Nissan Rogue (T33) 2021-Present Service Manual: Fuel Injector

Component Function Check

INSPECTION START

Turn ignition switch to START.

Are any cylinders ignited?

YES>>GO TO 2.

NO>>Refer to Diagnosis Procedure.

CHECK FUEL INJECTOR FUNCTION

With CONSULT

With CONSULT

-

Start engine.

-

Perform “POWER BALANCE” in “ACTIVE TEST” mode of “ENGINE” with CONSULT.

-

Check that each circuit produces a momentary engine speed drop.

Without CONSULT

Without CONSULT

-

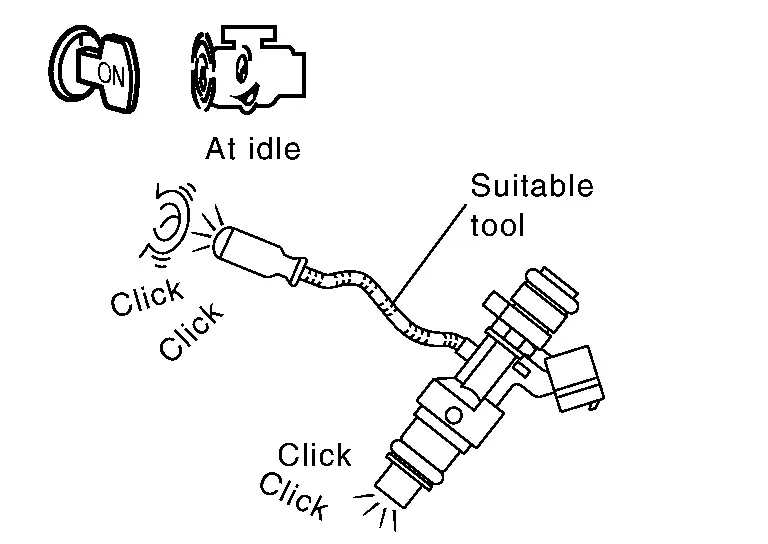

Start engine and let it idle.

-

Listen to each fuel injector operating sound.

Clicking sound should be heard.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Refer to Diagnosis Procedure.

Diagnosis Procedure

CHECK FUSE

-

Ignition switch OFF.

-

Check that the following fuse is not blowing.

Fuse No. Capacity #79 15 A #102 20 A

Is the fuse blown (open)?

YES>>Replace the fuse after repairing the applicable circuit.

NO>>GO TO 2.

CHECK FUEL INJECTOR DRIVER POWER SUPPLY

-

Disconnect ECM harness connector.

-

Ignition switch ON.

-

Check the voltage between ECM harness connector and ground.

+ ‚àí Voltage ECM Connector Terminal F72 1 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 9.

NO>>GO TO 3.

CHECK FUEL INJECTOR DRIVER POWER SUPPLY CIRCUIT

-

Ignition switch OFF.

-

Disconnect ECM harness connector.

-

Disconnect fuel injector relay harness connector.

-

Check the continuity between ECM harness connector and fuel injector relay harness connector.

ECM Fuel injector relay Continuity Connector Terminal Connector Terminal F72 1 F55 1 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>GO TO 4.

NO>>Repair or replace malfunctioning part.

CHECK FUEL INJECTOR RELAY POWER SUPPLY (CONTACT SIDE)

Check the voltage between fuel injector relay harness connector and ground.

| + | ‚àí | Voltage | |

|---|---|---|---|

| Fuel injector relay | |||

| Connector | Terminal | ||

| F55 | 2 | Ground | Battery voltage |

Is the inspection result normal?

YES>>GO TO 5.

NO>>Perform trouble diagnosis for power supply circuit.

CHECK FUEL INJECTOR RELAY POWER SUPPLY (EXCITATION COIL SIDE)

-

Install all removed parts.

-

Ignition switch ON.

-

Check the voltage between fuel injector relay harness connector and ground.

+ ‚àí Voltage Fuel injector relay Connector Terminal F55 4 Ground Battery voltage

Is the inspection result normal?

YES>>GO TO 7.

NO>>GO TO 6.

CHECK FUEL INJECTOR RELAY POWER SUPPLY CIRCUIT (EXCITATION COIL SIDE)

-

Ignition switch OFF.

-

Disconnect fuel injector relay harness connector.

-

Disconnect IPDM E/R harness connector.

-

Check the continuity between IPDM E/R harness connector and fuel injector relay harness connector.

IPDM E/R Fuel injector relay Continuity Connector Terminal Connector Terminal F35 73 F55 4 Existed -

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES>>Perform trouble diagnosis for power supply circuit.

NO>>Repair or replace malfunctioning part.

CHECK FUEL INJECTOR RELAY GROUND CIRCUIT

-

Ignition switch OFF.

-

Disconnect fuel injector relay harness connector.

-

Check the continuity between fuel injector relay harness connector and ground.

Fuel injector relay — Continuity Connector Terminal F55 3 Ground Existed -

Also check harness for short to power.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Repair or replace malfunctioning part.

CHECK FUEL INJECTOR RELAY

Refer to Component Inspection.

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Replace fuel injector relay.

CHECK ECM GROUND CIRCUIT

-

Ignition switch OFF.

-

Check the continuity between ECM harness connector and ground.

ECM — Continuity Connector Terminal F72 4 Ground Existed E21 156 157 160 -

Also check harness for short to power.

Is the inspection result normal?

YES>>GO TO 10.

NO>>Repair or replace malfunctioning part.

CHECK FUEL INJECTOR GROUND CIRCUIT

-

Ignition switch OFF.

-

Disconnect ECM harness connector.

-

Check the continuity between fuel injector harness connector and ECM harness connector.

Fuel injector ECM Continuity Cylinder Connector Terminal Connector Terminal 1 F202 1 F72 9 Existed 2 17 2 F203 1 11 2 20 3 F204 1 12 2 18 -

Also check harness for short to ground.

Is the inspection result normal?

YES>>GO TO 11.

NO>>Repair or replace malfunctioning part.

CHECK FUEL INJECTOR

Refer to Component Inspection.

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Repair or replace malfunctioning part.

Component Inspection

CHECK FUEL INJECTOR

-

Turn ignition switch OFF.

-

Disconnect fuel injector harness connector.

-

Check the resistance between fuel injector terminals.

Fuel injector Condition Resistance Terminal 1 2 Temperature [°C (°F)] 20 (68) 1.34 – 1.64 Ω

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace fuel injector. Refer to Removal and Installation.

Other materials:

Power Distribution System. Precaution. Precautions

Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along with a front seat belt, helps to reduce the

risk or severity of injury to the driver and ...

Telematics System. Basic Inspection

Diagnosis and Repair Work Flow

Work Flow

OVERALL SEQUENCE

Reference 1··· Refer to Consult Function

.

Reference 2··· Refer to DTC Index

.

Reference 3··· Refer to Symptom Table

.

DETAILED FLOWINTERVIEW AND SYMPTOM CONFIRMATION

Check the malfunction symptoms by performing the f ...

Rear-facing child restraint installation using the seat belts

WARNING

The three-point seat belt with Automatic Locking Retractor (ALR) must be used when installing a child restraint. If the ALR mode is not used, the restraint may not be properly secured and could tip or become loose, causing injury to a child in a sudden stop or collision.

For additional ...