Nissan Rogue Service Manual: Special Cautions to Ensure the Safe Disposal of Sodium-filled Exhaust Valves

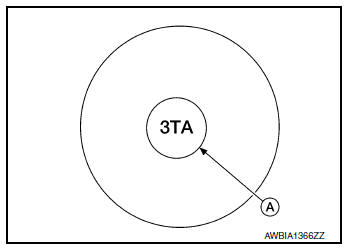

Handling and disposal of sodium-filled exhaust valves requires special care and consideration. Under conditions such as breakage with subsequent contact with water, metal sodium which lines the inner portion of exhaust valve will react violently, forming sodium hydroxide and hydrogen which may result in an explosion. Sodium-filled exhaust valve is identified on the top of its stem as shown in illustration.

(A) : Identification mark of sodium-filled exhaust valve

DEALER DISPOSAL INSTRUCTIONS

CAUTION:

- Use approved shatter-resistant eye protection when performing this procedure.

- Perform this and all subsequent disposal work procedures in an open room, away from flammable liquids. Keep a fire extinguisher, rated at least 10 ABC, in close proximity to the work area.

- Be sure to wear rubber gloves when performing the following operations.

- Make sure the resultant (high alkalinity) waste water does not contact your skin. If the waste water does contact you, wash the contacted area immediately with large quantities of water.

- Dealers should check their respective state and local regulations concerning any chemical treatment or waste water discharge permits which may be required to dispose of the resultant (high alkalinity) waste water.

- Clamp valve stem in a vice.

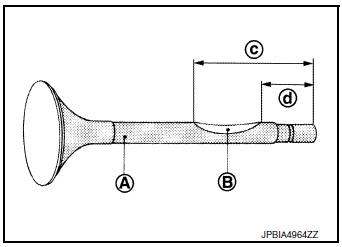

- The valve has a specially-hardened surface. To cut through it, first remove a half-round section, approximately 30 mm (1.18 in) long using air-powered grinder until black color is removed and silver color appears.

(A) : Black color

(B) : Silver color

(c) : 47 mm (1.85 in)

(d) : 17 mm (0.67 in)

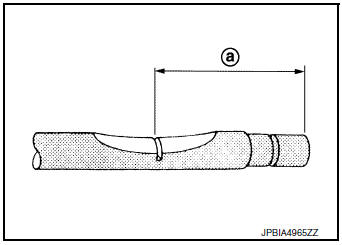

- Use hacksaw to cut through approximately half the diameter of valve stem. Make the serration at a point 40 mm (1.57 in) from the end of valve stem.

(a) : 40 mm (1.57 in)

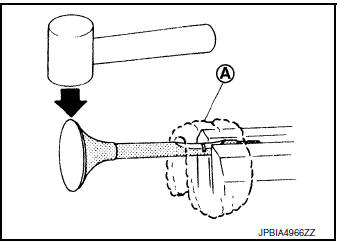

- Cover the serrated end of the valve with a large shop towel (A).

Strike the valve face end with a hammer, separating it into two pieces.

- Fill a bucket, such as a 20

(5-1/4 US gal, 4-3/8 Imp gal)

oil

can, with at least 10

(5-1/4 US gal, 4-3/8 Imp gal)

oil

can, with at least 10  (2-5/8 US

gal, 2-1/4 lmp gal) of water.

(2-5/8 US

gal, 2-1/4 lmp gal) of water.Carefully place the already cut (serrated) valves into the water one-at-a-time using a set of large tweezers and quickly move away at least 2.7 m (9 ft).

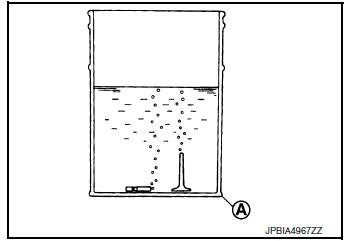

- The valves should be placed in a standing position as shown in

the illustration to allow complete reaction. After the bubbling

action has subsided, additional valves can be placed into the

bucket allowing each subsequent chemical reaction to subside.

However, no more than 8 valves should be placed in the same 10

(2-5/8 US gal, 2-1/4 lmp

gal) amount of water. The complete

chemical reaction may take as long as 4 to 5 hours.

(2-5/8 US gal, 2-1/4 lmp

gal) amount of water. The complete

chemical reaction may take as long as 4 to 5 hours.Remove the valves using a set of large tweezers after the chemical reaction has stopped. Afterwards, valves can be disposed as ordinary scrap.

A : Bucket [Such as 20 (5-1/4 US gal, 4-3/8 Imp gal) oil can]

Precaution

Precaution

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONERâ ...

Liquid Gasket

Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

After removing the bolts and nuts, separate the mating surface and

remove the liquid gasket using Tool (A).

Tool Number : KV10111100 (J-37228)

CAUTION:

Be c ...

Other materials:

Active ride control

This system senses upper body motion (based

on wheel speed information) and controls engine

torque and four wheel brake pressure. This will

enhance ride comfort in effort to restrain uncomfortable

upper body movement when passing

over undulated road surfaces . This system

comes into effect abo ...

Component parts

Component Parts Location

Steering column assembly

No.

Component

Function

1

ABS actuator and electric unit (control unit)

Transmits the following signal to EPS control unit via CAN

communication.

Vehicle speed signal (ABS)

...

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an

interview utilizing DAS-202, "Diagnostic

Work Sheet" and reproduce the symptom as well as fully understand it. Ask

customer ...