Nissan Rogue (T33) 2021-Present Service Manual: Cvt: Ge0f14a :: Basic Inspection

Diagnosis and Repair Work Flow

Work Flow

NOTE:

NOTE:

ŌĆ£DTCŌĆØ includes DTC at the 1st trip.

OBTAIN INFORMATION ABOUT SYMPTOM

Refer to Diagnostic Work Sheet and interview the customer to obtain the malfunction information (conditions and environment when the malfunction occurred) as much as possible when the customer brings in the Nissan Ariya vehicle.

>>

GO TO 2.

CHECK DTC

-

Before checking the malfunction, check whether any DTC exists.

-

If DTC exists, perform the following operations.

-

Records the DTCs. (Print out using CONSULT and affix to the Work Order Sheet.)

-

Erase DTCs.

-

Check the relation between the cause found by DTC and the malfunction information from customer. Symptom Table can be used effectively.

-

Do malfunction information and DTC exist?

Malfunction information and DTC exist.>>GO TO 3.

Malfunction information exists but no DTC.>>GO TO 4.

No malfunction information, but DTC exists.>>GO TO 5.

REPRODUCE MALFUCTION SYSTEM

Check the malfunction described by the customer on the Nissan Ariya vehicle.

Check if the behavior is fail safe or normal operation. Refer to Fail-safe (TCM) or Fail-safe (ELECTRIC SHIFT CONTROL MODULE).

Interview sheet can be used effectively when reproduce malfunction conditions. Refer to Diagnostic Work Sheet.

Verify the relationship between the symptom and the conditions in which the malfunction described by the customer occurs.

>>

GO TO 5.

REPRODUCE MALFUNCTION SYMPTOM

Check the malfunction described by the customer on the Nissan Ariya vehicle.

Check if the behavior is fail safe or normal operation. Refer to Fail-safe (TCM) or Fail-safe (ELECTRIC SHIFT CONTROL MODULE).

Interview sheet can be used effectively when reproduce malfunction conditions. Refer to Diagnostic Work Sheet.

Verify the relationship between the symptom and the conditions in which the malfunction described by the customer occurs.

>>

GO TO 6.

PERFORM ŌĆ£DTC CONFIRMATION PROCEDUREŌĆØ

Perform ŌĆ£DTC CONFIRMATION PROCEDUREŌĆØ of the appropriate DTC to check if DTC is detected again.

Refer to DTC Inspection Priority Chart (TCM) or DTC Inspection Priority Chart (ELECTRIC SHIFT CONTROL MODULE) when multiple DTCs are detected, and then determine the order for performing the diagnosis.

Is any DTC detected?

YES>>GO TO 7.

NO>>Follow Intermittent Incident to check.

IDENTIFY MALFUNCTIONING SYSTEM WITH ŌĆ£DIAGNOSIS CHART BY SYMPTOMŌĆØ

Use Symptom Table from the symptom inspection result in step 4. Then identify where to start performing the diagnosis based on possible causes and symptoms.

>>

GO TO 8.

REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the detected malfunctioning parts.

Reconnect parts or connector after repairing or replacing, and then erase DTC if necessary.

>>

GO TO 8.

FINAL CHECK

Perform ŌĆ£DTC CONFIRMATION PROCEDUREŌĆØ again to make sure that the repair is correctly performed.

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 3 or 4.

Is DTC or malfunction symptom reproduced?

YES-1>>DTC is reproduced : GO TO 5.

YES-2>>Malfunction is reproduced : GO TO 6.

NO>>Before delivering the Nissan Ariya vehicle to the customer, make sure that DTC is erased.

Diagnostic Work Sheet

DESCRIPTION

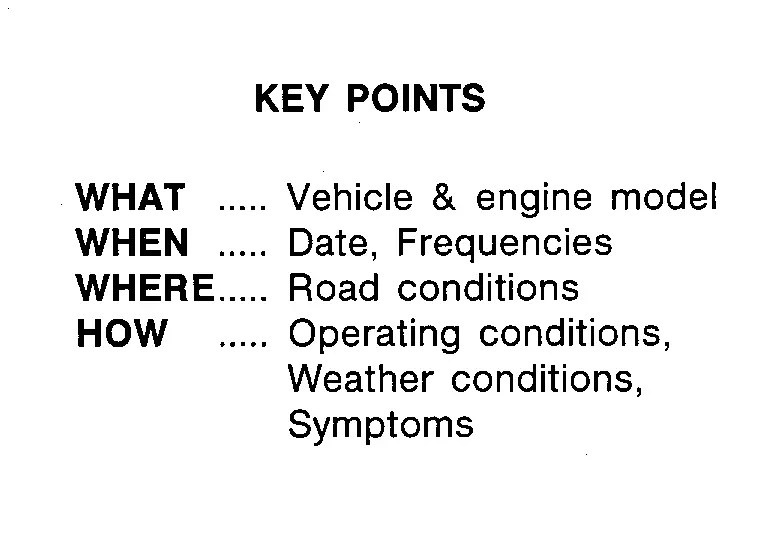

There are many operating conditions that may cause a malfunction of the transmission parts. By understanding those conditions properly, a quick and exact diagnosis can be achieved.

In general, perception of a problem varies depending on individuals. Ask the customer about his/her concerns carefully. It is important to understand the phenomenon or status. To systemize all the information for the diagnosis, prepare the question sheet referring to the question points.

In some cases, multiple conditions that appear simultaneously may cause a DTC to be detected.

Worksheet Sample

| Question sheet | |||||

|---|---|---|---|---|---|

| Customer's name | MR/MS | Registration number | Initial year registration |

YearŌĆāŌĆāMonthŌĆāŌĆā day | |

| Nissan Ariya Vehicle type | Chassis No. | ||||

| Storage date |

YearŌĆāŌĆāMonthŌĆāŌĆā day | Engine | Mileage | km/mile | |

| Symptom | Ō¢Ī Nissan Ariya Vehicle does not start. (Ō¢Ī R position ŌĆāŌ¢Ī D position Ō¢Ī M position) | ||||

| Ō¢Ī Upshifting does not occur. ŌĆāŌĆāŌ¢Ī Downshifting does not occur. | |||||

| Ō¢Ī Lock-up malfunction | |||||

| Ō¢Ī Shift point is too high. ŌĆāŌĆāŌĆāŌĆāŌĆāŌ¢Ī Shift point is too low. | |||||

| Ō¢Ī Shift shock (Ō¢Ī NŌćÆDŌĆāŌ¢Ī Lock-up ŌĆāŌ¢Ī R, D, and M position) | |||||

| Ō¢Ī Slip (Ō¢Ī NŌćÆDŌĆāŌ¢Ī Lock-up ŌĆāŌ¢Ī R, D, and L position) | |||||

| Ō¢Ī NoiseŌĆāŌĆāŌĆāŌ¢Ī Vibration | |||||

| When selector lever position is shifted, shift pattern does not change. | |||||

|

Ō¢Ī Other (ŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆāŌĆā) |

|||||

| First occurrence | Ō¢Ī Recently (as from monthŌĆāŌĆā of yearŌĆāŌĆā) | ||||

| Frequency of occurrence | Ō¢Ī Always Ō¢Ī Under certain conditions Ō¢Ī Sometimes (ŌĆāŌĆā time(s)/day) | ||||

| Climate conditions | Irrelevant | ||||

| Weather | Ō¢Ī ClearŌĆāŌĆāŌĆāŌ¢Ī CloudŌĆāŌĆāŌĆāŌ¢Ī RainŌĆāŌĆāŌĆāŌ¢Ī SnowŌĆāŌĆāŌĆāŌ¢Ī Others ) | ||||

| Temperature | Ō¢Ī HotŌĆāŌĆāŌĆāŌ¢Ī WarmŌĆāŌĆāŌ¢Ī CoolŌĆāŌĆāŌ¢Ī ColdŌĆāŌĆāŌ¢Ī Temperature (Approx.ŌĆāŌĆā┬░C/┬░F) | ||||

| Relative humidity | Ō¢Ī HighŌĆāŌĆāŌĆāŌĆāŌ¢Ī ModerateŌĆāŌĆāŌĆāŌĆāŌ¢Ī Low | ||||

| Transaxle condition |

Ō¢Ī In cold-start ŌĆāŌĆāŌ¢Ī During warm-up (approx. ┬░C/┬░F)ŌĆāŌĆāŌ¢Ī After warm-up Ō¢ĪEngine speed: rpm |

||||

| Road conditions |

Ō¢Ī Urban areaŌĆāŌĆāŌ¢Ī Suburb areaŌĆāŌĆāŌ¢Ī Highway ŌĆāŌĆā Ō¢Ī Mountainous road (uphill or downhill) |

||||

| Operating condition, etc. |

Irrelevant Ō¢Ī When engine startsŌĆāŌĆāŌ¢Ī During idlingŌĆāŌĆāŌ¢Ī During driving Ō¢Ī During accelerationŌĆāŌĆāŌĆāŌ¢Ī At constant speed drivingŌĆāŌĆāŌ¢Ī During deceleration Ō¢Ī During cornering (RH curve or LH curve) |

||||

| Other conditions | |||||

Additional Service When Replacing Tcm

Description

Description

Always perform the following work when TCM is repaced.

CAUTION:

When replacing the TCM, always replace it with a new one. The functions controlled by the TCM does not operate properly in case of reuse of the TCM from another Nissan Ariya vehicle.

Work Procedure

WORK BEFORE TCM REPLACEMENT

The following work must be performed before replacing the TCM.

-

IP characteristics value saving

NOTE:

NOTE:

TCM performs accurate control by retrieving data (IP characteristic value) of each solenoid.The control unit information must be saved to CONSULT before replacing the TCM to transfer the data to the new TCM after replacement.

SAVE IP CHARACTERISTICS VALUE

With CONSULT

With CONSULT

-

Ignition switch OFF and wait for 10 seconds.

-

Reconnect all disconnected connectors.

-

Ignition switch ON.

-

Select "TRANSMISSION" using CONSULT.

-

Select "Replace ECU".

-

Perform the work according to the CONSULT display.

NOTE:

NOTE:

Control unit information is automatically saved to CONSULT.

>>

Replace TCM. Refer to Removal and Installation.

WORK AFTER TCM REPLACEMENT

The following work must be performed after replacing the TCM.

-

Programming

NOTE:

NOTE:

Vehicle specification needs to be written with CONSULT because it is not written to the new TCM. A net work connection is needed for programming. CONSULT downloads Nissan Ariya vehicle specification from the server and writes it to the TCM.For details the operation, refer to ŌĆ£CONSULT Operation ManualŌĆØ.

-

IP characteristics value writing

NOTE:

NOTE:

TCM performs accurate control by retrieving data (IP characteristic value) of each solenoid. The control unit information saved to CONSULT needs to be written to the new TCM.

-

MAC key writing

-

G sensor calibration

-

Cutch point lerning

-

Torque converter clutch point lerning

-

Select learning (Drive/Reverse learning)

PERFORM "REPLACE ECU"

With CONSULT

With CONSULT

-

Ignition switch ON.

-

Select "TRANSMISSION" using CONSULT.

-

Select "Replace ECU".

-

Perform the work according to the CONSULT display.

NOTE:

NOTE:

Programming and control unit writing are done automatically.

>>

GO TO 2.

WRITE MAC KEY

Perform MAC key writing, Refer to Work Procedure.

YES>>

GO TO 3.

PERFORM G-SENSOR CALIBRATION

Perform G-sensor Calibration. Refer to Work Procedure.

>>

GO TO 4.

PERFORM CLUTCH POINT LEARNING

Perform Clutch Point Learning. Refer to Work Procedure.

>>

GO TO 5.

PERFORM TORQUE CONVERTER CLUTCH POINT LEARNING

Perform Torque Converter Clutch Point Learning. Refer to Work Procedure.

>>

GO TO 6.

PERFORM SELECT LEARNING (DRIVE/REVERSE LEARNING)

NOTE:

NOTE:

Always perform Clutch Point Learning before Select Learning.

-

Perform Select Learning. Refer to Work Procedure.

-

Clear any DTCs that may have set and then test drive the Nissan Ariya vehicle.

>>

WORK END

Additional Service When Replacing Transaxle Assembly

Description

Description

Perform the following work after the transaxle assembly is replaced.

Work Procedure

WORK AFTER TRANSAXLE ASSEMBLY REPLACEMENT

-

Programming

NOTE:

NOTE:

Vehicle specification needs to be written with CONSULT because it is not written to the new TCM. A net work connection is needed for programming. CONSULT downloads Nissan Ariya vehicle specification from the server and writes it to the TCM.For details the operation, refer to ŌĆ£CONSULT Operation ManualŌĆØ.

-

MAC key writing

-

Shift actuator learning

-

Select learning (Drive/Reverse learning)

-

G sensor calibration

REPLACE TRANSAXLE ASSEMBLY

-

Ignition switch OFF.

-

Replace transaxle assembly. Refer to Removal and Installation.

>>

GO TO 2.

PERFORM PROGRAMMING

With CONSULT

With CONSULT

-

Ignition switch ON.

-

Select "TRANSMISSION" using CONSULT.

-

Select "Replace ECU".

-

Perform the work according to the CONSULT display.

NOTE:

NOTE:

Programming is done automatically.

>>

GO TO 3.

WRITE MAC KEY

Perform MAC key writing, Refer to Work Procedure.

>>

GO TO 4.

PERFORM G-SENSOR CALIBRATION

Perform G-Sensor Calibration. Refer to Work Procedure.

>>

GO TO 5.

PERFORM SHIFT ACTUATOR LEARNING

Perform Shift Actuator Learning. Refer to Work Procedure.

>>

GO TO 6.

PERFORM SELECT LEARNING (DRIVE/REVERSE LEARNING)

-

Perform Select Learning. Refer to Work Procedure.

-

Clear any DTCs that may have set and then test drive the Nissan Ariya vehicle.

>>

WORK END

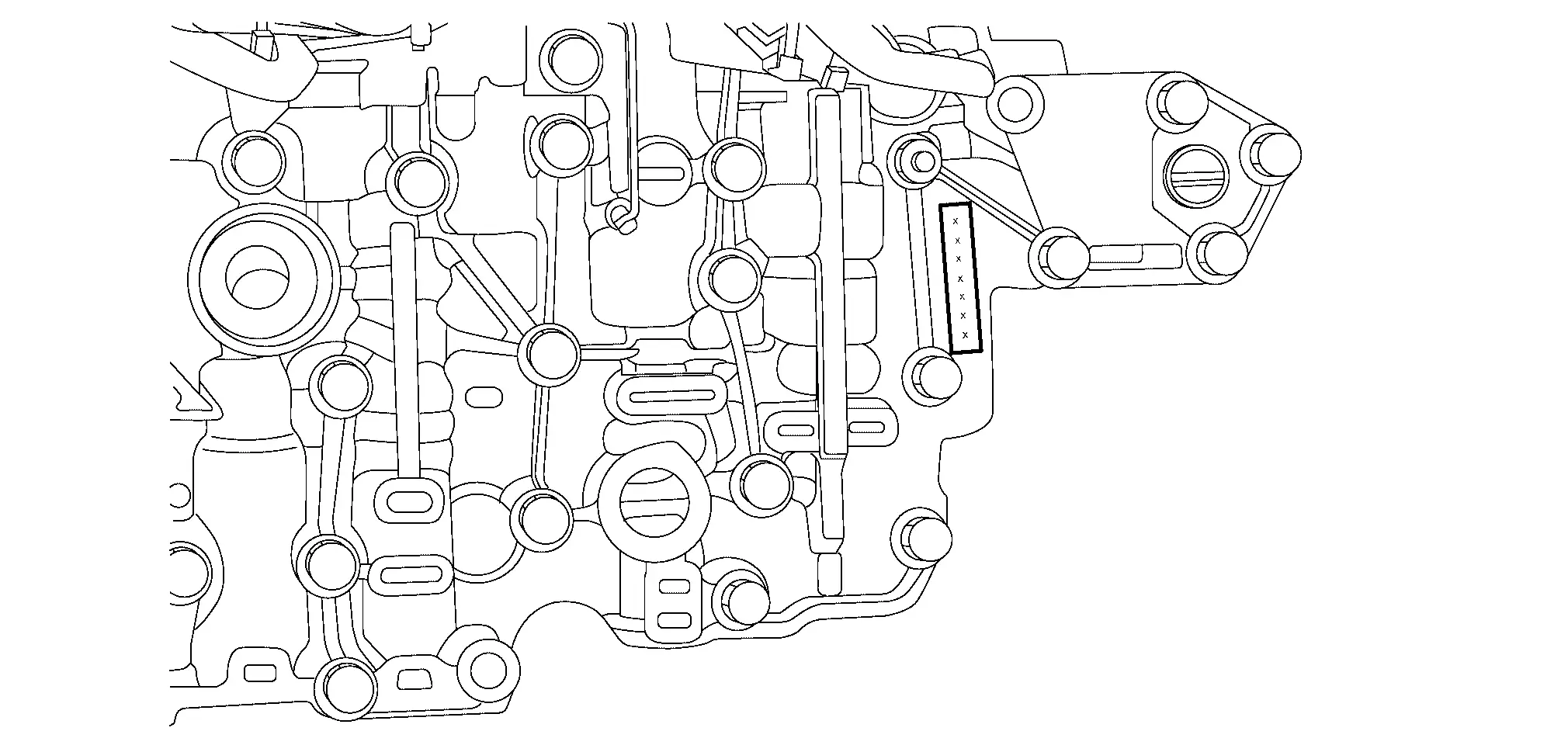

Additional Service When Replacing Control Valve

Description

Description

Perform the following work after the control valve is replaced.

NOTE:

NOTE:

New control valve assemblies may come with a CD-ROM, which is not used.

Work Procedure

WORK BEFORE CONTROL VALVE REPLACEMENT

The following work must be performed before replacing the control valve.

-

New control valve serial number checking

CHECK SERIAL NUMBER

-

Write down the serial number (calibration file number) of the new control valve.

-

Compare the serial number (calibration file number) on the CD, QR code label and new control valve. All numbers must match.

>>

Replace control valve. Refer to Removal and Installation.

WORK AFTER CONTROL VALVE REPLACEMENT

The following work must be performed before replacing the control valve.

-

IP characteristics value writing

NOTE:

NOTE:

-

TCM performs accurate control by retrieving data (IP characteristic value) of each solenoid. The control unit information saved to CONSULT needs to be written to the new TCM.

-

The server maintains IP characteristic values corresponding to the Nissan Ariya vehicle VIN.When the IP characteristic value writing operation is performed, the IP characteristic value is updated for the Nissan Ariya vehicle VIN information on the server side.

-

-

Cutch point learning

-

Torque converter clutch point learning

-

Select learning (Drive/reverse learning)

-

CVT fluid degradation level data erasing

WRITING IP CHARACTERISTICS VALUE

With CONSULT

With CONSULT

-

Ignition switch ON.

-

Select "TRANSMISSION" using CONSULT.

-

Select "Write IP characteristic - Input serial number" in "Work supoprts".

-

Perform the work according to the CONSULT display.

>>

GO TO 2.

PERFORM CLUTCH POINT LEARNING

Perform Clutch Point Learning. Refer to Work Procedure.

>>

GO TO 3.

PERFORM TORQUE CONVERTER CLUTCH POINT LEARNING

Perform Torque Converter Clutch Point Learning. Refer to Work Procedure.

>>

GO TO 4.

PERFORM SELECT LEARNING (DRIVE/REVERSE LEARNING)

NOTE:

NOTE:

Always perform Clutch Point Learning before Select Learning.

Perform Select Learning. Refer to Work Procedure.

>>

GO TO 5.

ERASE CVT FLUID DEGRADATION LEVEL DATA

With CONSULT

With CONSULT

-

Select ŌĆ£Work supportsŌĆØ in ŌĆ£TRANSMISSIONŌĆØ.

-

Select ŌĆ£Confirm AT/CVT fluid deteriorationŌĆØ.

-

Touch ŌĆ£ClearŌĆØ.

-

Clear any DTCs that may have set and then test drive the Nissan Ariya vehicle.

>>

WORK END

Clutch Point Learning

Description

TCM memorizes a clutch point (engagement timing), and this enables accurate control. For work procedure, refer to Work Procedure.

Work Procedure

CLUTCH POINT LEARNING

With CONSULT

With CONSULT

-

Start the engine.

-

Select ŌĆ£Work supportsŌĆØ in ŌĆ£TRANSMISSIONŌĆØ.

-

Select ŌĆ£Clutch point learningŌĆØ.

-

Perform learning according to the CONSULT display.

CAUTION:

After the completion in D position, perform in R position.

>>

WORK END

Torque Converter Clutch Point Learning

Description

TCM memorizes a torque converter clutch point (engagement timing), and this enables accurate control. For work procedure, refer to Work Procedure.

Work Procedure

TORQUE CONVERTER CLUTCH POINT LEARNING

With CONSULT

With CONSULT

-

Start the engine.

-

Select ŌĆ£Work supportsŌĆØ in ŌĆ£TRANSMISSIONŌĆØ.

-

Select ŌĆ£Torque converter clutch point learningŌĆØ.

-

Perform learning.

CAUTION:

During learning, maintain the following conditions:

-

Brake pedal: Depressed

-

Accelerator pedal: Not depressed

-

Shift position: D position

-

A/C switch: OFF

-

CVT fluid temperature: 60┬░C (140 ┬░F) ŌĆō 100┬░C (212 ┬░F)

-

Engine coolant temperature: 70┬░C (158 ┬░F) ŌĆō 110┬░C (230 ┬░F)

-

Nissan Ariya Vehicle speed: 3 km/h (2 MPH) or less

-

DTCs has not been detected.

>>

WORK END

Select Learning

Work Procedure

NOTE:

NOTE:

-

If Clutch Point Learning is also required, always perform Clutch Point Learning before Select Learning.

-

Perform Select Learning with CVT fluid temperature below 50┬░C (122┬░F) and again with fluid temperature above 50┬░C (122┬░F).

PERFORM SELECT LEARNING (DRIVE/REVERSE LEARNING)

-

Set the parking brake.

-

Start the engine and wait 5 seconds.

-

Depress the brake pedal

-

Shift to N position and keep more than 2 seconds, then shift to D position and wait for transaxle engagement.

-

Repeat step 4 ten (10) times.

-

Shift to N position and keep more than 2 seconds, then shift to R position and wait for transaxle engagement.

-

Repeat step 6 ten (10) times.

-

Shift to P position and ignition switch OFF.

>>

WORK END

Calibration of Decel G Sensor

Description

TCM stores calibration data (inherent characteristic value) of decel G sensor to provide accurate control. Therefore, it is required to perform calibration of decel G sensor after the following work is performed.

-

Removing/ installing ABS actuator and electric unit (control unit)

-

Replacing ABS actuator and electric unit (control unit)

-

Replacing TCM

-

Erasing the calibration data of TCM

Refer to Work Procedure.

Work Procedure

PERFORM CALIBRATION OF DECEL G SENSOR [ABS actuator and electric unit (control unit)]

Perform calibration of decel G sensor. Refer to Description.

>>

GO TO 2.

PREPARATION BEFORE CALIBRATION PROCEDURE

-

Park the Nissan Ariya vehicle on a level surface.

-

Adjust air pressure of all tires to the specified pressure. Refer to Tire Air Pressure.

>>

GO TO 3.

PERFORM CALIBRATION OF DECEL G SENSOR (TCM)

With CONSULT

With CONSULT

-

Ignition switch ON.

CAUTION:

Never start engine.

-

Select ŌĆ£Work supportsŌĆØ in ŌĆ£TRANSMISSIONŌĆØ.

-

Select ŌĆ£G sensor calibrationŌĆØ.

-

Touch ŌĆ£STARTŌĆØ.

CAUTION:

Never rock or jounce the Nissan Ariya vehicle during ŌĆ£G sensor calibrationŌĆØ.

Is ŌĆ£COMPLETEDŌĆØ displayed?

YES>>WORK END

NO>>Perform steps 3 again.

Mac Key Writing

Description

When replacing TCM, it is necessary to write MAC key to TCM. Write MAC key to TCM according to "MAC KEY writing" procedure of "CONSULT Operation Manual". Refer to Work Procedure.

CAUTION:

During MAC Key writing, maintain the following conditions:

-

Ignition switch ON

-

CONSULT is connected to internet

Work Procedure

PERFORM MAC KEY WRITING

-

Ignition switch ON.

-

Select "MAC KEY writing" on "Work supports" of "TRANSMISSION" using CONSULT.

-

Touch "Write".

YES>>

WORK END

Shift Actuator Learning

Description

Electric shift control module memorizes a shift actuator position, and this enables accurate control.

Therefore, it is required to perform learning value elase and relearning after the following work is performed.

-

Removing/installing shift actuator

-

Replacing shift actuator

-

Replacing transaxle assembly

-

Replacing electric shift control module (Learning only)

Refer to Work Procedure.

Work Procedure

NOTE:

NOTE:

If the electric shift control module has been replaced, start with step 2.

ERASE SHIFT ACTUATOR LERNING VALUE

With CONSULT

With CONSULT

-

Ignition switch ON.

-

Select ŌĆ£Work supportsŌĆØ in ŌĆ£SHIFTŌĆØ.

-

Select ŌĆ£Actuator learning value eliminationŌĆØ.

-

Touch ŌĆ£STARTŌĆØ.

-

Touch ŌĆ£ENDŌĆØ.

>>

GO TO 2.

SHIFT ACTUATOR LEARNING

-

Ignition switch ON.

-

Depress the brake pedal in "P" position and wait for 3 seconds.

-

Start the engine.

-

Depress the brake pedal.

-

Shift to "D" position and wait for 3 seconds.

-

Press the P position switch.

-

Ignition switch OFF and wait for 60 seconds.

>>

WORK END

Stall Test

Work Procedure

INSPECTION

Check the engine oil level. Replenish if necessary. Refer to Inspection.

Check for leak of the CVT fluid. Refer to Inspection.

Drive for about 10 minutes to warm up the Nissan Ariya vehicle so that the CVT fluid temperature is 50 to 80┬░C (122 to 176┬░F).

Be sure to apply the parking brake and block the tires.

Start the engine, depress the brake pedal and shift to the D position.

While depressing the brake pedal, depress the accelerator pedal gradually.

Read the stall speed quickly. Then, release your foot from the accelerator pedal quickly.

CAUTION:

Never depress the accelerator pedal for 5 seconds or more during the test.

| Stall speed | : Refer to Stall Speed. |

Shift to the N position

Cool the CVT fluid.

CAUTION:

Run the engine with the idle speed for at least 1 minute.

Shift to the R position and perform Step 6 to Step 9 again.

NARROWING-DOWN MALFUNCTIONING PARTS

| Shift position | Possible cause | ||

| D | R | ||

| Stall speed | H | O |

|

| O | H |

|

|

| L | L |

|

|

| H | H |

|

|

O: Within the stall speed standard value.

H: Stall speed is higher than the standard value.

L: Stall speed is lower than the standard value.

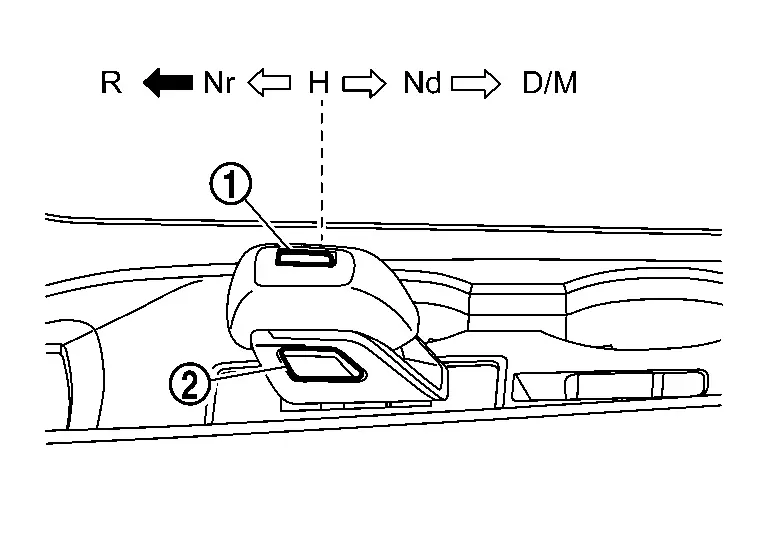

Cvt Position

Inspection

CHECK SELECTOR LEVER OPERATION

-

Shift the selector lever and check for excessive effort, sticking, noise or rattle.

-

The selector lever automatically moves back to the H (home) position after it is operated.

: P position switch

: P position switch : Press the button

: Press the button  to shift

to shift : Shift without pressing the button

: Shift without pressing the button

-

The selector lever cannot move to R position unless press the knob button.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace the electric shift selector. Refer to Removal and Installation.

CHECK SHIFT POSITION

Check the following during engine running.

-

When the selector lever shifts to each position during depressing the brake pedal, the shift position normally changes.

-

When the brake pedal is not depressed at the P position, the shift position does not change even if the selector lever is operated.

-

When the P position switch is pressed and released at any shift position except the P position, the shift position changes into the P position.

-

When the selector lever shifts to the D position again at the D position, the shift position changes into the M mode.

-

When the selector lever shifts to the D position again at the M mode, the shift position changes into the D position.

-

When the ignition switch turns off, the shift position automatically changes into the P position. (The selector indicator lamp of the P position turns ON.)

Is the inspection result normal?

YES>>INSPECTION END

NO>>Check the electric shift system.

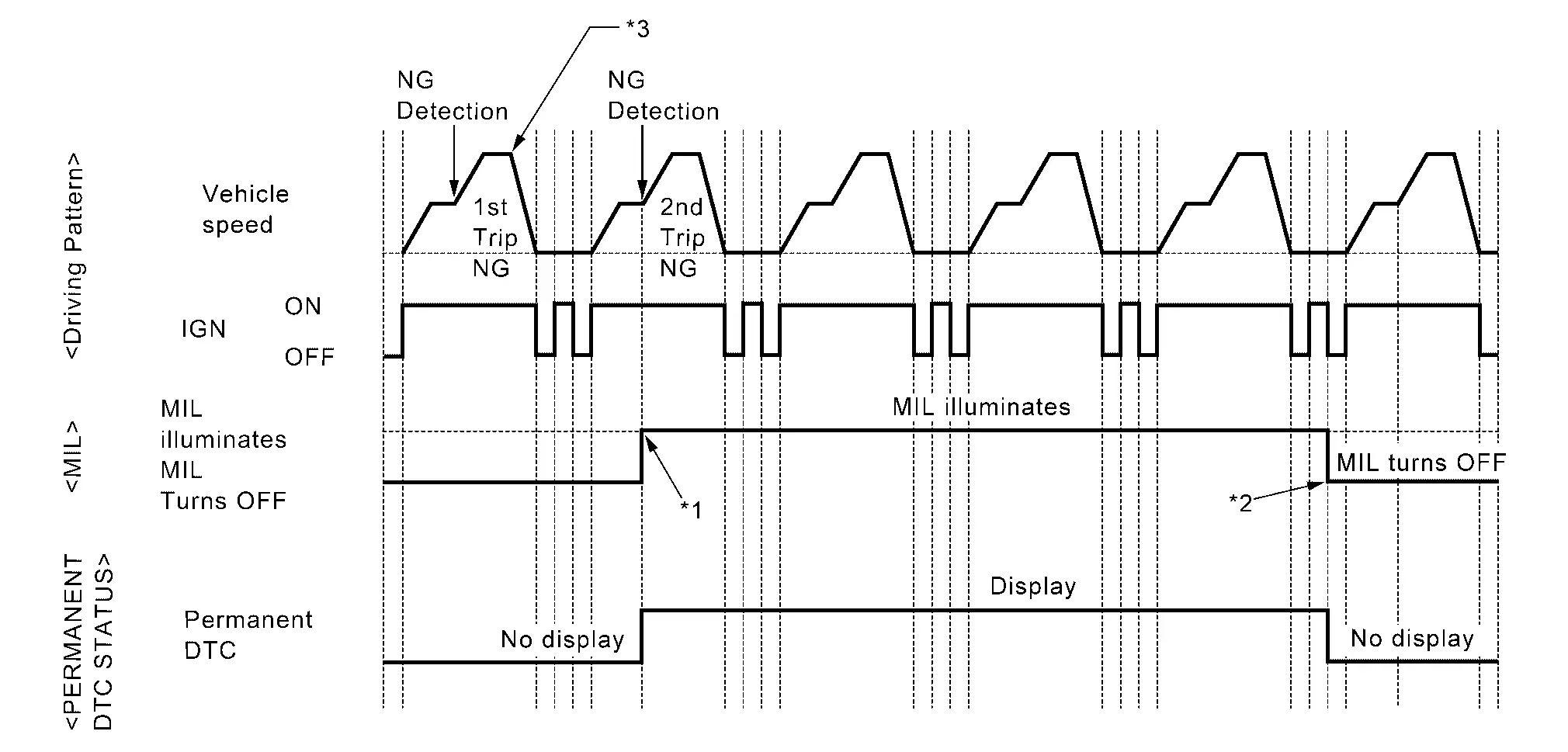

How to Erase Permanent Dtc

Description

WHEN A DTC IS STORED IN TCM

When a DTC is stored in TCM and MIL is ON, a permanent DTC is erased with MIL shutoff if the same malfunction is not detected after performing the driving pattern for MIL shutoff three times in a raw.

NOTE:

NOTE:

The following timing chart is for DTC of two trip detection diagnosis.

In case of DTC of one trip detection diagnosis, when NG is detected at one trip, MIL turns ON and permanent DTC is displayed.

| *1: | When the same malfunction is detected in two consecutive trips, MIL will illuminate. | *2: | MIL will turn off after Nissan Ariya vehicle is driven 3 times (driving pattern B) without any malfunctions. | *3: |

Diagnosis condition *A and diagnosis delay time *A for each DTC are satisfied. (*A: For details of these, refer to DTC/CIRCUIT DIAGNOSIS >> DTC (Pxxxx or Uxxx) >> DTC Description >> DTC DETECTION LOGIC.) |

WHEN A DTC IS NOT STORED IN TCM

The erasing method depends on a permanent DTC stored in TCM.

For erase procedure of permanent DTC, refer to Work Procedure.

PERMANENT DTC ITEM

For permanent DTC items, MIL turns ON. Refer to DTC Index.

Work Procedure

CHECK DTC

Check DTC.

Is any DTC detected?

YES>>Repair malfunction(s) and erase DTC.

NO>>GO TO 2.

CHECK PERMANENT DTC

With CONSULT

With CONSULT

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Select ŌĆ£PERMANENT DTC STATUSŌĆØ mode with CONSULT.

With GST

With GST

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Select Service $0A with GST.

Is any permanent DTC detected?

YES>>GO TO 3.

NO>>END

HOW TO ERASE PERMANENT DTC

CAUTION:

Always drive at a safe speed.

-

Perform "DTC CONFIRMATION PROCEDURE "of detected permanent DTC.

-

Drive the Nissan Ariya vehicle following to driving pattern.

-

The state of driving at 40 km/h (25 MPH) reaches 300 seconds or more in total.

-

Idle speed lasts 30 seconds or more.

-

A lapse of 600 seconds or more after engine start.

-

>>

GO TO 4.

CHECK PERMANENT DTC

With CONSULT

With CONSULT

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Select ŌĆ£PERMANENT DTC STATUSŌĆØ mode with CONSULT.

With GST

With GST

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Ignition switch OFF and wait at least 60 seconds.

-

Ignition switch ON.

-

Select Service $0A with GST.

Is any permanent DTC detected?

YES>>GO TO 1.

NO>>END

Other materials:

With Idle Start/stop. Service Data and Specifications (sds). Service Data and Specifications (sds)

Service Data and Specifications (sds)

Sub Starter & Generator

Part number*

448191

Manufacturer

Valeo make

Nominal rating

[V - A]

14 - 120

Ground polarity

-

Negative ground

Minimum revolution under no-load

(When 13.5 V is applied)

[rpm]

Less than 1,400 ...

Additional Service When Replacing Around View Monitor Control Unit

Description

CAUTION:

When replacing the around view monitor control unit, always replace

it with a new one. Intelligent around view monitor system does not

operate properly in case of reuse of the around view monitor control

unit from another Nissan Ariya vehicle.

When before writin ...

Dtc/circuit Diagnosis. B2490-13 Front Seat Heater Lh

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC detection condition

B2490-13

FRONT SEAT HEATER LH

(Front seat heater LH)

Diagnosis condition

Engine running

Signal (terminal)

ŌĆö

Threshold

CPU in front seat heater LH ...