Nissan Rogue (T33) 2021-Present Service Manual: With Idle Start/stop :: Basic Inspection

Diagnosis and Repair Work Flow

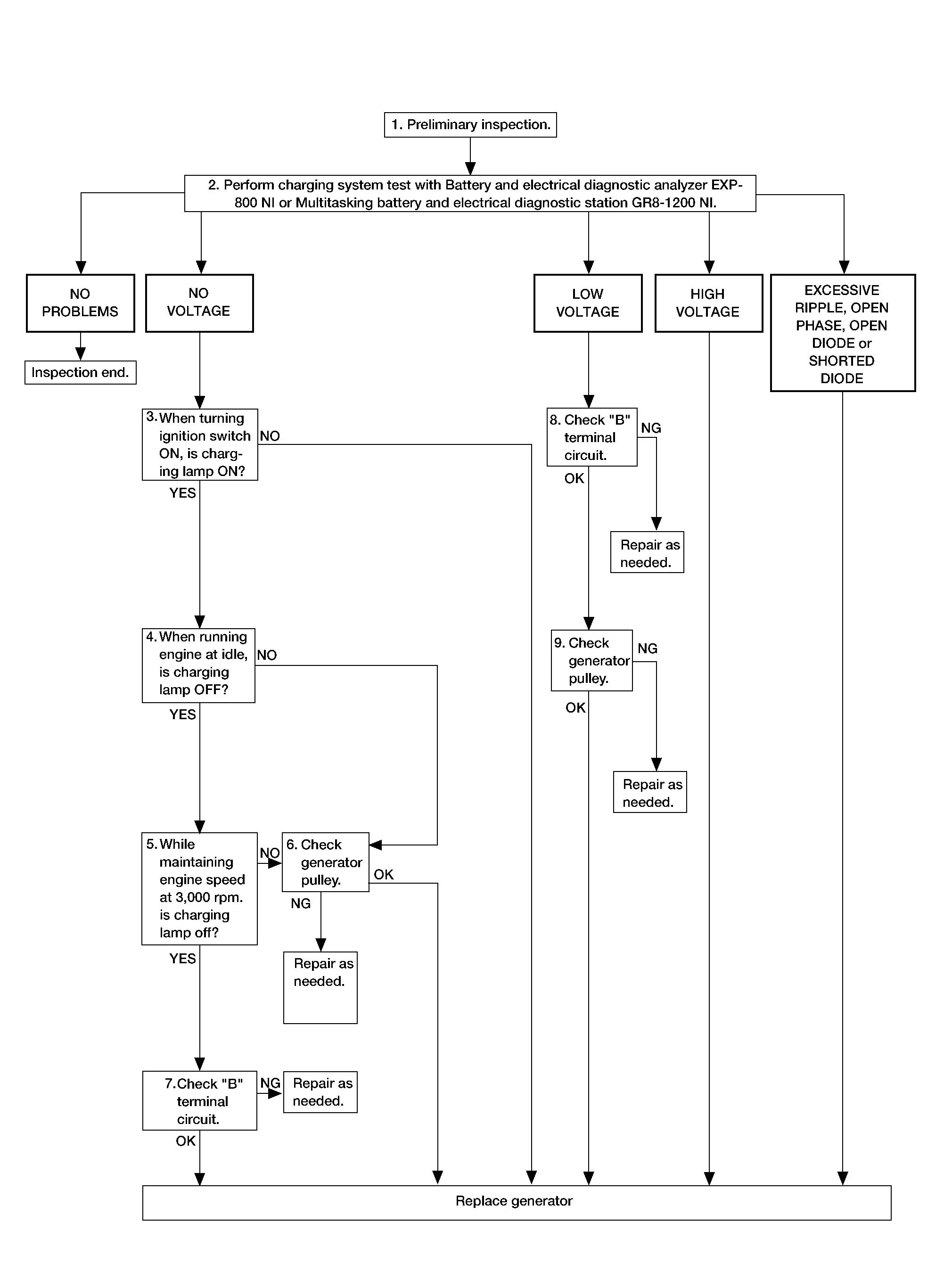

Work Flow (With EXP-800 NI or GR8-1200 NI)

CHARGING SYSTEM DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

To test the charging system, use the following special service tools:

-

EXP-800 NI Battery and electrical diagnostic analyzer

-

GR8-1200 NI Multitasking battery and electrical diagnostic station

NOTE:

NOTE:

Refer to the applicable Instruction Manual for proper charging system diagnosis procedures.

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

NOTE:

To ensure a complete and thorough diagnosis, the 12V battery, starter motor and generator test segments must be done as a set from start to finish.

PRELIMINARY INSPECTION

Perform preliminary inspection. Refer to Refer to Inspection Procedure.

>>

GO TO 2.

DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

Perform the charging system test using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI. Refer to the applicable Instruction Manual for proper testing procedures.

Test result

NO PROBLEMS>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO VOLTAGE>>GO TO 3.

LOW VOLTAGE>>GO TO 8.

HIGH VOLTAGE>>Replace generator. Refer to Removal and Installation (KR15DDT engine models).

EXCESSIVE RIPPLE, OPEN PHASE, OPEN DIODE or SHORTED DIODE>>Replace generator. Refer Removal and Installation (KR15DDT engine models). Perform “DIODE RIPPLE” test again using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI to confirm repair.

INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Ignition switch ON.

Does the charge warning lamp illuminate?

YES>>GO TO 4.

NO>>Replace generator. Refer Removal and Installation (KR15DDT engine models).

INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES>>GO TO 5.

NO>>GO TO 6.

INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 3,000 RPM)

Increase and maintain the engine speed at 3,000 rpm.

Does the charge warning lamp remain off?

YES>>GO TO 7.

NO>>GO TO 6.

INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to Inspection (KR15DDT engine models).

Is generator pulley normal?

YES>>Replace generator. Refer toRemoval and Installation (KR15DDT engine models).

NO>>Repair as needed.

“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure.

Is “B” terminal circuit normal?

YES>>Replace generator. Refer to Removal and Installation (KR15DDT engine models).

NO>>Repair as needed.

“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure.

Is “B” terminal circuit normal?

YES>>GO TO 9.

NO>>Repair as needed.

INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to Inspection (KR15DDT engine models).

Is generator pulley normal?

YES>>Replace generator. Refer to Removal and Installation (KR15DDT engine models).

NO>>Repair as needed.

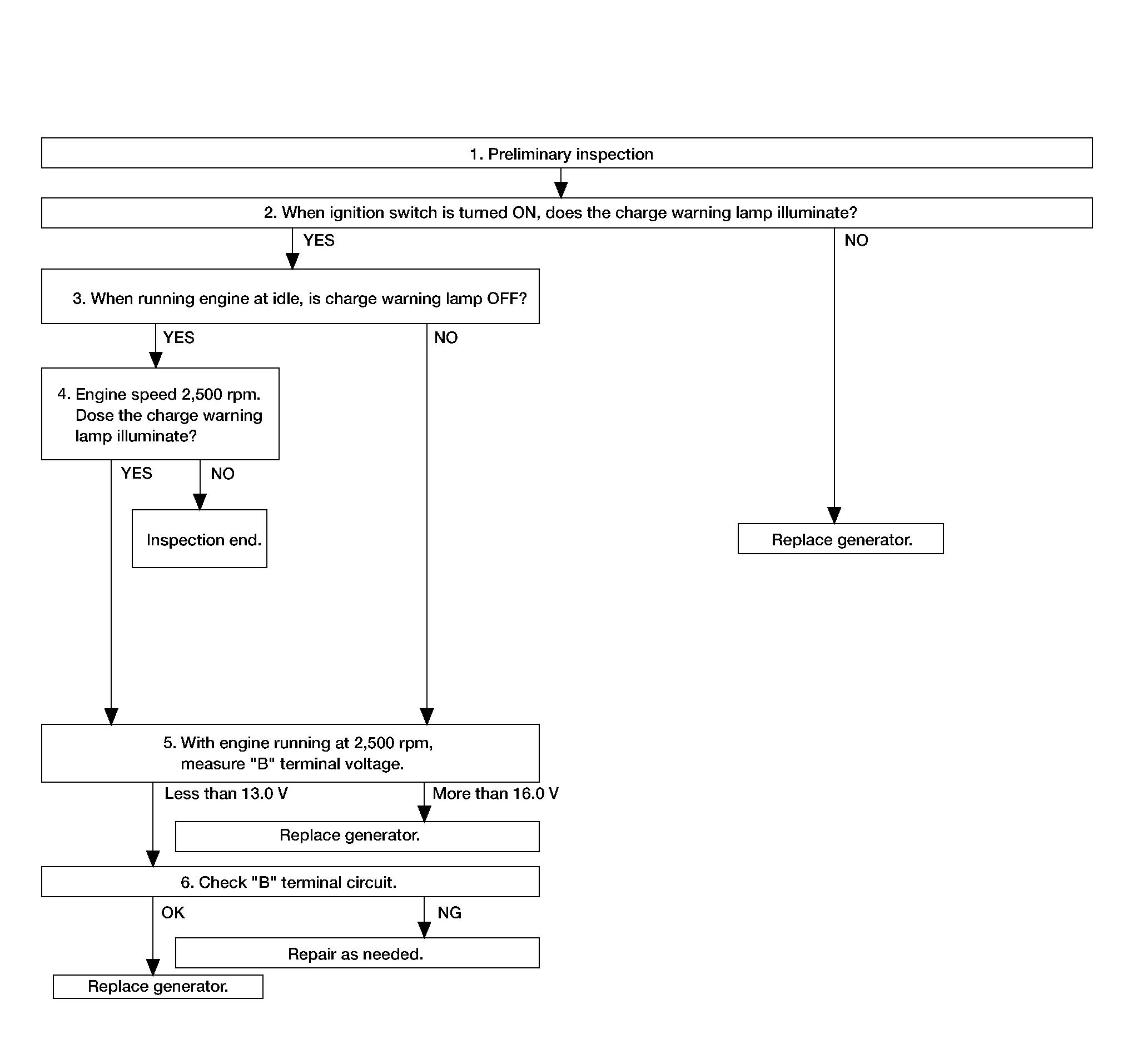

Work Flow (Without EXP-800 NI or GR8-1200 NI)

Before performing a generator test, make sure that the 12V battery is fully charged. A 30-volt voltmeter and suitable test probes are necessary for the test.

-

Before starting, inspect the fusible link.

-

Use fully charged 12V battery.

OVERALL SEQUENCE

DETAILED FLOW

PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to Inspection Procedure.

>>

GO TO 2.

INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS TURNED ON)

When ignition switch is turned ON.

Does the charge warning lamp illuminate?

YES>>GO TO 3.

NO>>Replace generator. Refer toRemoval and Installation (KR15DDT engine models).

INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle

Does the charge warning lamp turn OFF?

YES>>GO TO 4.

NO>>GO TO 5.

INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 2,500 RPM)

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate?

YES>>GO TO 5.

NO>>Inspection End.

MEASURE “B” TERMINAL VOLTAGE

Start engine. With engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show?

Less than 13.0 V>>GO TO 6.

More than 16.0 V>>Replace generator. Refer toRemoval and Installation (KR15DDT engine models).

“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to Diagnosis Procedure.

Is the inspection result normal?

YES>>Replace generator. Refer toRemoval and Installation (KR15DDT engine models).

NO>>Repair as needed.

Charging System Preliminary Inspection

Inspection Procedure

CHECK 12V BATTERY TERMINALS CONNECTION

Check if 12V battery terminals are clean and tight.

Is the inspection result normal?

YES>>GO TO 2.

NO>>Repair 12V battery terminals connection.

CHECK “B” TERMINAL CONNECTION

Check if “B” terminal (generator ground harness) is clean and tight.

Is the inspection result normal?

YES>>GO TO 3.

NO>>Repair “E” terminal connection.

CHECK 12V BATTERY STATUS

Check 12V battery status. Refer to Work Flow (With EXP-800 NI or GR8-1200 NI) or Work Flow (Without EXP-800 NI or GR8-1200 NI).

Is the inspection result normal?

YES>>GO TO 4.

NO>>Replace 12V battery. Refer to Removal and Installation.

CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to Inspection (KR15DDT engine models).

Is the inspection result normal?

YES>>Inspection End.

NO>>Repair as needed.

Configuration (sub Starter & Generator)

Description

Description

Vehicle specification needs to be written with CONSULT because it is not written after replacing the sub starter & generator.

The configuration requires network connection. CONSULT connects to network and then it downloads the configuration data from the server.

Then CONSULT writes the vehicle specification to the sub starter & generator. Refer to Work Procedure.

NOTE:

NOTE:

For details the network connection and operation, refer to “CONSULT Operation Manual”.

The configuration no need to “save” configuration data from the sub starter & generator. The configuration data is always generated freshly at the server and then downloaded to the CONSULT.

CAUTION:

-

Complete the procedure of “Configuration” in order.

-

If incorrect “Configuration”, incidents might occur.

Work Procedure

Work Procedure

WRITING VEHICLE SPECIFICATION

CONSULT

CONSULT

Perform writing Nissan Ariya vehicle specification to sub starter & generator following "Automatic Configuration" procedure of "Configuration" according to CONSULT Operation Manual.

NOTE:

NOTE:

-

Log in the network according to CONSULT guidance.

-

For details the network connection and operation, refer to “CONSULT Operation Manual”.

>>

Work End.

Additional Service When Replacing Sub Starter & Generator

Description

AFTER REPLACEMENT

CAUTION:

When after replacing sub starter & generator, the following items must be performed. Or not doing so, sub starter & generator control function does not operate normally:

Writing Nissan Ariya vehicle specification.

Work Procedure

REPLACE SUB STARTER & GENERATOR

Replace sub starter & generator. Refer to Removal and Installation.

>>

GO TO 2.

WRITING Nissan Ariya Vehicle SPECIFICATION

Perform configuration (sub starter & generator). Refer to Description.

>>

Work End.

Other materials:

A/f Sensor 1

Component Function Check

PERFORM COMPONENT FUNCTION CHECK

With GST

Start engine and warm it up to normal operating temperature.

Drive the Nissan Ariya vehicle at a speed of 80 km/h (50 MPH) for a few minutes in the suitable gear position.

Shift the selector lever to the D position, ...

Ecu Diagnosis Information. Hands Free Sensor Control Unit

Reference Value

TERMINAL LAYOUTPHYSICAL VALUES

Terminal No.

(Wire color) Description Condition

Voltage

(Approx.)

(+) (–) Signal name Input/Output

1

(GR)

Ground

Serial communication

Input/Output

Ignition switch ON

2

(L)

Ground

Power supply (BAT)

...

Idling Stop System

Basic information

The Idling Stop System activates to reduce unnecessary fuel consumption, emissions and noise.

When the vehicle stops, the engine automatically turns off.

When the brake pedal is released, the engine automatically restarts.

WARNING

If the vehicle begins to move at approximate ...