Nissan Rogue (T33) 2021-Present Service Manual: Kr15ddt :: Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

|

Tool number (Tech Mate No.) Tool name | Description | |

|---|---|---|

|

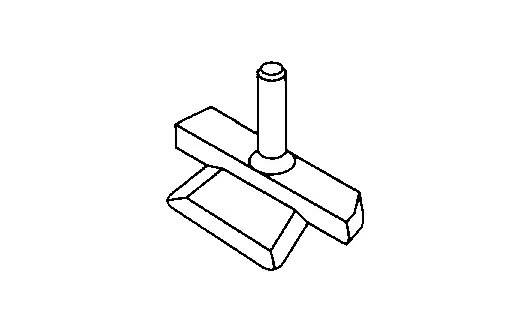

KV10111100 (NI-37228) Seal cutter |

|

Removing oil pan (upper and lower), etc. |

|

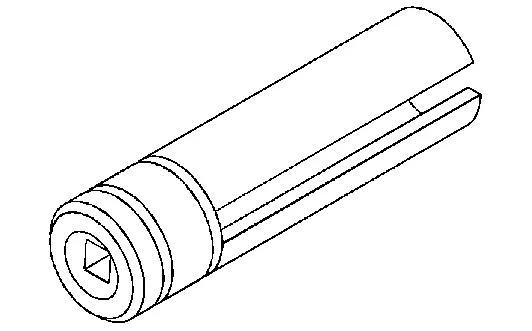

KV10117100 (NI-36471–A) Heated oxygen sensor wrench |

|

Loosening or tightening air fuel ratio (A/F) sensor 1 and heated oxygen sensor 2 |

|

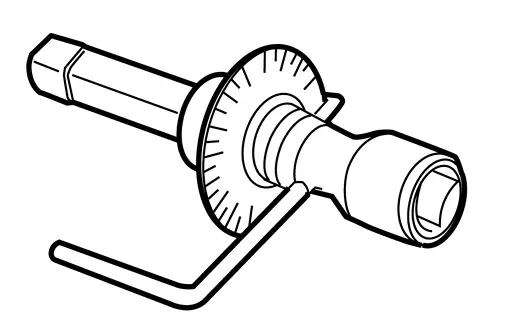

KV10112100 (BT8653–A) Angle wrench |

|

Tightening bolts for main bearing cap, cylinder head, etc. |

|

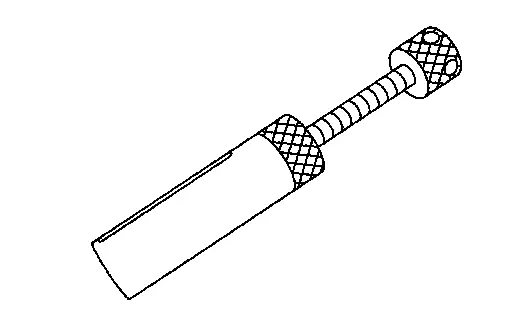

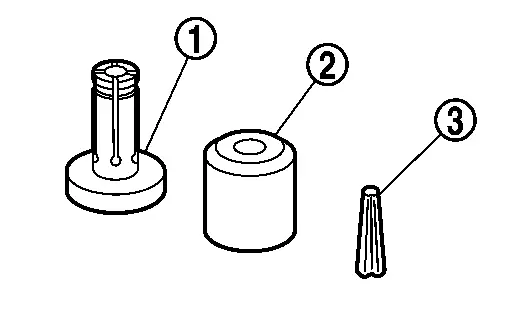

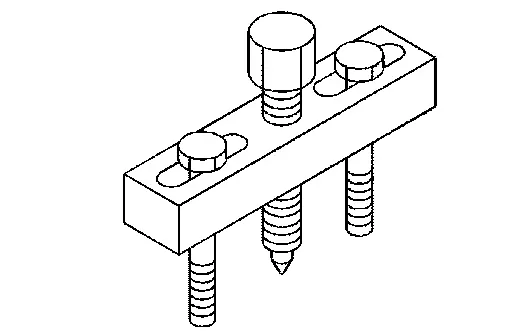

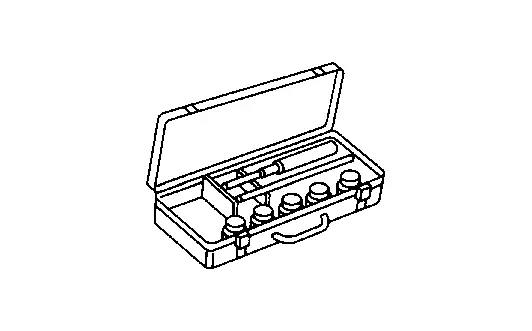

KV101296S0 (NI-53166) Direct injection puller |

|

Removing fuel injector |

|

KV10119990 (NI-53151) Injector seal drift set

|

|

Installing fuel injector seal |

Commercial Service Tools

| Tool name | Description | |

|---|---|---|

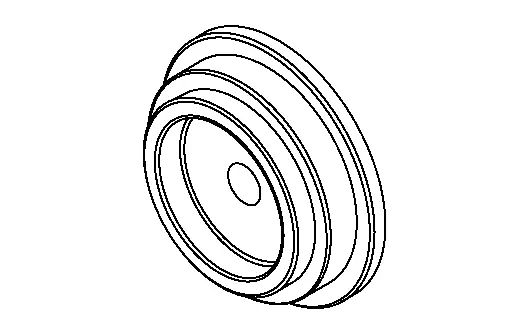

| Drift |

|

Installing camshaft sprocket (INT) oil seal |

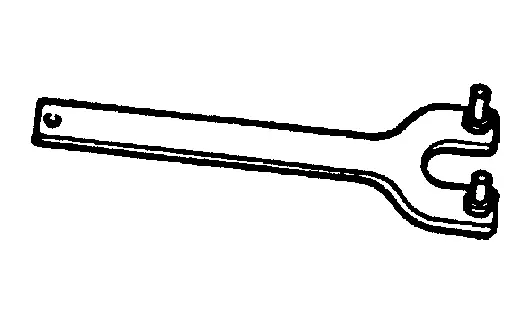

| Pulley holder |

|

Removing and installing drive plate and crankshaft pulley |

|

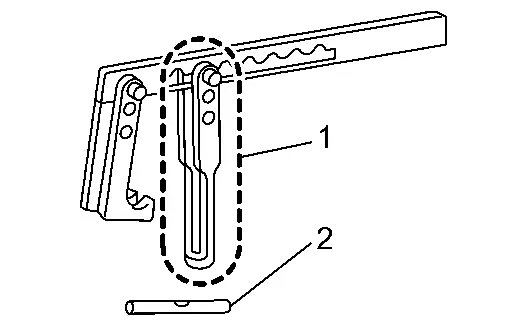

Valve spring compressor Attachment Adapter |

|

Disassembling and assembling valve mechanism Part (1) is a component of KV10116200, but Part (2) is not so. |

| Valve oil seal puller |

|

Removing valve oil seal |

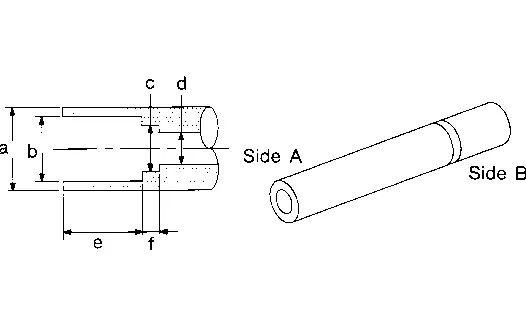

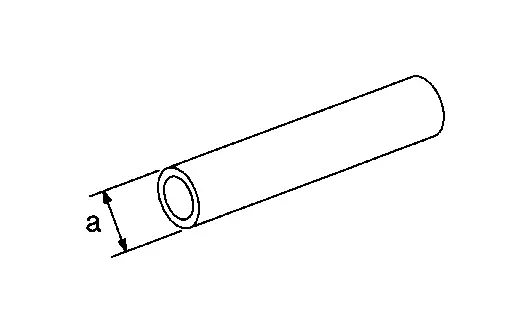

| Valve oil seal drift |

|

Installing valve oil seal Use side A. a: 20 (0.79) dia. d: 8 (0.31) dia. b: 13 (0.51) dia. e: 10.7 (0.421) c: 10.3 (0.406) dia. f: 5 (0.20) Unit: mm (in) |

| Pulley puller |

|

Removing crankshaft pulley |

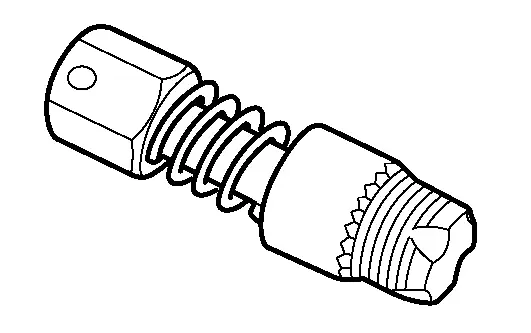

| Oxygen sensor thread cleaner |

|

Reconditioning the exhaust system threads before installing a new oxygen sensor (Use with anti-seize lubricant shown below.)

|

| Anti-seize lubricant (Permatex 133AR or equivalent meeting MIL specification MIL-A-907) |

|

Lubricating oxygen sensor thread cleaning tool when reconditioning exhaust system threads |

| Valve seat cutter set |

|

Finishing valve seat dimensions |

| Valve guide drift |

|

Removing and installing valve guide |

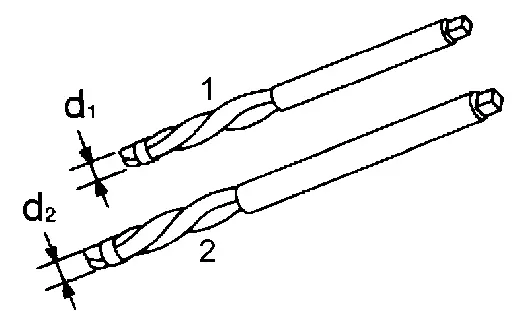

| Valve guide reamer |

|

1: Reaming valve guide inner hole 2: Reaming hole for oversize valve guide d1: 6.0 mm (0.236 in) dia. d2: 10.2 mm (0.402 in) dia. |

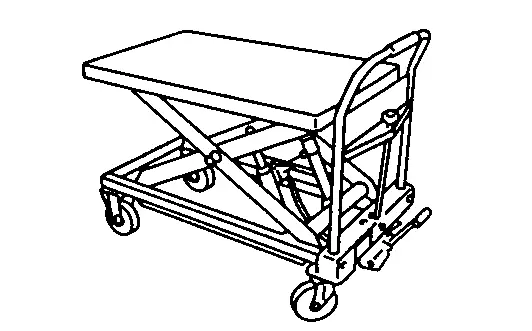

| Manual lift table caddy |

|

Removing and installing engine |

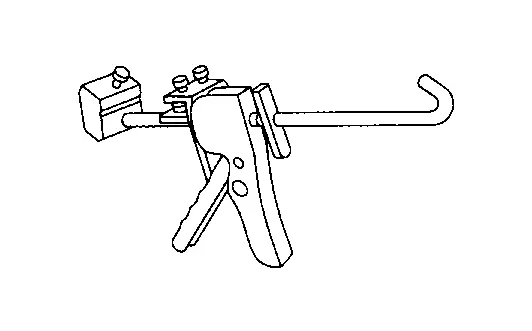

| Tube presser |

|

Pressing the tube of liquid gasket |

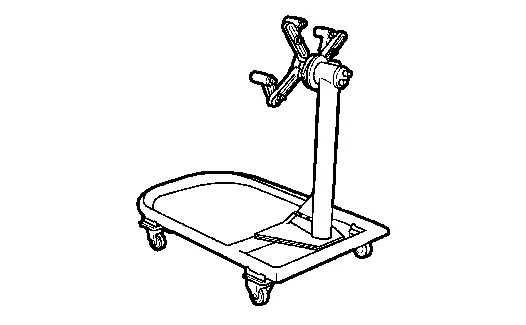

| Engine stand |

|

Engine overhaul |

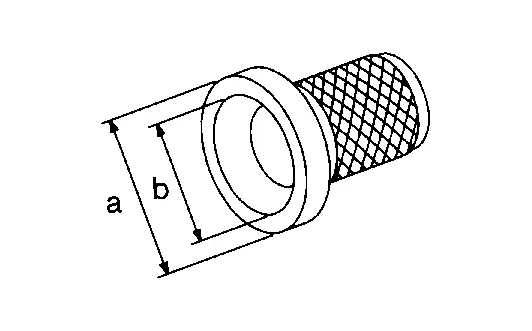

| Drift |

|

Installing front oil seal a: φ57.0 mm (2.244 in). b: φ45.0 mm (1.772 in). |

| Drift |

|

Installing rear oil seal a: φ115.0 mm (4.528 in). b: φ90.0 mm (3.543 in). |

| Stick |

|

Installing rear oil seal a: φ18.0 mm (0.709 in). |

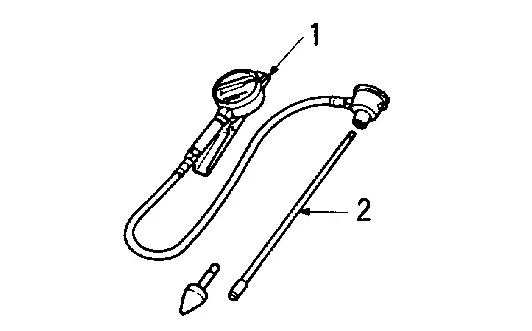

| Compression gauge set |

|

Compression pressure 1: Compression gauge 2: Adapter |

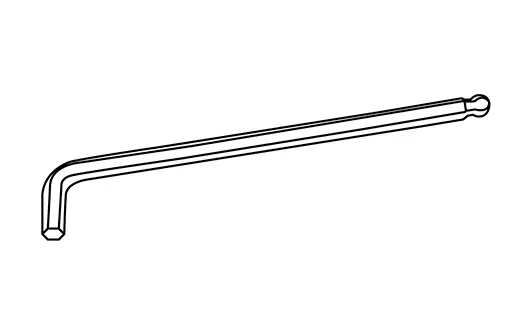

| Ball point hex wrench |

|

Removing and installing oil drain plug. |

Always Replace with New Parts

| Never Reuse These Parts | Part Code | For additional information: |

|---|---|---|

| Mass air flow | 22680 | Exploded View |

| Insulator | 16523S | Exploded View |

| Sensor assy - boost pressure | 25085MA | Exploded View |

| Seal - rubber | 14465Q | Exploded View |

| Sensor assy - boost pressure | 25085M | Exploded View |

| Gasket - intake manifold | 14035 | Exploded View |

| Gasket - intake adapter | 14040E | Exploded View |

| Bolt | 14716A | Exploded View |

| Gasket - EGR guide tube | 14722 | Exploded View |

| Gasket - EGR cooler | 14722M | Exploded View |

| EGR valve gasket | 14719 | Exploded View |

| EGR temperature sensor | 14730 | Exploded View |

| Gasket - convertor | 20813 | Exploded View |

| Clamp | 20080H | Exploded View |

| Seal - O-ring | 15066R | Exploded View |

| Seal - O-ring | 15066RA | Exploded View |

| Bolt | 14420A | Exploded View |

| Gasket - eyebolt | 15192F | Exploded View |

| Turbocharger inlet gasket | 14415 | Exploded View |

| Stud - oil filter | 15213 | Exploded View |

| Washer - drain plug | 11128A | Exploded View |

| Gasket - oil strainer | 15053 | Exploded View |

| Gasket - oil pan | 11121 | Exploded View |

| Seal - Oing | 12200E | Exploded View |

| Tube assy - fuel | 17520 | Exploded View |

| Fuel pump assy - high pressure | 16630 | Exploded View |

| Seal - O-ring | 16618N | Exploded View |

| Insulator - injector | 16603FA | Exploded View |

| Insulator - injector | 16603F | Exploded View |

| Stud | 16610X | Exploded View |

| Pipe assy - fuel | 17520U | Exploded View |

| Seal - O-ring | 16412F | Exploded View |

| Seal - O-ring | 16412FB | Exploded View |

| Holder - injector | 16610Q | Exploded View |

| Seal - O-ring | 16412FA | Exploded View |

| Fuel rail pressure sensor | 16638M | Exploded View |

| Gasket - rocker cover | 13270 | Exploded View |

| Gasket - rocker cover | 13270+A | Exploded View |

| Insulator - PCV valve | 11812 | Exploded View |

| Seal - O-ring | 22100EA | Exploded View |

| Target assy - sensor, VTC | 13093M | Exploded View |

| Oil filter | 15200P | Exploded View |

| Seal - oil, camshaft | 13042M | Exploded View |

| Seal - O-ring | 13010H | Exploded View |

| Seal - O-ring | 13042N | Exploded View |

| Seal - oil, crankshaft front | 13042 | Exploded View |

| Seal - oil level gauge guide | 15148 | Exploded View |

| Seal - O-ring | 15056 | Exploded View |

| Seal - O-ring | 13012JA | Exploded View |

| Seal - O-ring | 13012J | Exploded View |

| Seal - O-ring | — | Exploded View |

| Seal - O-ring, oil pump | 15066M | Exploded View |

| Seal - O-ring, oil pump | 15066MA | Exploded View |

| Timing chain oil jet | — | Exploded View |

| Tensioner arm shaft | — | Exploded View |

| Seal O-ring | 22100E | Exploded View |

| Gasket - cylinder head | 11044 | Exploded View |

| Seal - oil, valve | 13207+A | Exploded View |

| Seal - oil, valve | 13207 | Exploded View |

| Guide - valve, exhaust | 13213 | Exploded View |

| Guide - valve, intake | 13212 | Exploded View |

| Seat - valve, exhaust | 11099 | Exploded View |

| Seat - valve, intake | 11098 | Exploded View |

| Spark plug tube | — | Exploded View |

| Seal - oil, crankshaft rear | 12279 | Exploded View |

| Gasket - breather separator | 13270Y | Exploded View |

| Plug-drain | 11128 | Exploded View |

Other materials:

Ecu Diagnosis Information. Automatic Back Door Control Unit

Reference Value

VALUES ON THE DIAGNOSIS TOOLNOTE:

The following table includes information (items)

inapplicable to this Nissan Ariya vehicle. For information (items)

applicable to this vehicle, refer to CONSULT display items.

CONSULT MONITOR ITEM Monitor Item Condition Value/Status

Autom ...

Power Distribution System. Symptom Diagnosis. Push-Button Ignition Switch Does Not Operate

Push-Button Ignition Switch Does Not Operate

Diagnosis Procedure

DescriptionCheck that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and check each symptom.NOTE:

The engine start function, door lock function, power

distribution system, and NATS-I ...

Driver Assistance System. Precaution. Precautions

Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along with a front seat belt, helps to reduce the

risk or severity of injury to the driver and ...