Nissan Rogue (T33) 2021-Present Service Manual: Crankcase Ventilation Valve

Diagnosis Procedure

CHECK CRANKCASE VENTILATION VALVE POWER SUPPLY CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect IPDM E/R harness connector.

-

Check the continuity between crankcase ventilation valve harness connector and IPDM E/R harness connector.

Crankcase ventilation valve IPDM E/R Continuity Connector Terminal Connector Terminal F130 1 E35 66 Existed -

Also check harness for short to ground.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair or replace error-detected parts.

CHECK CRANKCASE VENTILATION VALVE INPUT SIGNAL CIRCUIT

-

Turn ignition switch OFF.

-

Disconnect ECM harness connector.

-

Check the continuity between crankcase ventilation valve harness connector and ECM harness connector.

Crankcase ventilation valve ECM Continuity Connector Terminal Connector Terminal F130 1 F72 10 Existed -

Also check harness for short to ground and to power.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair or replace error-detected parts.

CHECK CRANKCASE VENTILATION VALVE

Check the crankcase ventilation valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace crankcase ventilation valve. Refer to Exploded View.

Component Inspection

CHECK CRANKCASE VENTILATION VALVE

-

Turn ignition switch OFF.

-

Disconnect crankcase ventilation valve harness connector.

-

Disconnect Fresh air hose and air duct connected to crankcase ventilation valve.

-

Remove resonator. Refer to Exploded View.

-

Check air passage continuity of crankcase ventilation valve as per the following conditions.

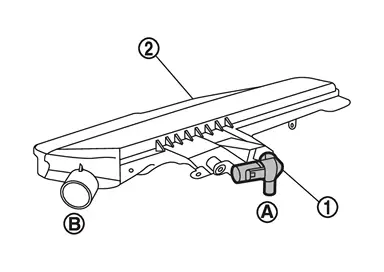

Crankekase ventilation valve

Crankekase ventilation valve Resonator

Resonator

Condition Air passage continuity between  and

and

12 V direct current supply between terminals 1 and 2 Not existed No supply Existed

Is the inspection result normal?

YES>>INSPECTION END

NO>>Replace crankcase ventilation valve. Refer to Exploded View.

Other materials:

Av Control Unit

Nissanconnect with 8" Color Display

Reference Value

VALUES ON THE DIAGNOSIS TOOLNOTE:

The following table includes information (items)

inapplicable to this Nissan Ariya vehicle. For information (items)

applicable to this vehicle, refer to CONSULT display items.

Monitor Item Condition Va ...

Diagnosis System (head up Display Unit)

CONSULT Function (HEAD UP DISPLAY)

APPLICATION ITEMSCONSULT can perform the following diagnosis modes via CAN communication and the combination meter. Diagnosis mode Function

Self diagnosis result

The Head Up Display unit self diagnosis results are displayed.

ECU Identification

The H ...

Symptom Diagnosis. Squeak and Rattle Trouble Diagnoses

Work Flow

CUSTOMER INTERVIEWInterview

the customer if possible, to determine the conditions that exist when

the noise occurs. Use the Diagnostic Worksheet during the interview to

document the facts and conditions when the noise occurs and any of

customer's comments. Refer to Diagnostic Work ...