Nissan Rogue (T33) 2021-Present Service Manual: P054b Camshaft Position Bank 1

DTC Description

DTC DETECTION LOGIC

| DTC |

CONSULT screen terms (Trouble diagnosis content) |

DTC detection condition | ||

| P054B | 00 |

Cold start B camshaft position bank 1 (Cold start B camshaft position timing over-retarded bank 1) |

Diagnosis condition | Cold condition |

| Signal (terminal) | Exhaust camshaft position sensor | |||

| Threshold | There is a gap between angle of target and actual angle when the engine is in a cold condition. | |||

| Diagnosis delay time | 30 seconds | |||

POSSIBLE CAUSE

Exhaust valve timing intermediate lock control solenoid valve

FAIL-SAFE

Engine Control System

| Fail safe mode | Nissan Ariya Vehicle behavior | |

|---|---|---|

| Device fix mode |

|

|

Stop/Start System

Not applicable

DTC Confirmation Procedure

PRECONDITIONING

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is 10 V or more at idle.

With CONSULT

With CONSULT

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

Turn ignition switch OFF and wait at least 10 seconds.

-

Turn ignition switch ON.

-

On the CONSULT screen, select ŌĆ£ENGINEŌĆØ >> ŌĆ£DATA MONITORŌĆØ >> ŌĆ£COOLANT TEMP/SŌĆØ.

-

Check ŌĆ£COOLANT TEMP/SŌĆØ indication value.

With GST

With GST

Follow the procedure ŌĆ£With CONSULTŌĆØ above.

Is the value of ŌĆ£COOLANT TEMP/SŌĆØŌłÆ5┬░C (23┬░F) and 45┬░C (113┬░F)?

YES>>GO TO 2.

NO-1 [if it is below ŌłÆ5┬░C (23┬░F)]>>Warm up the engine until the value of ŌĆ£COOLANT TEMP/SŌĆØ indicates ŌłÆ5┬░C (23┬░F) and 45┬░C (113┬░F). And then GO TO 2.

NO-2 [if it is above 45┬░C (113┬░F)]>>Cool the engine down to the value of ŌĆ£COOLANT TEMP/SŌĆØ indicates ŌłÆ5┬░C (23┬░F) and 45┬░C (113┬░F). And then GO TO 2.

PERFORM DTC CONFIRMATION PROCEDURE-I

-

Turn ignition switch OFF and wait at 10 seconds.

-

Turn ignition switch ON.

-

Set the selector lever in N range.

-

Start the engine and let it idle for 20 seconds or more.

-

Check 1st trip DTC.

Is 1st trip DTC detected?

YES>>Proceed to DTC Diagnosis Procedure.

NO-1>>To check malfunction symptom before repair: Refer to Intermittent Incident.

NO-2>>Confirmation after repair: INSPECTION END

DTC Diagnosis Procedure

INSPECTION START

With CONSULT>>

GO TO 2.

Without CONSULT>>GO TO 3.

CHECK VTC POSITION

With CONSULT

With CONSULT

-

Turn ignition switch ON.

-

On the CONSULT screen, select ŌĆ£ENGINEŌĆØ >> ŌĆ£DATA MONITORŌĆØ >> ŌĆ£COOLANT TEMP/SŌĆØ.

-

Check that the ŌĆ£COOLANT TEMP/SŌĆØ indication value is between ŌłÆ5┬░C (23┬░F) and 45┬░C (113┬░F).

-

Start engine and wait at least 5 seconds.

-

On the CONSULT screen, select ŌĆ£ENGINEŌĆØ >> ŌĆ£DATA MONITORŌĆØ >> ŌĆ£EXH/V TIM B1ŌĆØ.

-

Check that the data monitor item indicates as follows:

Item Value (┬░CA) EXH/V TIM B1 10 ┬▒ 2

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>GO TO 3.

CHECK OIL PRESSURE WARNING LAMP

-

Start engine.

-

Check that oil pressure warning lamp is not illuminated.

Is oil pressure warning lamp illuminated?

YES>>Refer to Inspection.

NO>>GO TO 4.

CHECK EXHAUST VALVE TIMING INTERMEDIATE LOCK CONTROL SOLENOID VALVE

Perform Component Inspection of the exhaust valve timing intermediate lock control solenoid valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 5.

NO>>Repair or replace error-detected parts.

CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE

Perform Component Inspection of the exhaust valve timing control solenoid valve. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 6.

NO>>Repair or replace error-detected parts.

CHECK CRANKSHAFT POSITION SENSOR

Perform Component Inspection of the crankshaft position sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 7.

NO>>Repair or replace error-detected parts.

CHECK EXHAUST CAMSHAFT POSITION SENSOR

Perform Component Inspection of the exhaust camshaft position sensor. Refer to Component Inspection.

Is the inspection result normal?

YES>>GO TO 8.

NO>>Repair or replace error-detected parts.

CHECK CAMSHAFT (EXHAUST)

Check the following.

-

Accumulation of debris on the signal plate of camshaft

front end

front end

-

Chipping signal plate of camshaft front end

Is the inspection result normal?

YES>>GO TO 9.

NO>>Remove debris and clean the signal plate of camshaft front end or replace camshaft. Refer to Removal and Installation.

CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misalignment.

Are there any service records that may cause timing chain misalignment?

YES>>Check timing chain installation. Refer to Removal and Installation.

NO>>GO TO 10.

CHECK LUBRICATION CIRCUIT

Perform ŌĆ£Inspection of Camshaft Sprocket (EXHAUST) Oil GrooveŌĆØ. Refer toInspection .

Is the inspection result normal?

YES>>Check intermittent incident. Refer to Intermittent Incident.

NO>>Clean lubrication line.

Other materials:

P1c90-49 Sub Starter & Generator

DTC Description

DTC DETECTION LOGIC DTC No. CONSULT screen terms (Trouble diagnosis content) DTC detection condition

P1C90-49

Sub starter & generator

(Sub starter & generator)

Diagnosis condition

Engine running at idle

Signal (terminal)

-

Threshold

Sub starte ...

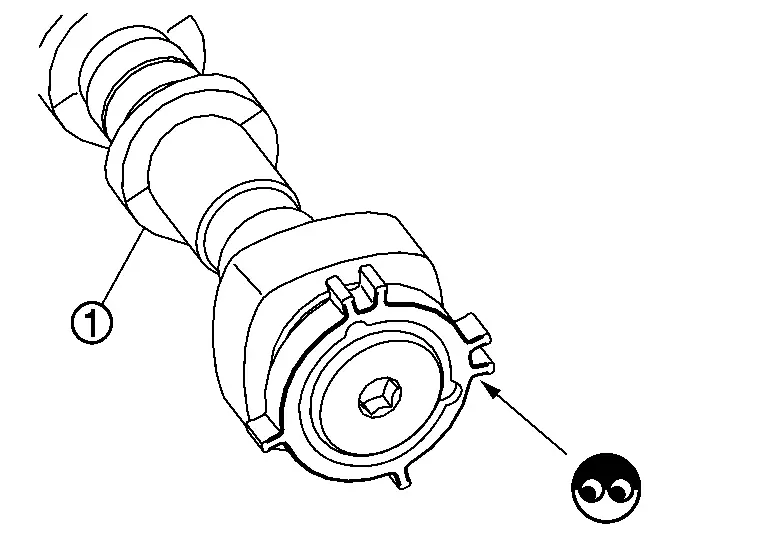

Power Socket. Removal and Installation. Power Socket

Power Socket

Console Power Socket

Removal and Installation

REMOVALRemove switch panel. Refer to Removal and Installation.

Press the power socket fixing pawls from the back of the switch panel to remove the power socket.

: Pawl

INSTALLATIONNote the following, and install in the reve ...

Dtc/circuit Diagnosis. B100e-1a Knee Air Bag Module Rh

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC Detection Condition

B100E-1A

Knee air bag module RH

(Knee air bag module right hand)

Diagnosis condition

When ignition switch is ON.

Signal (terminal)

Knee air bag module RH si ...