Nissan Rogue (T33) 2021-Present Service Manual: Rear Propeller Shaft: Cvj-Cvj-C :: Periodic Maintenance. Rear Propeller Shaft

Rear Propeller Shaft

Inspection

LOOSENESS OF CONNECTED PART

Check each fixing bolt and nut for looseness using torque wrench. For each tightening torque, refer to Exploded View.

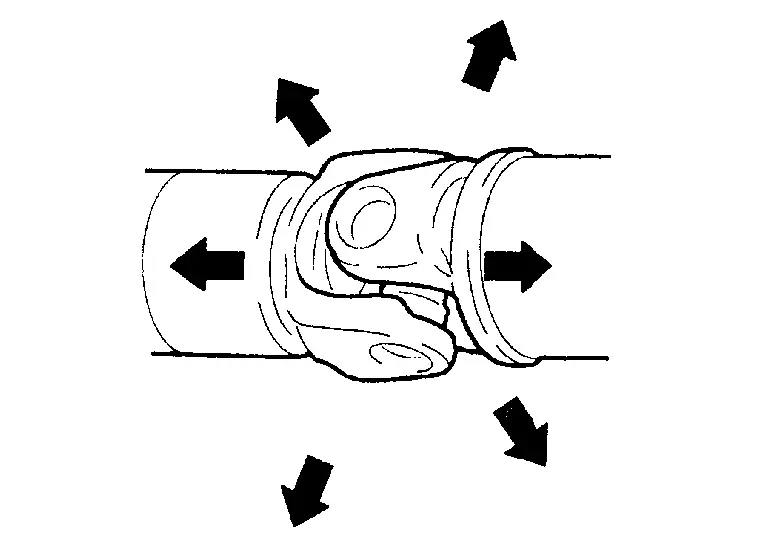

BACKLASH OF JOINT PART

Move the joint of propeller shaft up and down and from side to side (axial direction of shaft and right angle to shaft) to check that the joint has no backlash. If the joint has a malfunction, remove propeller shaft and perform inspection.

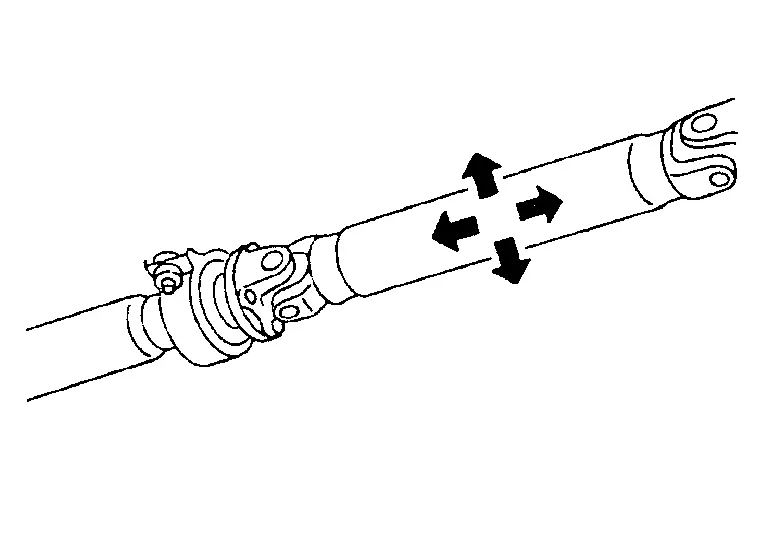

BACKLASH OF CENTER BEARING

Move the shaft near center bearing up and down and from side to side (axial direction of shaft and right angle to shaft) to check that the bearing has no backlash. If the bearing has a malfunction, remove propeller shaft and perform inspection.

APPEARANCE AND NOISE

-

Check the propeller shaft tube surface for dents or cracks. If malfunction is detected, replace propeller shaft assembly.

-

If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, adjust the propeller shaft phase first.

Check the propeller shaft for bend and damage. If damaged, replace propeller shaft assembly.

Perform a cruise test drive to check the propeller shaft for runout. If vibration occurs, separate propeller shaft at final drive companion flange; then change the phase between companion flange and propeller shaft by the one bolt hole at a time and install propeller shaft.

If vibration is still detected, measure propeller shaft runout after removing it. Refer to Inspection.

Other materials:

C1f03-73 Stop Lamp Relay

Without Propilot Assist 2.1

DTC Description

DTC DETECTION LOGIC DTC

CONSULT screen terms

(Trouble diagnosis content) DTC detection condition

C1F03

73

OPERATION SW CIRC

(Operation switch circuit)

Diagnosis condition

When engine is running

When AEB system is ...

Precaution. Precautions

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as ŌĆ£AIR BAGŌĆØ and ŌĆ£SEAT BELT

PRE-TENSIONERŌĆØ, used along with a front seat belt, helps to reduce the

risk or severity of injury to the driver and front passeng ...

Additional Service When Replacing Around View Monitor Control Unit

Description

CAUTION:

When replacing the around view monitor control unit, always replace

it with a new one. Intelligent around view monitor system does not

operate properly in case of reuse of the around view monitor control

unit from another Nissan Ariya vehicle.

When before writin ...