Nissan Rogue (T33) 2021-Present Service Manual: Drive Plate

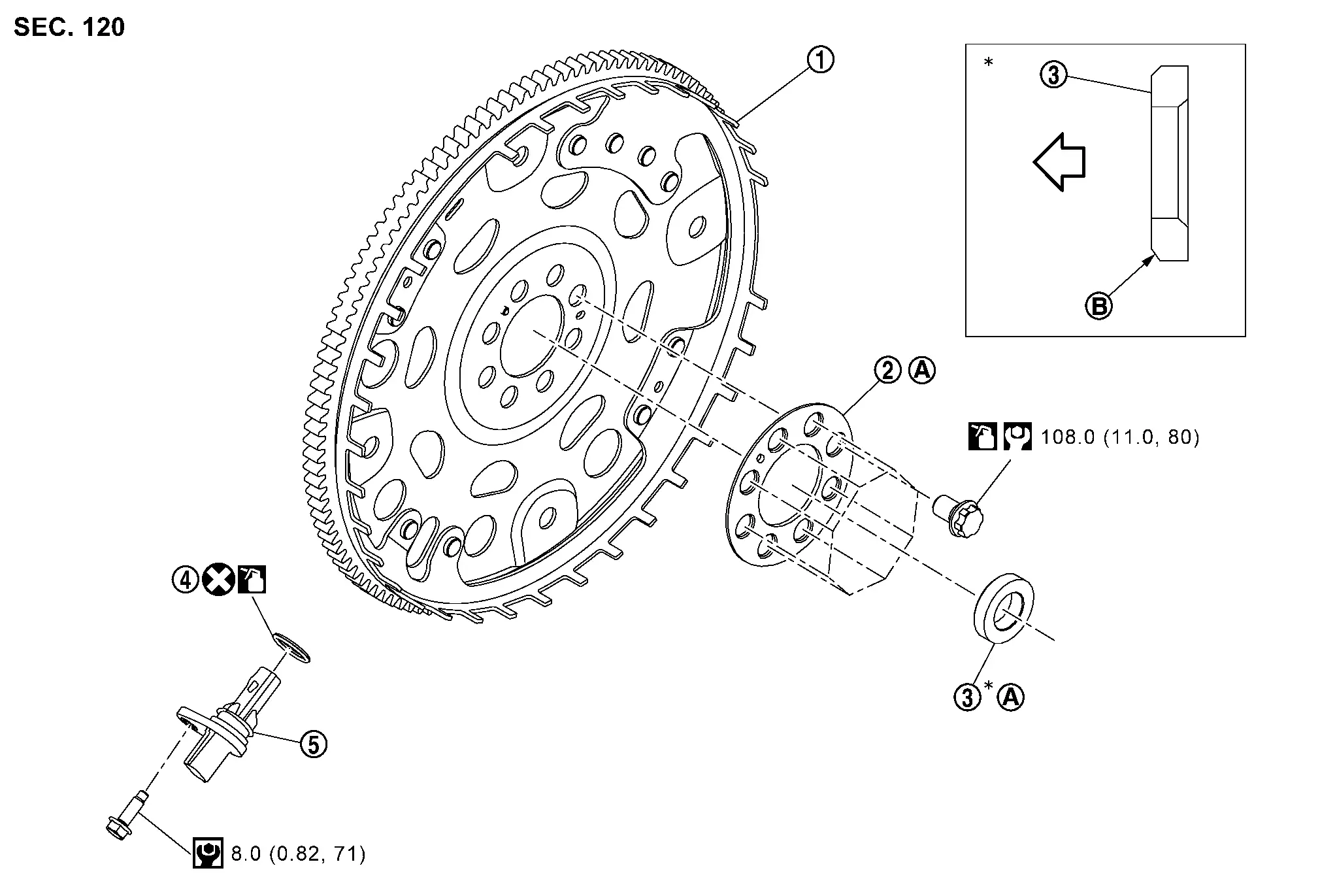

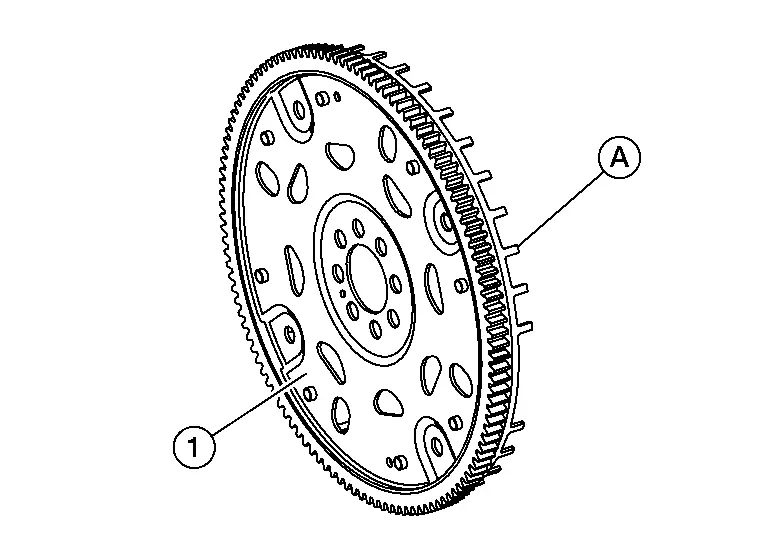

Exploded View

|

Drive plate |  |

Drive plate reinforcement |  |

Pilot converter |

|

O-ring (NMK production only) |  |

Crankshaft position sensor | ||

|

Comply with the assembly procedure when installing. Refer to Removal and Installation. |  |

: Chamfered | ||

|

: Crankshaft side | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: Should be lubricated with oil. | ||||

|

: Always replace after every disassembly. | ||||

Removal and Installation

REMOVAL

Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the engine. Refer to Removal and Installation.

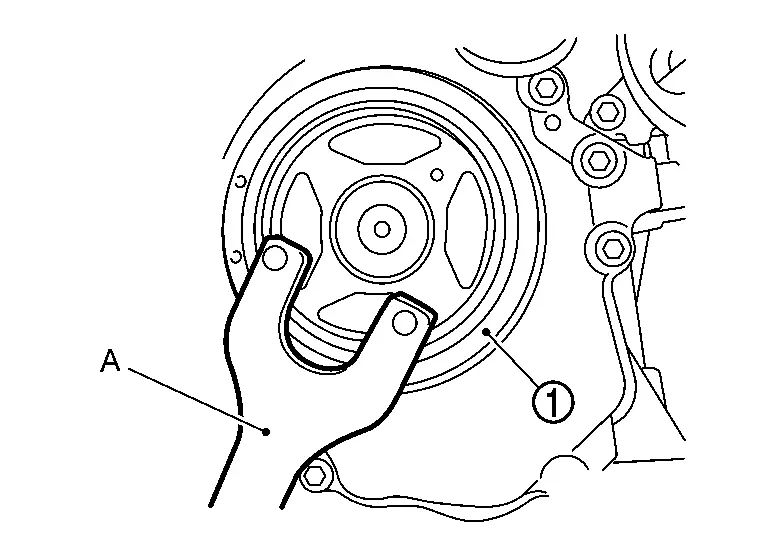

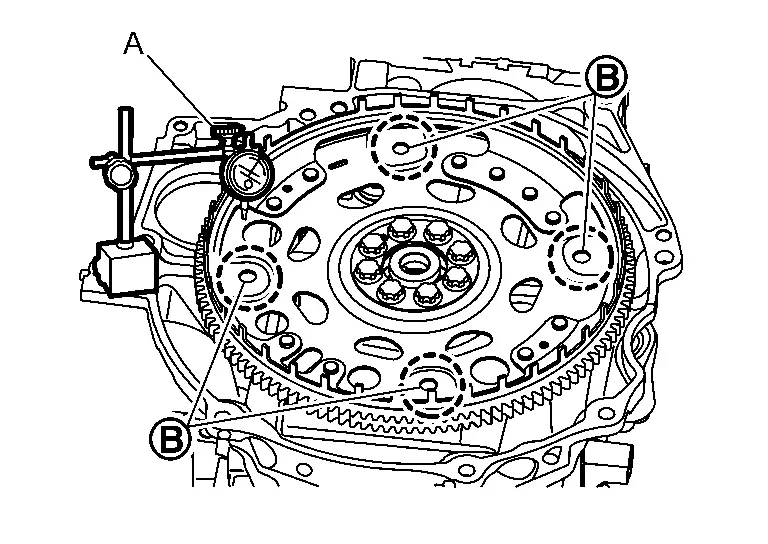

Remove the drive plate using the following procedure:Secure crankshaft pulley  with a pulley holder (A).

with a pulley holder (A).

CAUTION:

-

Do not disassemble drive plate.

-

Do not place drive plate with signal plate facing down.

-

When handling signal plate, take care not to damage or scratch drive plate and signal plate.

-

Handle signal plate in a manner that prevents them from becoming magnetized.

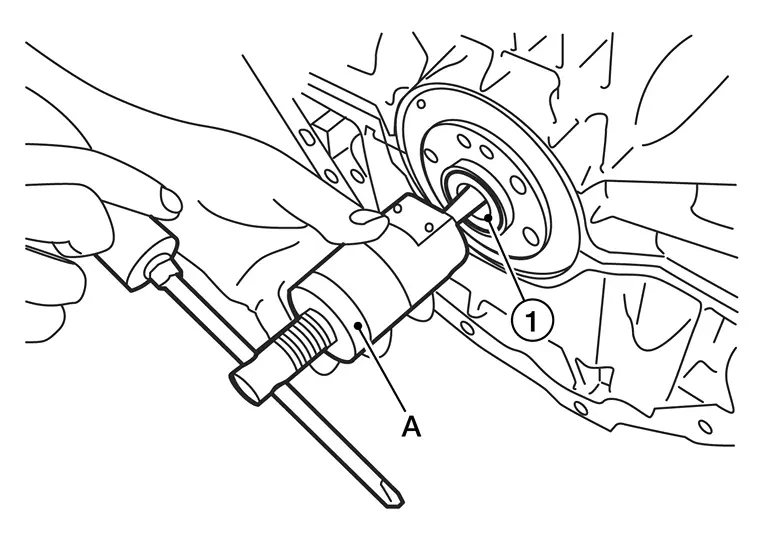

Remove the pilot converter  from the rear end of the crankshaft. Use a suitable tool (A) if necessary.

from the rear end of the crankshaft. Use a suitable tool (A) if necessary.

Remove the crankshaft position sensor if necessary.

INSTALLATION

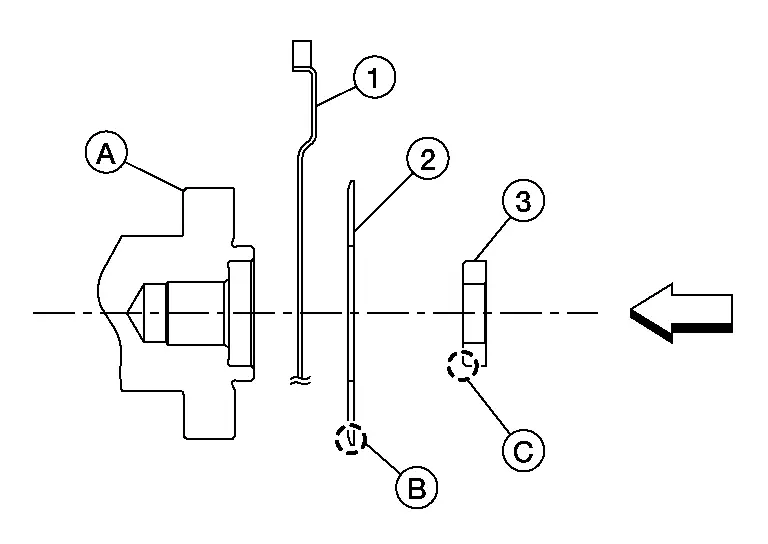

Install drive plate  , drive plate reinforcement

, drive plate reinforcement  and pilot converter

and pilot converter  as shown.

as shown.

-

Using a suitable drift of 33 mm (1.30 in) in diameter, press fit the pilot converter into the end of the crankshaft

until it stops.

until it stops.CAUTION:

Be careful not to damage or scratch the drive plate and signal plate.

: Rounded

: Chamfered

: Engine front

Hand tighten drive plate bolts in a diagonal order over several steps.

Tighten drive plate bolts using a suitable tool in a diagonal order over several steps.

If removed, install the crankshaft position sensor.

Installation of the remaining components is in the reverse order of removal.

CAUTION:

If crankshaft position sensor replaced, perform "ELECTRIC IVT CONTROL ACTUATOR POSITION LEARNING". Refer to Description.

Inspection

DRIVE PLATE DEFLECTION

Appearance of Drive Plate

Check the drive plate  and signal plate

and signal plate  for defamation or damage.

for defamation or damage.

CAUTION:

-

Do not disassemble drive plate.

-

Do not place drive plate with signal plate

facing down.

facing down. -

When handling signal plate, take care not to damage or scratch it.

-

Handle signal plate that prevents it from becoming magnetized.

Check drive plate signal plate for deformation or damage.

Replace drive plate if dents, scratches or damage exist.

Drive Plate Lateral Run-Out

-

Install drive plate to crankshaft and measure deflection with dial indicator (A).

CAUTION:

-

Do not disassemble drive plate.

-

Do not place drive plate with signal plate facing down.

-

When handling signal plate, take care not to damage or scratch it.

-

Handle signal plate that prevents it from becoming magnetized.

-

If damage is found, replace drive plate.

-

-

Measure deflection on the drive plate to torque converter contact surface

. Measurements should be taken 11.0 - 20.6 mm (0.43 - 0.811 in) from the center of the torque converter bolt hole.

. Measurements should be taken 11.0 - 20.6 mm (0.43 - 0.811 in) from the center of the torque converter bolt hole.Standard : 0.35 mm (0.014 in) or less. -

If the measurement value is outside the reference value, replace drive plate.

Other materials:

Adas Control Unit. Precaution. Precautions

Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along with a front seat belt, helps to reduce the

risk or severity of injury to the driver and ...

Symptom Diagnosis. Tire Pressure Monitoring System Symptom

Symptom Table

LOW TIRE PRESSURE WARNING LAMP SYMPTOM CHART Diagnosis items

Symptom

(Ignition switch ON) Low tire pressure warning lamp Cause Action

Low tire pressure warning lamp

The low tire pressure warning lamp illuminates for 1 second, then turns OFF.

Wake-up operation fo ...

Symptom Diagnosis. Squeak and Rattle Trouble Diagnoses

Work Flow

CUSTOMER INTERVIEWInterview

the customer if possible, to determine the conditions that exist when

the noise occurs. Use the Diagnostic Worksheet during the interview to

document the facts and conditions when the noise occurs and any of

customer's comments. Refer to Diagnostic Work ...