Nissan Rogue Service Manual: P0112, P0113 IAT sensor

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0112 | IAT SEN/CIRCUIT- B1 (Intake air temperature sensor 1 circuit low bank 1) | An excessively low voltage from the intake air temperature sensor is sent to ECM. |

| P0113 | IAT SEN/CIRCUIT- B1 (Intake air temperature sensor 1 circuit high bank 1) | An excessively high voltage from the intake air temperature sensor is sent to ECM. |

POSSIBLE CAUSE

- Harness or connectors (Intake air temperature sensor circuit is open or shorted.)

- Intake air temperature sensor

- Sensor power supply 2 circuit

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-208, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK INTAKE AIR TEMPERATURE SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect mass air flow sensor (with intake air temperature sensor) harness connector.

- Turn ignition switch ON.

- Check the voltage between mass air flow sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK INTAKE AIR TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

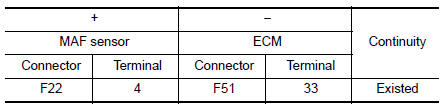

- Check the continuity between mass air flow sensor harness connector and ECM harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK INTAKE AIR TEMPERATURE SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

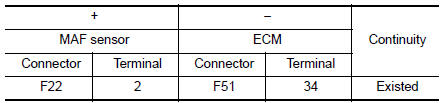

- Check the continuity between mass air flow sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK INTAKE AIR TEMPERATURE SENSOR

Check the intake air temperature sensor. Refer to EC-207, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace mass air flow sensor (with intake air temperature sensor). Refer to EM-24, "Exploded View".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK INTAKE AIR TEMPERATURE SENSOR

- Turn ignition switch OFF.

- Disconnect mass air flow sensor harness connector and reconnect it again.

- Turn ignition switch ON.

- Select “DATA MONITOR” mode with CONSULT.

- Check that “INT/A TEMP SEN” indicates as per following condition.

| Monitor item | Condition | Value (Approx.) |

| INT/A TEMP SEN | Temperature [°C (°F)] 25 (77) | 1.9 - 2.1 (V) |

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace mass air flow sensor (with intake air temperature sensor). Refer to EM-24, "Exploded View".

P0111 IAT sensor

P0111 IAT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0111

IAT SENSOR 1 B1

(Intake air temperature sens ...

P0116 ECT sensor

P0116 ECT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0116

ECT SENSOR

(Engine coolant temperature senso ...

Other materials:

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-39570)

Chassis Ear

Locating the noise

—

(J-50397)

NISSAN Squeak and Rattle Kit

...

Removal and installation

REAR PROPELLER SHAFT

Exploded View

Center bearing mounting bracket

(upper)

Clip

Propeller shaft assembly

Center bearing mounting bracket

(lower)

: Vehicle front

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

Shif ...

P0713 transmission fluid temperature sensor A

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0713

FLUID TEMP SENSOR A

(Transmission Fluid Temperature Sensor A Circuit

High)

When all of the following conditions are satisfied and this state i ...