Nissan Rogue (T33) 2021-Present Service Manual: Repair Information :: Preparation

Repairing Material

Foam Repair

During factory body assembly, foam insulators are installed in certain body panels and locations around the Nissan Ariya vehicle. Use the following procedure(s) to replace any factory-installed foam insulators.

URETHANE FOAM APPLICATIONS

Use commercially available Urethane foam for sealant (foam material) repair of material used on vehicle.

| <Urethane foam for foaming agent> | 3M™ Flexible Foam 08463 or equivalent |

CAUTION:

To avoid the risk of minor personal injury or property damage:

Always install urethane foam after welded panels are installed and welding is complete.

Read instructions on product for fill procedures.

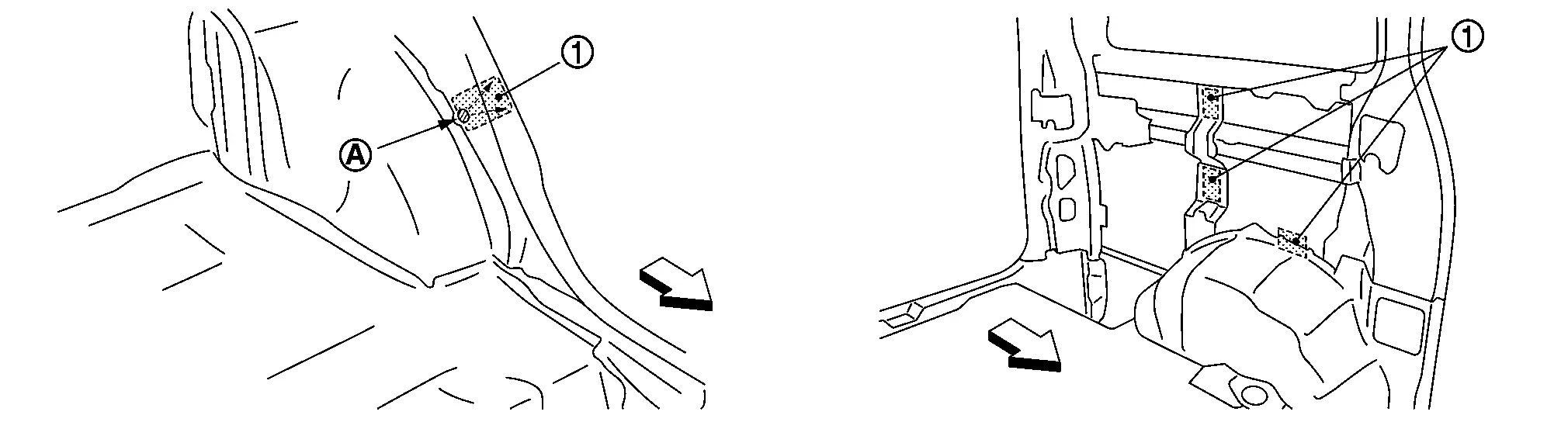

Example of foaming agent filling operation procedure

Fill procedures after installation of service part.Eliminate foam material remaining on vehicle side. Clean area after eliminating foam insulator and foam material. Install service part. Insert nozzle into hole near fill area and fill foam material or fill enough to close gap with the service part.

|

Urethane foam |

|

Nozzle insert hole |

: Nissan Ariya Vehicle front : Nissan Ariya Vehicle front |

|

Fill procedures before installation of service part.Eliminate foam material remaining on Nissan Ariya vehicle side. Clean area after eliminating foam insulator and foam material. Fill foam material on wheelhouse outer side.

|

Urethane foam |

|

Fill while avoiding flange area |

: Nissan Ariya Vehicle front : Nissan Ariya Vehicle front |

|

NOTE:

NOTE:

Fill enough to close gap with service part while avoiding flange area.

Install service part. NOTE:

NOTE:

Refer to label for information on working times.

Body Component Parts

Ultra High Strength Steel Part

DESCRIPTION

Ultra high strength steel parts signify high strength steel plates with tensile strength of 980 MPa or more.

When replacing parts made of ultra high strength steel or parts including ultra high strength steel, never perform the prohibition described below:

PROHIBITION

WARNING:

Never cut ultra high strength steel parts or perform butt welding. Violation of this prohibition causes extreme strength degradation, and the strength before damage cannot be secured.

PART REPLACEMENT

To replace an ultra high strength part, be sure to replace it by panel supply unit of ultra high strength steel part.

For the welding method, refer to Welding of Ultra High Strength Steel.

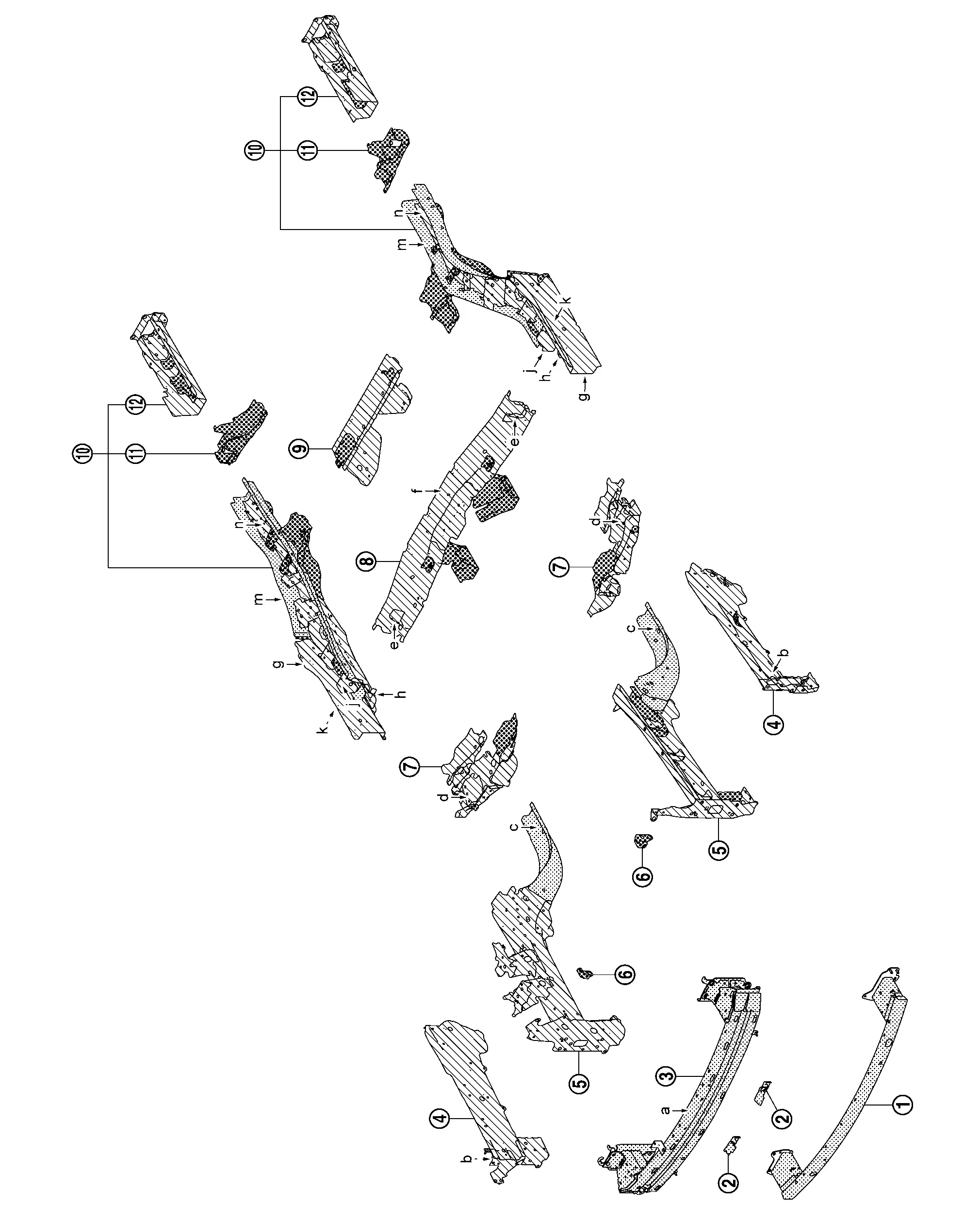

Underbody Component Parts

ENGINE COMPARTMENT

Refer to parts catalogue for the replacement parts.

|

: Both sided anti-corrosive steel and HSS sections : Both sided anti-corrosive steel and HSS sections |

| No. | Parts name |

Tensile strength (MPa) |

Both sided anti-corrosive precoated steel sections | ||

|---|---|---|---|---|---|

|

Upper radiator core support assembly (RH & LH) | 590 | Ă— | ||

|

Hoodledge reinforcement (RH & LH) | 440 | Ă— | ||

|

Front hoodledge reinforcement (RH & LH) | 590 | Ă— | ||

|

Front fender bracket (Front RH & LH) | Under 440 | Ă— | ||

|

Front fender bracket (Rear RH & LH) | Under 440 | Ă— | ||

|

Front strut housing assembly (RH & LH) | 590 | Ă— | ||

|

Lower dash crossmember | a. |

1300MPacaution T=1.6 mm (0.063 in) |

Under 440 | - |

|

Lower dash complete | b. |

980MPacaution T=1.4 mm (0.055 in) |

Under 440 | Ă— |

|

Side dash (RH & LH) | c. |

980MPacaution T=1.2 mm (0.047 in) |

590 | Ă— |

|

Upper dash assembly | Under 440 | Ă— | ||

|

Cowl assembly | 590 | Ă— | ||

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part.

NOTE:

NOTE:

-

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

-

Tensile strength column shows the largest strength value of a part in the component part.

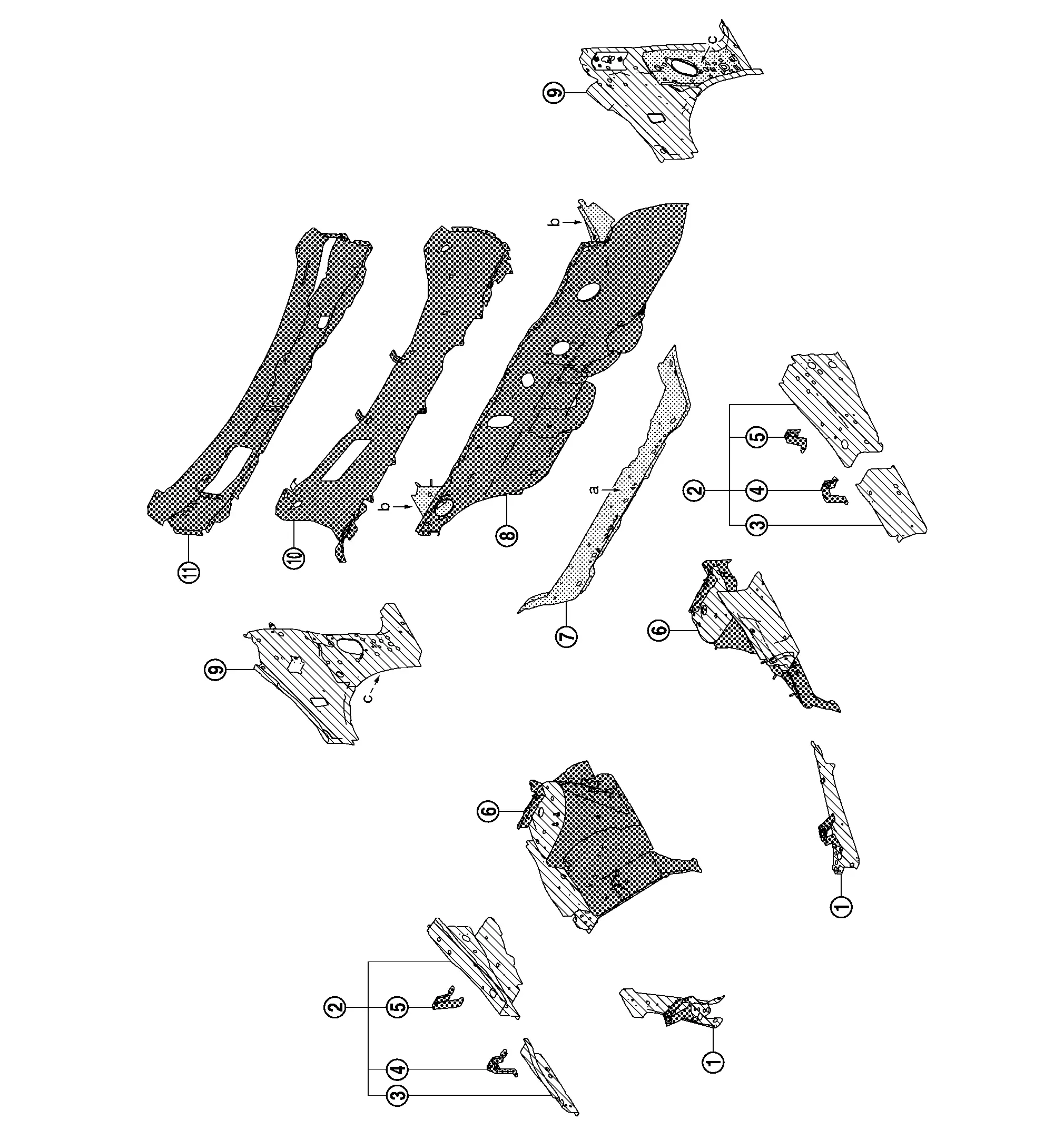

FLOOR

Refer to parts catalogue for the replacement parts.

|

Front floor bottom view | ||||

|

: Both sided anti-corrosive steel and HSS sections : Both sided anti-corrosive steel and HSS sections |

|||||

| No. | Parts name |

Tensile strength (MPa) |

Both sided anti-corrosive precoated steel sections | ||

|---|---|---|---|---|---|

|

Inner sill (RH & LH) | b. |

980MPacaution T=1.8 mm (0.071 in) |

590 | Ă— |

| c. |

980MPacaution T=1.6 mm (0.063 in) |

||||

| d. |

980MPacaution T=1.6 mm (0.063 in) |

||||

| e. |

980MPacaution T=1.8 mm (0.071 in) |

||||

| f. |

980MPacaution T=1.2 mm (0.047 in) |

||||

|

Front floor (RH & LH) | g. |

980MPacaution T=1.0 mm (0.039 in) |

590 (Japan production) 780 (USA Production) | Ă— |

| h. |

1300MPacaution T=1.4 mm (0.055 in) |

||||

| j. |

980MPacaution T=1.6 mm (0.063 in) |

||||

| k. |

980MPacaution T=1.4 mm (0.055 in) |

||||

|

Center front floor | 780 | Ă— | ||

|

Rear seat crossmember assembly | m. |

980MPacaution T=1.6 mm (0.063 in) |

440 | Ă— |

|

Rear seat back support assembly | 590 | - | ||

|

Rear side floor assembly (RH & LH) | 590 | Ă— | ||

|

Rear floor front | Under 440 | Ă— | ||

|

Spare wheel crossmember assembly | Under 440 | Ă— | ||

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part.

NOTE:

NOTE:

-

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

-

Tensile strength column shows the largest strength value of a part in the component part.

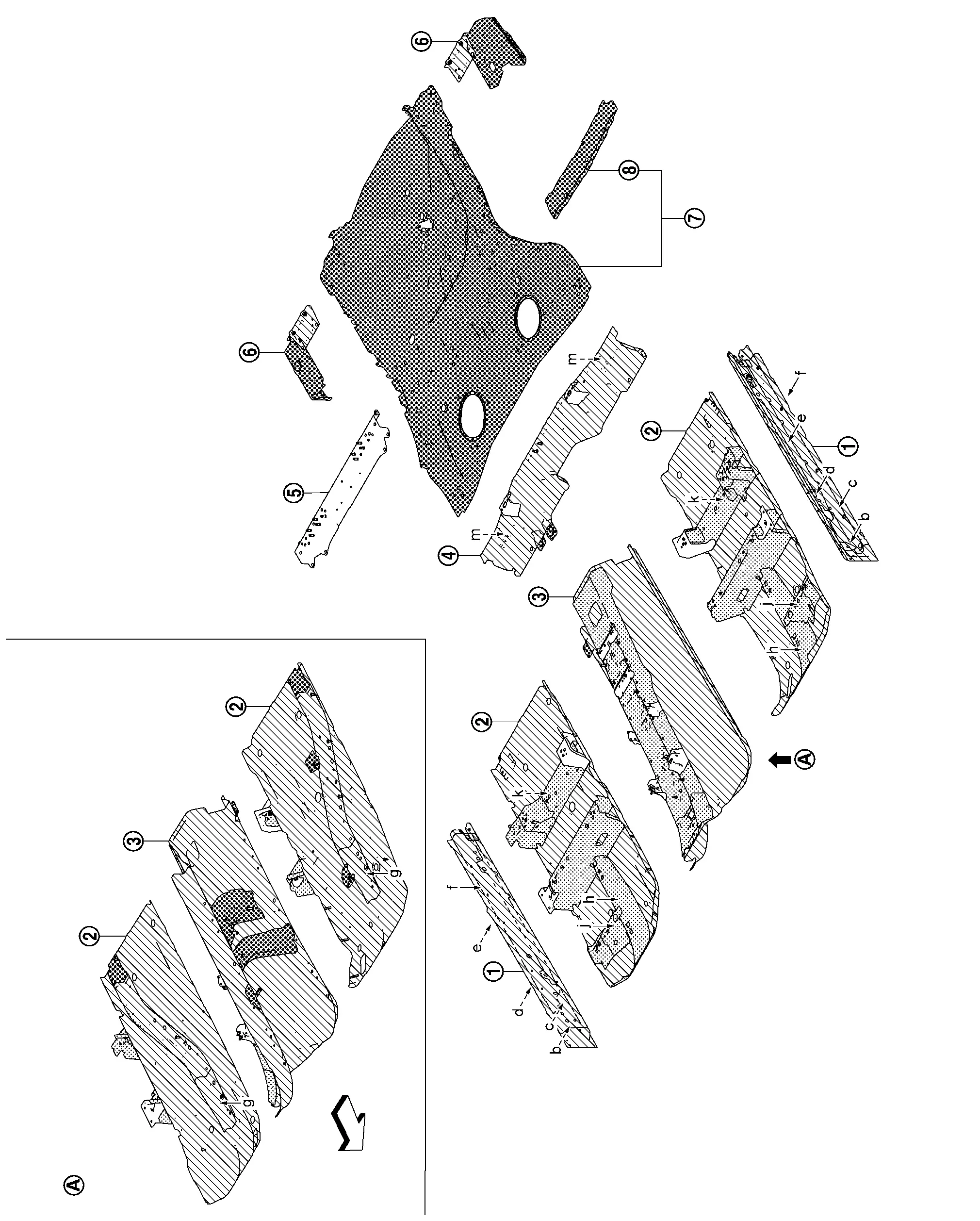

FRONT AND REAR MEMBER

Refer to parts catalogue for the replacement parts.

|

: Both sided anti-corrosive steel and HSS sections : Both sided anti-corrosive steel and HSS sections |

| No. | Parts name |

Tensile strength (MPa) |

Both sided anti-corrosive precoated steel sections | ||

|---|---|---|---|---|---|

|

Front bumper reinforcement assembly | 780 | - | ||

|

Lower front bumper retainer (RH & LH) | 590 | - | ||

|

Inner center front bumper reinforcement | a. |

1500MPacaution T=1.1 mm (0.043 in) |

780 | - |

|

Front side member closing plate (RH & LH) | b. |

980MPacaution T=1.6 mm (0.063 in) |

780 | Ă— |

|

Front side member assembly (RH & LH) | c. |

1300MPacaution T=2.0 mm (0.079 in) |

780 | Ă— |

|

Side radiator core support (RH & LH) | Under 440 | Ă— | ||

|

Front suspension mounting bracket (RH & LH) | d. |

980MPacaution T=1.6 mm (0.063 in) |

590 | Ă— |

|

Rear floor front extension | e. |

980MPacaution T=1.6 mm (0.063 in) |

590 | Ă— |

| f. |

980MPacaution T=1.0 mm (0.039 in) |

||||

|

Center rear crossmember assembly | 590 | Ă— | ||

|

Rear side member (RH & LH) | g. |

980MPacaution T=1.2 mm (0.047 in) |

590 | Ă— |

| h. |

980MPacaution T=1.2 mm (0.047 in) |

||||

| j. |

980MPacaution T=1.0 mm (0.039 in) |

||||

| k. |

980MPacaution T=1.0 mm (0.039 in) |

||||

| m. |

1300MPacaution T=1.4 mm (0.055 in) |

||||

| n. |

980MPacaution T=1.2 mm (0.047 in) |

||||

|

Suspension rod bracket (RH & LH) | Under 440 | Ă— | ||

|

Rear side member extension (RH & LH) | 780 | Ă— | ||

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part.

NOTE:

NOTE:

-

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

-

Tensile strength column shows the largest strength value of a part in the component part.

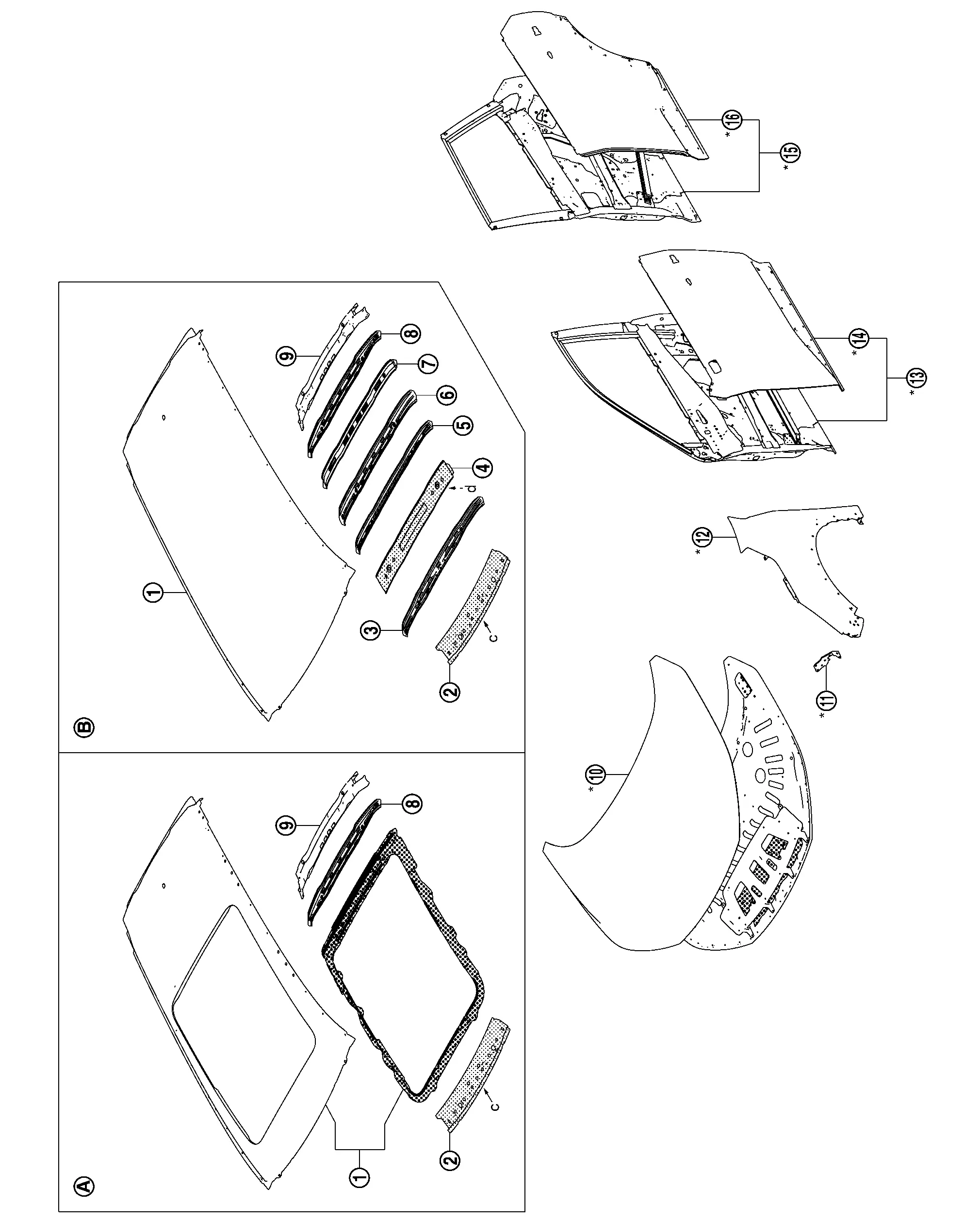

Body Component Parts

ROOF AND DOORS

Refer to parts catalogue for the replacement parts.

|

With moonroof models |  |

Without moonroof models | ||

|

: Aluminum portion : Aluminum portion |

|||||

| No. | Parts name |

Tensile strength (MPa) |

Both sided anti-corrosive precoated steel sections |

Aluminum portion | ||

|---|---|---|---|---|---|---|

|

Roof | Under 440 | - | - | ||

|

Front roof rail | c. |

1180MPacaution T=1.0 mm (0.039 in) |

Under 440 | - | - |

|

Roof bow | Under 440 | - | - | ||

|

2nd roof bow | d. |

1180MPacaution T=1.0 mm (0.039 in) |

590 | - | - |

|

3rd roof bow | Under 440 | - | - | ||

|

4th roof bow | Under 440 | - | - | ||

|

5th roof bow | Under 440 | - | - | ||

|

Rear roof bow | Under 440 | - | - | ||

|

Rear roof rail | Under 440 | - | - | ||

|

Hood | - | - | Ă— | ||

|

Front fender bracket (RH & LH) | - | - | Ă— | ||

|

Front fender (RH & LH) | - | - | Ă— | ||

|

Front door assembly (RH & LH) | 590 | - | Ă— | ||

|

Outer front door panel (RH & LH) | - | - | Ă— | ||

|

Rear door assembly (RH & LH) | - | - | Ă— | ||

|

Outer rear door panel (RH & LH) | - | - | Ă— | ||

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part.

NOTE:

NOTE:

-

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

-

Tensile strength column shows the largest strength value of a part in the component part.

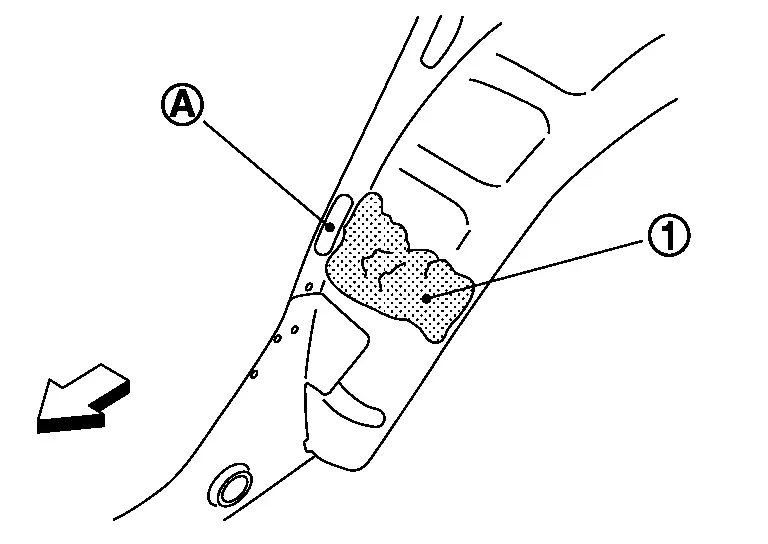

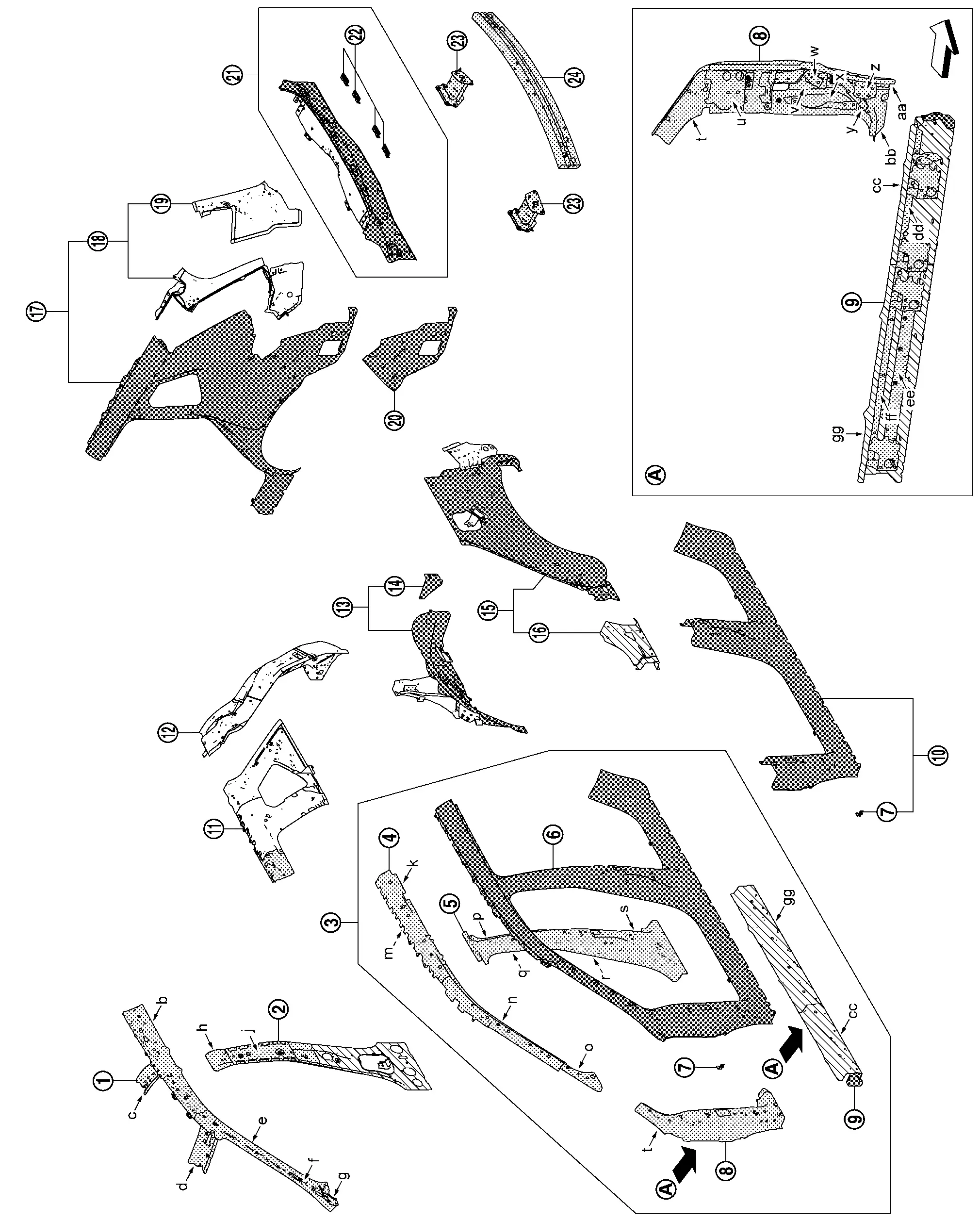

BODY SIDE

Refer to parts catalogue for the replacement parts.

|

Back view | ||||

|

: Both sided anti-corrosive steel and HSS sections : Both sided anti-corrosive steel and HSS sections |

|||||

| No. | Parts name |

Tensile strength (MPa) |

Both sided anti-corrosive precoated steel sections | ||

|---|---|---|---|---|---|

|

Upper inner front pillar (RH & LH) | b. |

1180MPacaution T=1.0 mm (0.039 in) |

Under 440 | - |

| c. |

980MPacaution T=1.4 mm (0.055 in) |

||||

| d. |

980MPacaution T=1.4 mm (0.055 in) |

||||

| e. |

1180MPacaution T=1.2 mm (0.047 in) |

||||

| f. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| g. |

980MPacaution T=1.4 mm (0.055 in) |

||||

|

Inner center pillar assembly (RH & LH) | h. |

1180MPacaution T=1.2 mm (0.047 in) |

590 | Ă— |

| j. |

1180MPacaution T=1.0 mm (0.039 in) |

||||

|

Side body assembly (RH & LH) | Refer to No.  – –  |

|||

|

Outer front pillar reinforcement (RH & LH) | k. |

1300MPacaution T=1.0 mm (0.039 in) |

- | - |

| m. |

1180MPacaution T=1.0 mm (0.039 in) |

||||

| n. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| o. |

1300MPacaution T=2.0 mm (0.079 in) |

||||

|

Lower center pillar brace (RH & LH) | p. |

1180MPacaution T=1.2 mm (0.047 in) |

Under 440 | - |

| q. |

1300MPacaution T=2.0 mm (0.079 in) |

||||

| r. |

1300MPacaution T=1.6 mm (0.063 in) |

||||

| s. |

980MPacaution T=1.2 mm (0.047 in) |

||||

|

Outer front side body (RH & LH) | Under 440 | Ă— | ||

|

Front fender bracket assembly (RH & LH) | Under 440 | Ă— | ||

|

Lower front pillar hinge brace (RH & LH) | t. |

980MPacaution T=1.0 mm (0.039 in) |

590 | - |

| u. |

980MPacaution T=2.0 mm (0.079 in) |

||||

| v. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| w. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| x. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| y. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| z. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| aa. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| bb. |

980MPacaution T=1.4 mm (0.055 in) |

||||

|

Outer sill reinforcement (Front RH & LH) | cc. |

980MPacaution T=1.2 mm (0.047 in) |

590 | Ă— |

| dd. |

980MPacaution T=1.6 mm (0.063 in) |

||||

| ee. |

1180MPacaution T=1.4 mm (0.055 in) |

||||

| ff. |

980MPacaution T=1.6 mm (0.063 in) |

||||

| gg. |

980MPacaution T=1.2 mm (0.047 in) |

||||

|

Outer sill assembly (RH & LH) | Under 440 | Ă— | ||

|

Inner rear pillar (RH & LH) | 590 | - | ||

|

Back pillar main assembly (RH & LH) | 440 | - | ||

|

Inner rear wheelhouse (RH & LH) | 590 | Ă— | ||

|

Inner rear wheelhouse extension (RH & LH) | Under 440 | Ă— | ||

|

Outer rear wheelhouse (RH & LH) | Under 440 | Ă— | ||

|

Outer sill reinforcement (Rear RH & LH) | 590 | Ă— | ||

|

Rear fender assembly (RH & LH) | Under 440 | Ă— | ||

|

Outer back pillar (RH & LH) | Under 440 | - | ||

|

Back pillar assembly (RH & LH) | Under 440 | - | ||

|

Rear fender extension (RH & LH) | Under 440 | Ă— | ||

|

Upper rear panel | 440 | Ă— | ||

|

Upper rear bumper retainer | Under 440 | Ă— | ||

|

Rear bumper stay (RH & LH) | 780 | - | ||

|

Inner center rear bumper reinforcement |

1500MPacaution T=1.2 mm (0.047 in) |

- | - | |

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part.

NOTE:

NOTE:

-

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

-

Tensile strength column shows the largest strength value of a part in the component part.

Other materials:

B2e32-11 Av Control Unit

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

B2E32-11

Audio unit

(Audio unit)

Diagnosis condition

When ignition switch is ON

Signal (terminal)

Sound signal

Threshold

0.5 V or less

Diagnosi ...

P026b Injection Timing

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P026B

00

Injection timing

Diagnosis condition

—

Signal

—

Threshold

ECM does not control fuel injection timing properly when engine is running ...

Dtc/circuit Diagnosis. B14e0-4a Wheel Sensor

DTC Description

DTC DETECTION LOGIC DTC No. CONSULT screen terms DTC detection condition

B14E0

4A

Wheel sensor

Diagnosis condition

Ignition switch is ON.

Signal (terminal)

Front left wheel sensor signal

Threshold

When front left wheel sensor is installed to wrong po ...

: Both sided anti-corrosive precoated steel sections

: Both sided anti-corrosive precoated steel sections : High strength steel (HSS) sections

: High strength steel (HSS) sections