Nissan Rogue (T33) 2021-Present Service Manual: Replacement Operations

Precautions for Body Repair

WARNING:

-

The repair information in this section is intended for trained body repair technicians who have attained a high level of skill and experience (e.g. ASE Collision Repair Certification, I-CAR Professional Development Program [PDP] training, etc.) in repairing collision damaged Nissan Ariya vehicles using appropriate tools and equipment. Performing repairs without the proper training, tools or equipment could damage the Nissan Ariya vehicle or cause personal injury or death to you or others.

-

The information in this Body Repair Manual is a guideline for repairing collision damaged Nissan Ariya vehicles. However, this information cannot cover all possible ways that a vehicle can be damaged. As such, the body repair technician is responsible for making sure that the repair does not affect the structural integrity or safety of the Nissan Ariya vehicle. Improper repair of a damaged vehicle may result in a collision, property damage, personal injury or death.

-

Nissan recommends using only new genuine Nissan replacement body parts. Use of used, salvaged or aftermarket body parts is not recommended by Nissan. Non-genuine Nissan components may affect the Nissan Ariya vehicle's structural integrity and crash safety performance, which could result in serious personal injury or death in an accident.

Description

-

Technicians are encouraged to read the Body Repair Manual (Fundamentals) in order to ensure that the original functions and quality of the Nissan Ariya vehicle are maintained. The Body Repair Manual (Fundamentals) contains additional information, including cautions and warnings, that are not including in this manual. Technicians should refer to both manuals to ensure proper repair.

-

Please note that this information is prepared for worldwide usage, and as such, certain procedures might not apply in some regions or countries.

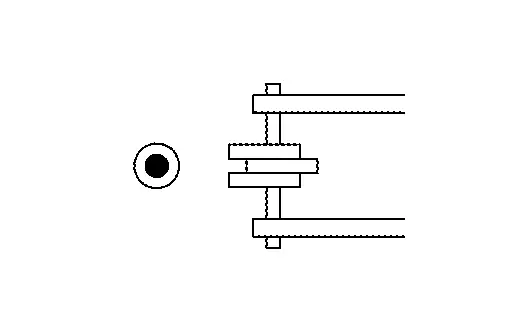

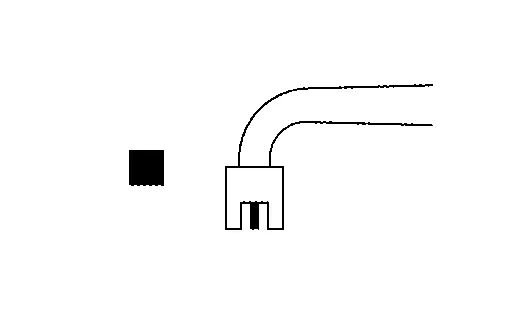

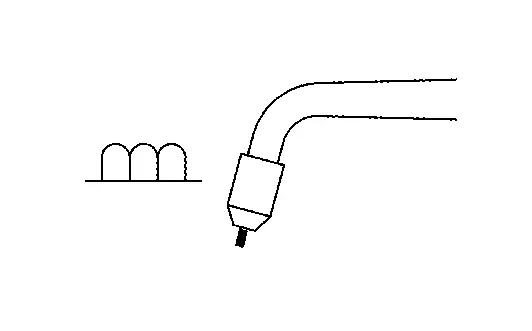

The symbols used in this section for welding operations are shown below.

| Symbol marks | Description | |

|---|---|---|

| ″Number″ |

″Number″ after symbol mark is the total number of welds to apply. Example 1:  ″1″× 20 (0.79) = 1 MAG seam weld by length 20 mm (0.79 in). ″1″× 20 (0.79) = 1 MAG seam weld by length 20 mm (0.79 in). |

|

|

|

2-panel spot weld |

|

|

|

3-panel spot weld | |

|

|

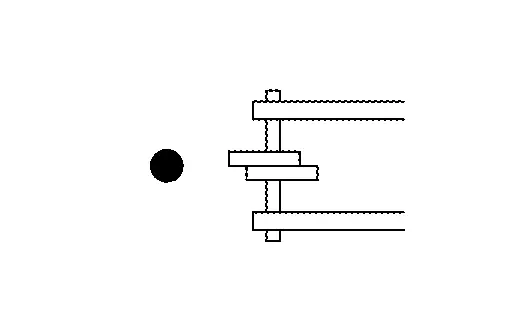

MAG plug weld |

|

|

For 3-panel plug weld method

|

||

|

|

MAG seam weld / Point weld |

|

|

|

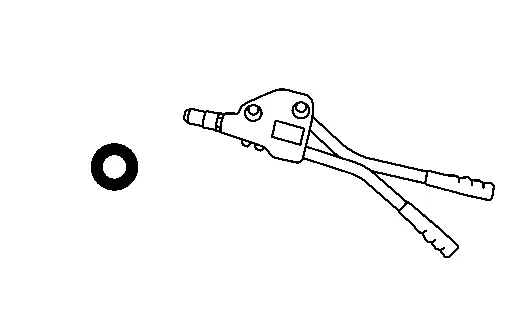

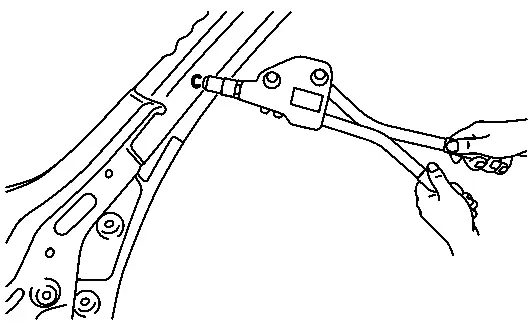

Rivet |

|

-

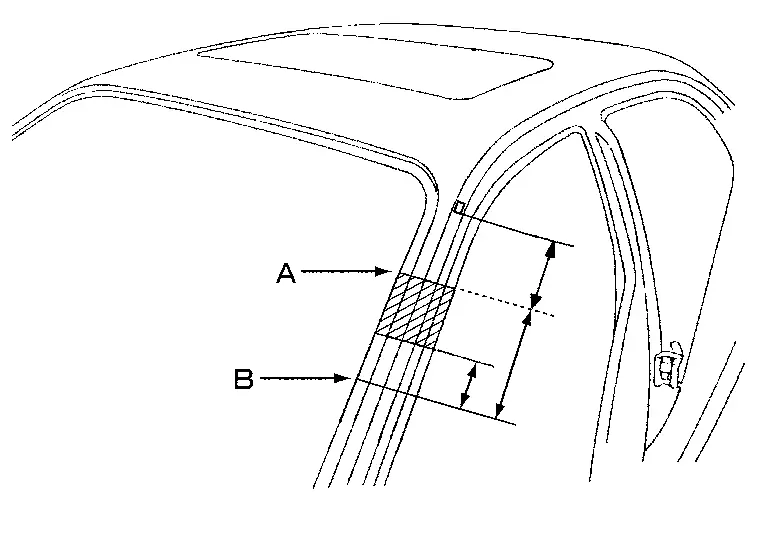

Front pillar butt joint can be determined anywhere within shaded area as shown in the figure. The best location for the butt joint is at position A due to the construction of the Nissan Ariya vehicle.

-

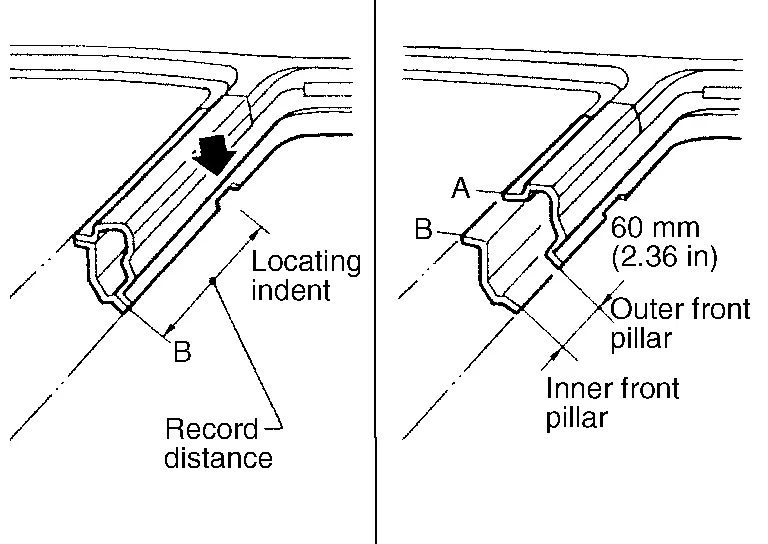

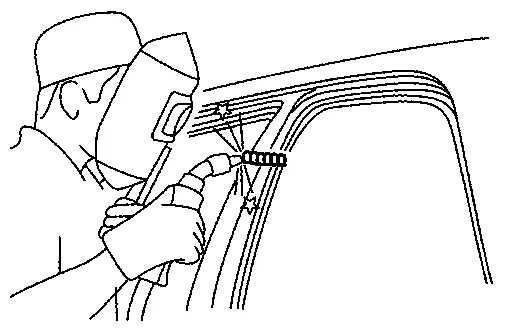

Determine cutting position and record distance from the locating indent. Use this distance when cutting the service part. Cut outer front pillar over 60 mm (2.36 in) above the inner front pillar cut position.

-

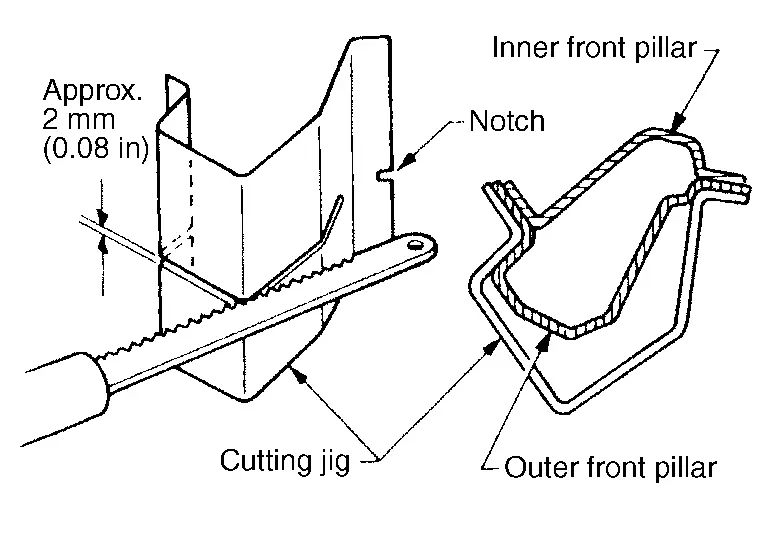

Prepare a cutting jig to make outer pillar easier to cut. Also, this will permit the service part to be accurately cut at the joint position.

-

An example of cutting operation using a cutting jig is as per the following.

-

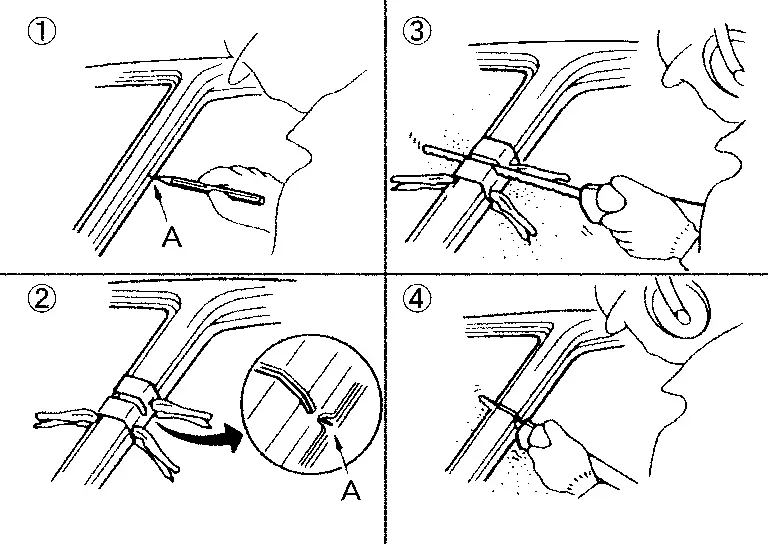

Mark cutting lines.

A: Cut position of outer pillar

B: Cut position of inner pillar

-

Align cutting line with notch on jig. Clamp jig to pillar.

-

Cut outer pillar along groove of jig (at position A).

-

Remove jig and cut remaining portions.

-

Cut inner pillar at position B in same manner.

Welding of Ultra High Strength Steel

SPOT WELDING

Spot welding is limited to ultra high strength steel (tensile strength: 980 MPa) according to the welding conditions listed below.

CAUTION:

-

If the below welding conditions cannot be met, then perform plug welding.

-

Never spot weld ultra high strength steel of tensile strength more than 980 MPa. For this type of ultra high strength steel, perform plug welding.

-

The below welding condition is applicable only to this Nissan Ariya vehicle. Never apply this same welding condition to other vehicles.

| Welder tip diameter | 6 mm |

| Welding pressure (Gun force) | 3650 N |

| Welding current | 8010 A |

| Weld time | 0.2 sec (10 cyc: 50 Hz area, 12 cyc: 60 Hz area) |

| Panel configuration | Combination of a plate of tensile strength 980 MPa and that of tensile strength less than 980 MPa. (Up to 3 plates) |

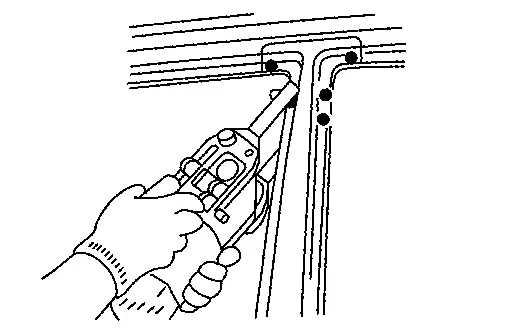

PLUG WELDING

To weld ultra high strength steel of tensile strength 980 MPa or more, perform plug welding observing the welding hole diameter described in the manual.

CAUTION:

-

To perform plug welding, use fuel mixture (Ar 80% + CO2 20%) for shielding gas of welder.

-

Never use carbon dioxide gas (CO2 100%) as shielding gas of welder. Using CO2 100% gas results in inadequate weld strength.

-

When welding hole diameter cannot be met, make multiple holes (smaller diameter) so that the sum of the hole areas equals the area of the original weld hole.

EXAMPLE

|

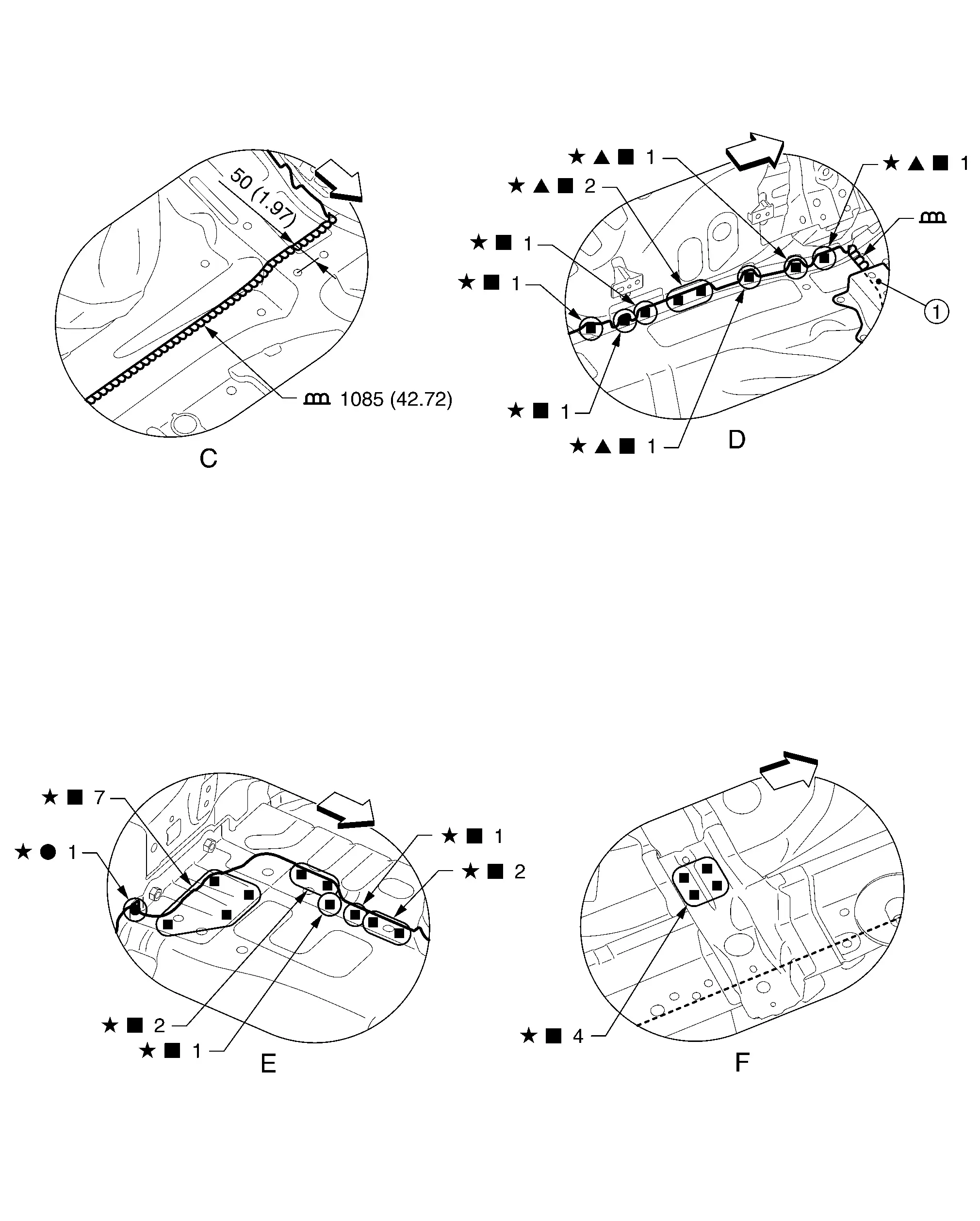

Body sealing | ||||

|

: For spot welding of steel plate

of tensile strength 980 MPa, observe the indicated welding conditions.

Refer to ″Welding of Ultra High Strength Steel″. : For spot welding of steel plate

of tensile strength 980 MPa, observe the indicated welding conditions.

Refer to ″Welding of Ultra High Strength Steel″. |

|||||

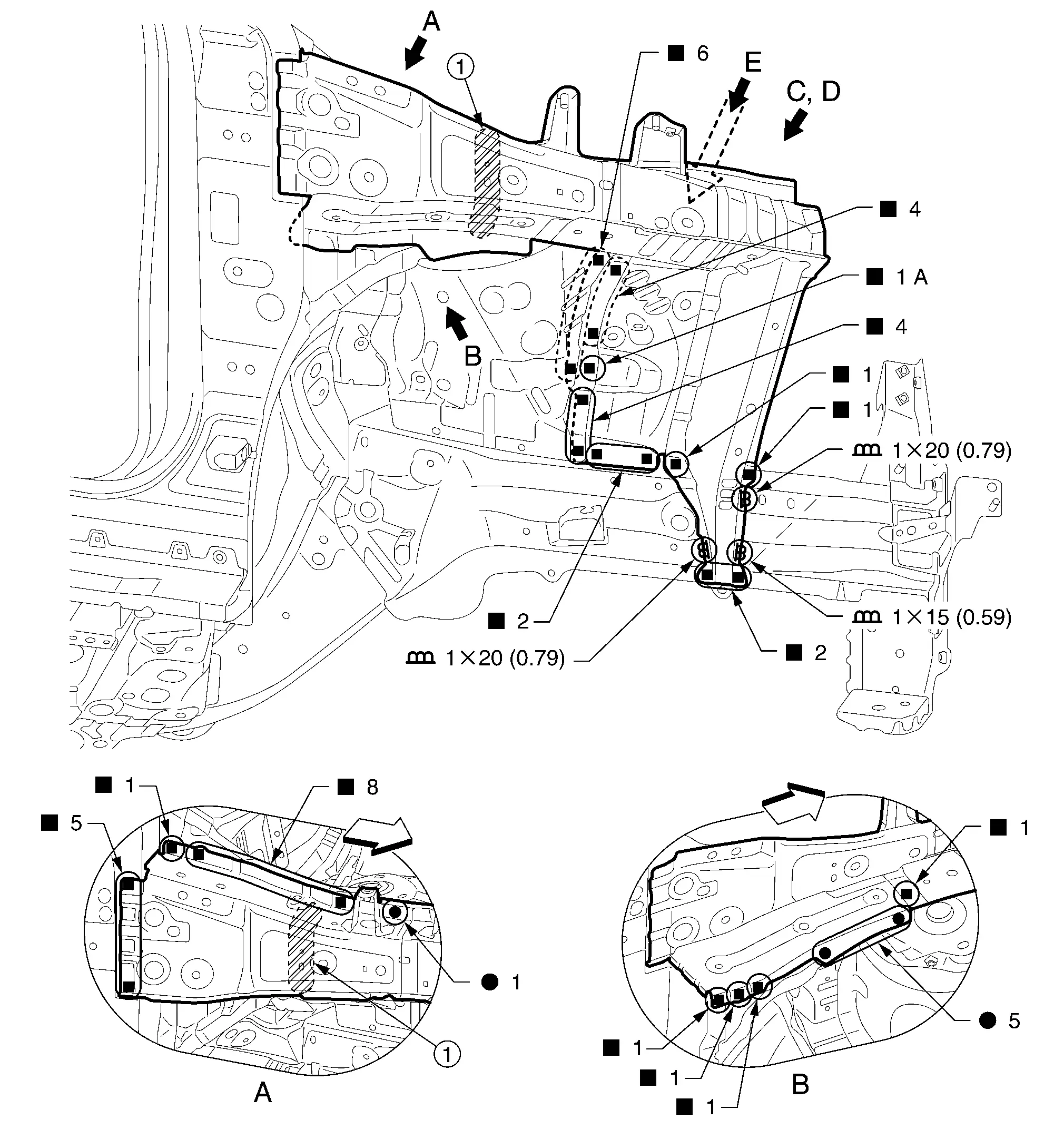

Radiator Core Support

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

| Replacement part | |||||

| • | Upper radiator core support assembly | • | Side radiator core support | ||

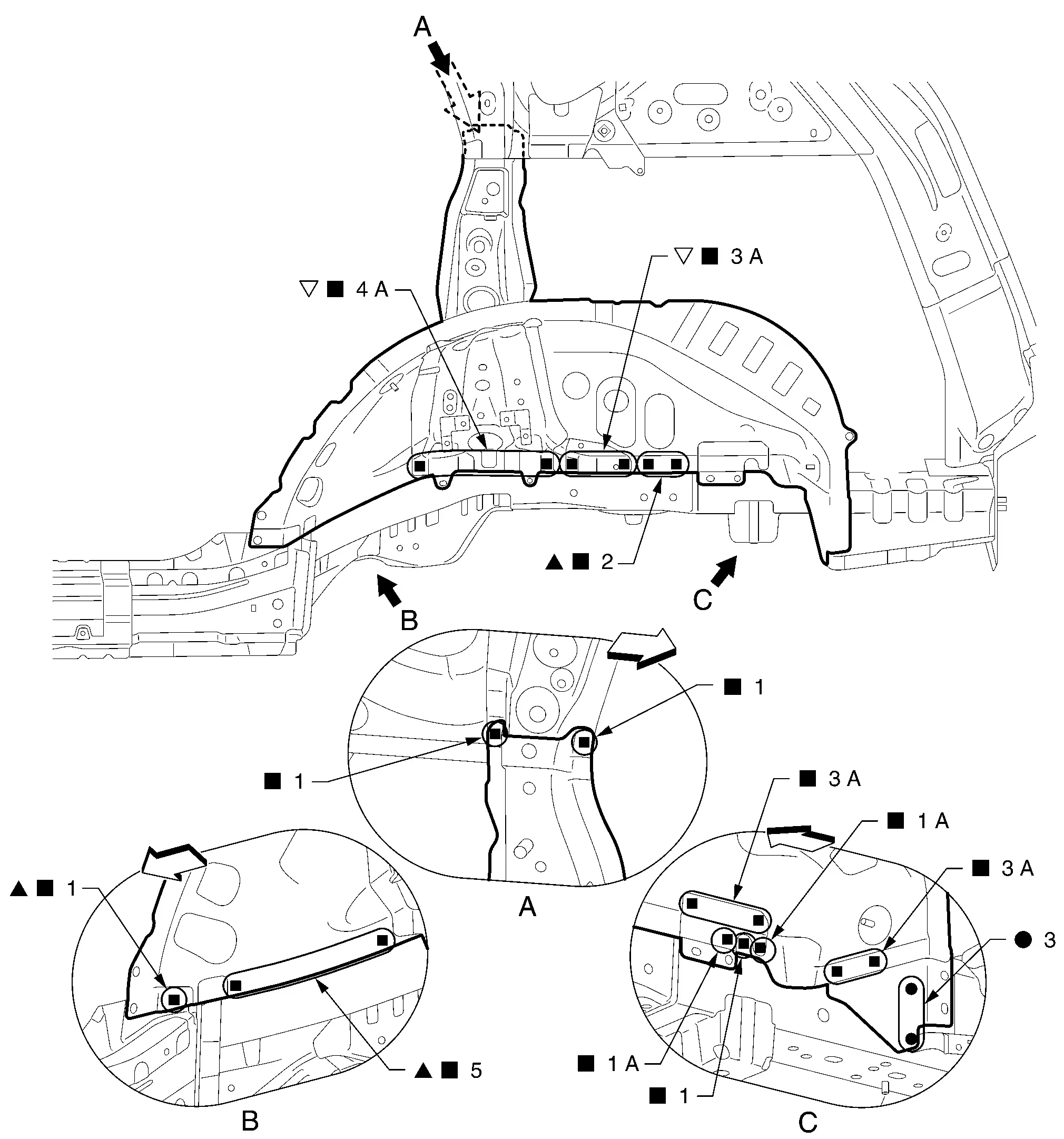

Hoodledge

Work after radiator core support is removed.

|

Urethane foam | ||||

| Unit: mm (in) | |||||

: Nissan Ariya Vehicle front : Nissan Ariya Vehicle front |

|||||

| Replacement part | |||||

| • | Front strut housing assembly | • | Hoodledge reinforcement | ||

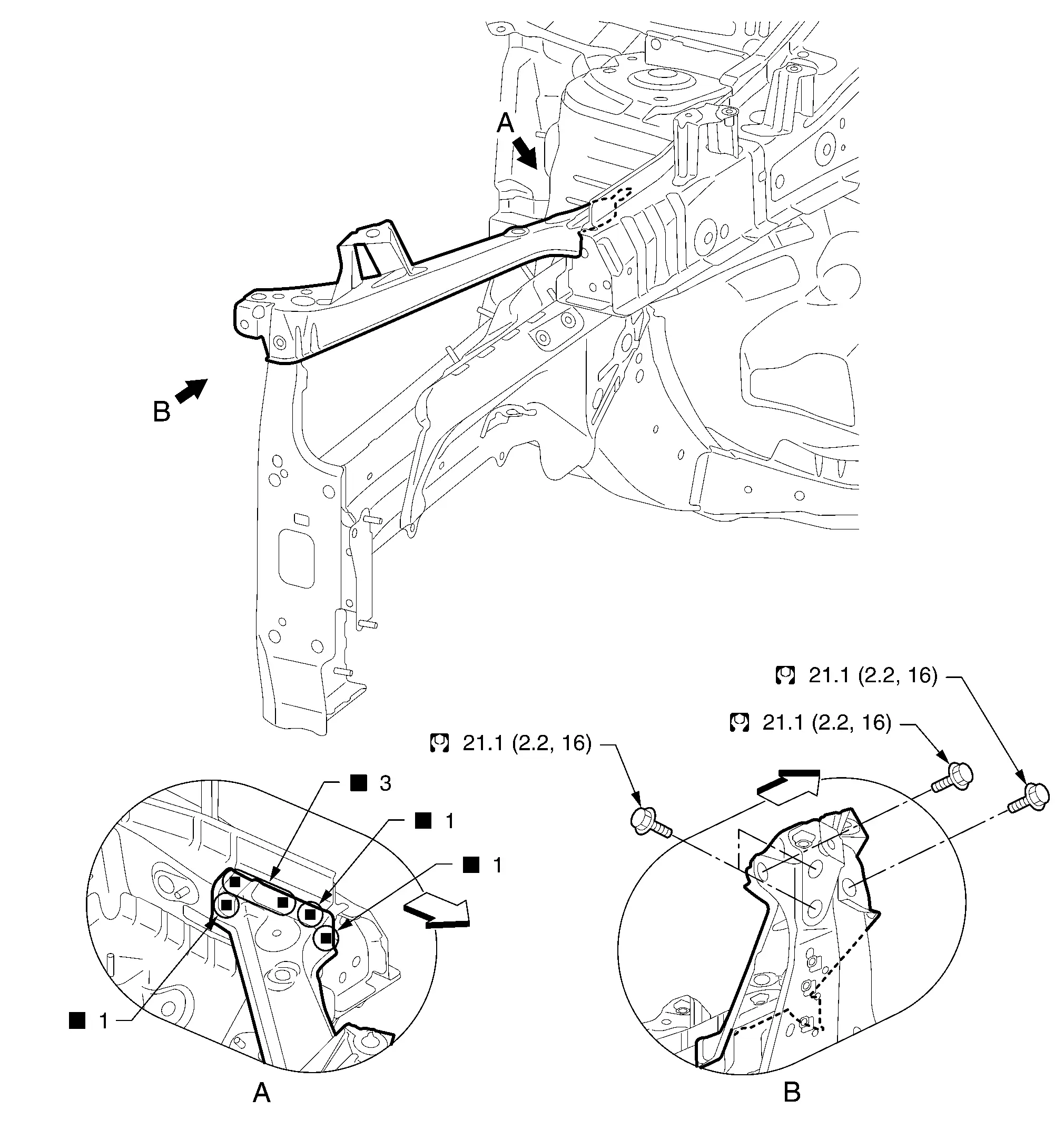

View B: Before installing hoodledge reinforcement

|

Urethane foam | ||||

: Nissan Ariya Vehicle front : Nissan Ariya Vehicle front |

|||||

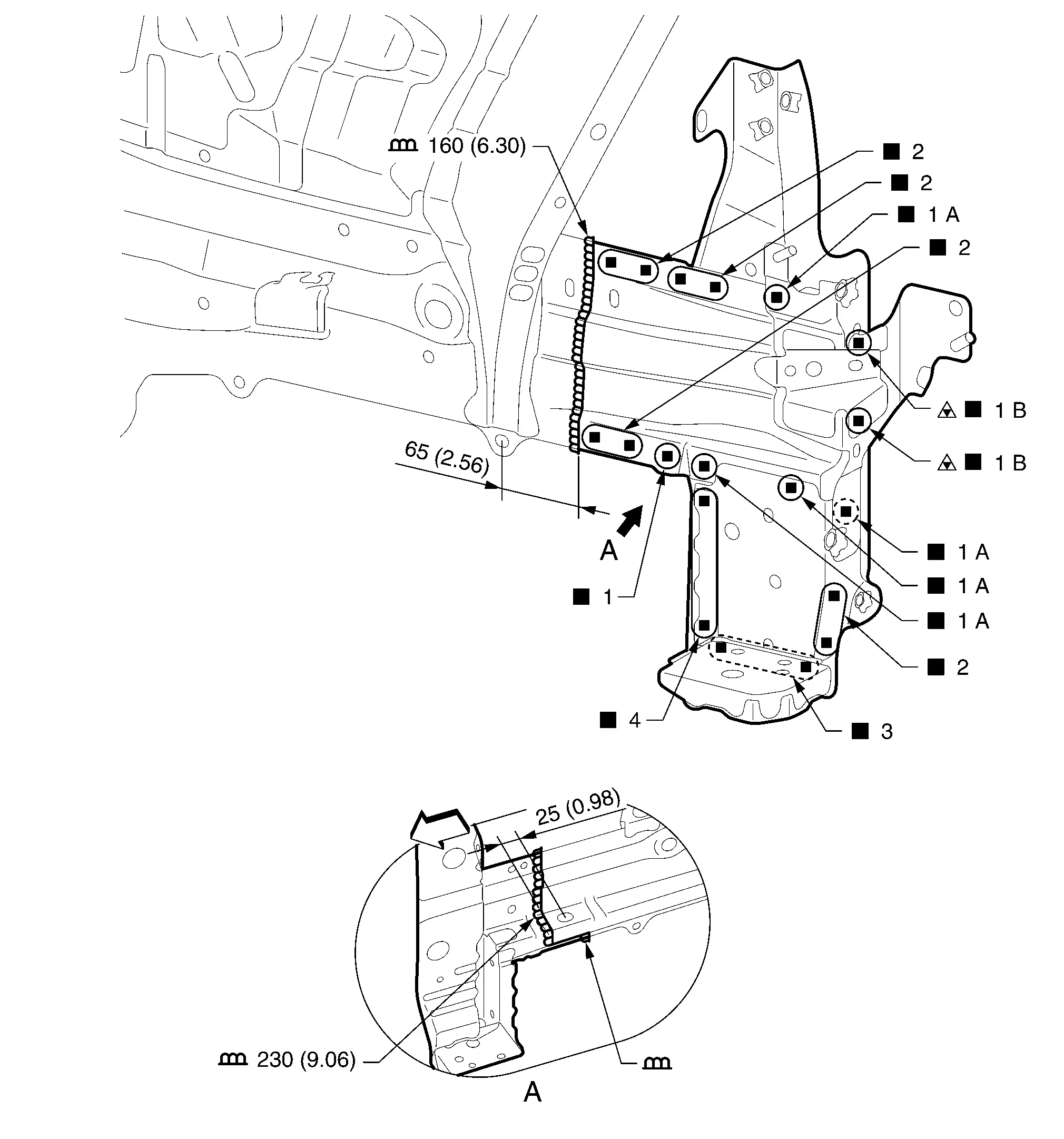

PARTIAL REPLACEMENT

Work after radiator core support is removed.

|

Urethane foam | ||||

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

| Replacement part | |||||

| • | Front strut housing assembly | • | Hoodledge reinforcement | ||

: Nissan Ariya Vehicle front : Nissan Ariya Vehicle front |

View D: Before installing hoodledge reinforcement

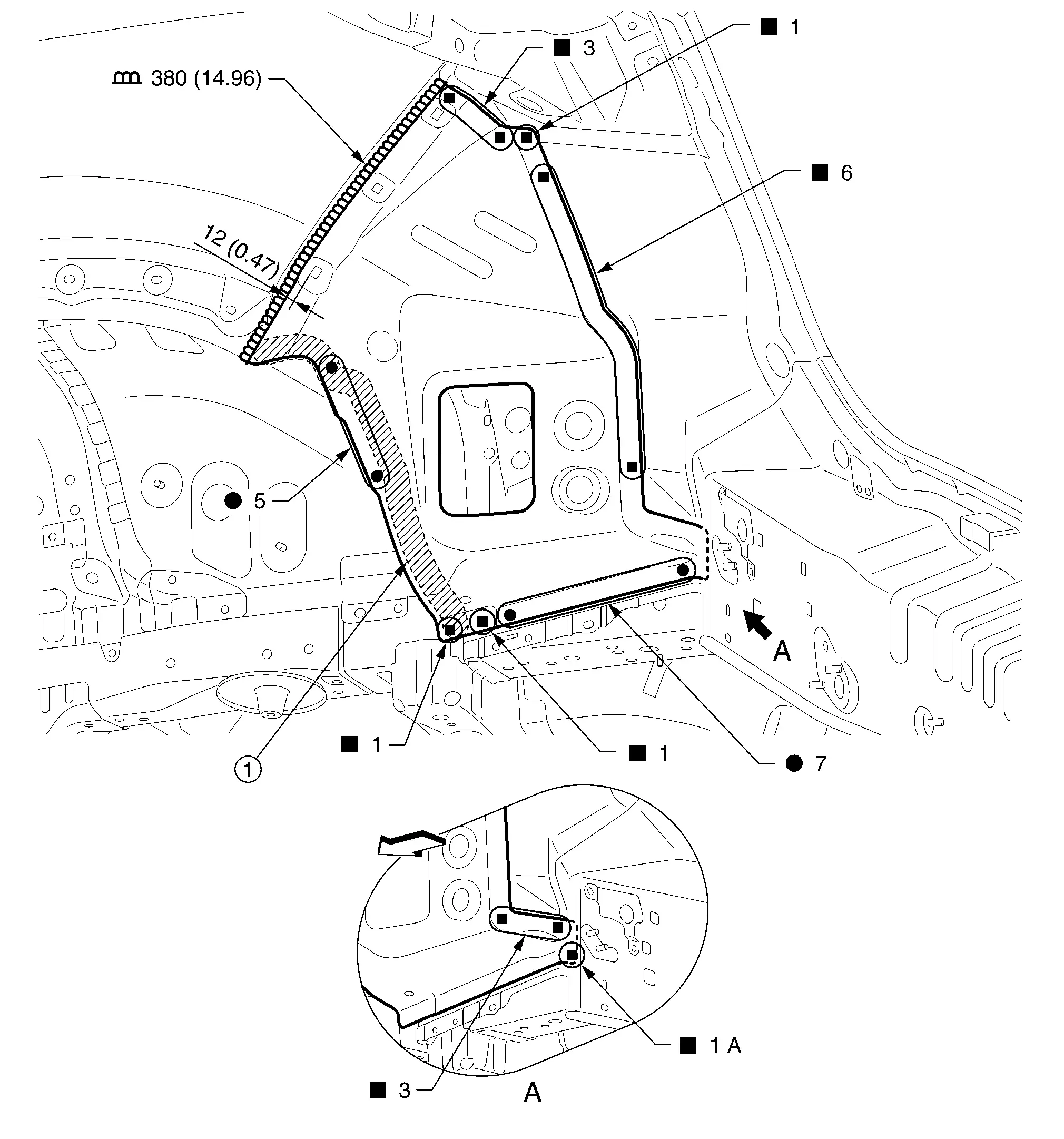

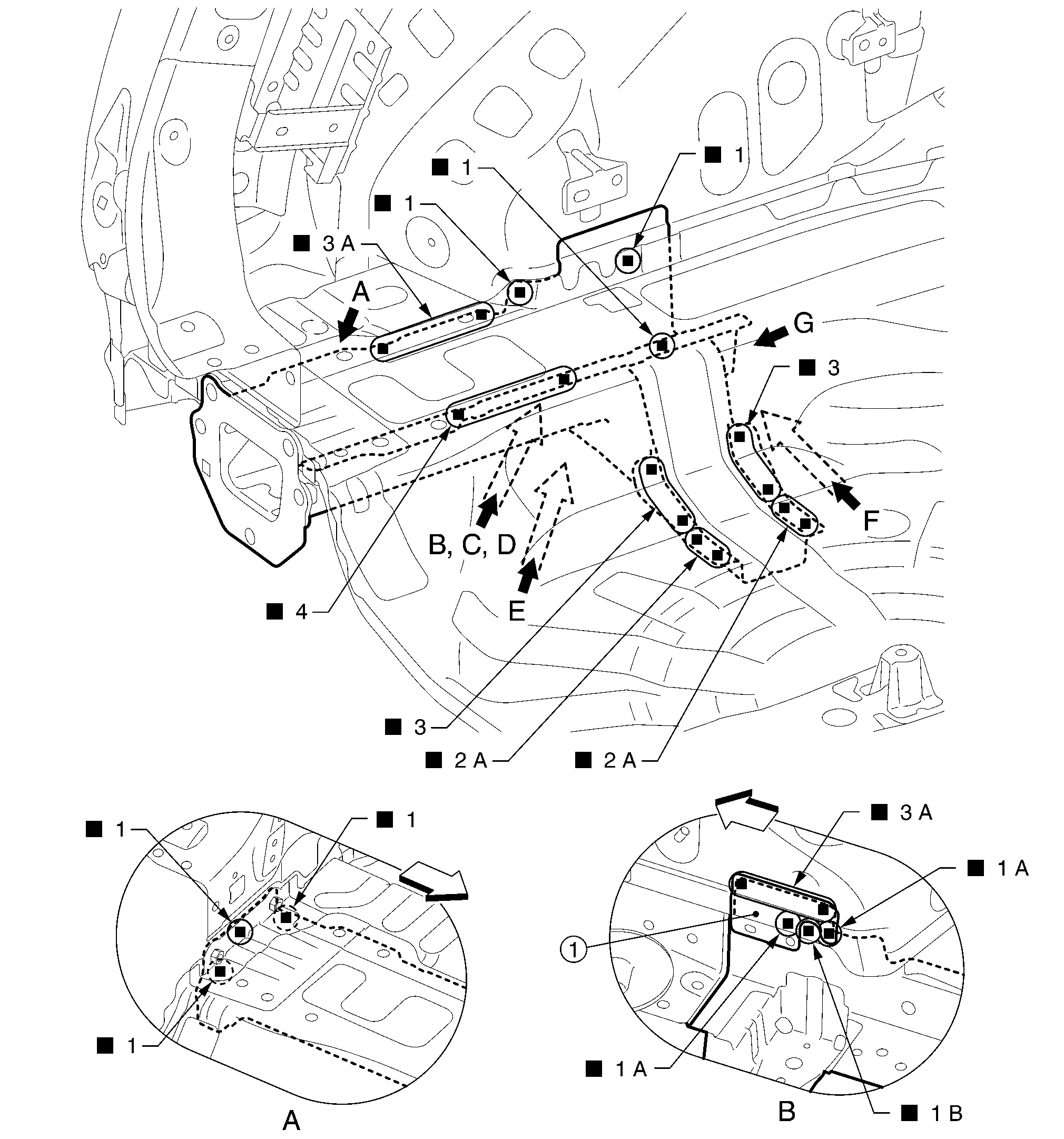

Front Side Member

Work after radiator core support and hoodledge are removed.

|

: Drill φ12 mm (0.47 in) hole for the plug welding hole (ultra high strength steel). : Drill φ12 mm (0.47 in) hole for the plug welding hole (ultra high strength steel). |

|||||

| Replacement part | |||||

| • | Front side member assembly | • | Front side member closing plate | ||

|

: Drill φ10 mm (0.39 in) hole for the plug welding hole (ultra high strength steel). : Drill φ10 mm (0.39 in) hole for the plug welding hole (ultra high strength steel). |

PARTIAL REPLACEMENT

Work after radiator core support is removed.

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

| Replacement part | |||||

| • | Front side member assembly | • | Front side member closing plate | ||

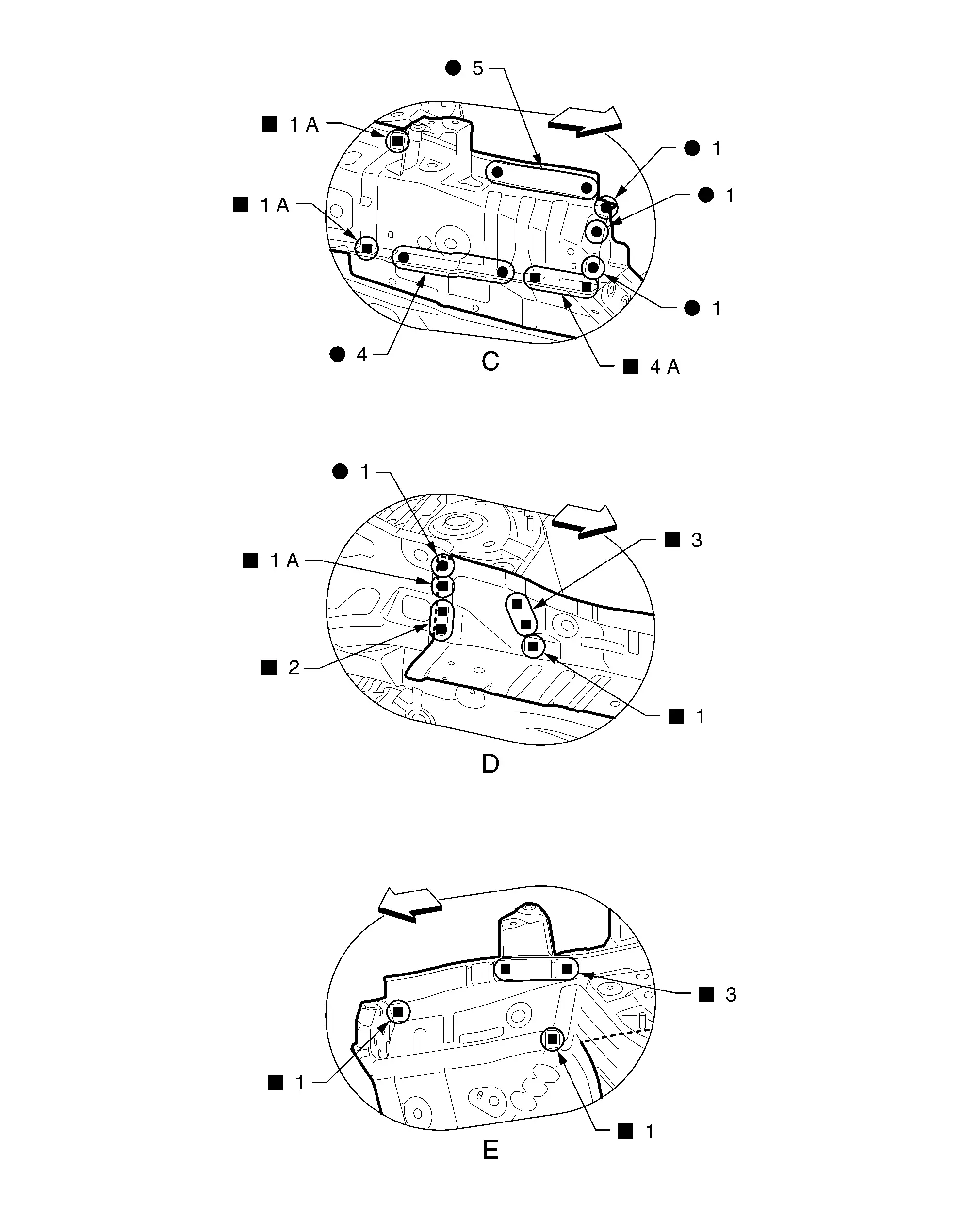

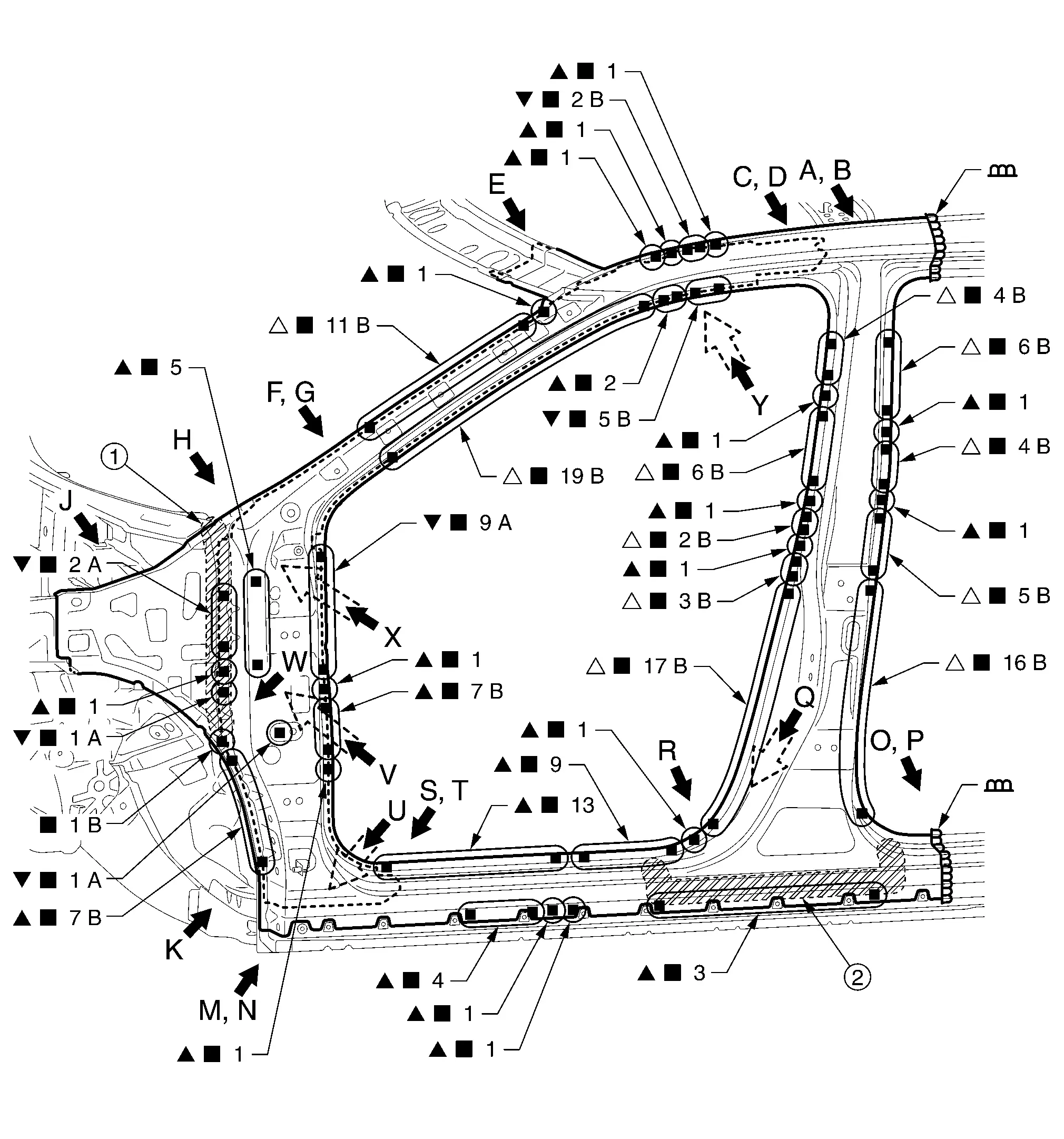

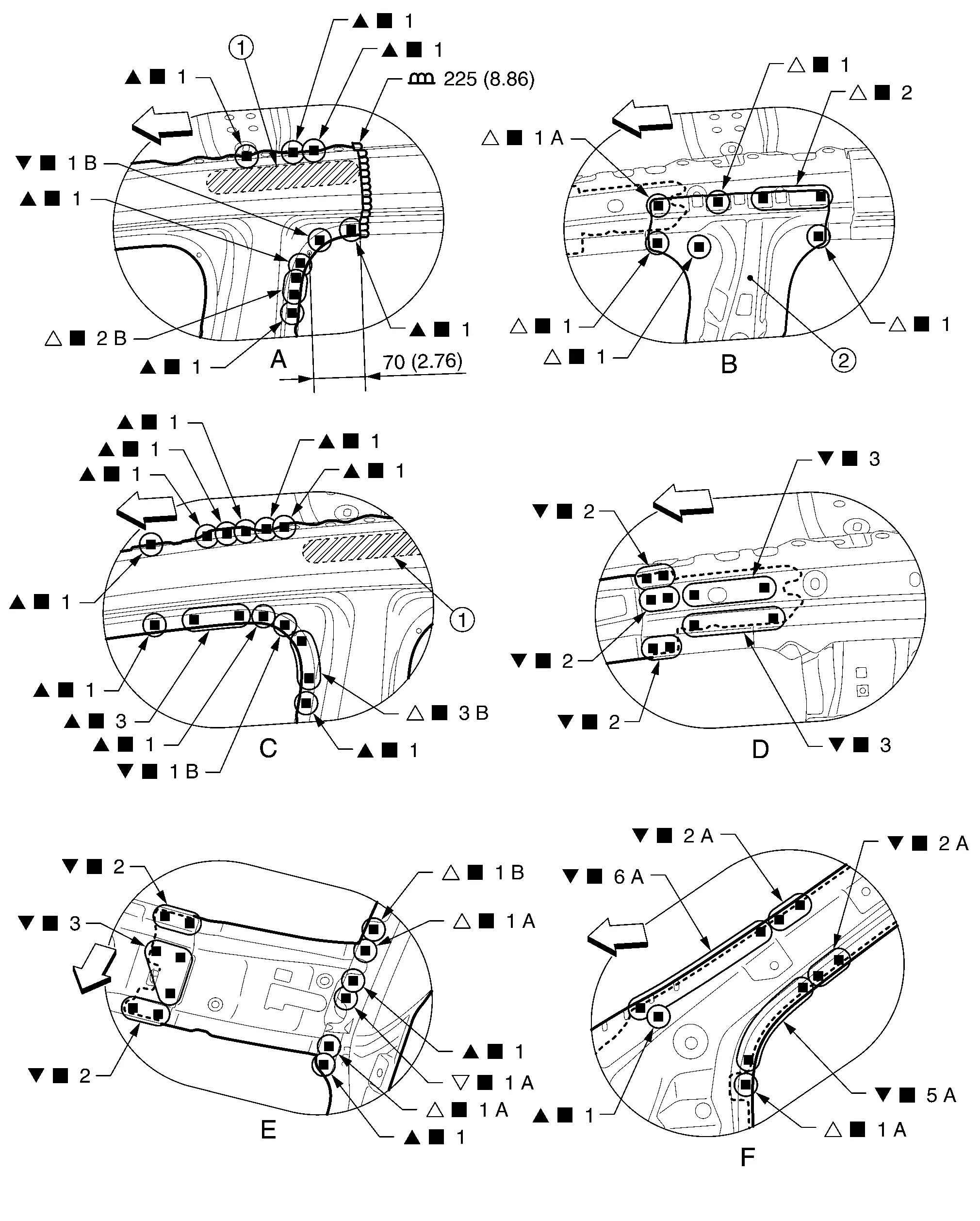

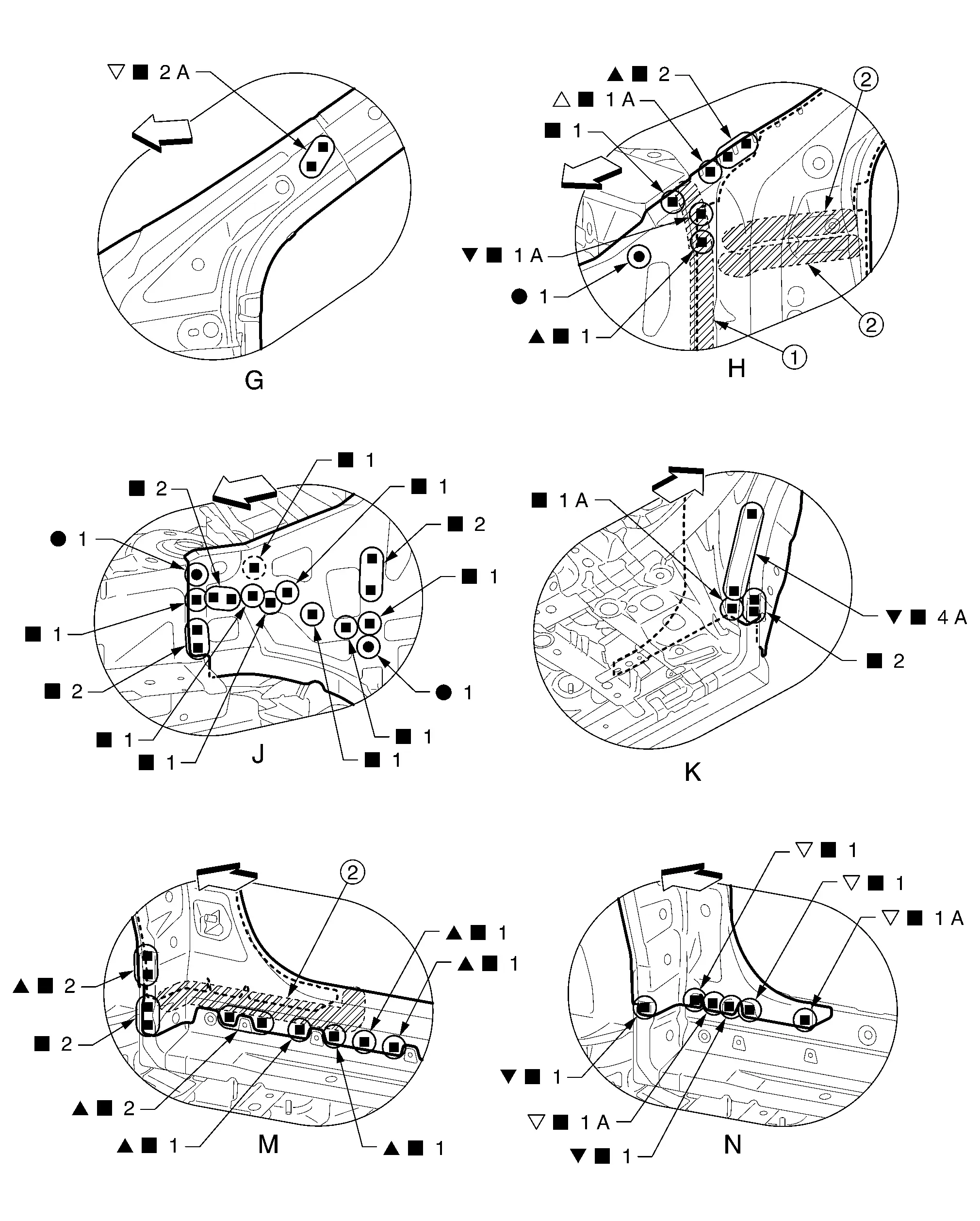

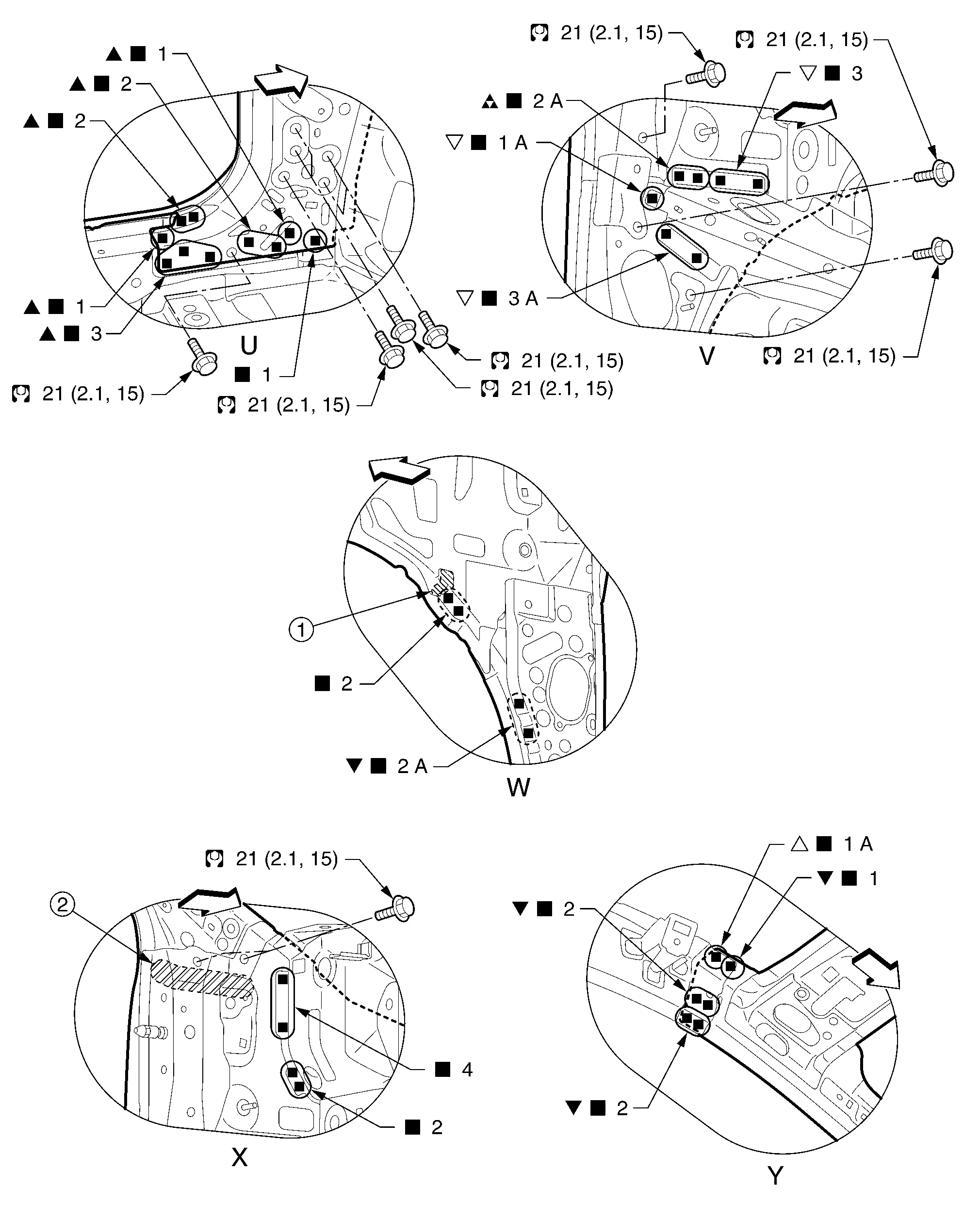

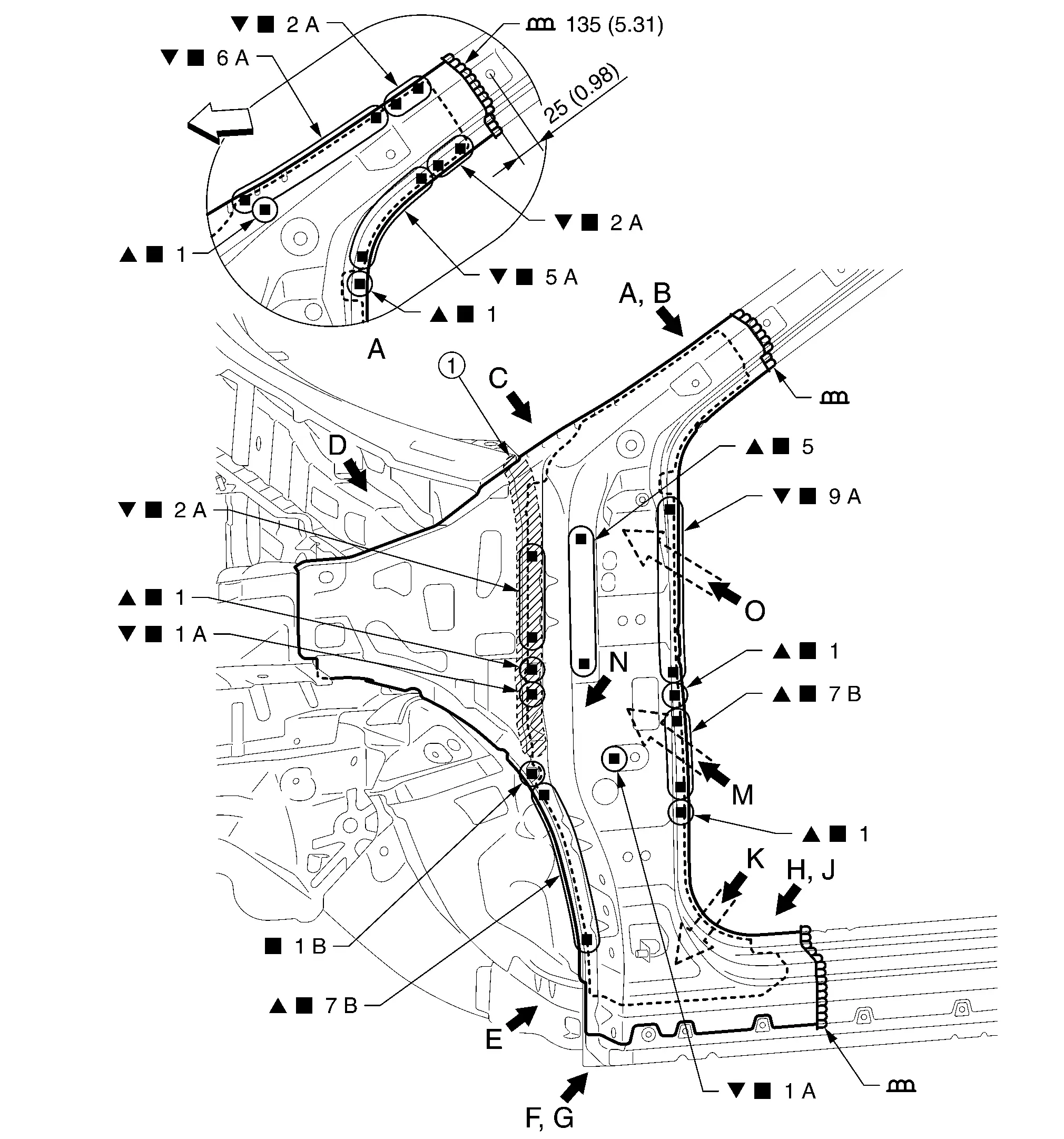

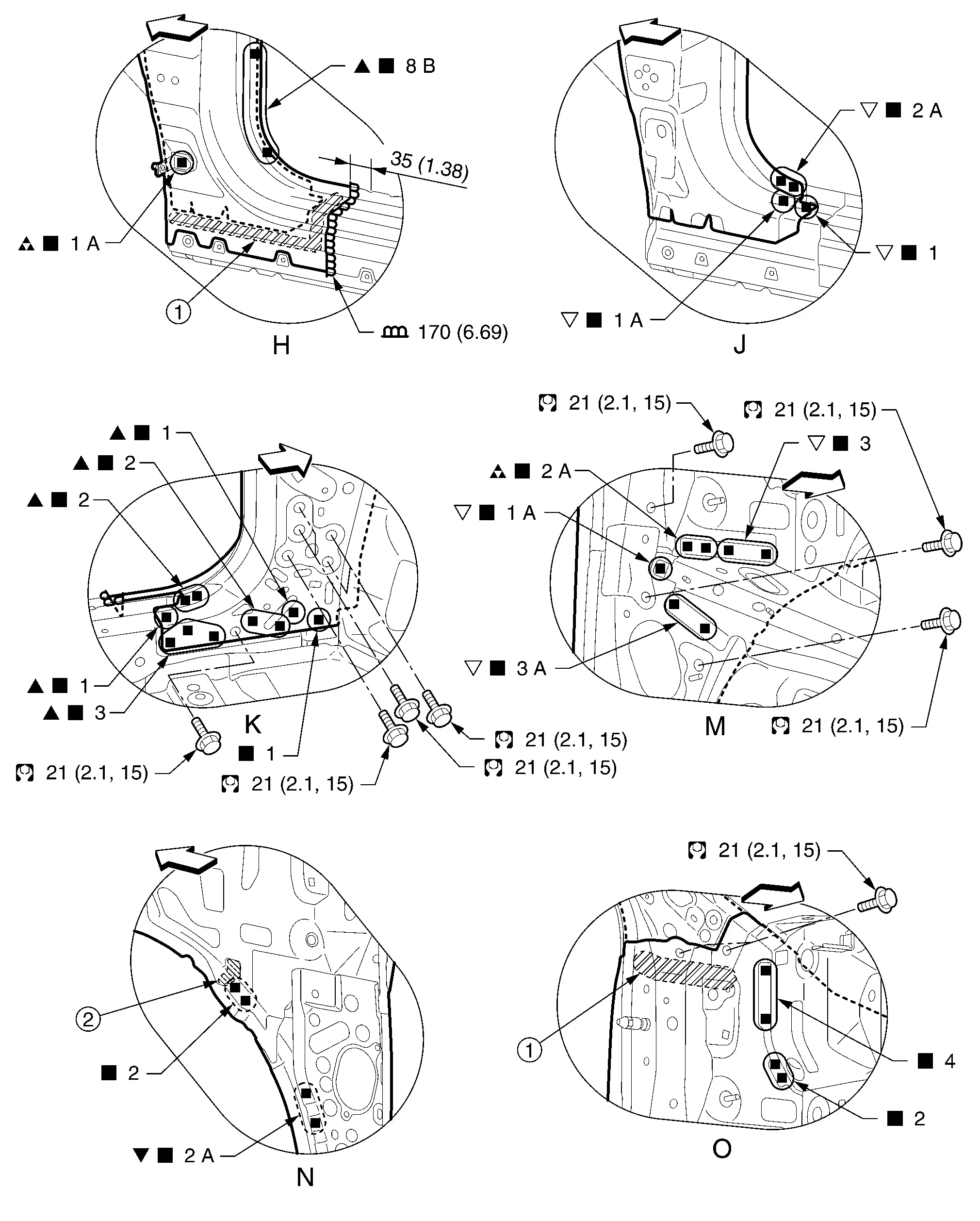

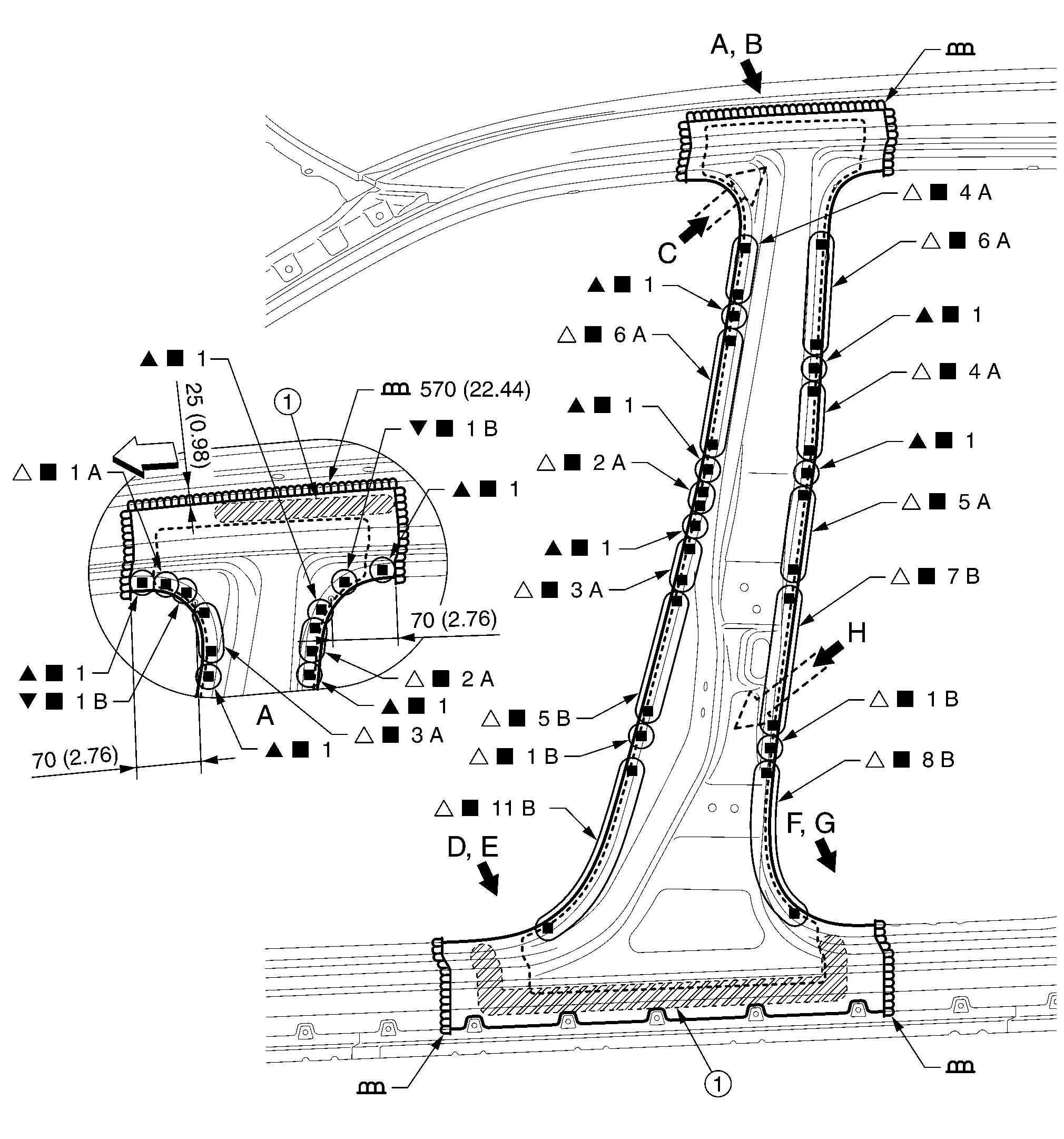

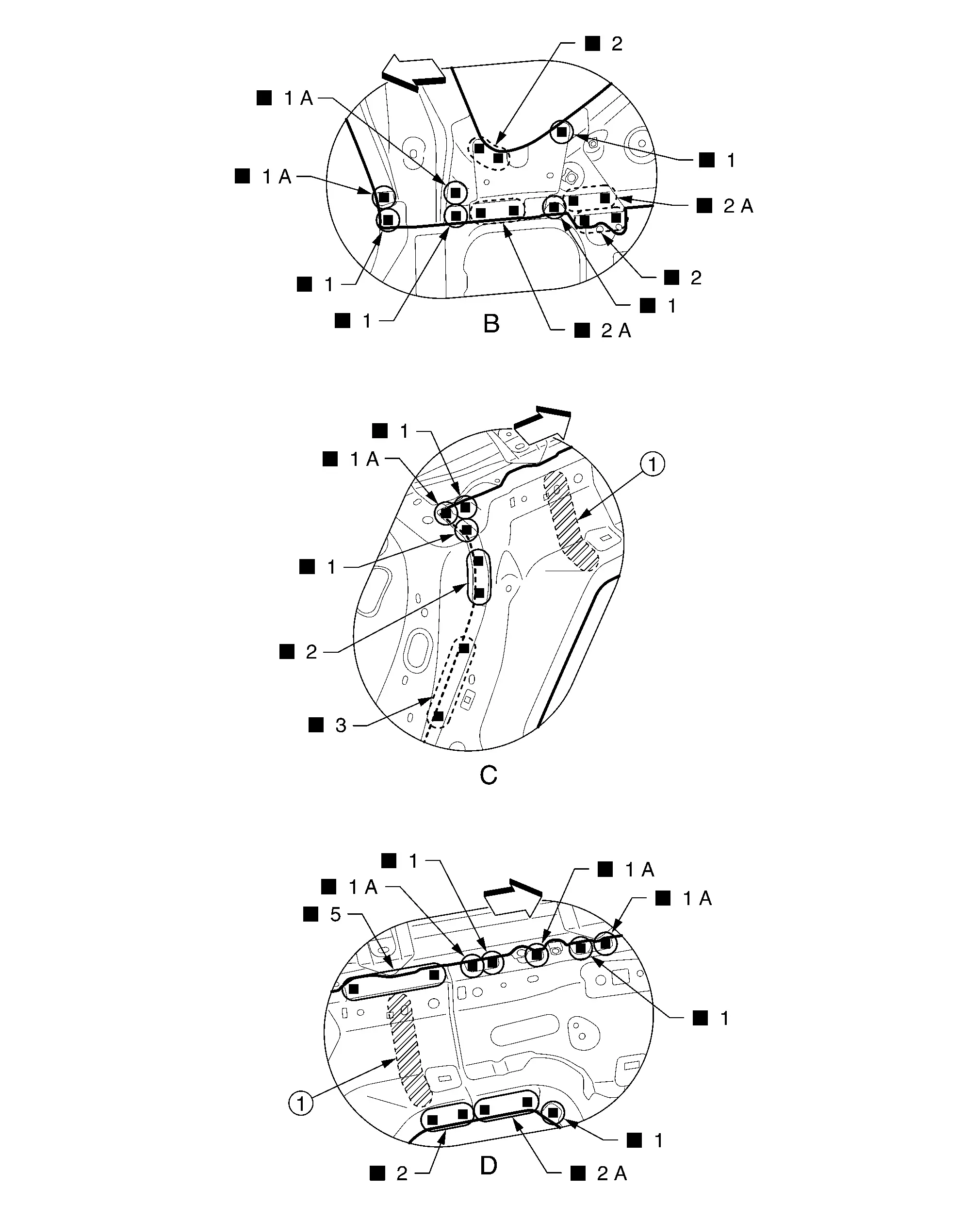

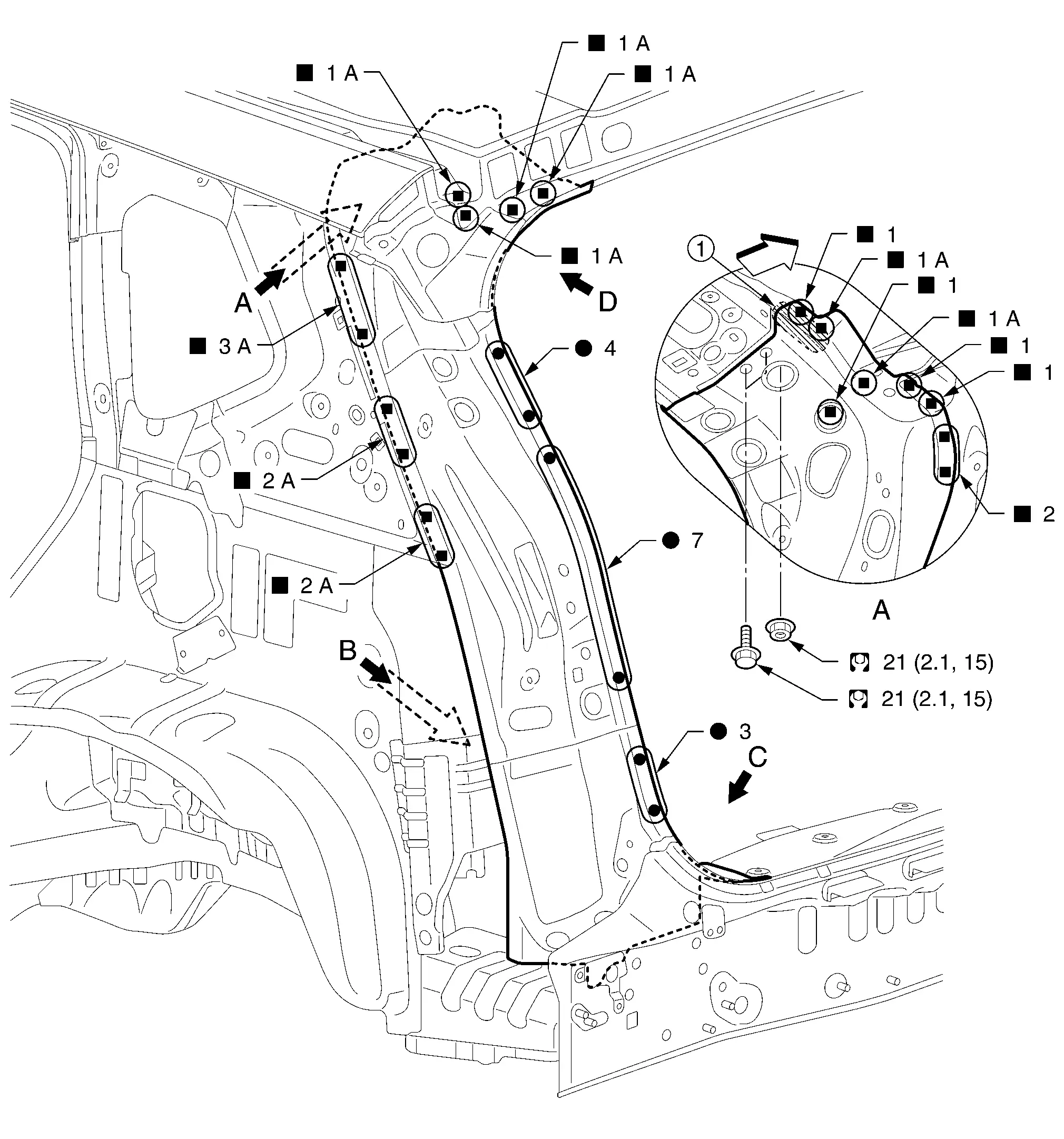

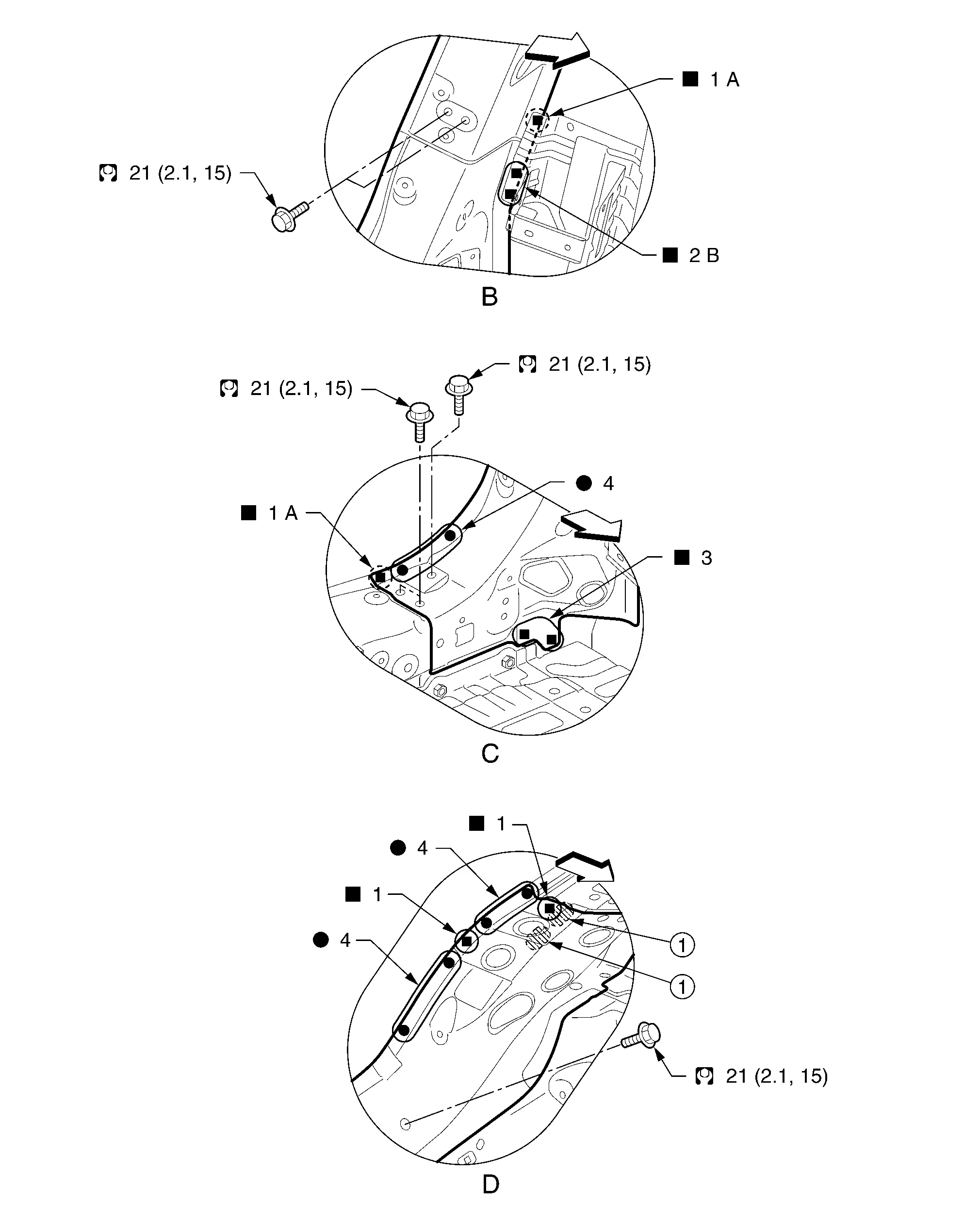

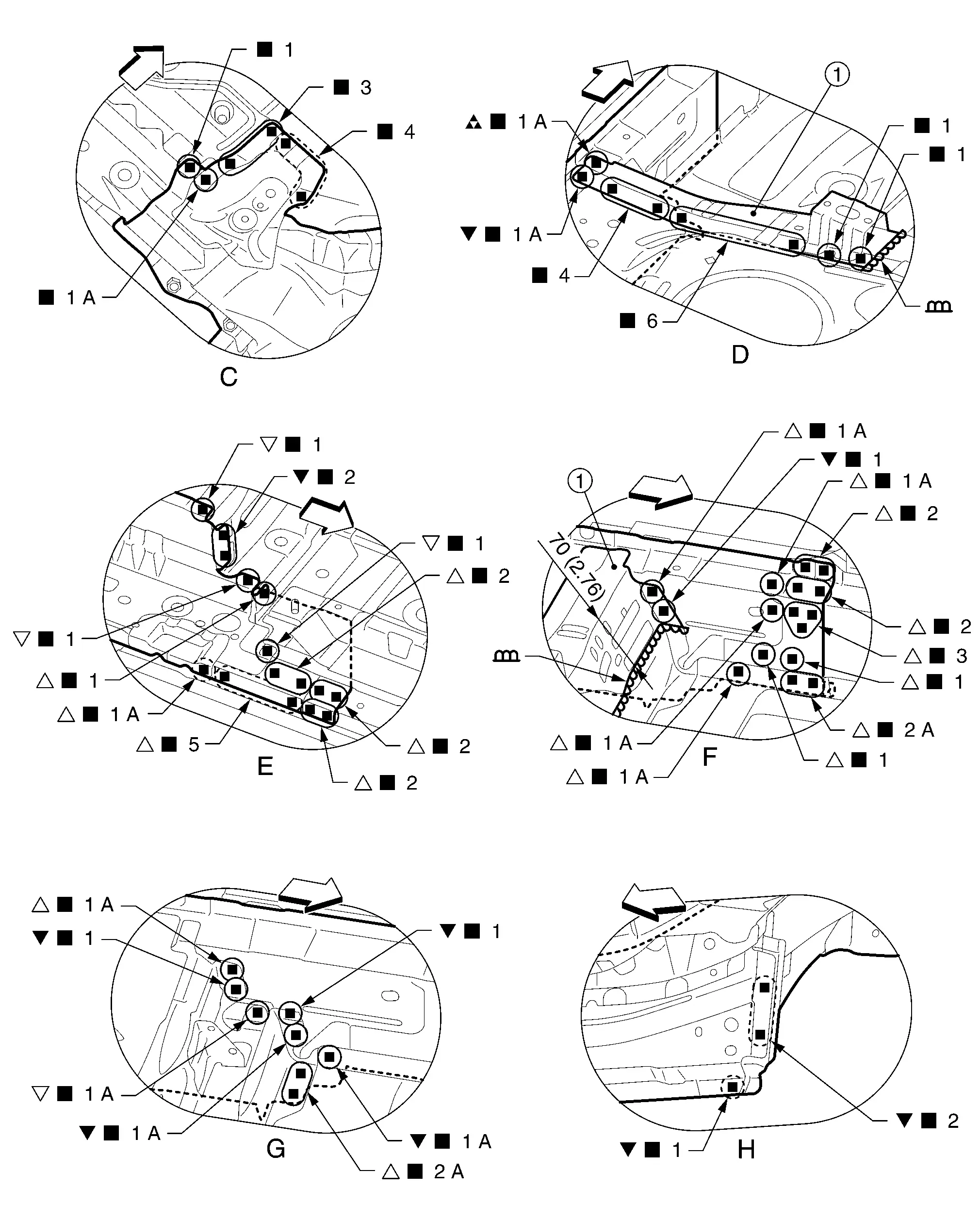

Front Pillar

Work after hoodledge reinforcement and roof are removed.

Remove the lower center pillar brace (reusable) from the vehicle for easier installation.

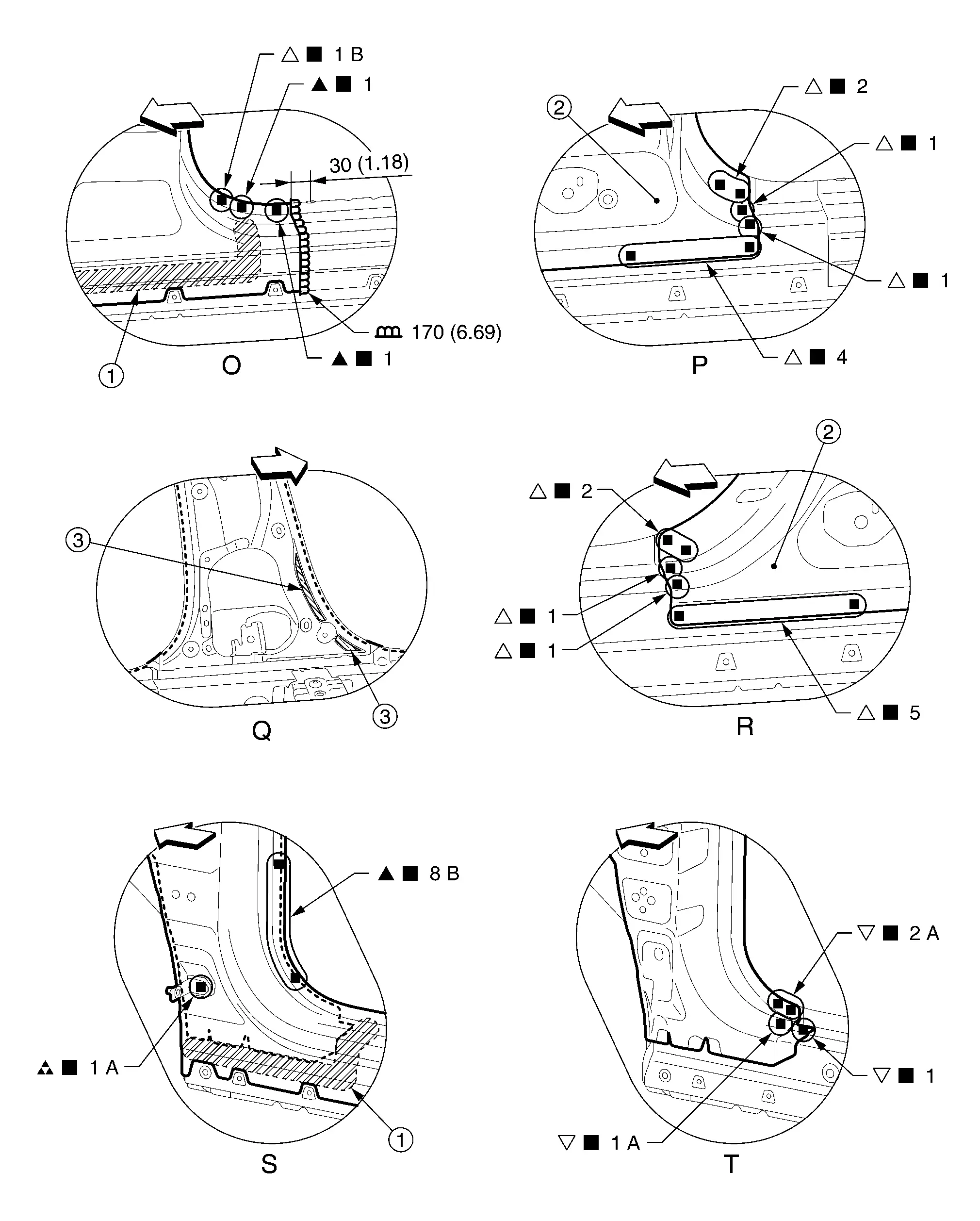

|

Body sealing |  |

Urethane foam | ||

|

: Drill φ8 mm (0.31 in) hole for the plug welding hole (ultra high strength steel). : Drill φ8 mm (0.31 in) hole for the plug welding hole (ultra high strength steel). |

|||||

| Replacement part | |||||

| • | Outer front side body | • | Side dash | • | Upper inner front pillar |

| • | Lower front pillar hinge brace | • | Outer front pillar reinforcement | • | Front fender bracket assembly |

|

Urethane foam |  |

Lower center pillar brace (reusable) | ||

| Unit: mm (in) | |||||

|

: Drill φ9 mm (0.35 in) hole for the plug welding hole (ultra high strength steel). : Drill φ9 mm (0.35 in) hole for the plug welding hole (ultra high strength steel). |

|||||

View B: Before installing outer front side body

View D: Before installing outer front side body and lower center pillar brace (reusable)

|

Body sealing |  |

Urethane foam | ||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

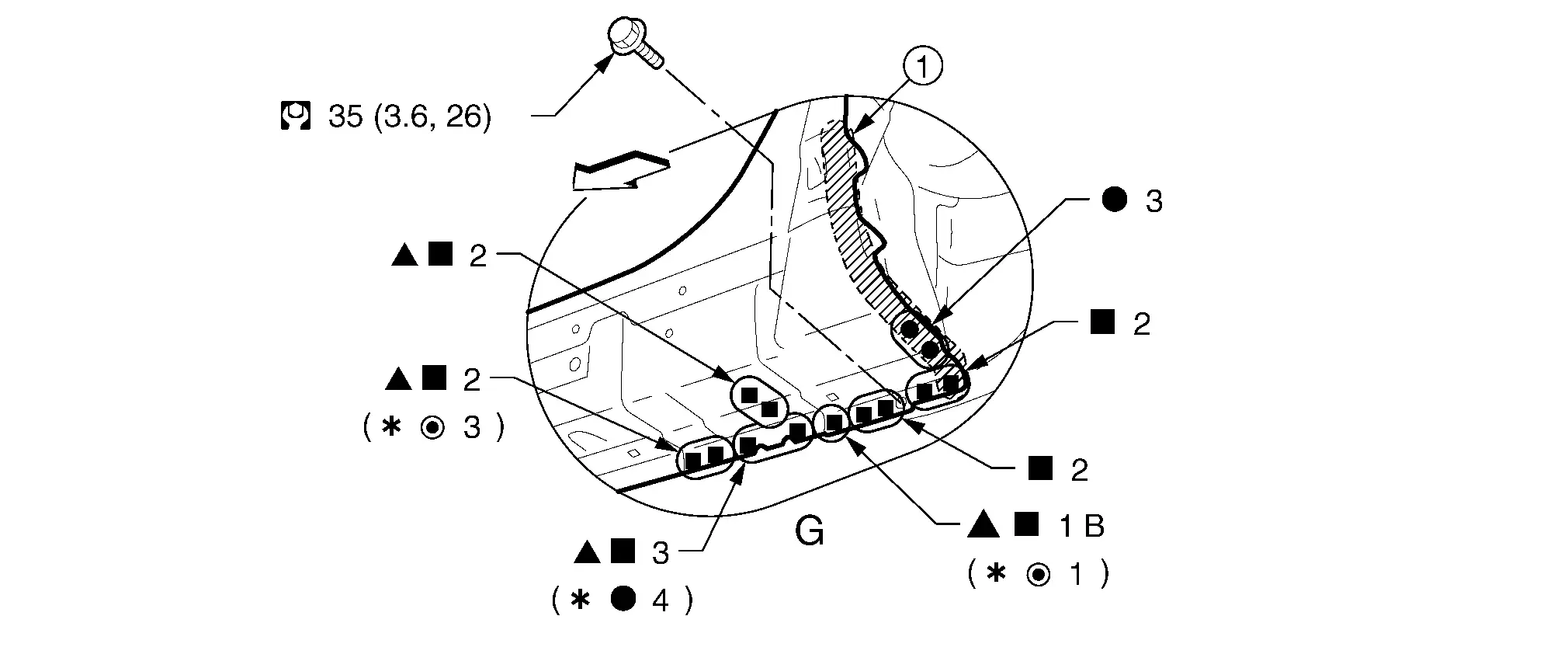

View G and N: Before installing outer front side body

|

Urethane foam |  |

Lower center pillar brace (reusable) |  |

3M™ 08115 Panel Bonding Adhesive |

| Unit: mm (in) | |||||

|

: Drill φ10 mm (0.39 in) hole for the plug welding hole (ultra high strength steel). : Drill φ10 mm (0.39 in) hole for the plug welding hole (ultra high strength steel). |

|||||

View P, R, and T: Before installing outer front side body

|

3M™ 08115 Panel Bonding Adhesive |  |

Urethane foam | ||

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

View W: Before installing outer front side body and front pillar hinge brace

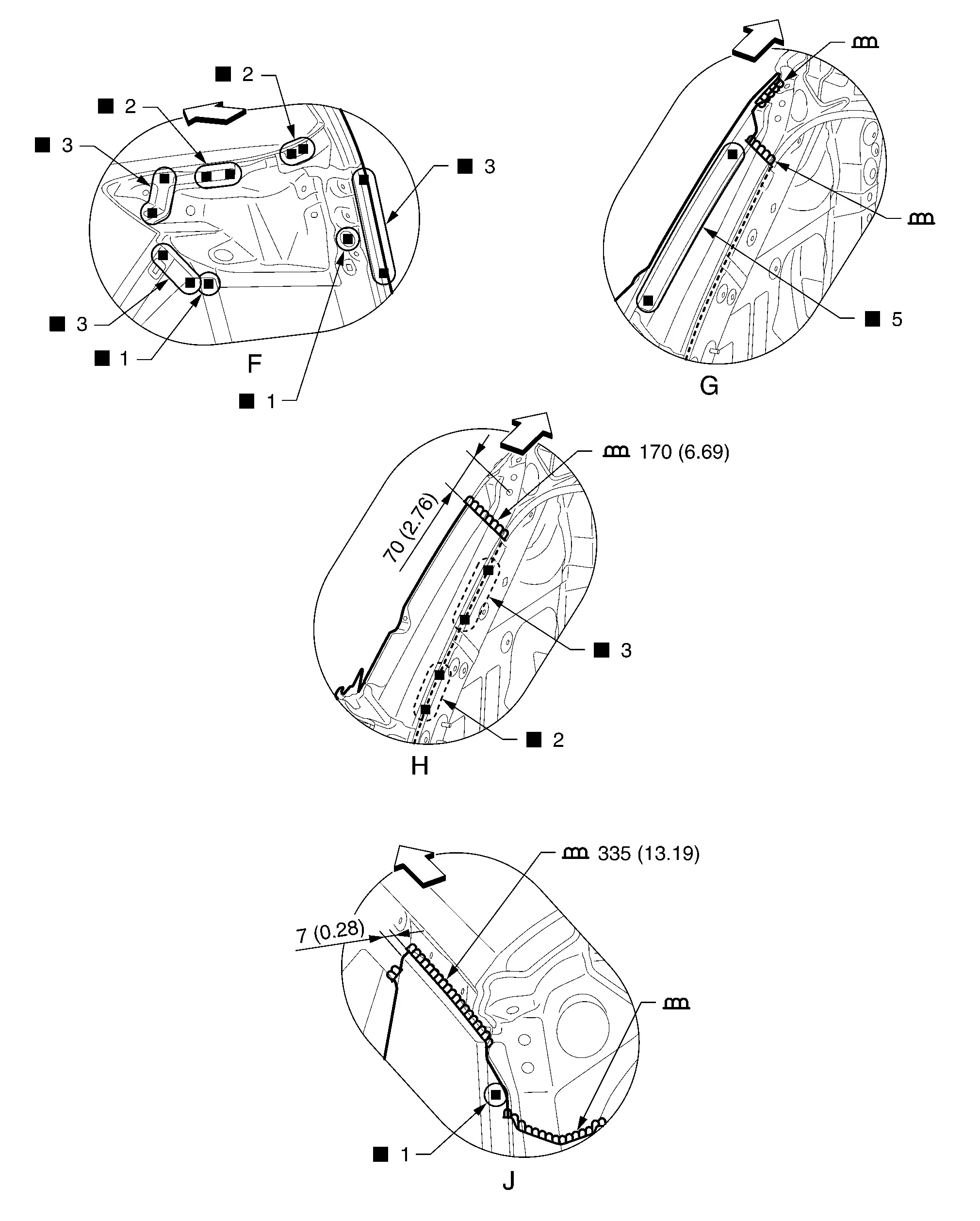

PARTIAL REPLACEMENT

Work after hoodledge reinforcement is removed.

|

Body sealing | ||||

| Unit: mm (in) | |||||

|

: Drill φ7 mm (0.28 in) hole for the plug welding hole (ultra high strength steel). : Drill φ7 mm (0.28 in) hole for the plug welding hole (ultra high strength steel). |

|||||

| Replacement part | |||||

| • | Outer front side body | • | Side dash | • | Lower front pillar hinge brace |

| • | Front fender bracket assembly | ||||

|

Body sealing |  |

Urethane foam | ||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

View B and G: Before installing outer front side body

|

Urethane foam |  |

3M™ 08115 Panel Bonding Adhesive | ||

| Unit: mm (in) | |||||

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

View J: Before installing outer front side body

View N: Before installing outer front side body and lower front pillar hinge brace

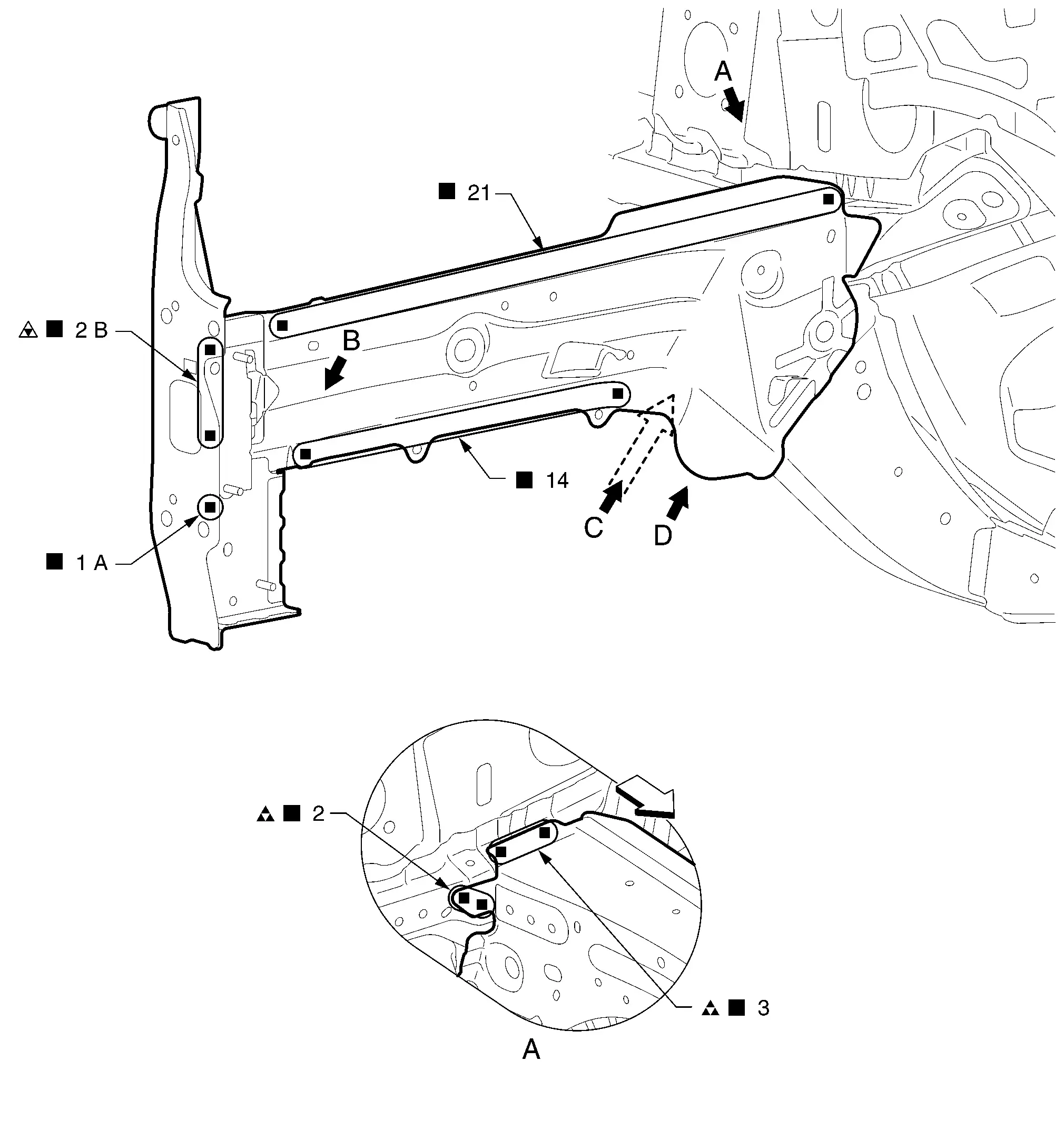

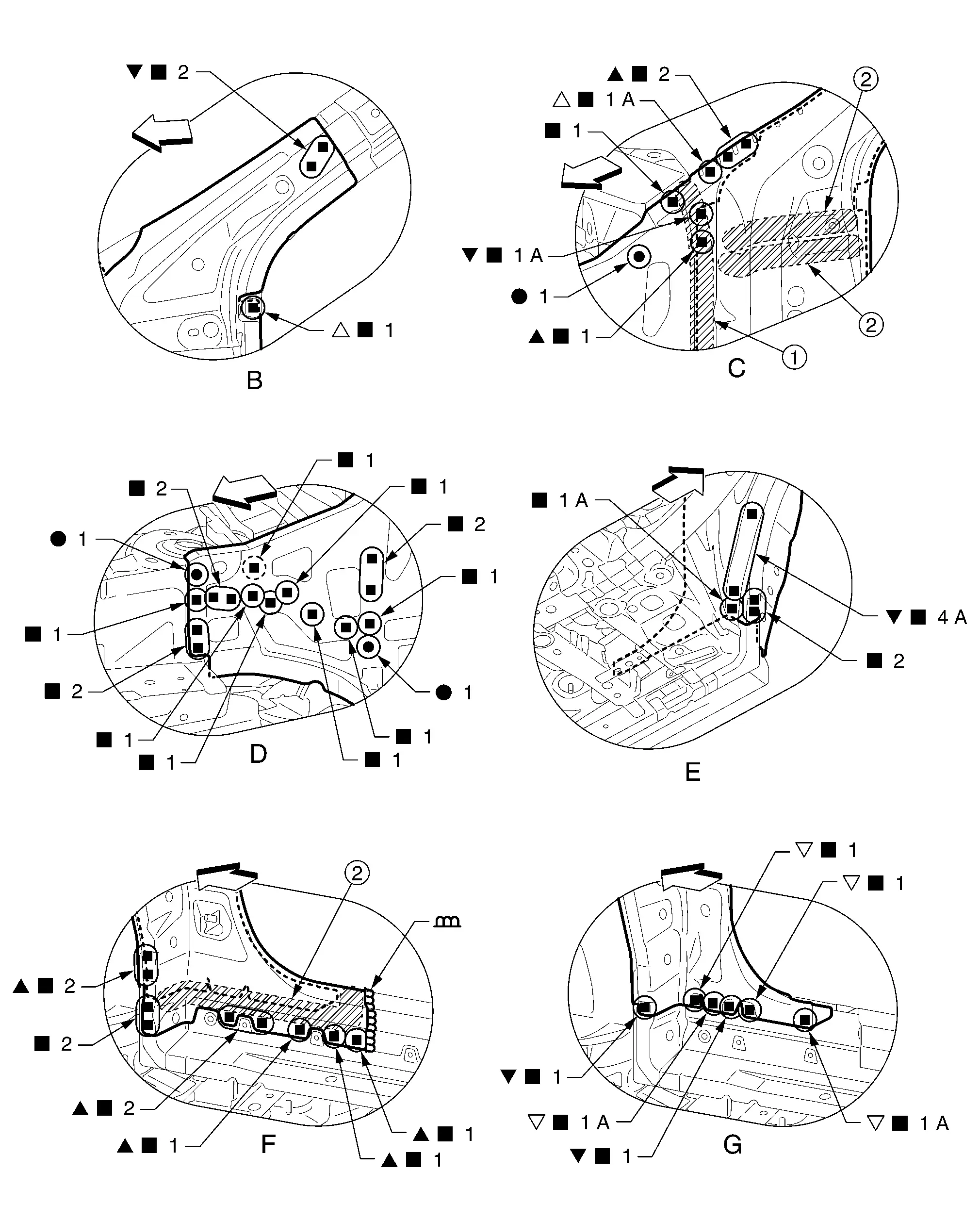

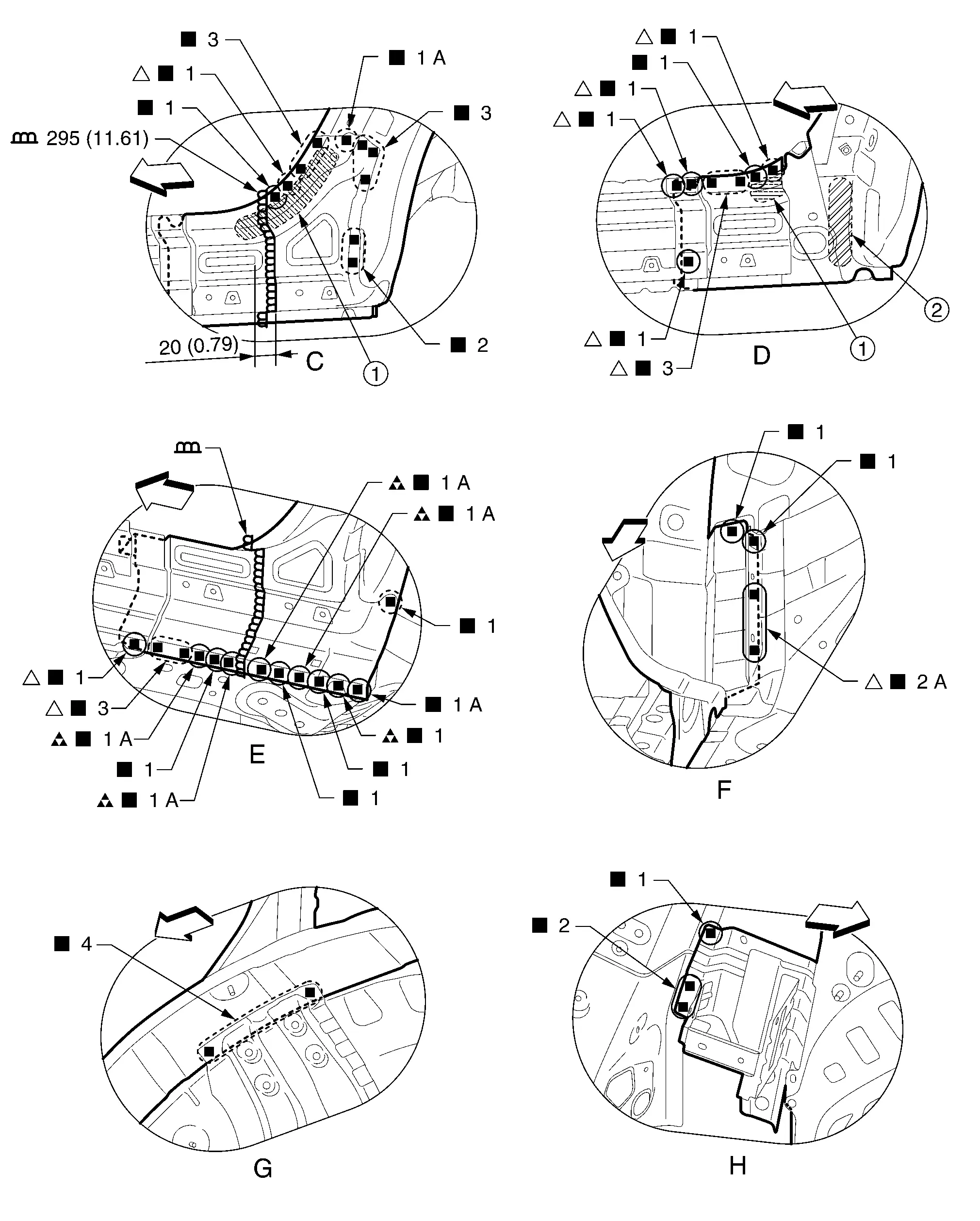

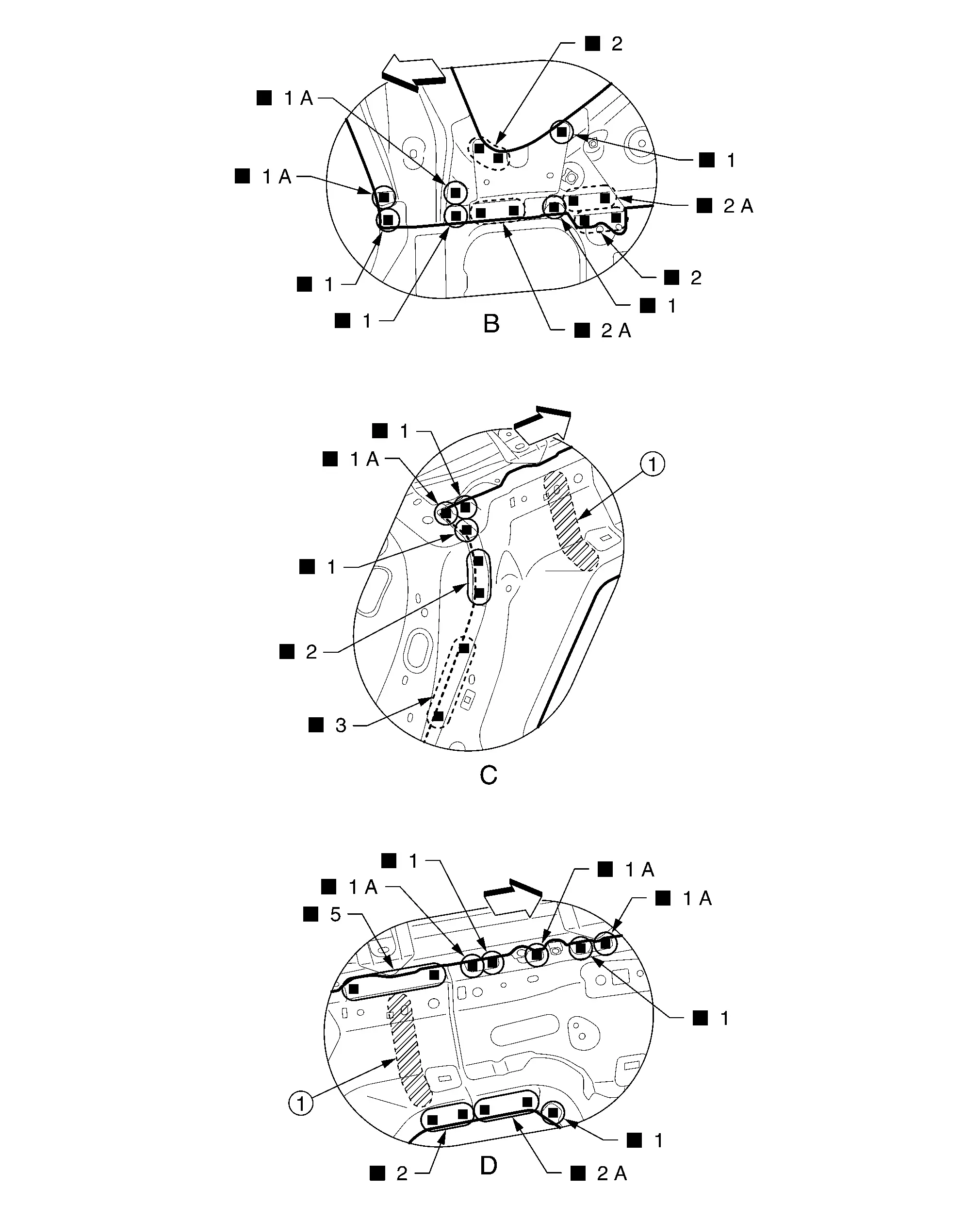

Center Pillar

|

Urethane foam | ||||

| Unit: mm (in) | |||||

|

: Drill φ8 mm (0.31 in) hole for the plug welding hole (ultra high strength steel). : Drill φ8 mm (0.31 in) hole for the plug welding hole (ultra high strength steel). |

|||||

| Replacement part | |||||

| • | Outer front side body | • | Lower center pillar brace | • | Inner center pillar assembly |

|

Urethane foam |  |

3M™ 08115 Panel Bonding Adhesive | ||

| Unit: mm (in) | |||||

|

: Drill φ8 mm (0.31 in) hole for the plug welding hole (ultra high strength steel). : Drill φ8 mm (0.31 in) hole for the plug welding hole (ultra high strength steel). |

|||||

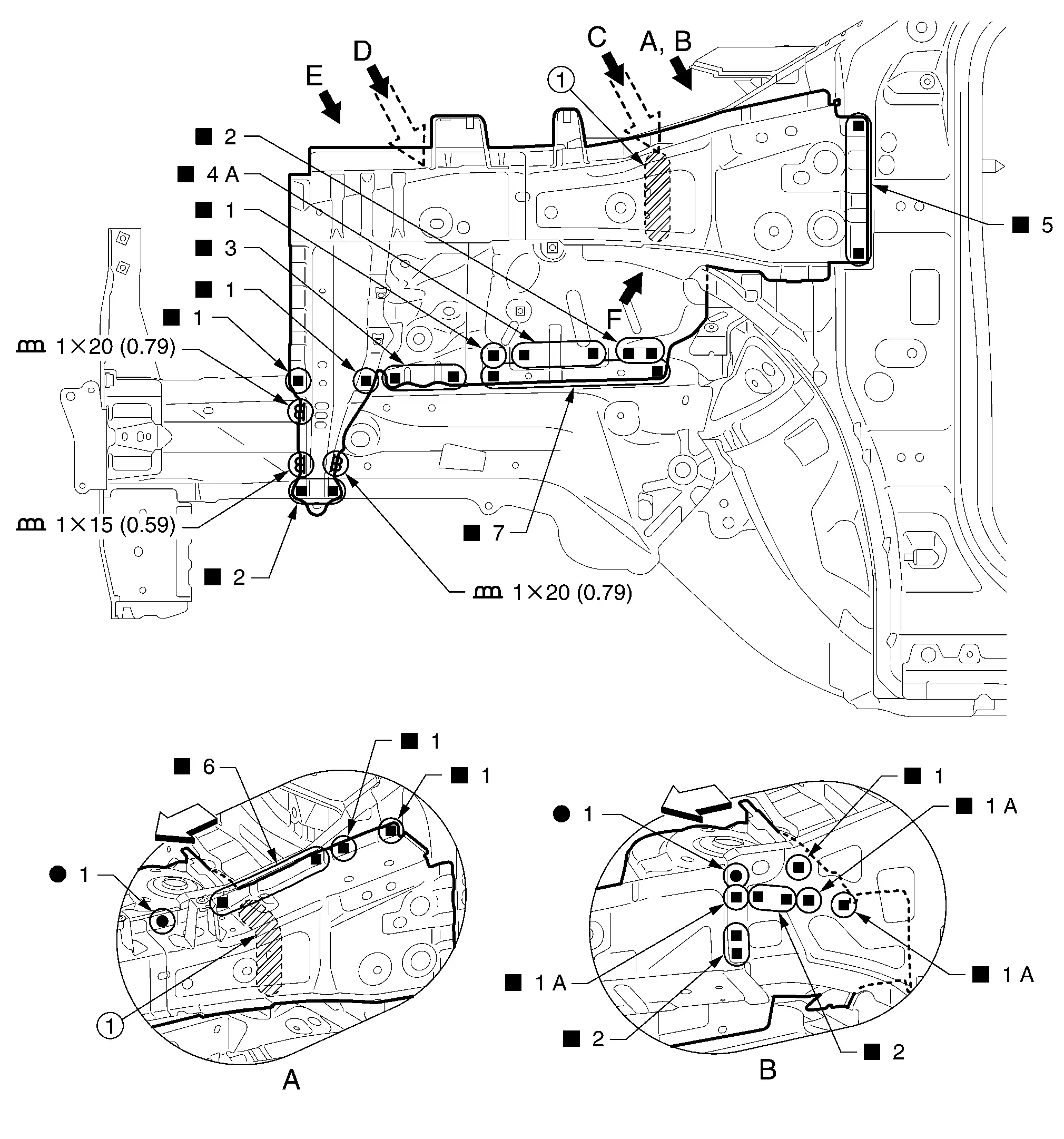

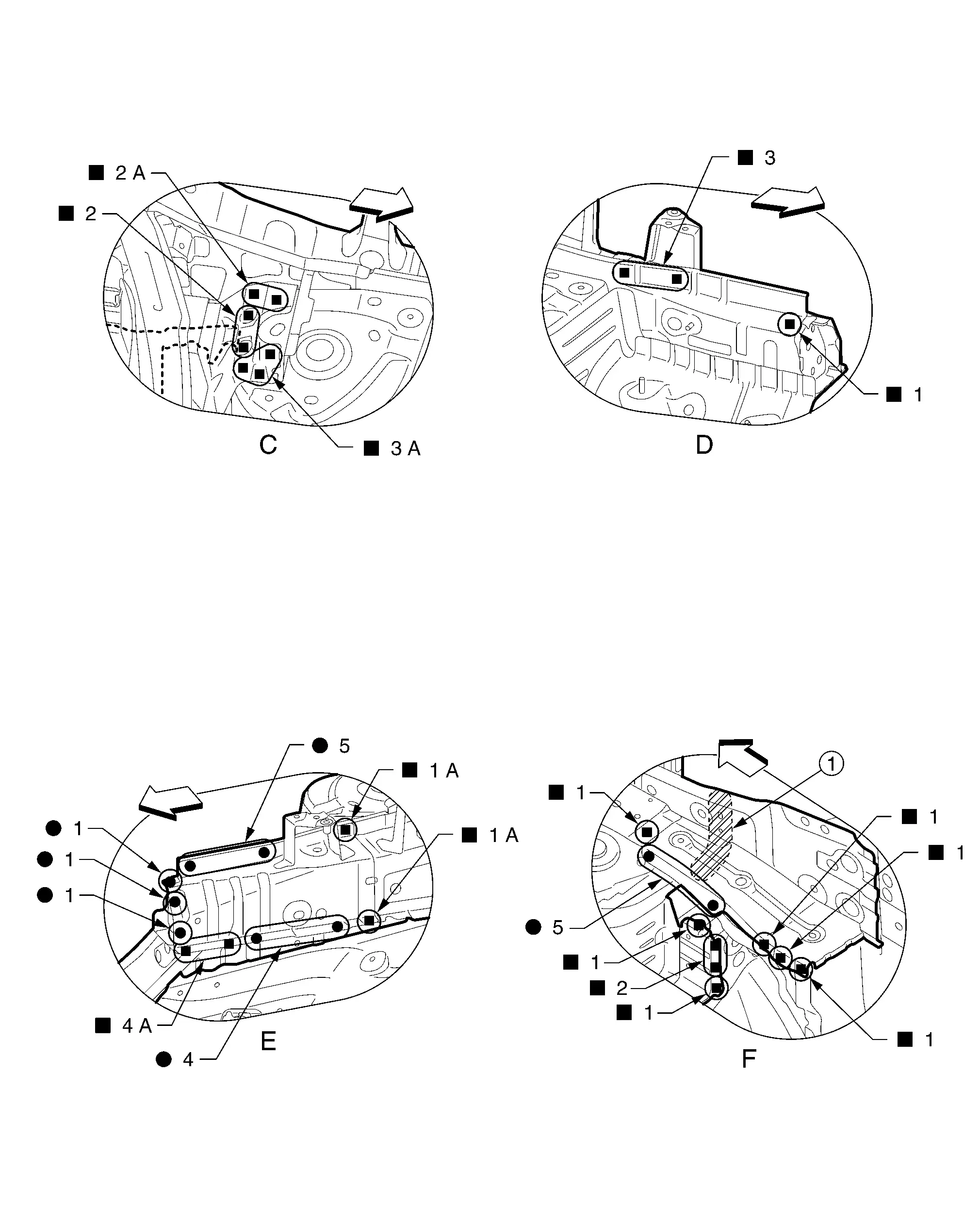

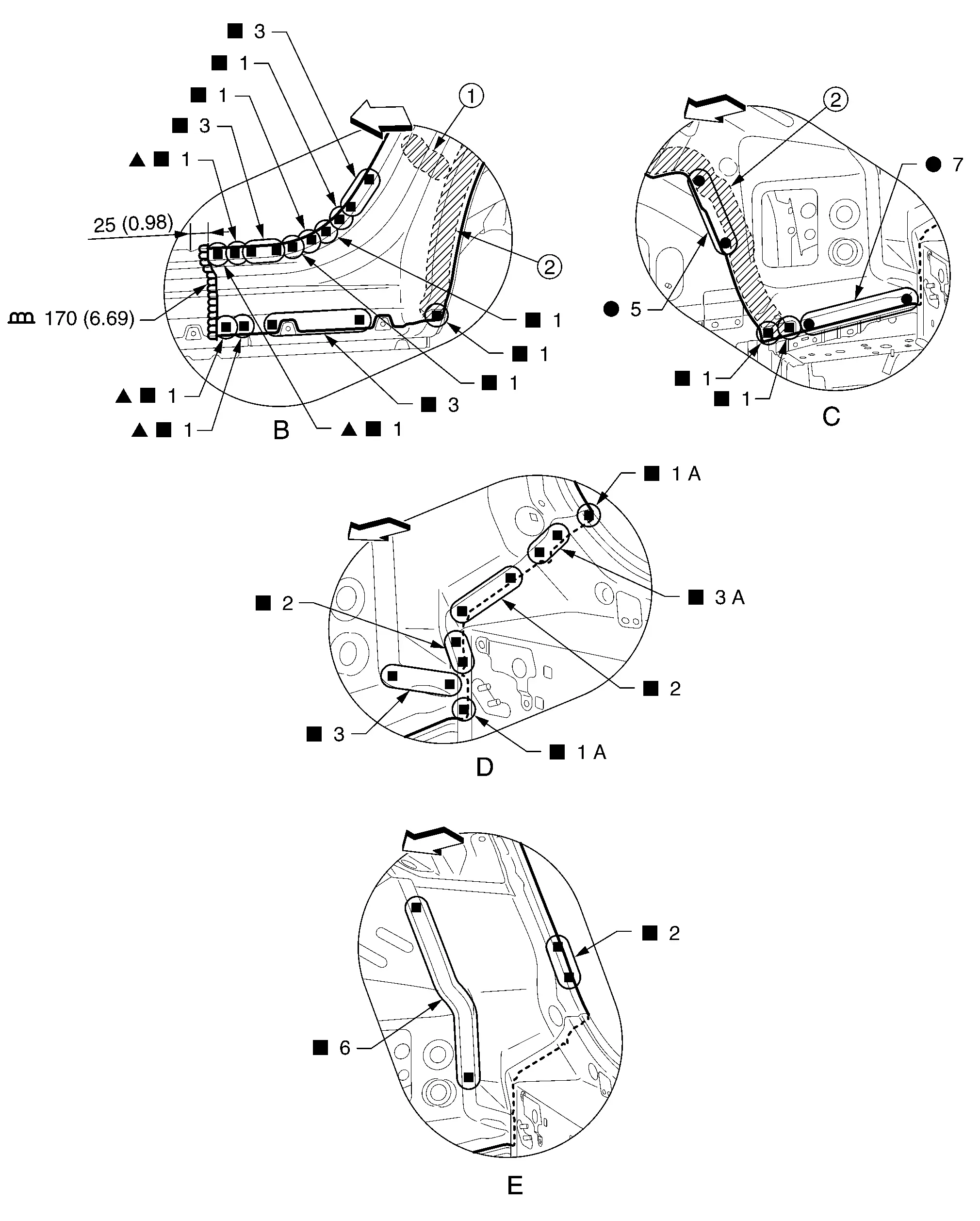

View B, E, and G: Before installing outer front side body

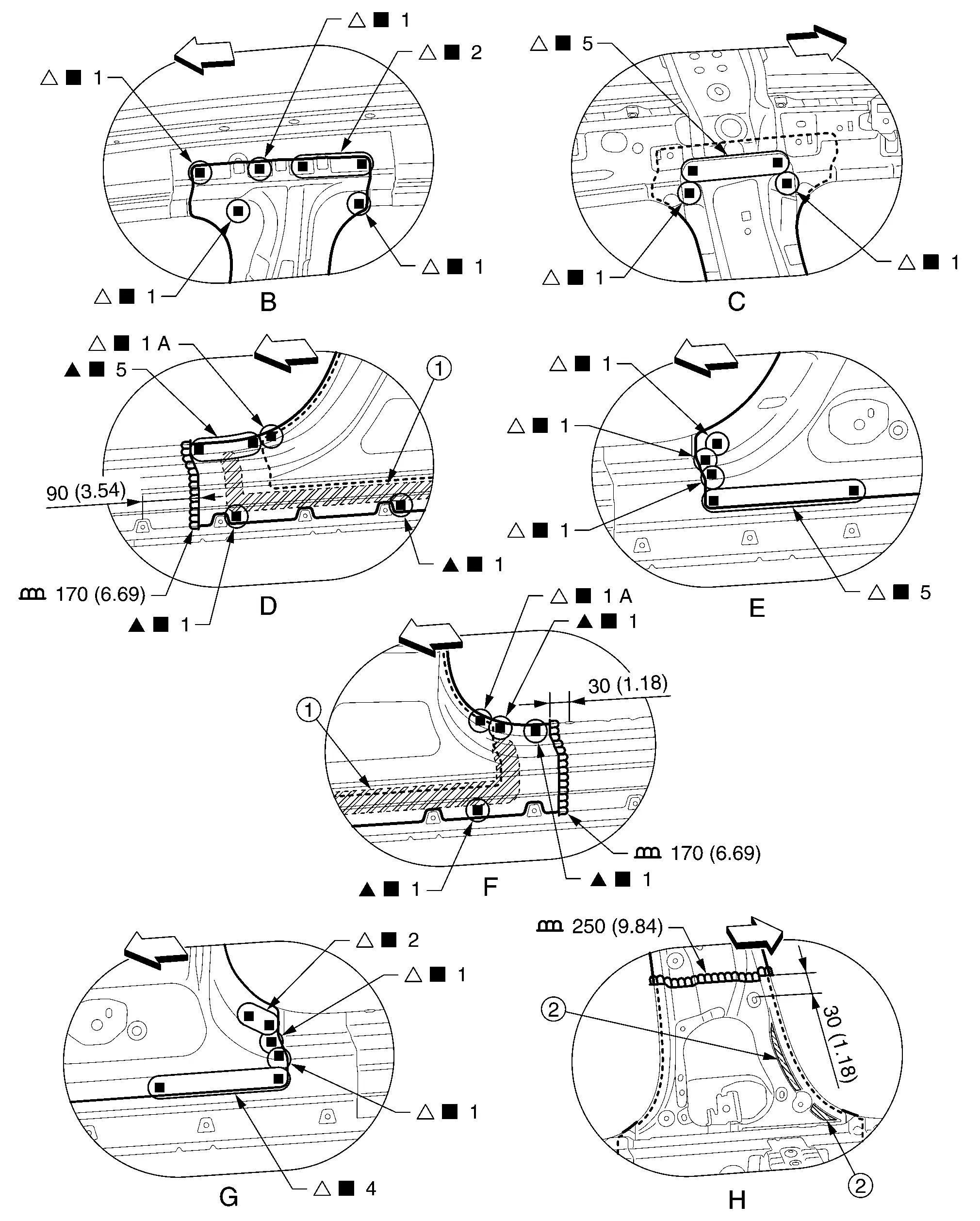

Outer Sill

Remove the inner sill together when removing the outer sill.

Replace the inner sill too if it is damaged.

Remove the inner center pillar assembly (reusable) and front suspension mounting bracket (reusable) from the Nissan Ariya vehicle for easier removal of outer sill reinforcement.

|

Urethane foam | ||||

| Unit: mm (in) | |||||

|

: For spot welding of steel plate

of tensile strength 980 MPa, observe the indicated welding conditions.

Refer to Welding of Ultra High Strength Steel. : For spot welding of steel plate

of tensile strength 980 MPa, observe the indicated welding conditions.

Refer to Welding of Ultra High Strength Steel. |

|||||

| Replacement part | |||||

| • | Outer sill assembly | • | Outer sill reinforcement (Front) | • | Outer sill reinforcement (Rear) |

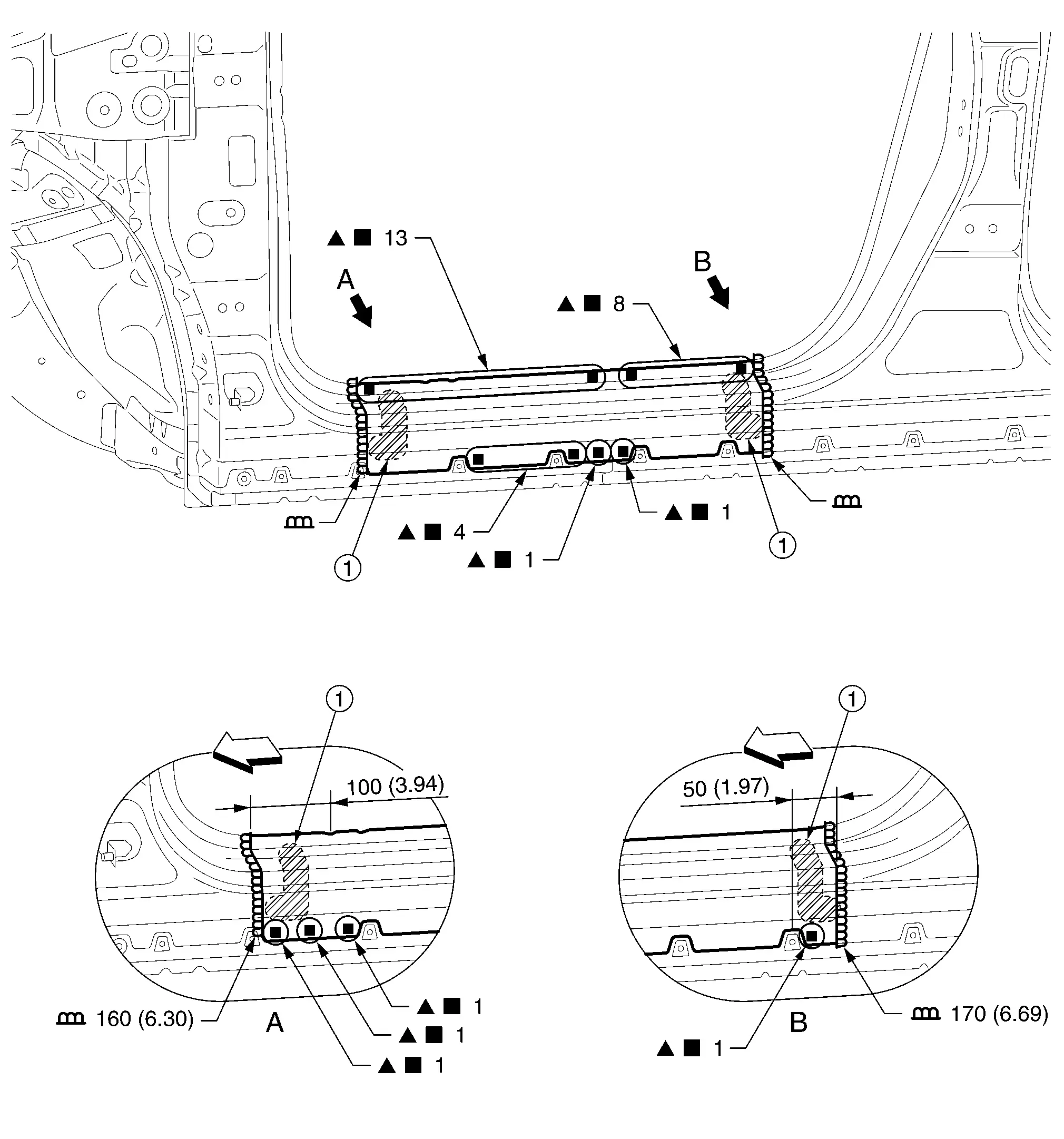

View B: Before installing outer sill assembly

|

Inner center pillar assembly (reusable) |  |

Urethane foam |  |

Front suspension mounting bracket (reusable) |

| Unit: mm (in) | |||||

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

View G: Before installing outer sill assembly

|

Urethane foam |  |

Front suspension mounting bracket (reusable) |  |

Body sealing |

| Unit: mm (in) | |||||

|

: For spot welding of steel plate

of tensile strength 980 MPa, observe the indicated welding conditions.

Refer to Welding of Ultra High Strength Steel. : For spot welding of steel plate

of tensile strength 980 MPa, observe the indicated welding conditions.

Refer to Welding of Ultra High Strength Steel. |

|||||

View M and Q: Before installing outer sill assembly

|

3M™ 08115 Panel Bonding Adhesive |  |

Urethane foam |  |

Inner center pillar assembly (reusable) |

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

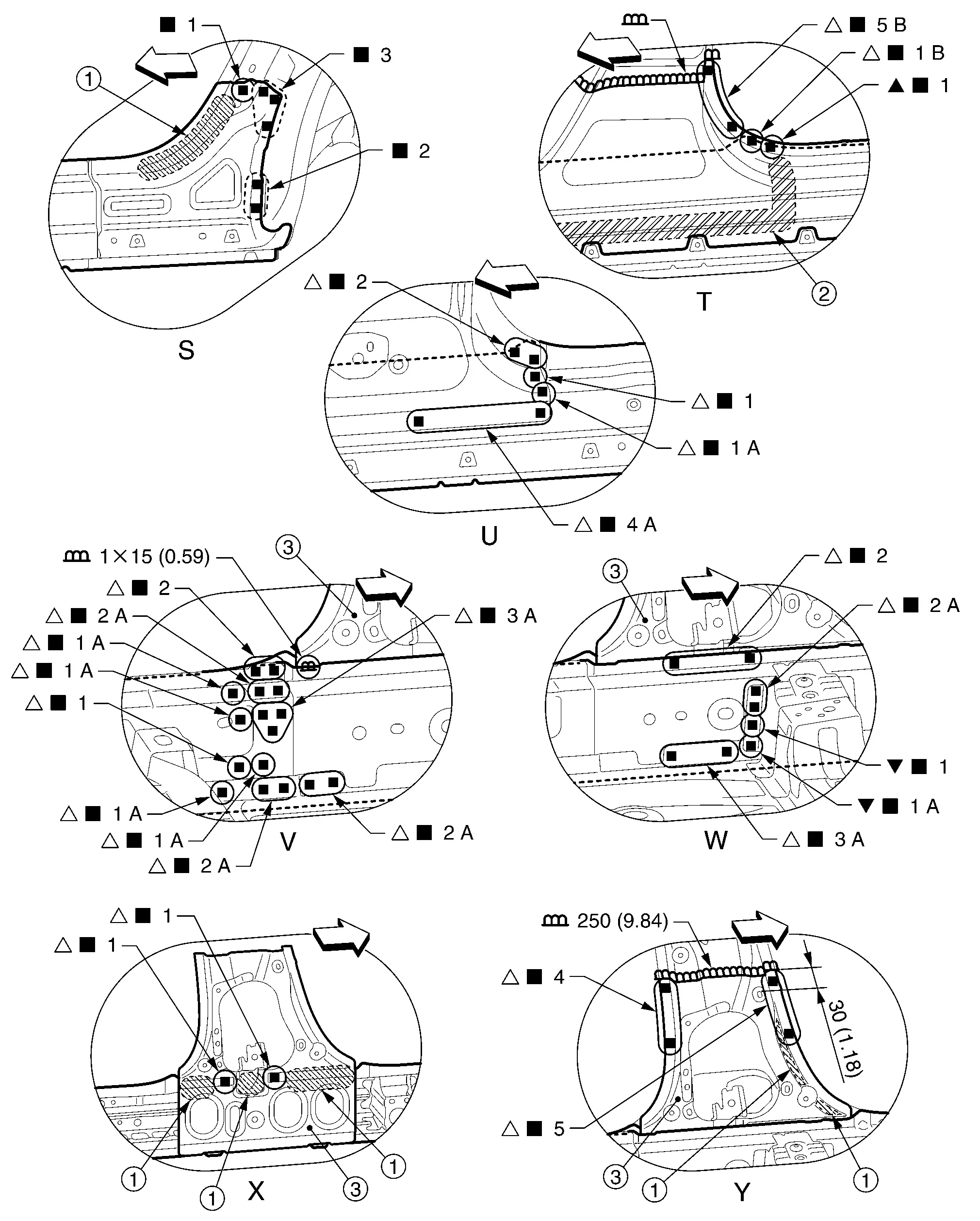

View S and U: Before installing outer sill assembly

View X: Outer sill reinforcement (Front, replacement part) and inner center pillar assembly (reusable)

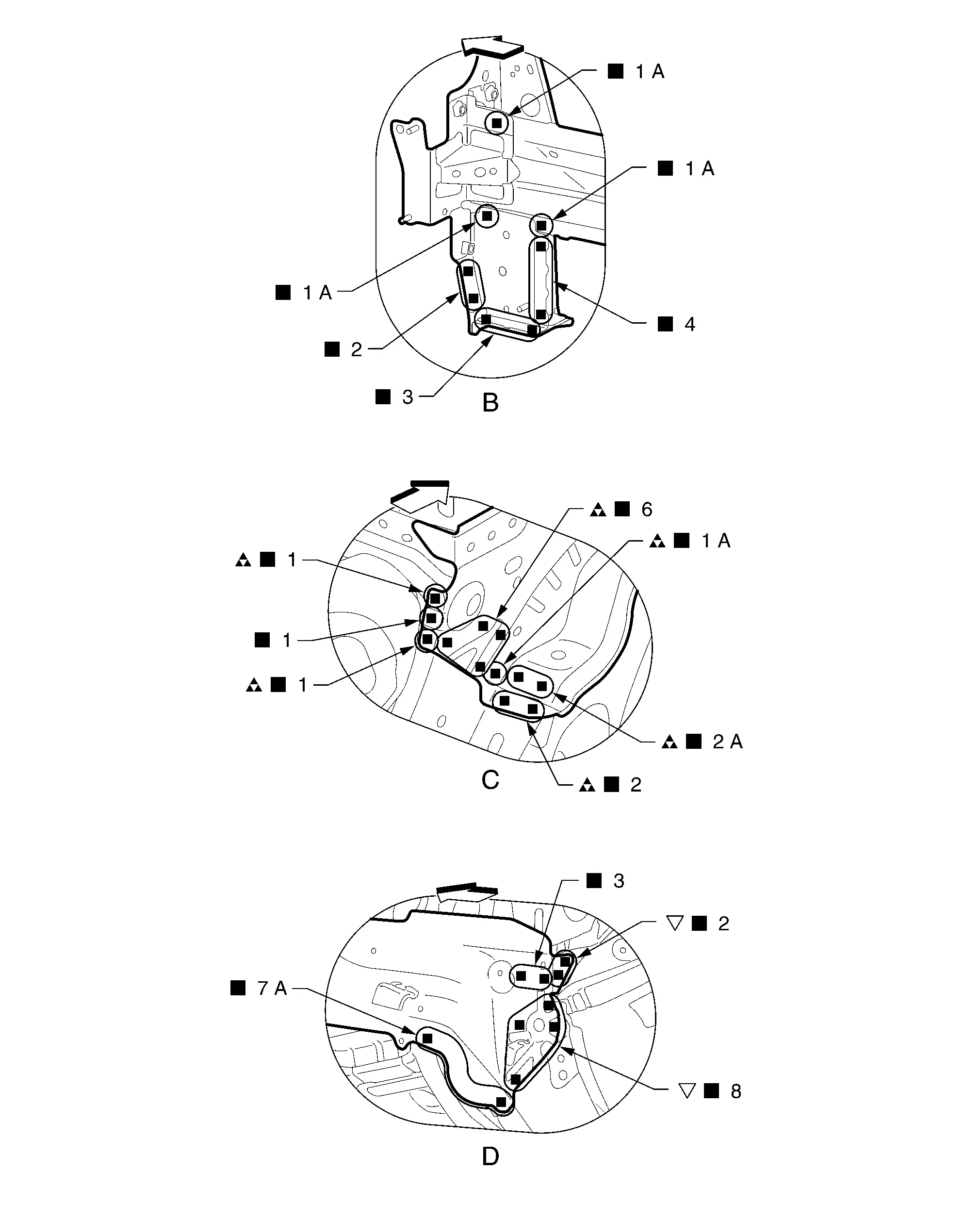

PARTIAL REPLACEMENT

|

Urethane foam | ||||

| Unit: mm (in) | |||||

|

: Drill φ6 mm (0.24 in) hole for the plug welding hole (ultra high strength steel). : Drill φ6 mm (0.24 in) hole for the plug welding hole (ultra high strength steel). |

|||||

| Replacement part | |||||

| • | Outer sill assembly | ||||

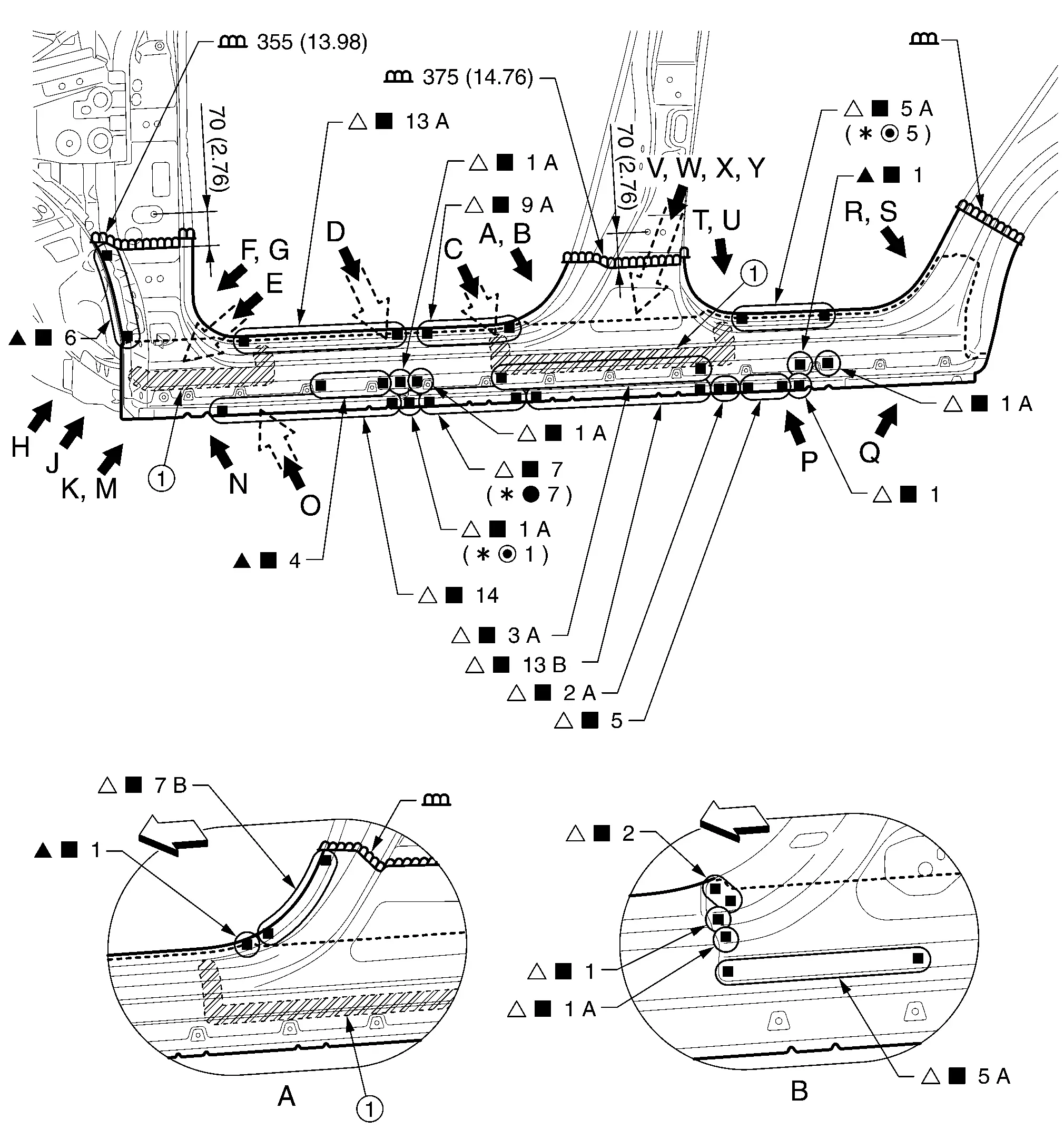

Rear Fender

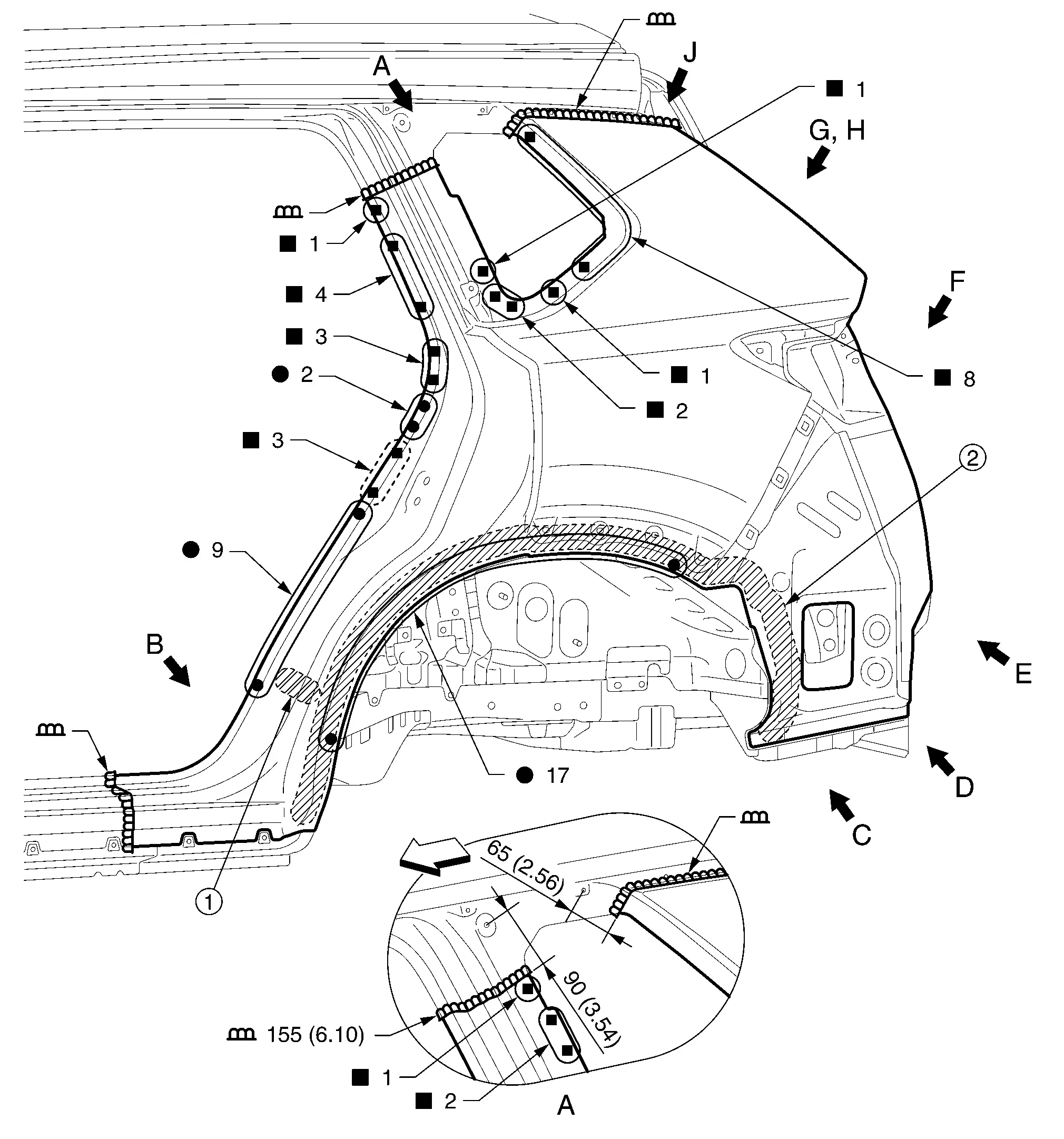

|

Urethane foam |  |

Body sealing | ||

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

| Replacement part | |||||

| • | Rear fender assembly | ||||

|

Urethane foam |  |

Body sealing | ||

| Unit: mm (in) | |||||

|

: Drill φ6 mm (0.24 in) hole for the plug welding hole (ultra high strength steel). : Drill φ6 mm (0.24 in) hole for the plug welding hole (ultra high strength steel). |

|||||

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

View H: Before installing outer side body

Rear Fender Extension

|

Body sealing | ||||

| Unit: mm (in) | |||||

: Nissan Ariya Vehicle front : Nissan Ariya Vehicle front |

|||||

| Replacement part | |||||

| • | Rear fender extension | ||||

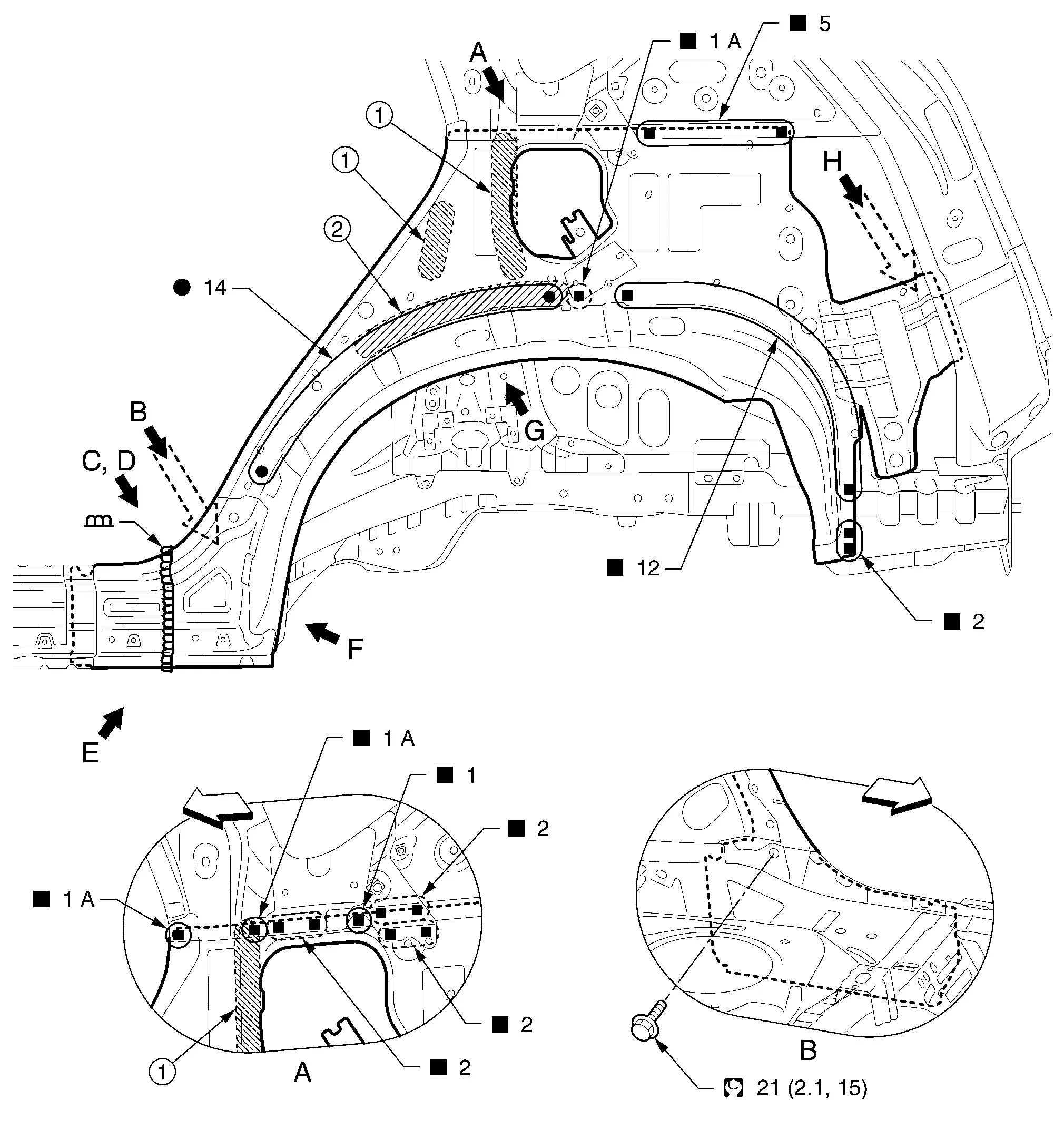

Outer Rear Wheelhouse

Work after rear fender is removed.

|

3M™ 08115 Panel Bonding Adhesive |  |

Body sealing | ||

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

| Replacement part | |||||

| • | Outer rear wheelhouse | ||||

|

3M™ 08115 Panel Bonding Adhesive |  |

Urethane foam | ||

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

View D: Before installing outer sill reinforcement (Rear)

Inner Rear Wheelhouse

Work after rear fender and outer rear wheelhouse are removed.

|

: Drill φ9 mm (0.35 in) hole for the plug welding hole (ultra high strength steel). : Drill φ9 mm (0.35 in) hole for the plug welding hole (ultra high strength steel). |

|||||

| Replacement part | |||||

| • | Inner rear wheelhouse | ||||

Inner Rear Pillar (Without Moonroof models)

Work after rear fender is removed.

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

| Replacement part | |||||

| • | Inner rear pillar | ||||

|

3M™ 08115 Panel Bonding Adhesive |  |

Urethane foam | ||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

Inner Rear Pillar (With Moonroof models)

Work after rear fender is removed.

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

| Replacement part | |||||

| • | Inner rear pillar | ||||

|

3M™ 08115 Panel Bonding Adhesive |  |

Urethane foam | ||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

Inner Back Pillar

Work after rear fender is removed.

|

3M™ 08115 Panel Bonding Adhesive | ||||

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

| Replacement part | |||||

| • | Back pillar main assembly | ||||

|

3M™ 08115 Panel Bonding Adhesive | ||||

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

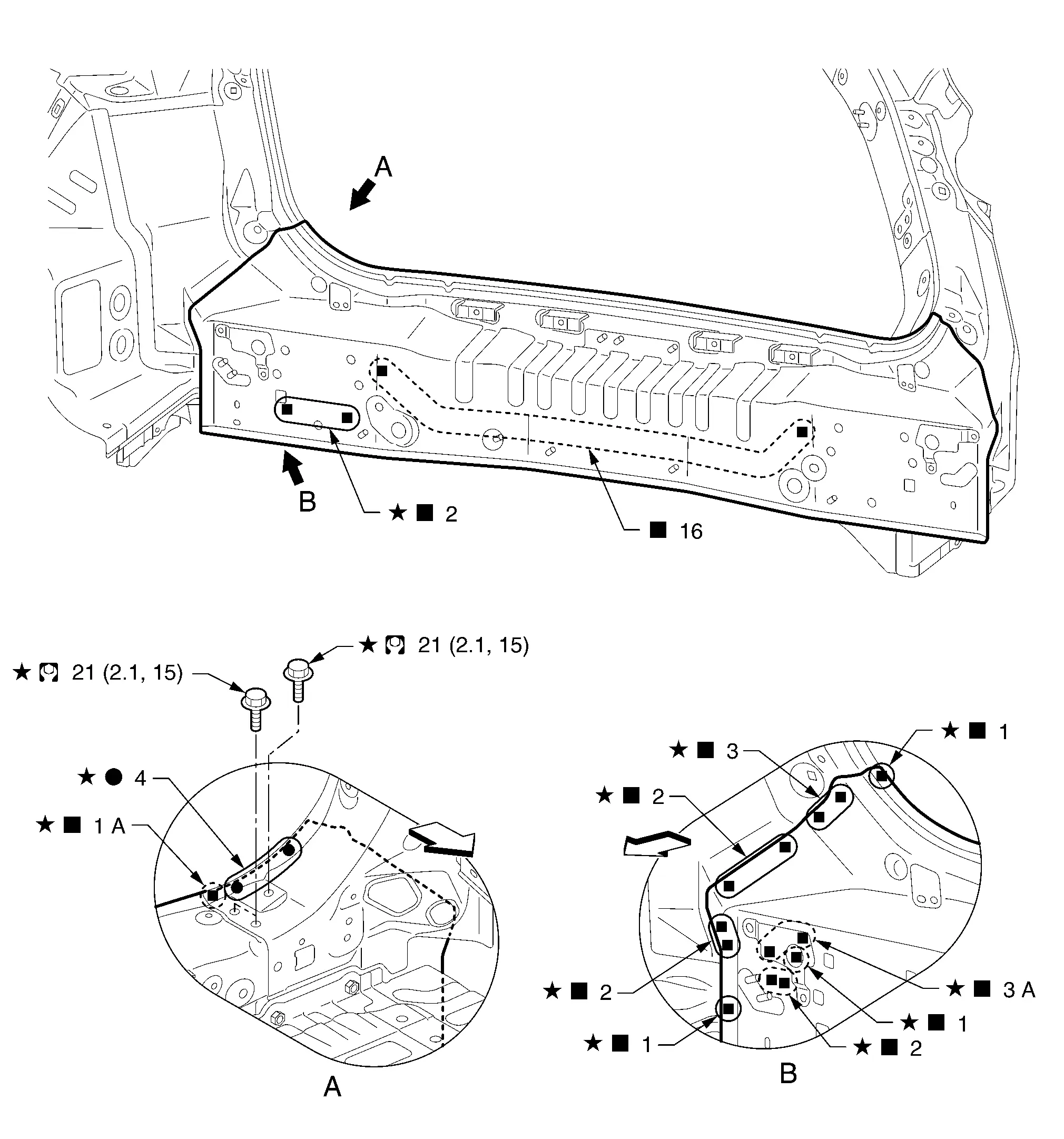

Rear Panel

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

| Replacement part | |||||

| • | Upper rear panel | ||||

Rear Floor Rear

Work after rear panel is removed.

Remove the rear seat back support assembly (reusable) from the vehicle for easier installation.

|

Rear seat back support assembly (reusable) | ||||

|

: Welding method and the number of welding points apply to both sides of the Nissan Ariya vehicle. : Welding method and the number of welding points apply to both sides of the Nissan Ariya vehicle. |

|||||

| Replacement part | |||||

| • | Rear floor front | ||||

|

Rear seat back support assembly (reusable) | ||||

| Unit: mm (in) | |||||

|

: Welding method and the number of welding points apply to both sides of the Nissan Ariya vehicle. : Welding method and the number of welding points apply to both sides of the Nissan Ariya vehicle. |

|||||

View C: Before installing rear seat back support assembly (reusable)

Rear Side Member

Work after rear fender, rear panel, rear floor rear, outer rear wheelhouse, and inner rear wheelhouse are removed.

Remove the rear seat crossmember assembly (reusable) from the vehicle for easier installation.

|

Rear seat crossmember assembly (reusable) | ||||

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

| Replacement part | |||||

| • | Rear side member | • | Rear side floor assembly | ||

|

Rear seat crossmember assembly (reusable) | ||||

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

View G: Before installing rear seat crossmember assembly (reusable)

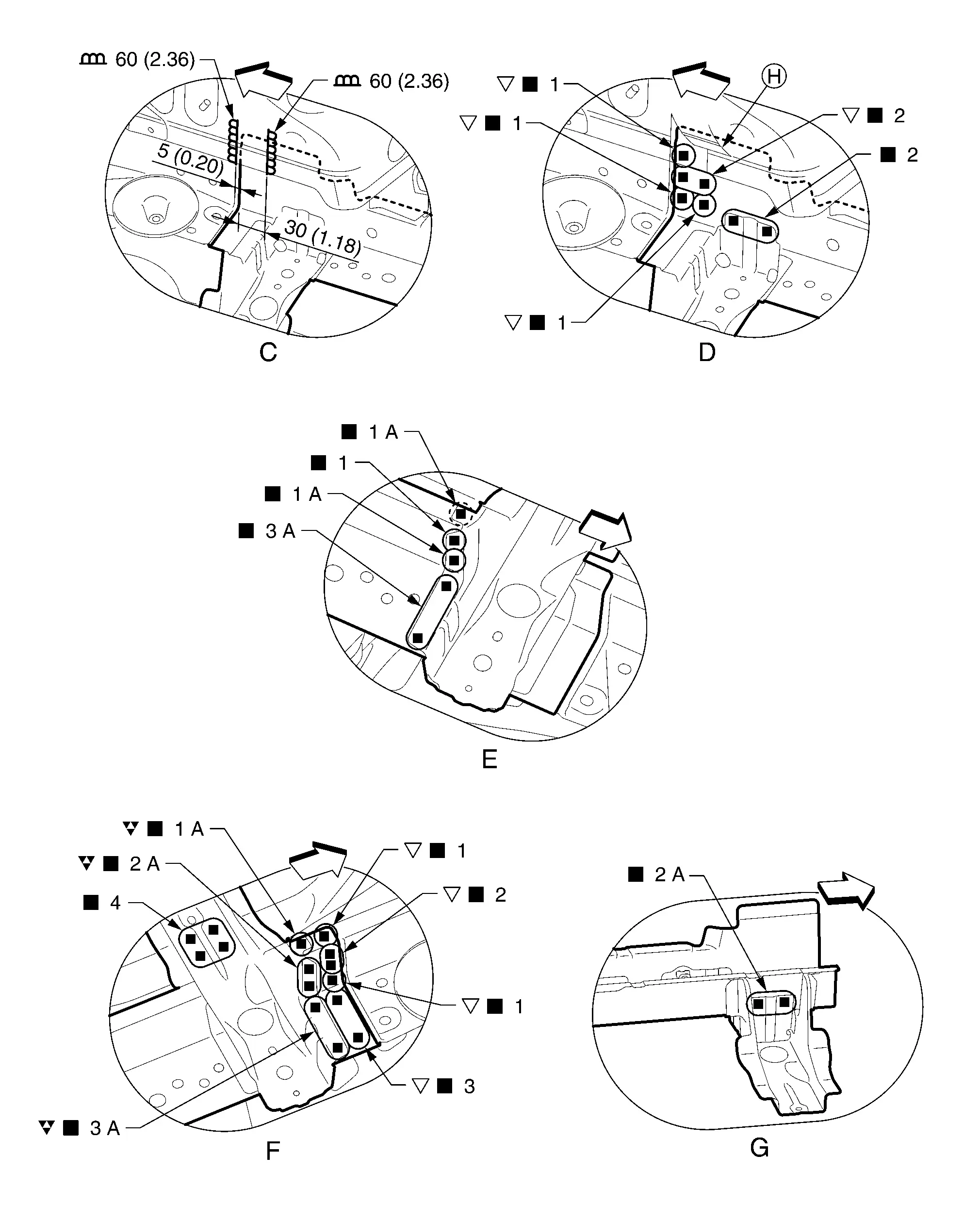

Rear Side Member Extension

Work after rear panel is removed.

Remove the inner rear wheelhouse reinforcement (reusable) from the vehicle for easier removal of rear side member extension.

Cut two places of inner rear wheelhouse, and raise a panel edge for easier installation.

|

Inner rear wheelhouse reinforcement (reusable) | ||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

| Replacement part | |||||

| • | Rear side member extension | • | Suspension rod bracket | ||

|

The state that raised the inner rear wheelhouse edge. | ||||

| Unit: mm (in) | |||||

|

: Weld the parts onto the back of the component part. : Weld the parts onto the back of the component part. |

|||||

View C and D: Before installing inner rear wheelhouse reinforcement (reusable)

View G: Rear side member extension (replacement part) and suspension rod bracket (replacement part)

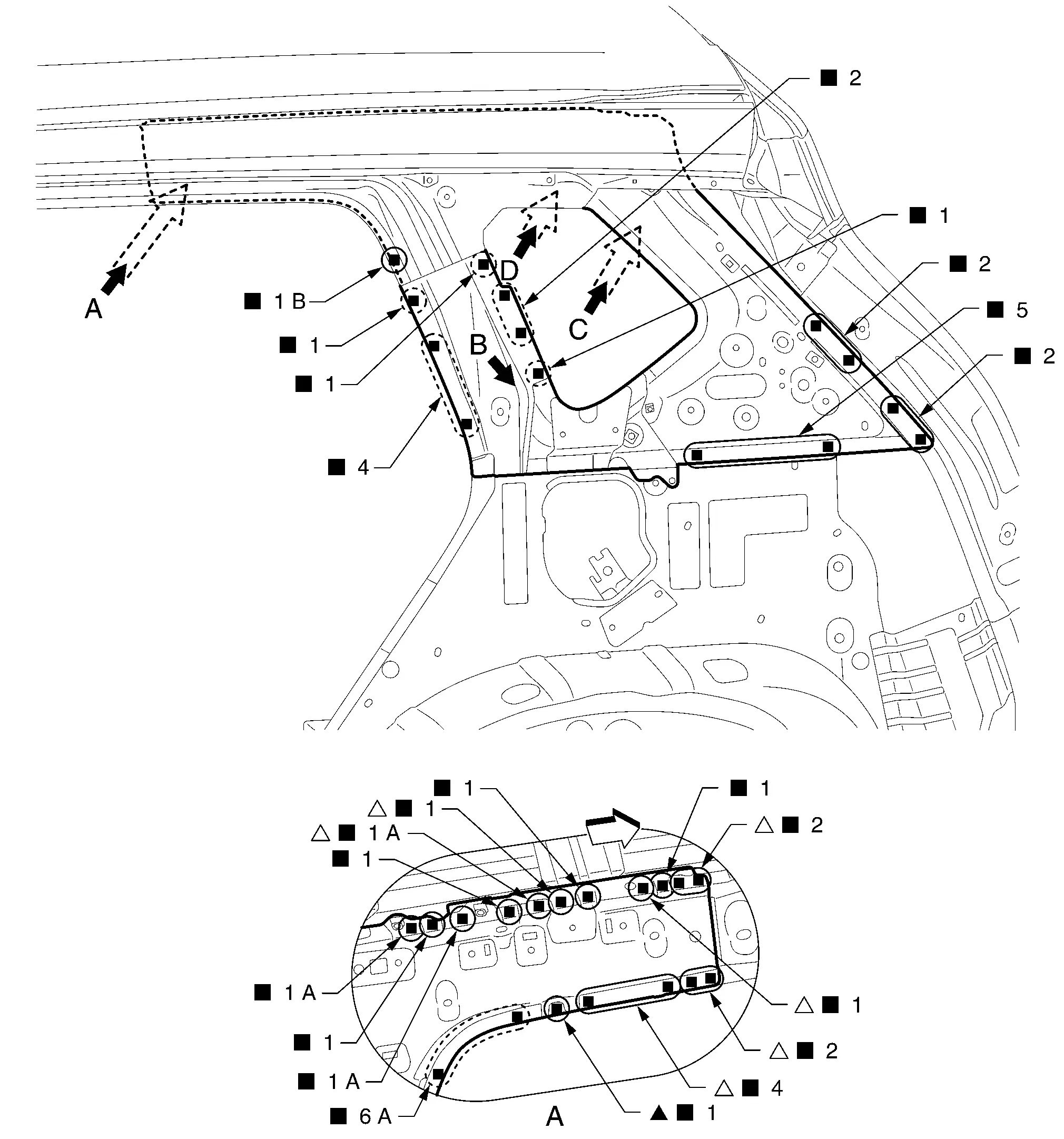

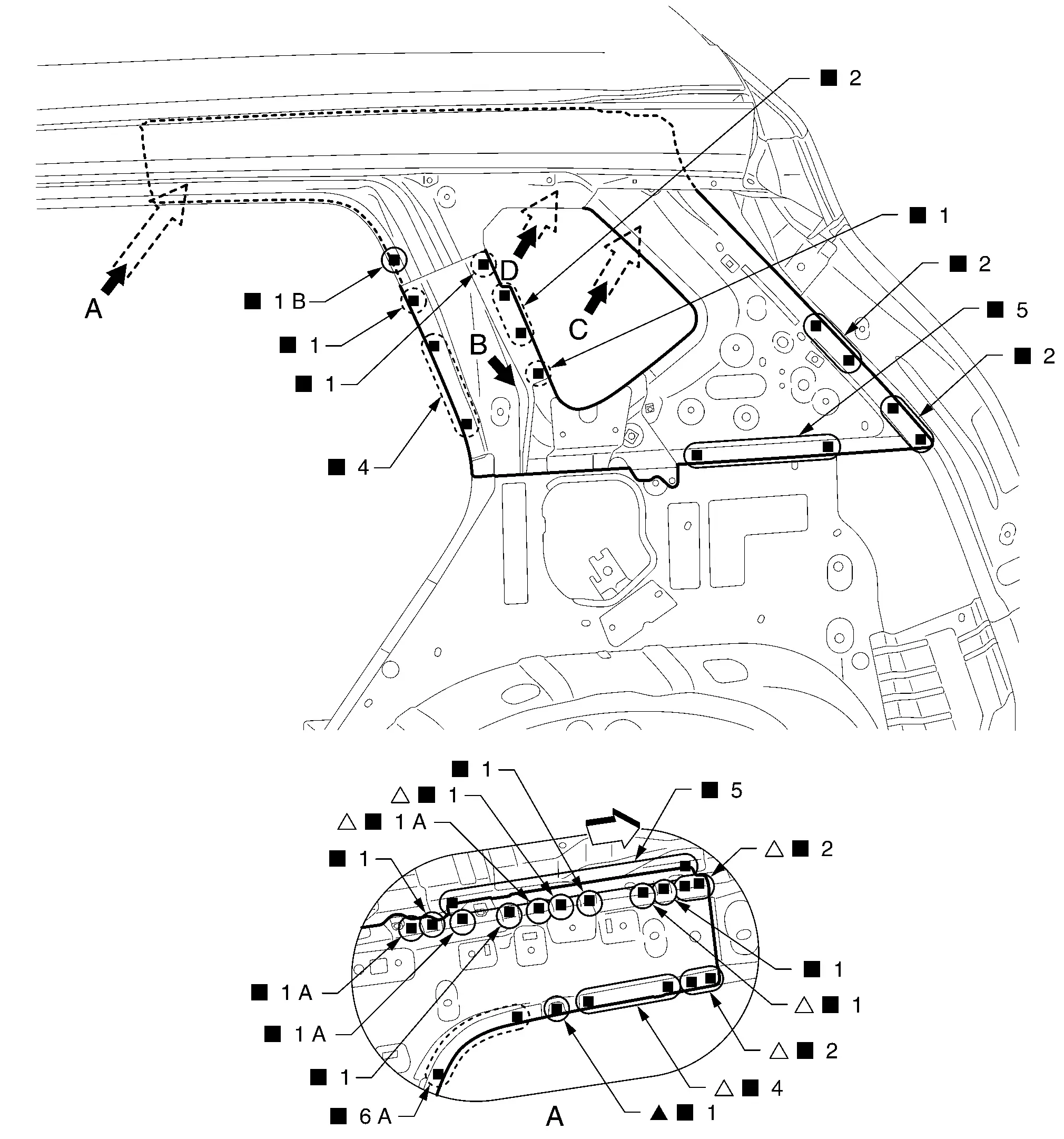

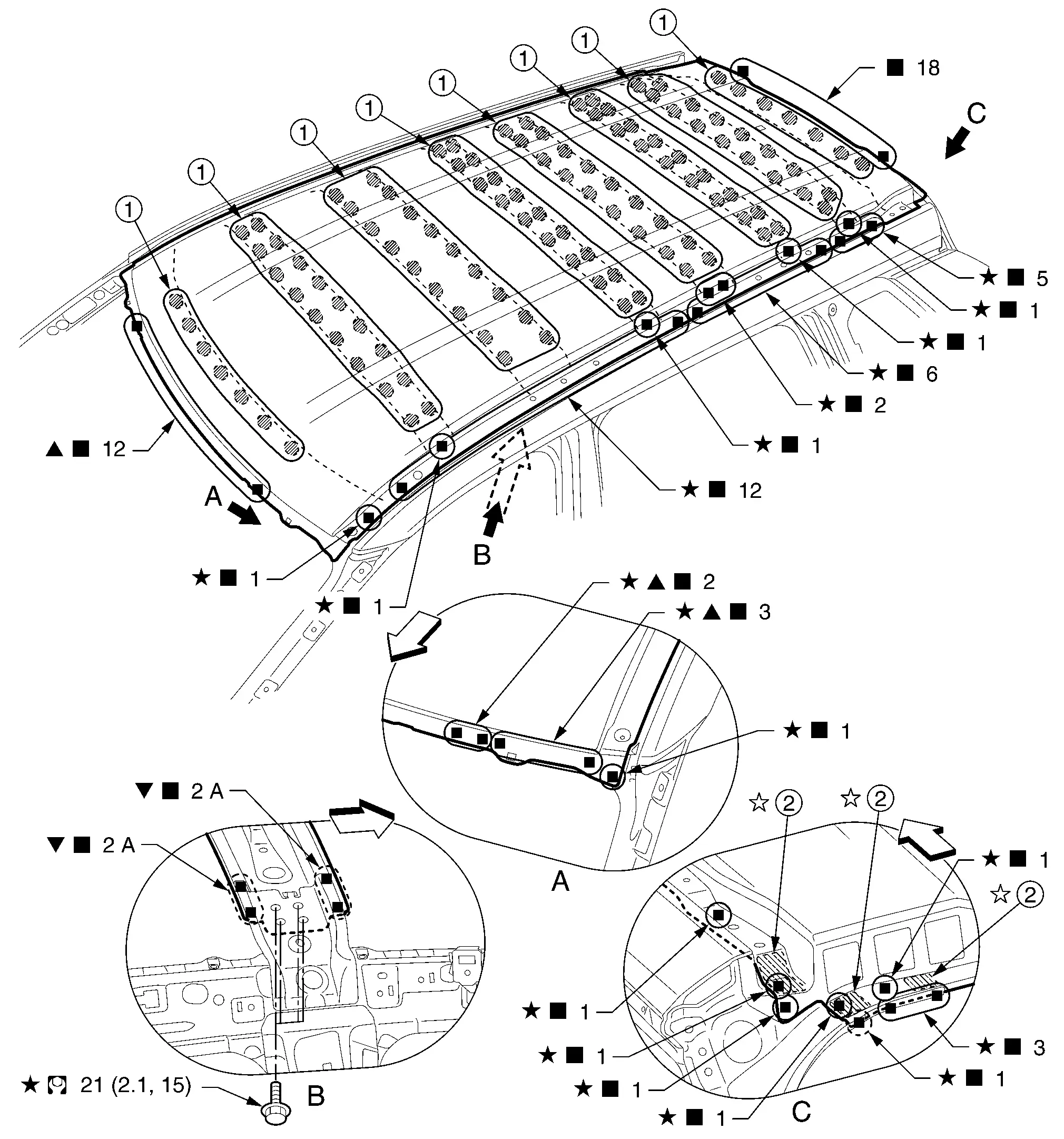

Roof (Without Moonroof models)

|

Body sealing |  |

3M™ 08115 Panel Bonding Adhesive | ||

|

: N·m (kg-m, ft-lb) : N·m (kg-m, ft-lb) |

|||||

| Replacement part | |||||

| • | Roof | • | Roof bow | • | 2nd roof bow |

| • | 3rd roof bow | • | 4th roof bow | • | 5th roof bow |

| • | Rear roof bow | ||||

Roof (With Moonroof models)

|

Body sealing |  |

3M™ 08115 Panel Bonding Adhesive | ||

|

: Adhesive portion apply to both sides of the vehicle. : Adhesive portion apply to both sides of the vehicle. |

|||||

| Replacement part | |||||

| • | Roof | • | Rear roof bow | ||

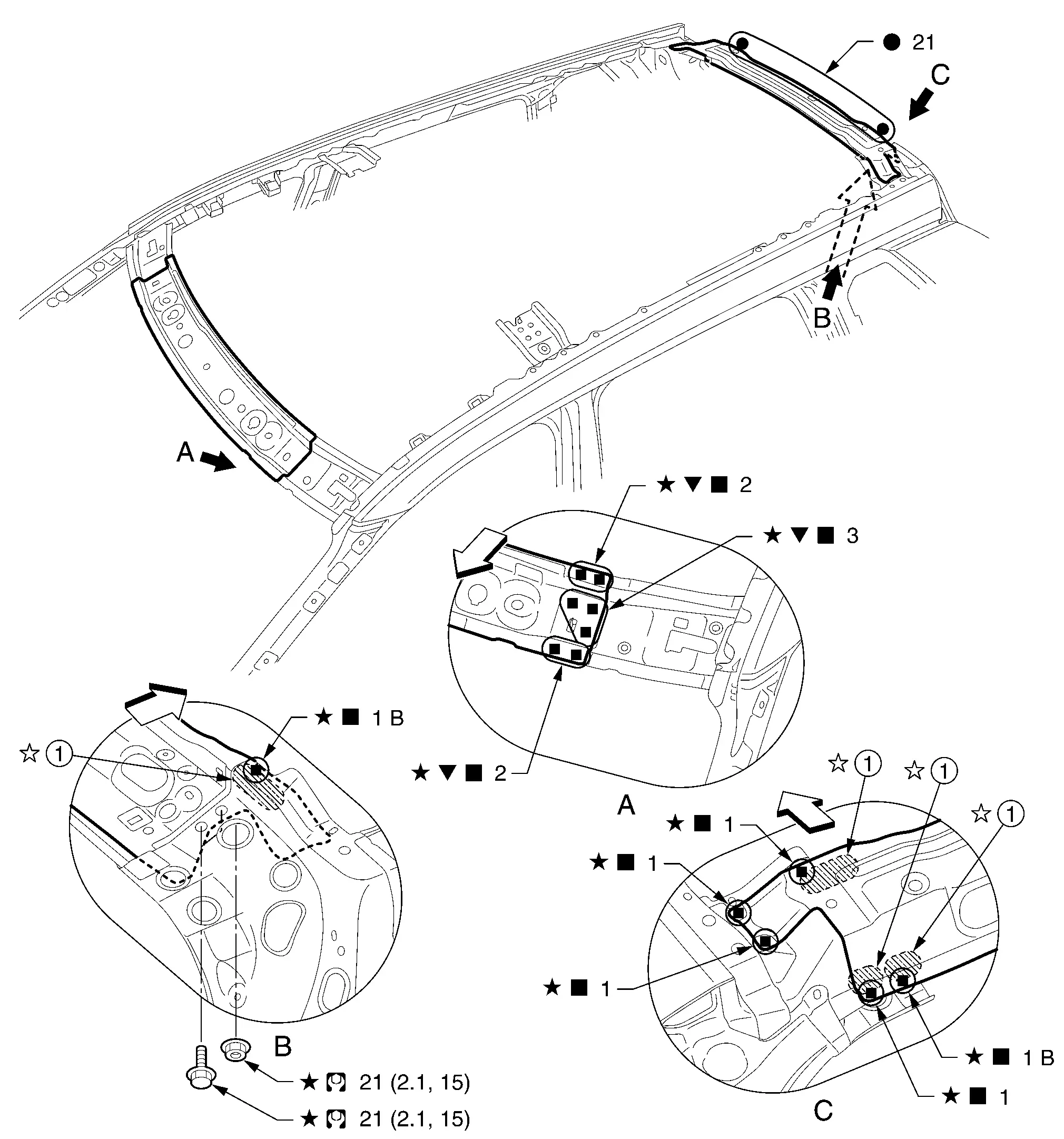

Roof Rail

Work after roof is removed.

|

3M™ 08115 Panel Bonding Adhesive | ||||

|

: N•m (kg-m, ft-lb) : N•m (kg-m, ft-lb) |

|||||

| Replacement part | |||||

| • | Front roof rail | • | Rear roof rail | ||

Other materials:

Basic Inspection. Additional Service When Replacing Power Steering Control Module Control Unit

Work Procedure

DESCRIPTIONWhen replacing the power steering control

module, the procedures of BEFORE REPLACEMENT and AFTER REPLACEMENT must

be performed. For work procedure, refer to the following:

Before power steering control module replacement.

After power steering control module rep ...

Adjustment of Steering Angle Sensor Neutral Position

Description

Always adjust the neutral position of steering angle sensor before

driving when the following operation is performed. Refer to Work

Procedure.×: Required —: Not required Procedure Adjust the neutral position of steering angle sensor

Removing/ installing ABS actuator and elect ...

U0073-00 Control Module Comm Bus a Off

DTC Description

CAN (Controller Area Network) is a serial communication line for real

time applications. It is an on-Nissan Ariya vehicle multiplex

communication line with high data communication speed and excellent

error detection ability. Modern Nissan Ariya vehicle is equipped with

many ...

″4″A = 4 MAG plug welds for 3-panel plug weld method.

″4″A = 4 MAG plug welds for 3-panel plug weld method.

: Drill φ11 mm (0.43 in) hole for the plug welding hole (ultra high strength steel).

: Drill φ11 mm (0.43 in) hole for the plug welding hole (ultra high strength steel).