 1. | : Fuel level sensor unit, fuel filter and fuel pump assembly |

| 4. | : Fuel feed tube |

Disconnect quick connector as follows:

-

Hold the sides of connector, push in tabs (B) and pull out fuel feed tube.

A. : Pull -

If quick connector sticks to tube of fuel level sensor unit, fuel filter and fuel pump assembly, push and pull quick connector several times until they start to move. Then disconnect them by pulling.

CAUTION:

-

Quick connector (1) can be disconnected when the tabs (F) are completely depressed. Never twist it more than necessary.

B. : Connection (cross-section) D. : To under floor fuel line E. : To fuel tank G. : Disconnection -

Never use any tools to disconnected quick connector.

-

Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

-

Prevent acid liquid such as battery electrolyte, etc. from getting on resin tube.

-

Never bend or twist resin tube during installation and disconnection.

-

Never remove the remaining retainer (2) on hard tube (or the equivalent) (A) except when resin tube or retainer is replaced.

-

When resin tube or hard tube (or the equivalent) is replaced, also replace retainer with new one.

-

To keep the connecting portion clean and to avoid damage and foreign materials, cover them completely with plastic bags (A) or something similar.

Remove lock ring from fuel level sensor, fuel filter, and fuel pump assembly using Tool (A).

| Tool number (A) |

: (NI-45747) (shown) : KV101207S0 |

|

: Front |

Raise fuel level sensor unit, fuel filter and fuel pump assembly.

CAUTION:

-

Never bend float arm during removal.

-

Never pollute the inside by residue fuel. Draw out avoiding inclination by supporting with a cloth.

-

Never cause impacts such by dropping when handling components.

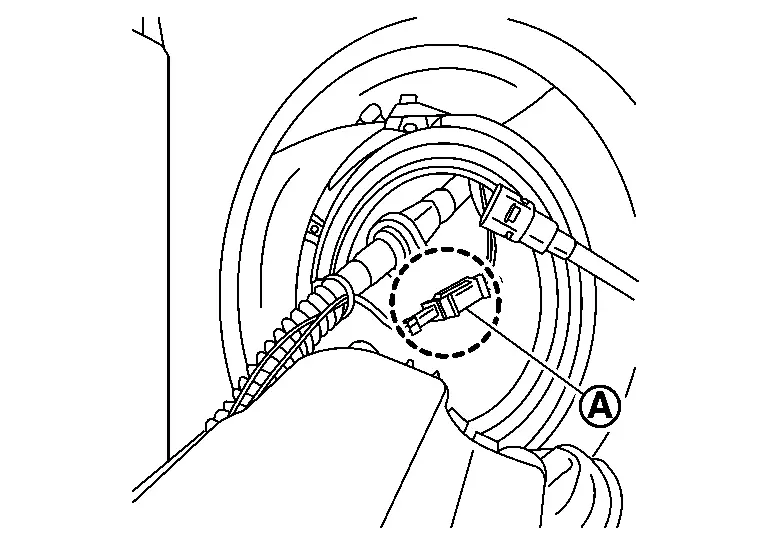

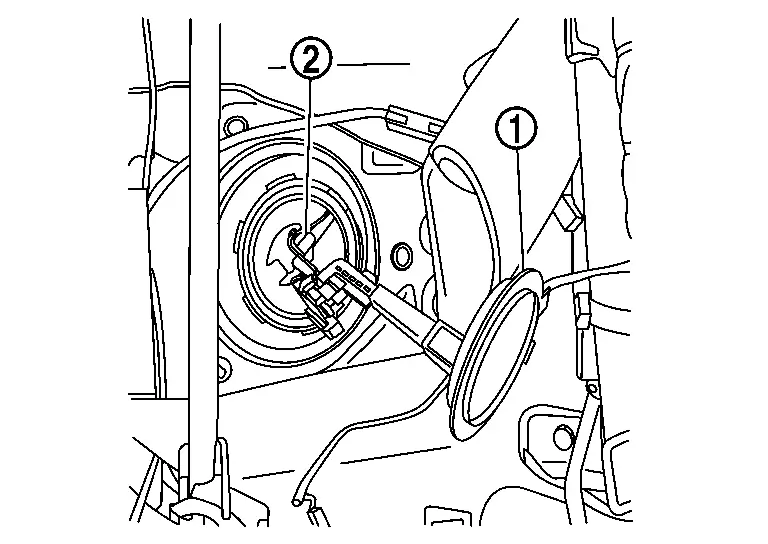

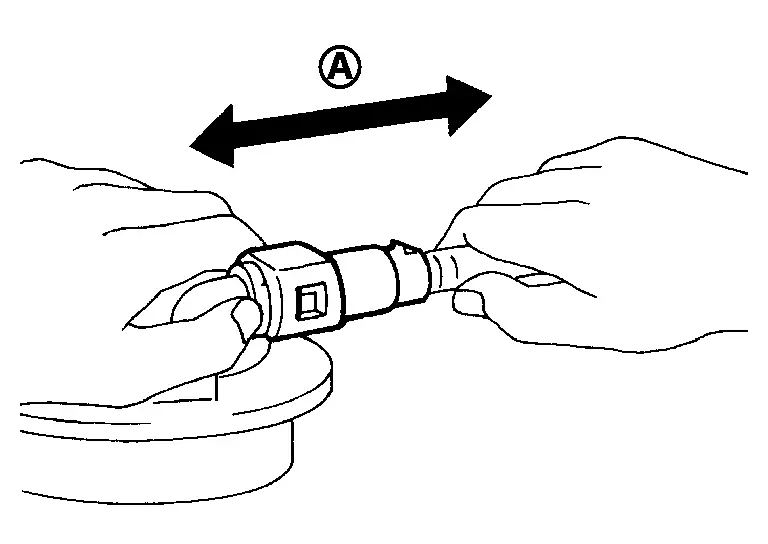

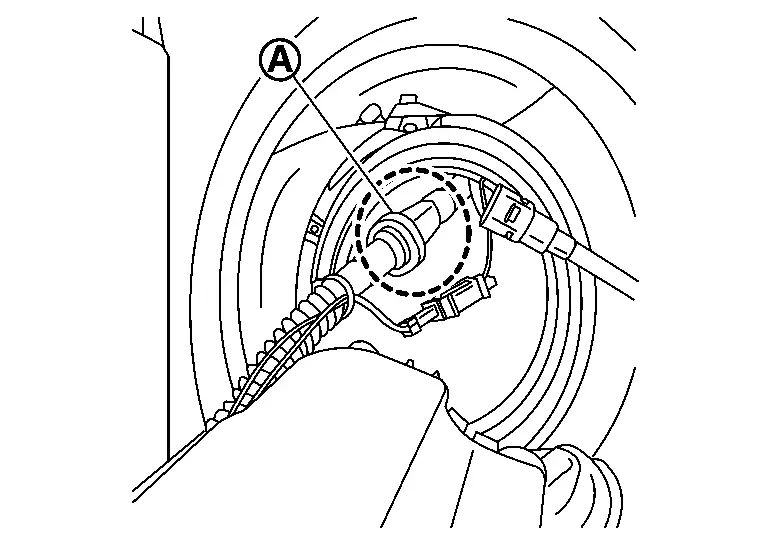

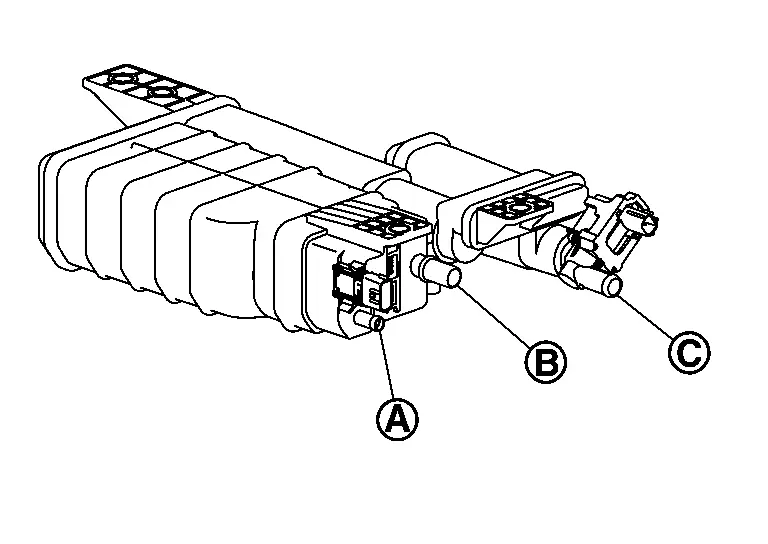

Separate fuel tube as per the following steps to remove fuel level sensor unit, fuel filter and fuel pump assembly.

-

Disconnect harness connector (A).

-

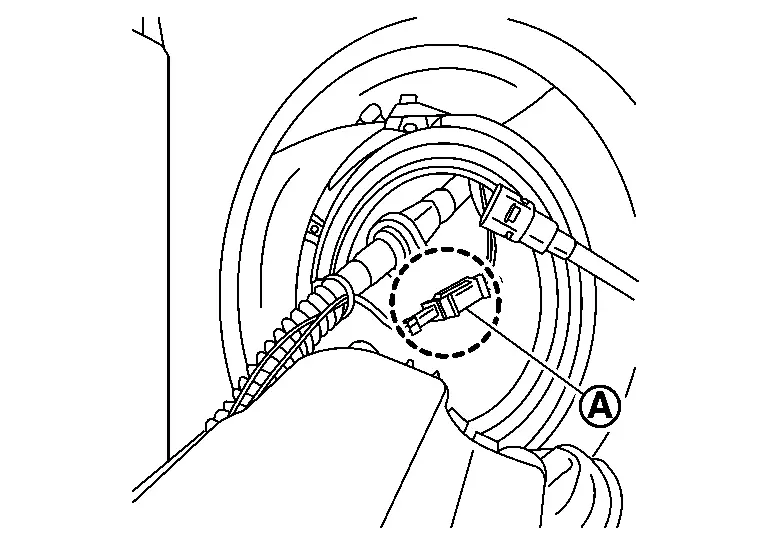

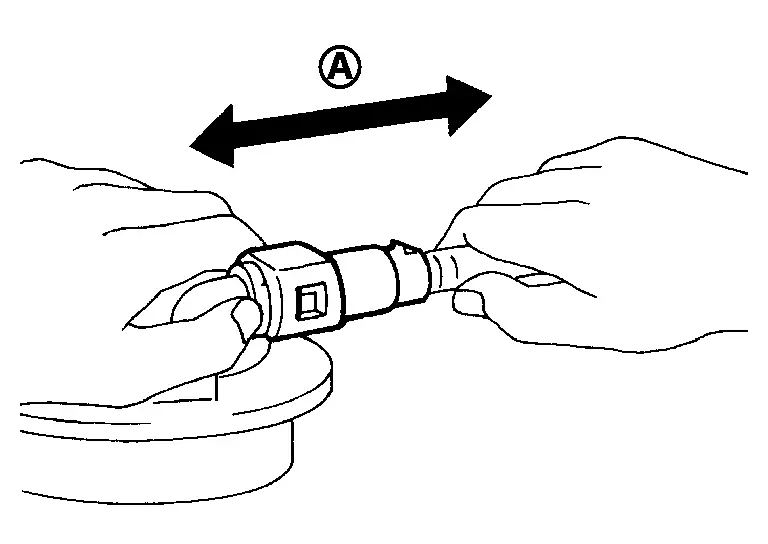

Pinch quick connector (A) square-part with your fingers, and pull out the quick connector by hand.

-

If quick connector and tube on sender unit are stuck, push several times until they move, and pull out.

NOTE:

NOTE:

When separating the fuel tube, tie a gasoline-resistance rope to the tip of the fuel tube and leave the rope on the fuel tank side to easily pull the fuel tube for installation.

Sub Fuel Level Sensor Assembly

Remove lock ring from sub fuel level sensor assembly using Tool (A).

| Tool number (A) |

: (NI-45747) (shown) : KV101207S0 |

|

: Front |

Remove sub fuel level sensor assembly (1)

CAUTION:

-

Never disassemble a fuel tube (2) from sub fuel sensor assembly.

-

Never bend float arm during removal.

-

Never pollute the inside by residue fuel. Draw out avoiding inclination by supporting with a cloth.

-

Never cause impacts such by dropping when handling components.

NOTE:

NOTE:

Tie a gasoline-resistance rope to a tip of the tube. Draw and leave the rope to the fuel tank side sothat the rope can be the guide for installation.

INSTALLATION

2WD

Fuel Level Sensor Unit, Fuel Filter and Fuel Pump Assembly

Note to the following, and install in the reverse order of removal.

Install new O-ring to fuel tank without any twist.

CAUTION:

Do not reuse O-rings.

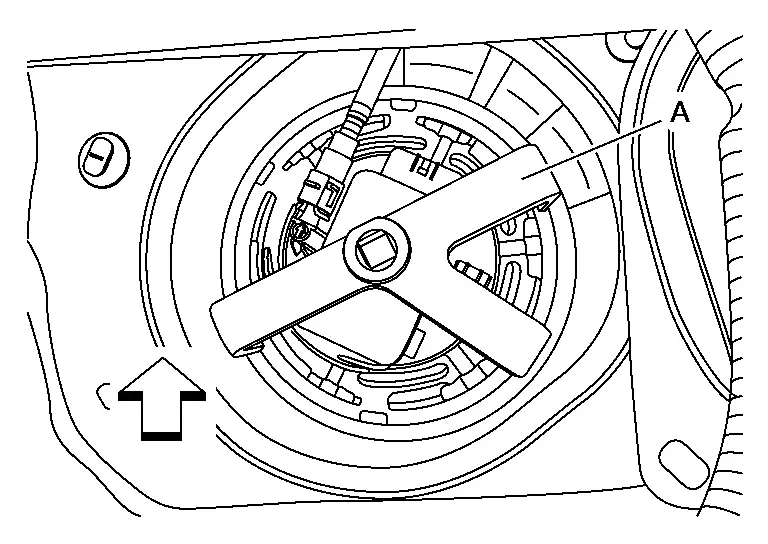

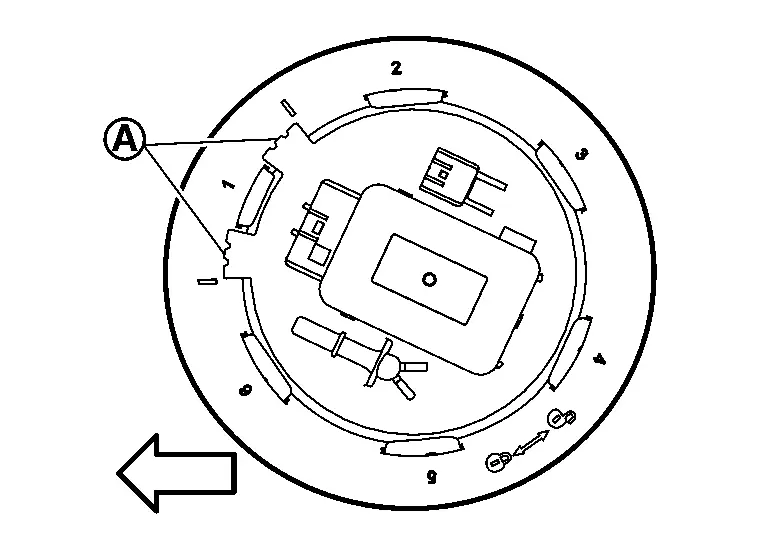

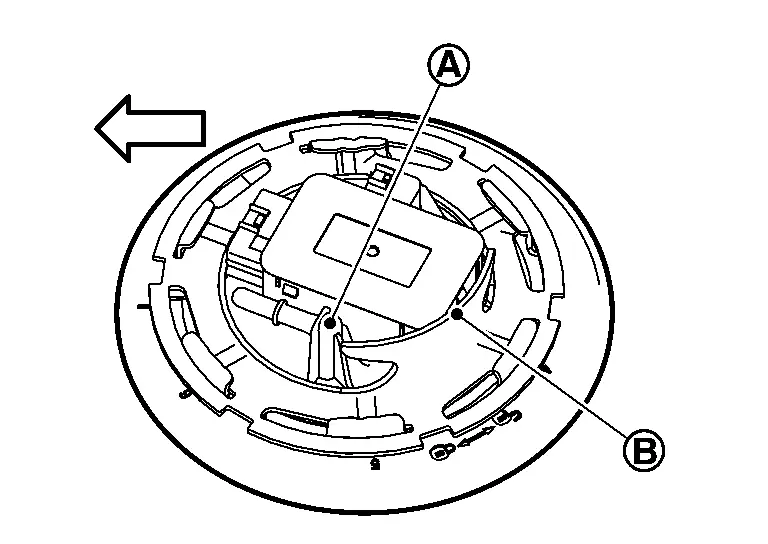

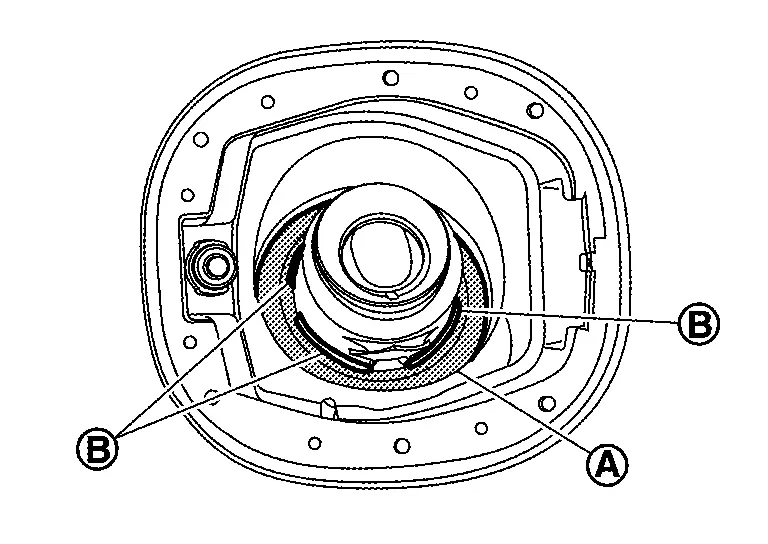

Install the fuel level sensor unit, fuel filter and fuel pump assembly on the fuel tank with the fuel level sensor unit, fuel filter and fuel pump assembly face (A) faced the shown in the figure against the arrow Nissan Ariya vehicle front.

|

: Nissan Ariya Vehicle front |

CAUTION:

-

Never allow seal packing to drop.

-

Never bend float arm during installing.

Install it so that the guard part (B) of the lock ring is at the position shown in the figure with respect to the fuel pump pipe part (A).

|

: Nissan Ariya Vehicle front |

Install lock ring for fuel level sensor, fuel filter and fuel pump assembly using Tool (A).

| Tool number (A) |

: (NI-45747) (shown) : KV101207S0 |

|

: Front |

CAUTION:

-

Install lock ring horizontally.

-

Turn the lock ring (A) until it is engaged in the fuel tank side.

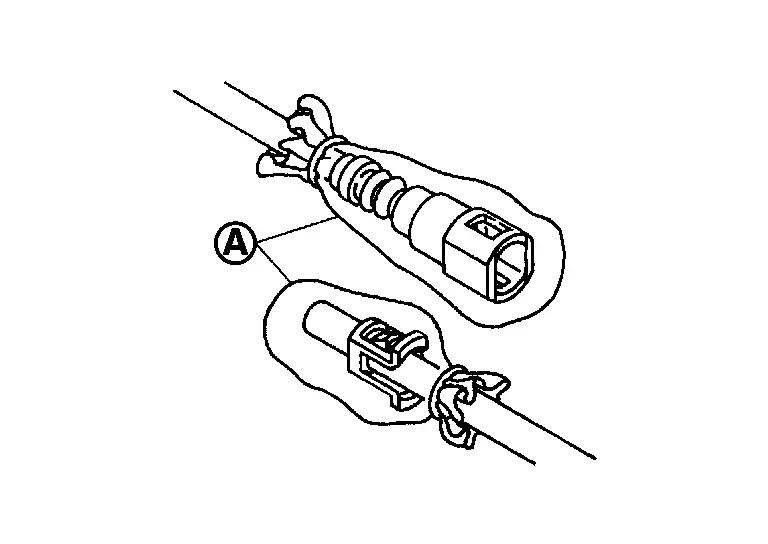

Connect quick connector of fuel feed tube as per following procedures.Check the connection for damage or any foreign materials. Align the connector with the tube, then insert the connector straight into the tube until a “click” sound is heard. After connecting, check that the connection is secured with following procedures.

-

Visually confirm that the two tabs are connected to the connector.

-

Pull (A) the tube and the connector to check that they are securely connected.

Connect harness connector.

NOTE:

NOTE:

Before installing inspection hole cover, check that the connecting part has no fuel leakage. Refer to Inspection.

Install inspection hole covers with the front mark (arrow) facing front of vehicle.

Lock clips by turning counterclockwise.

AWD

Sub Fuel Level Sensor Assembly

Note to the following, and install in the reverse order of removal.

Install new O-ring to fuel tank without any twist.

CAUTION:

Do not reuse O-rings.

Using the rope left on the fuel tank side at removal, run the fuel tube inside the fuel tank to install the sub fuel level sensor assembly to the fuel tank.

CAUTION:

-

Never bend float arm during installation.

-

To install, fuel tube (1) must run to the front (

) of the Nissan Ariya vehicle to avoid the interference with the float arm (2), as shown in the figure.

) of the Nissan Ariya vehicle to avoid the interference with the float arm (2), as shown in the figure.

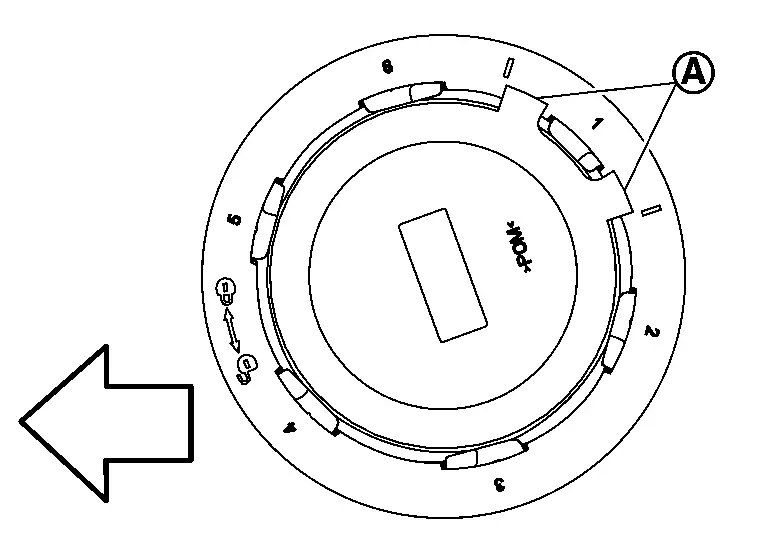

Install the sub fuel level sensor assembly on the fuel tank with the fuel level sensor unit, fuel filter and fuel pump assembly face (A) faced the shown in the figure against the arrow Nissan Ariya vehicle front.

|

: Nissan Ariya Vehicle front |

CAUTION:

-

Never allow seal packing to drop.

-

Never bend float arm during installing.

Install lock ring for sub fuel level sensor assembly using Tool (A).

| Tool number (A) |

: (NI-45747) (shown) : KV101207S0 |

|

: Front |

CAUTION:

-

Install lock ring horizontally.

-

Turn the lock ring (A) until it is engaged in the fuel tank side. .

Fuel Level Sensor Unit, Fuel Filter and Fuel Pump Assembly

Install new O-ring to fuel tank without any twist.

CAUTION:

Do not reuse O-rings.

Connect the fuel tube as per the following steps.

-

Insert the quick connector (A) straight to the fuel level sensor unit, fuel filter and fuel pump assembly.

-

Judge a good fit from connecting sound and tactile feedback.

-

Pull the fuel tube by hand to check a secure fit.

Connect harness connector (A).

Install the fuel level sensor unit, fuel filter and fuel pump assembly on the fuel tank with the fuel level sensor unit, fuel filter and fuel pump assembly face (A) faced the shown in the figure against the arrow Nissan Ariya vehicle front.

|

: Nissan Ariya Vehicle front |

CAUTION:

-

Never allow seal packing to drop.

-

Never bend float arm during installing.

-

To install, fuel tube (1) must run to the front (

) of the Nissan Ariya vehicle to avoid the interference with the float arm (2), as shown in the figure.

) of the Nissan Ariya vehicle to avoid the interference with the float arm (2), as shown in the figure.

Install it so that the guard part (B) of the lock ring is at the position shown in the figure with respect to the fuel pump pipe part (A).

|

: Nissan Ariya Vehicle front |

Install lock ring for fuel level sensor unit, fuel filter and fuel pump assembly using Tool (A).

| Tool number (A) |

: (NI-45747) (shown) : KV101207S0 |

|

: Front |

CAUTION:

-

Install lock ring horizontally.

-

Turn the lock ring (A) until it is engaged in the fuel tank side.

Connect quick connector of fuel feed tube as per following procedures.Check the connection for damage or any foreign materials. Align the connector with the tube, then insert the connector straight into the tube until a “click” sound is heard. After connecting, check that the connection is secured with following procedures.

-

Visually confirm that the two tabs are connected to the connector.

-

Pull (A) the tube and the connector to check that they are securely connected.

Connect harness connector.

Inspection Hole Cover

-

Before installing inspection hole cover, check that the connecting part has no fuel leakage. Refer to Inspection.

Install inspection hole covers with the front mark (arrow) facing front of vehicle.

Lock clips by turning counterclockwise.

Disassembly and Assembly

Disassembly

2WD

NOTE:

NOTE:

Before disassembly, note the proper placement of the wires to the correct terminals and correct wire routing to the terminals.

Disconnect fuel level sensor unit and fuel tank temperature sensor harness connectors  .

.

Remove wires from wire clips  .

.

CAUTION:

Be careful not to damage wires when removing them from wire clips.

Release tab using suitable tool, then slide fuel level sensor unit in direction.

Inspection

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

Place the ignition switch in the “ON” position (with engine stopped), then check connections for leakage by applying fuel pressure to fuel piping.

Start engine. Then let it idle and check that there is no fuel leakage at the fuel system connections.

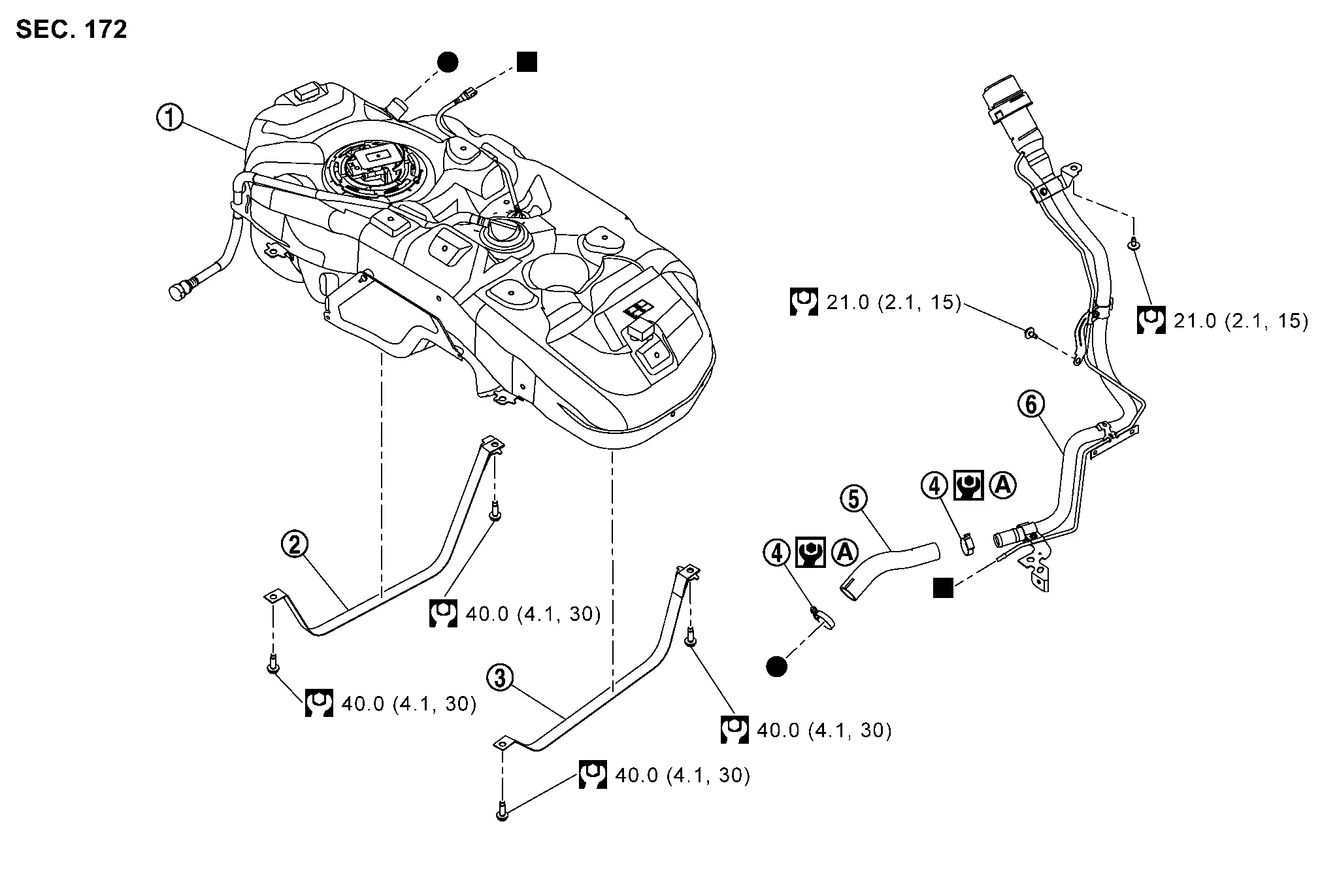

Fuel Tank

Exploded View

2WD

|

Fuel tank |  |

Fuel tank band (RH) |  |

Fuel tank band (LH) |

|

Clamp |  |

Fuel filler hose |  |

Fuel filler tube |

|

Comply with the assembly procedure when tightening. Refer to Removal and Installation | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

, ,  : Indicates that the parts is connected at points with same symbols in actual Nissan Ariya vehicle. : Indicates that the parts is connected at points with same symbols in actual Nissan Ariya vehicle. |

|||||

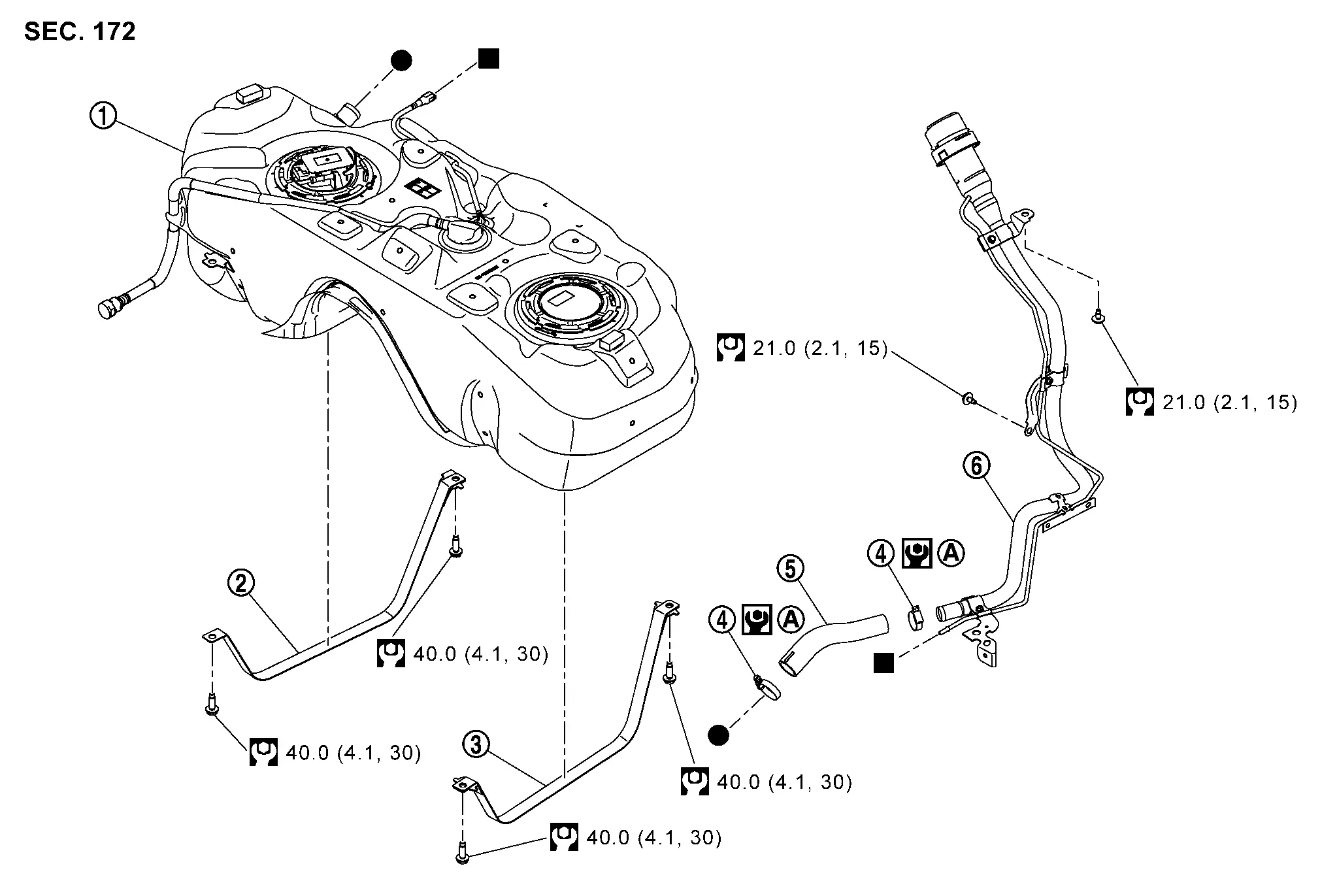

AWD

|

Fuel tank |  |

Fuel tank band (RH) |  |

Fuel tank band (LH) |

|

Clamp |  |

Fuel filler hose |  |

Fuel filler tube |

|

Comply with the assembly procedure when tightening. Refer to Removal and Installation | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

, ,  : Indicates that the parts is connected at points with same symbols in actual Nissan Ariya vehicle. : Indicates that the parts is connected at points with same symbols in actual Nissan Ariya vehicle. |

|||||

Removal and Installation

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to General Precautions .

Perform the steps 1 to 7 of “REMOVAL” in “ FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY”. Refer to Removal and Installation.

Drain fuel from fuel tank if necessary. Refer to Removal and Installation.

CAUTION:

-

Because fuel tank forwardly inclines and becomes unstable when installing/removing, fuel should be drained if found the remaining quantity.

-

Situate Nissan Ariya vehicle on a flat and solid surface.

Remove main muffler. Refer to Removal and Installation.

Remove rear propeller shaft. (AWD models) Refer to Removal and Installation.

Remove under cover LH and under cover RH.

Disconnect EVAP tube  from EVAP canister.

from EVAP canister.

Remove fuel filler hose  at fuel filler tube side.

at fuel filler tube side.

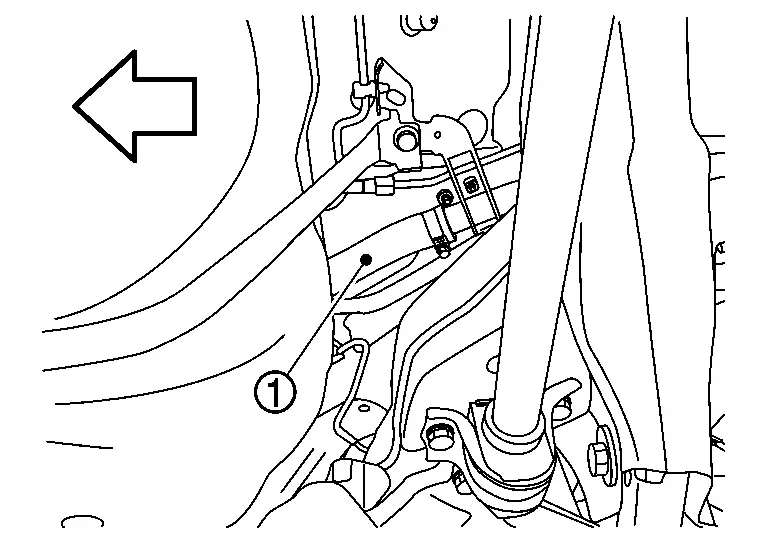

|

: Nissan Ariya Vehicle front |

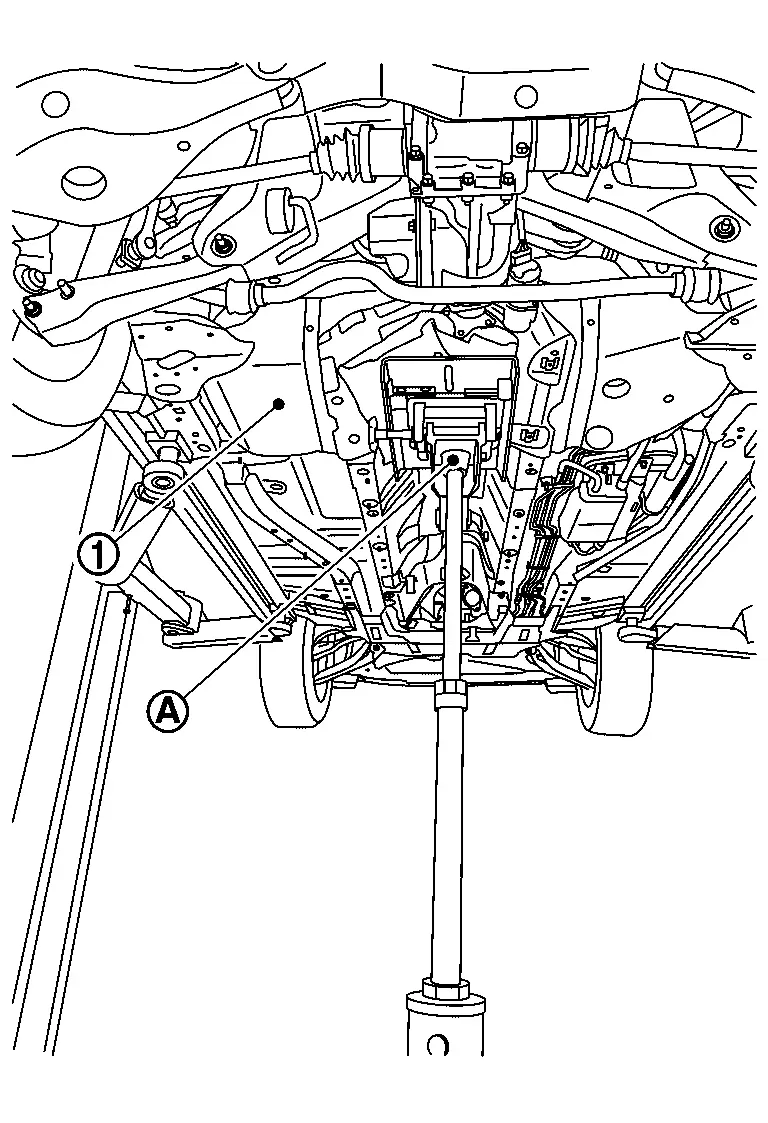

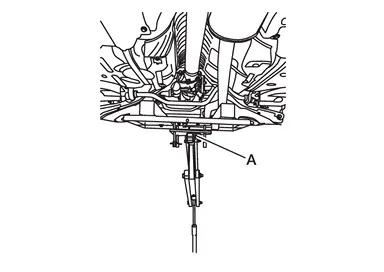

Support center of fuel tank  with suitable jack

with suitable jack  .

.

Remove fuel tank bands.

Tilt the fuel tank forward and lower the fuel tank front 10 cm (3.94 in).

Disconnect vent hose  at rear side of fuel tank.

at rear side of fuel tank.

-

Instruction for quick connector

of EVAP tube. Refer to Quick Connector.

of EVAP tube. Refer to Quick Connector.

: Nissan Ariya Vehicle front

Lower suitable jack carefully to remove fuel tank while holding it by hand.

CAUTION:

Fuel tank may be in an unstable condition, due to the shape of the fuel tank bottom. Be sure to secure tank at all times.

If replacing the fuel tank, remove the fuel level sensor unit, fuel filter and fuel pump assembly to transfer to the new fuel tank. Remove and discard the O-ring. Refer to Removal and Installation.

INSTALLATION

Installation is in the reverse order of removal.

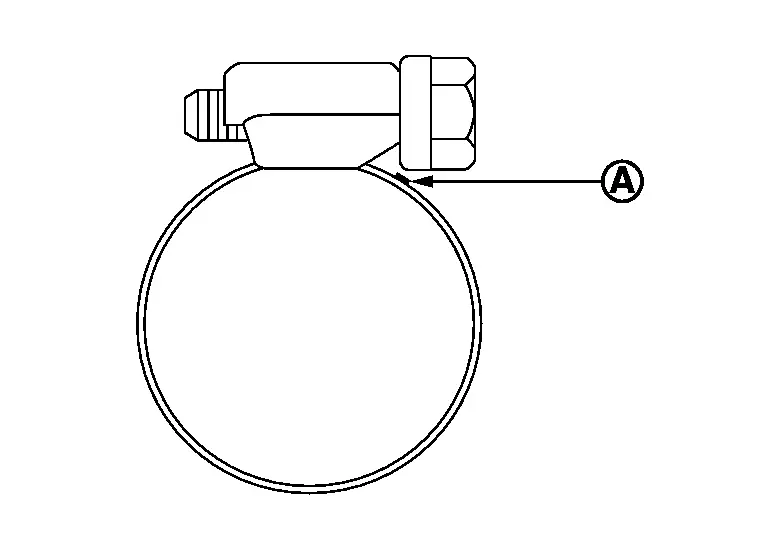

Fuel Filler Hose

-

Insert fuel filler hose to the length below.

35 mm (1.38 in) -

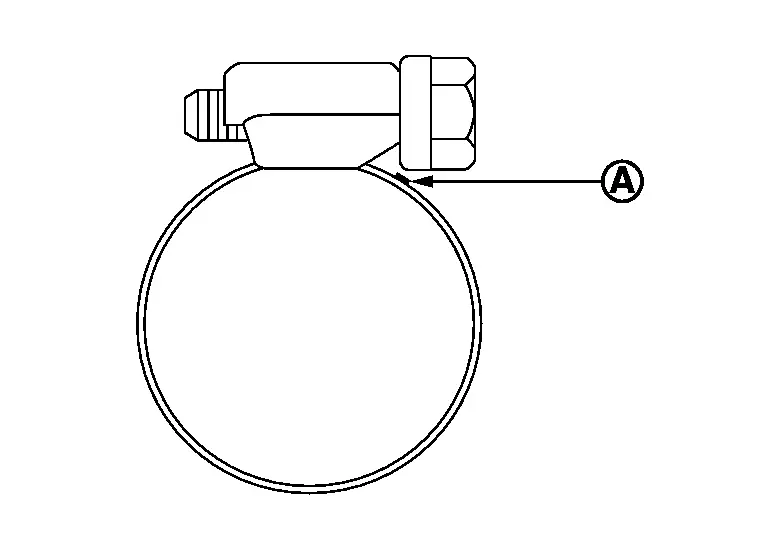

Be sure hose clamp is not placed on swelled area of fuel filler tube.

-

Tighten the clamp hand with the top mark

until the mark is on the bolt head flange.

until the mark is on the bolt head flange.

Fuel Filler Tube

-

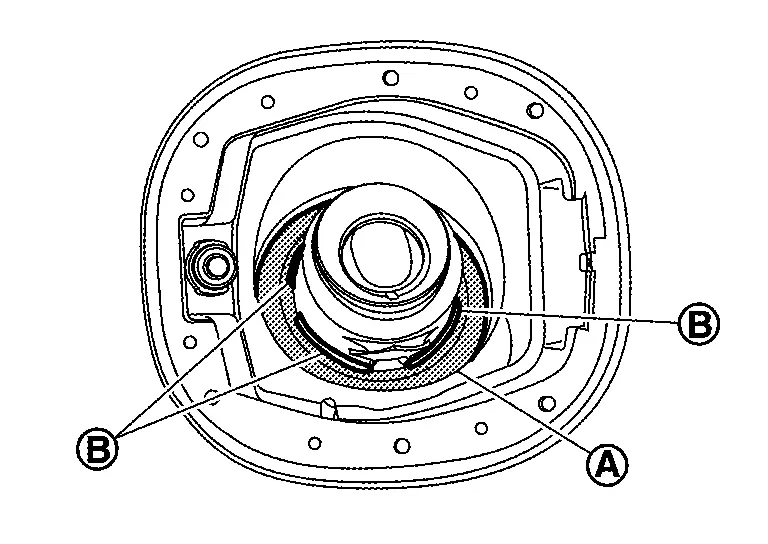

When installing the fuel filler tube, make sure that the lip

of the fuel filler base is firmly attached to the rib

of the fuel filler base is firmly attached to the rib  of the cap less unit part.

of the cap less unit part.

Inspection

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

Place the ignition switch in the “ON” position (with engine stopped), then check connections for leakage by applying fuel pressure to fuel piping.

Start engine. Then let it idle and check that there is no fuel leakage at the fuel system connections.

Fuel Filler Tube

Removal and Installation

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to General Precautions.

Remove rear wheel housing protector. Refer to Removal and Installation.

Remove and reposition rear brake caliper assembly. Refer to Removal and Installation.

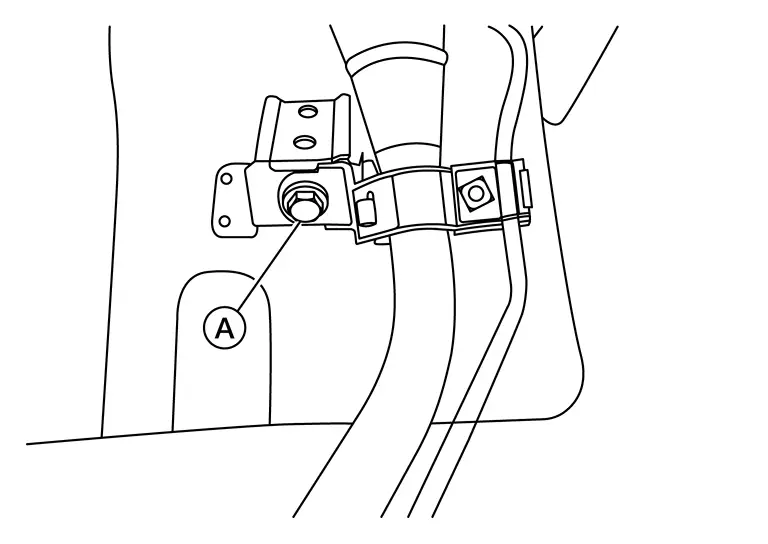

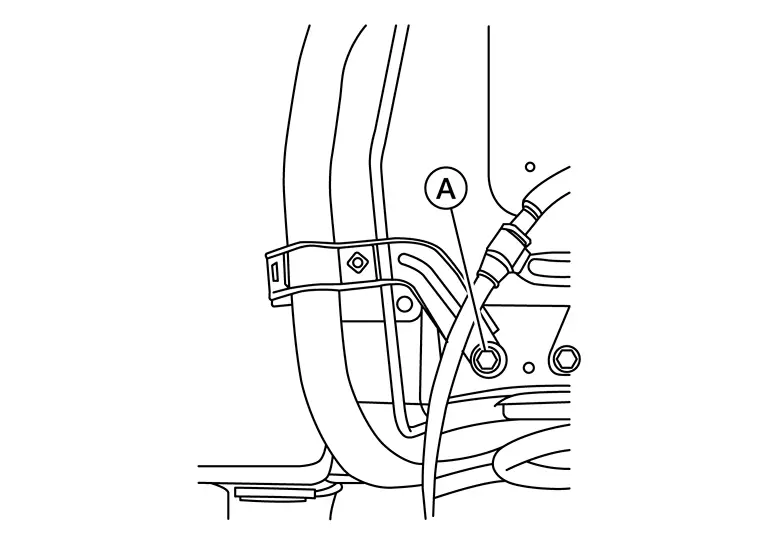

Remove brake hose locking plates (A) from rear knuckle.

Remove rear shock absorber. Refer to Removal and Installation.

Remove rear coil spring. Refer to Removal and Installation.

Remove main muffler system. Refer to Removal and Installation.

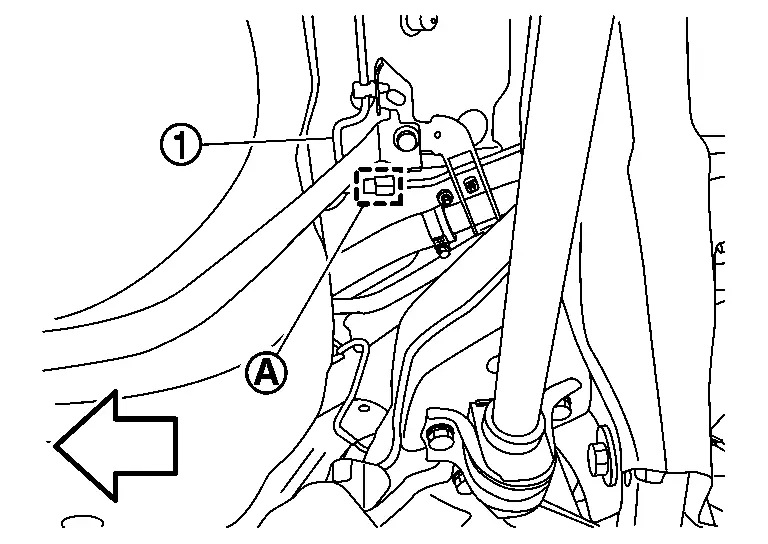

Disconnect EVAP tube (A) from fitting (1) and (2), Disconnect fuel filler hose clamp (B) from fuel filler hose (3) to fuel filler tube (4).

-

Instruction for quick connector of EVAP tube. Refer to Quick Connector.

Using a suitable jack support the fuel tank and remove fuel tank band bolt (C).

CAUTION:

Fuel tank may be in an unstable condition, due to the shape of the fuel tank bottom. Be sure to secure tank at all times.

Remove upper fuel filler tube bolt (A).

Remove lower fuel filler tube bolt (A).

Set a suitable jack under the rear suspension member (A).

Remove bolts from right side of rear suspension member.

Partially loosen suspension member bolts on LH side.

Partially lower suspension member.

Remove fuel filer tube.

INSTALLATION

Installation is in the reverse order of removal.

Fuel Filler Hose

-

Insert fuel filler hose to the length below.

35 mm (1.38 in) -

Be sure hose clamp is not placed on swelled area of fuel filler tube.

-

Tighten the clamp hand with the top mark (A) until the mark is on the bolt head flange.

Fuel Filler Tube

-

When installing the fuel filler tube, make sure that the lip (A) of the fuel filler base is firmly attached to the rib (B) of the cap less unit part.

Evap Canister

Hydraulic Layout

HYDRAULIC LAYOUT

2WD

| 1. | EVAP line (EVAP canister to EVAP canister purge volume control solenoid valve) | 2. | Fuel level sensor unit, fuel filter and fuel pump assembly | 3. | Fuel filler tube |

| 4. | Fuel tank | 5. | EVAP canister | 6. | Fuel feed line |

| 7. | High pressure fuel pump | 8. | EVAP canister purge volume control solenoid valve | — | — |

CAUTION:

Do not use soapy water or any type of solvent while installing vacuum hose or purge hoses.

AWD

| 1. | EVAP line (EVAP canister to EVAP canister purge volume control solenoid valve) | 2. | Fuel level sensor unit, fuel filter and fuel pump assembly | 3. | Sub fuel level sensor assembly |

| 4. | Fuel filler tube | 5. | Fuel tank | 6. | EVAP canister |

| 7. | Fuel feed line | 8. | High pressure fuel pump | 9. | EVAP canister purge volume control solenoid valve |

CAUTION:

Do not use soapy water or any type of solvent while installing vacuum hose or purge hoses.

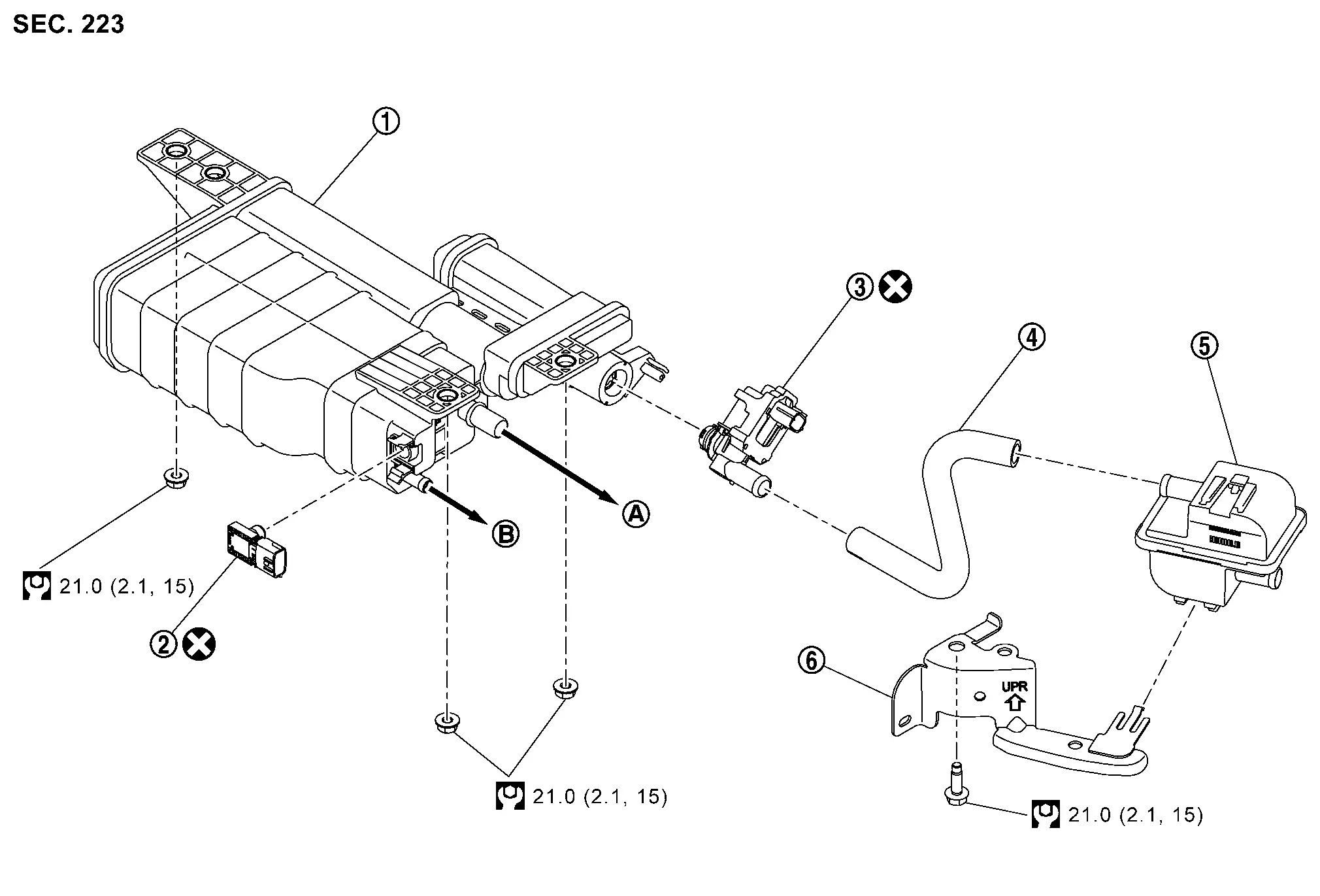

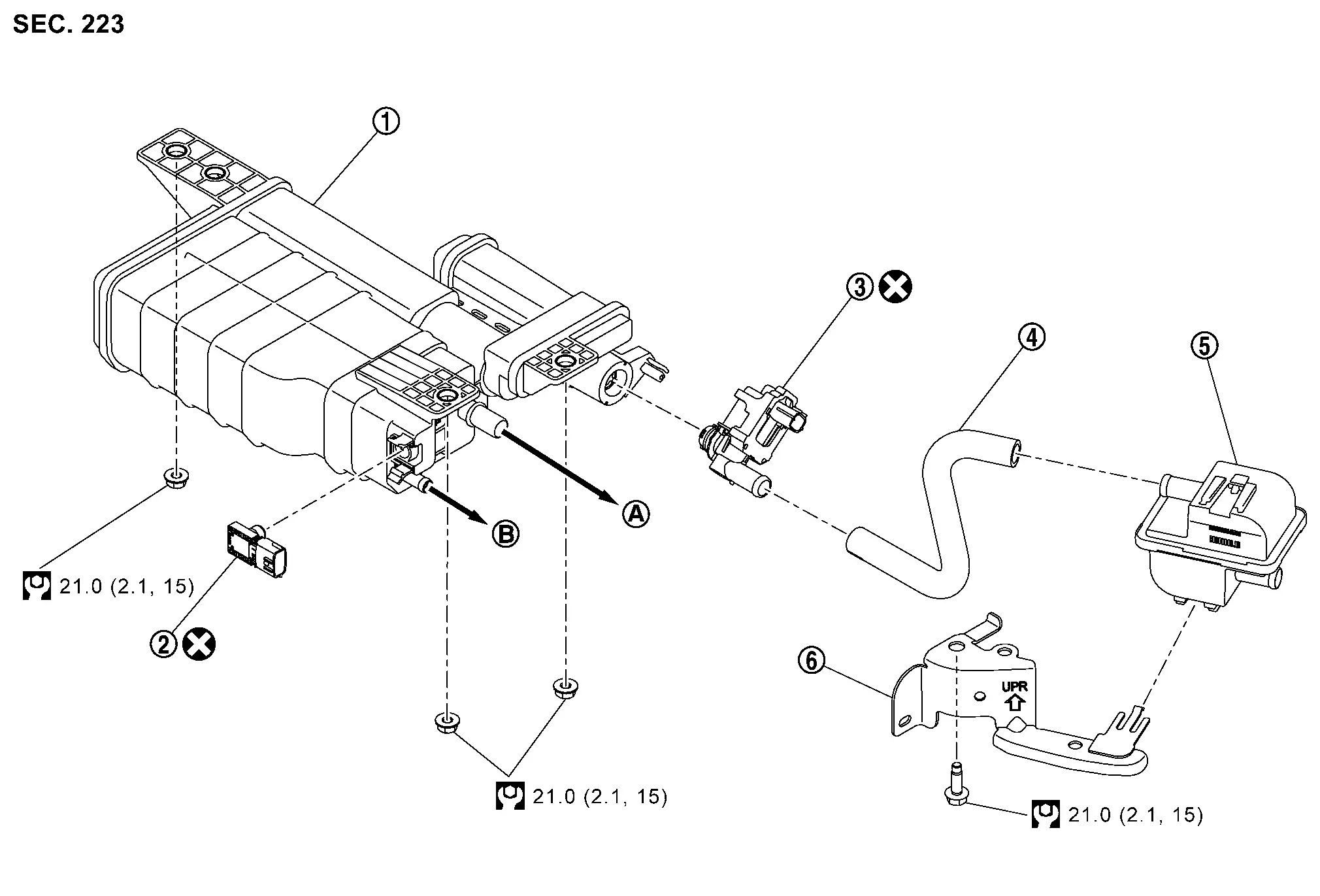

DISASSEMBLY

| 1. | EVAP canister | 2. | EVAP canister control pressure sensor | 3. | EVAP canister vent control valve |

| 4. | EVAP canister vent control valve hose | 5. | EVAP canister filter | 6. | EVAP canister filter bracket |

| A. | To fuel tank. Exploded View | B. | To vacuum delay valve assembly. Exploded View | — | — |

|

: N·m (kg-m, ft-lb) | — | — | — | — |

|

: Always replace after every disassembly. | ||||

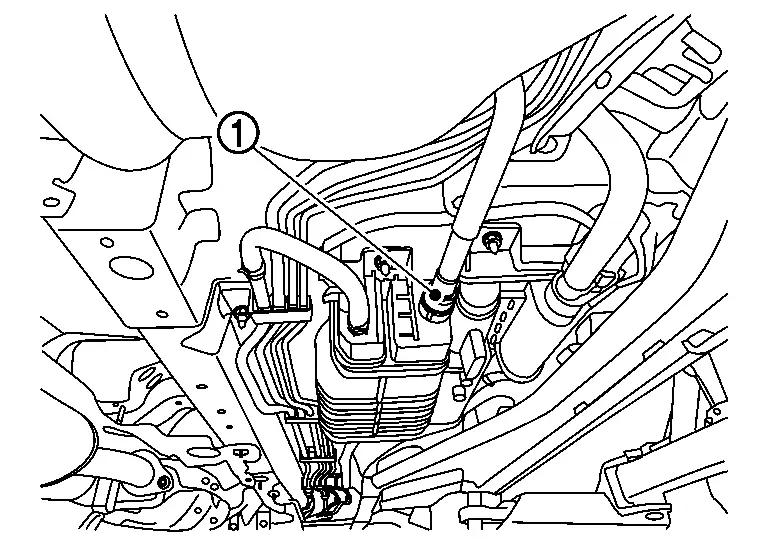

Removal and Installation

NOTE:

NOTE:

The EVAP canister vent control valve and EVAP canister control pressure sensor can be removed without removing the EVAP canister.

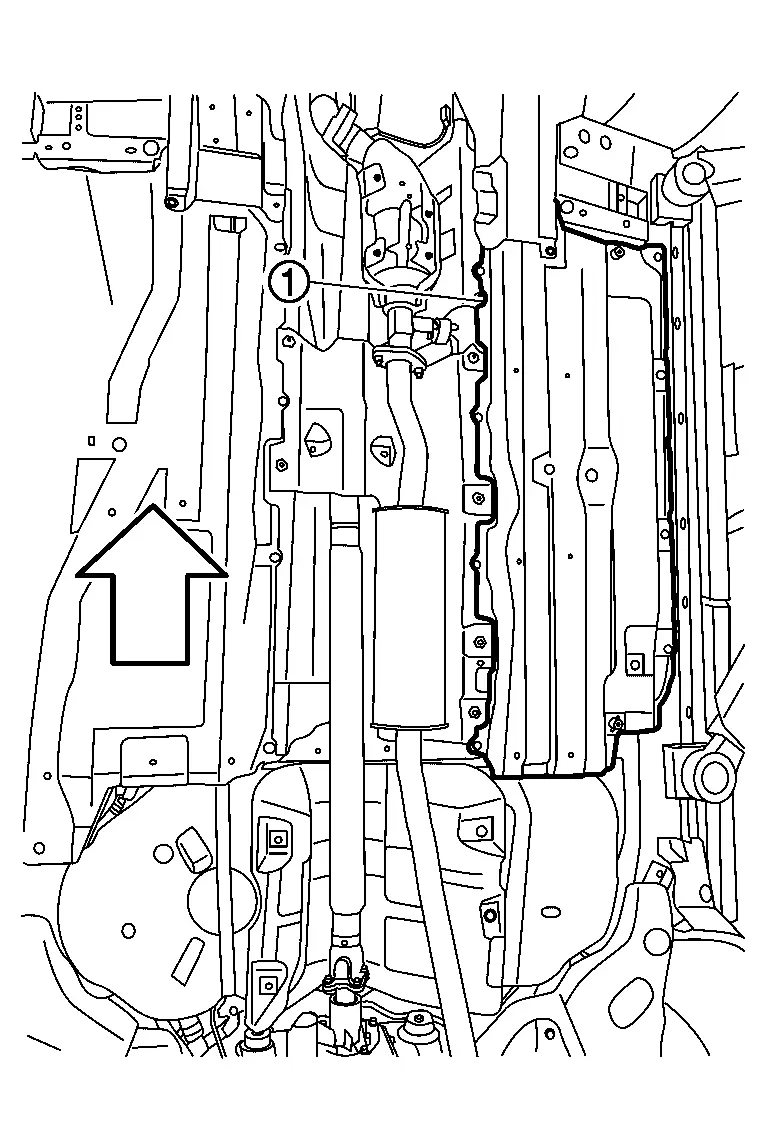

REMOVAL

Remove under cover RH (1).

|

: Nissan Ariya Vehicle front |

Disconnect the harness connector from EVAP canister control pressure sensor and the EVAP canister vent control valve.

Disconnect the EVAP canister purge hose, the EVAP canister vent line, and the EVAP canister vent control valve hose.

Remove the EVAP canister bolt.

Remove the EVAP canister from the Nissan Ariya vehicle.

Remove the following from the EVAP canister (if necessary).

-

EVAP canister control pressure sensor.

-

EVAP canister vent control valve.

INSTALLATION

Installation is in the reverse order of removal.

Install the EVAP canister then tighten the nuts to specification in sequence

| EVAP canister nuts | : 21 Nm (2.1 kg-m, 15 ft-lb) |

Inspection

Check EVAP canister as follows.

Block port  .

.

Blow air into port  and check that it flows freely out of port

and check that it flows freely out of port  .

.

Release blocked port  .

.

Apply vacuum pressure to port  and check that vacuum pressure exists at the ports

and check that vacuum pressure exists at the ports  and

and  .

.

Block port  and

and  .

.

Apply pressure to port  and check that there is no leakage.

and check that there is no leakage.

Evap Canister Filter

Exploded View

|

EVAP canister |  |

EVAP canister control pressure sensor |  |

EVAP canister vent control valve |

|

EVAP canister vent control valve hose |  |

EVAP canister filter |  |

EVAP canister filter bracket |

|

To fuel tank. Exploded View. |  |

To vacuum delay valve assembly. Exploded View. | ||

|

: N·m (kg-m, ft-lb) | ||||

|

: Always replace after every disassembly. | ||||

Removal and Installation

REMOVAL

Disconnect EVAP canister vent control valve hose from EVAP canister filter.

Disconnect EVAP canister drain hose from EVAP canister filter.

Remove the bolt and the EVAP canister filter.

INSTALLATION

Installation is in the reverse order of removal.

Other materials:

P0531 A/c Refrigerant Pressure Sensor

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0531

00

REFRIGERANT PRESS SENSOR A

(A/C refrigerant pressure sensor A circuit range/performance

Diagnosis condition

Engine running at idle

Signal (termin ...

C10b0-01 Parking Brake Actuator (rh)

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

C10B0

01

Parking brake actuator (RH)

[Parking brake actuator (right)]

Diagnosis condition

When parking brake is apply or release

Signal (terminal)

—

...

Fonctionnement du système LDW

Témoin LDW (affiché sur l’écran d’informations du véhicule)

Écran d’informations du véhicule

Commandes au volant (côté gauche)

Le système LDW du Nissan Rogue active la fonction d’alerte sortie de voie lorsque la vitesse du véhicule atteint environ 60 km/h (37 mi ...