Nissan Rogue (T33) 2021-Present Service Manual: Oil Pan (lower)

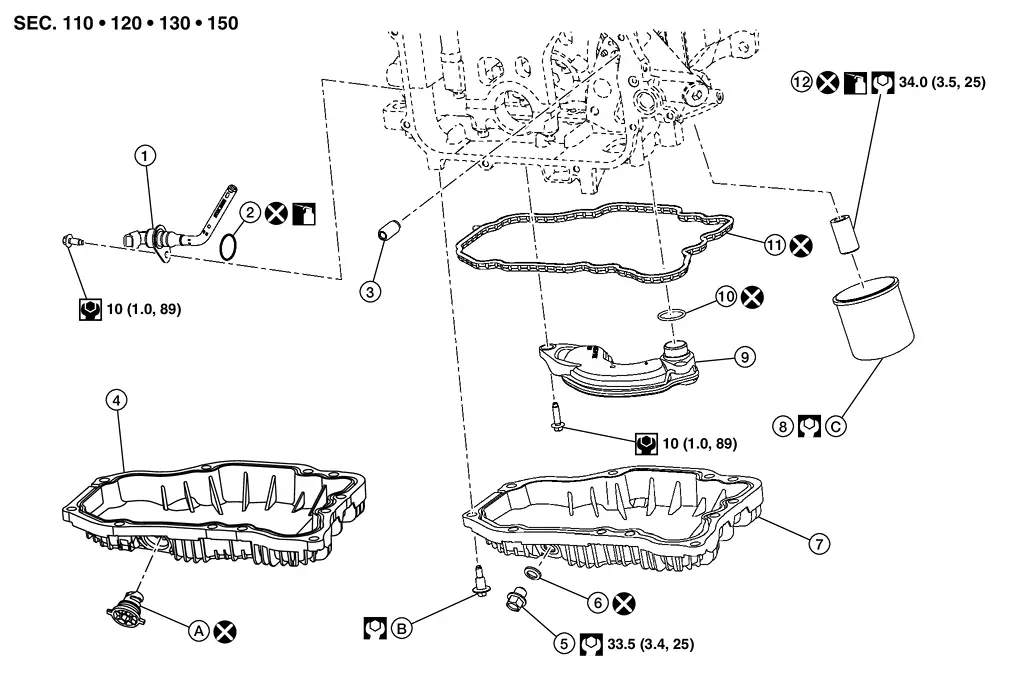

Exploded View

| 1. | Engine oil level sensor | 2. | O-ring 1 | 3. | Relief valve |

| 4. | Oil pan (lower) (With plastic drain plug) | 5. | Drain plug | 6. | Drain plug washer |

| 7. | Oil pan (lower) (With metal drain plug) | 8. | Oil filter | 9. | Oil strainer |

| 10. | O-ring 2 | 11. | Oil pan gasket | 12. | Oil filter stud |

| A. | Comply with the installation procedure when tightening. Refer to Removal and Installation. | B. | Comply with the installation procedure when tightening. Refer to Removal and Installation. | C. | Comply with the installation procedure when tightening. Refer to Removal and Installation. |

|

: Always replace after every disassembly. | ||||

|

: N·m (kg-m, in-lb) | ||||

|

: N·m (kg-m, ft-lb) | ||||

|

: Should be lubricated with oil. | ||||

Removal and Installation

With metal drain plug

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

Remove engine under cover. Refer to Removal and Installation.

Drain engine oil. Refer to Draining.

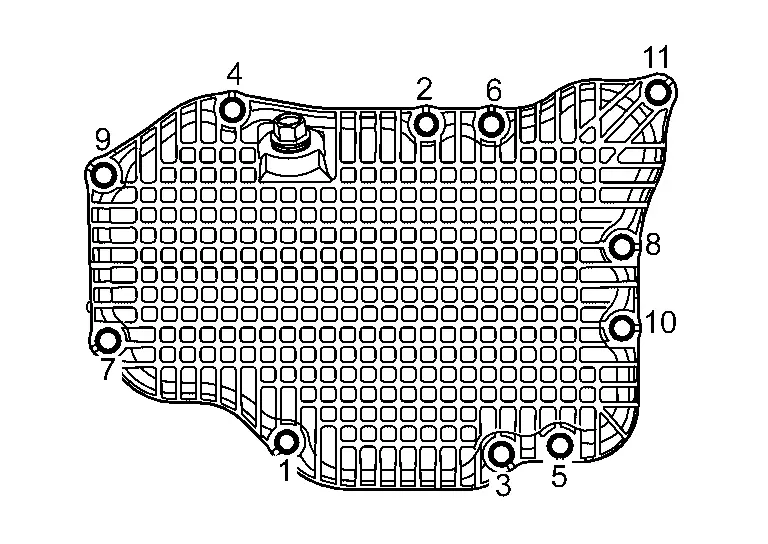

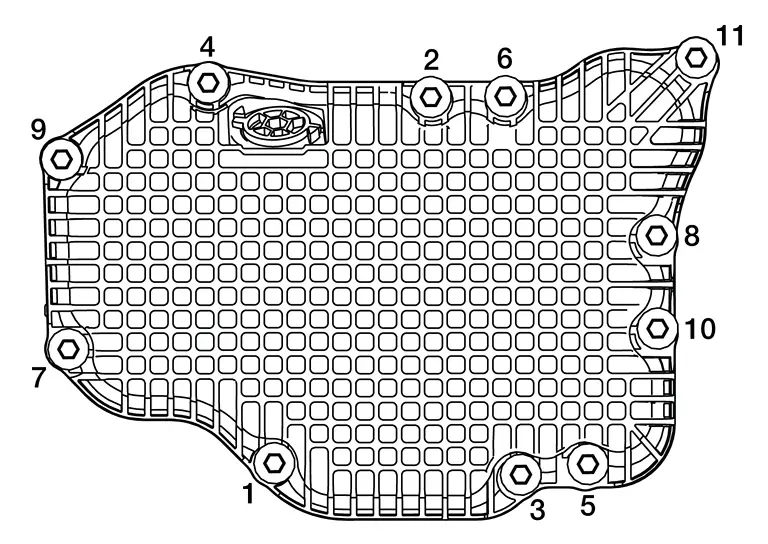

Loosen mounting bolts in reverse order as shown in the figure, and then remove oil pan (lower).

INSTALLATION

CAUTION:

-

Do not reuse o-ring 1 and o-ring 2.

-

Do not reuse drain plug washer.

-

Do not reuse oil pan gasket.

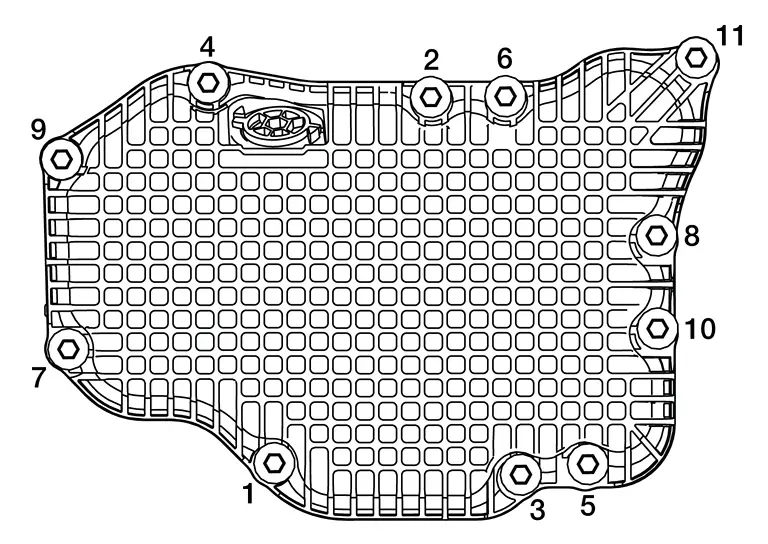

Tighten bolts in numerical order as shown in the figure.

| Oil pan (lower) bolts | ||

First tighten  |

: 2.96 N·m (0.30 kg-m, 26 in-lb) | |

Second tighten  |

: 8.33 N·m (0.85 kg-m, 74in-lb) | |

Install drain plug.

-

Refer to the figure of components of former page for installation direction of washer. Refer to Exploded View.

CAUTION:

Do not reuse drain plug washer.

Install in the reverse order of removal after this step.

With plastic drain plug

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

Remove engine under cover. Refer to Removal and Installation.

Drain engine oil. Refer to Draining.

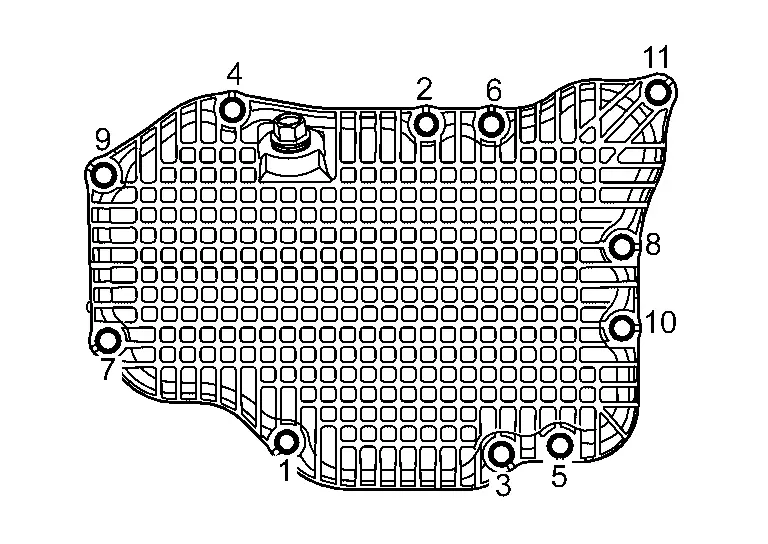

Loosen mounting bolts in reverse order as shown in the figure, and then remove oil pan (lower).

INSTALLATION

CAUTION:

-

Do not reuse o-ring 1 and o-ring 2.

-

Do not reuse drain plug.

-

Use genuine drain plug.

-

Do not reuse oil pan gasket.

Tighten bolts in numerical order as shown in the figure.

| Oil pan (lower) bolts | ||

First tighten  |

: 2.96 N·m (0.30 kg-m, 26 in-lb) | |

Second tighten  |

: 8.33 N·m (0.85 kg-m, 74in-lb) | |

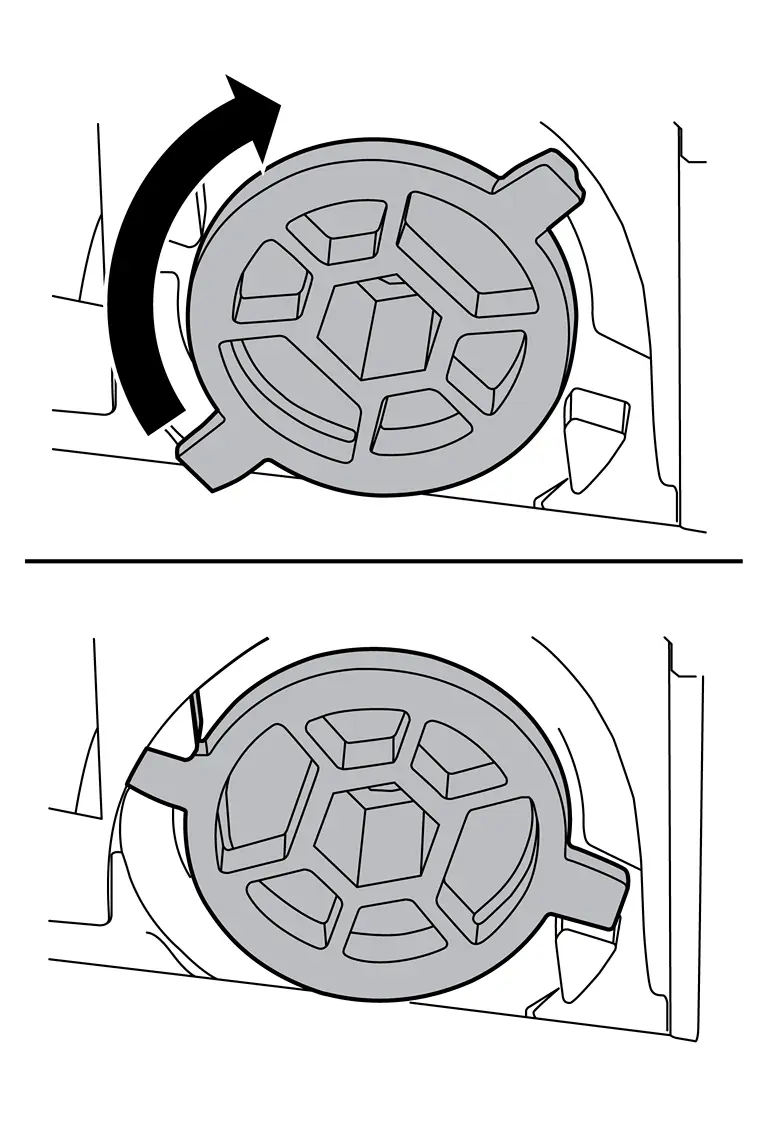

Using suitable tool, install new drain plug and tighten to the lock position in the direction shown.

CAUTION:

-

Do not reuse drain plug.

-

Use genuine drain plug.

| Tightening torque | 3 N·m (0.31 kg-m, 27 in-lb | |

Install in the reverse order of removal after this step.

Inspection

INSPECTION AFTER REMOVAL

Clean oil strainer portion if any object attached.

INSPECTION AFTER INSTALLATION

Check the engine oil level and adjust engine oil. Refer to Inspection.

Start engine, and check there is no leakage of engine oil.

Stop engine and wait for 10 minutes.

Check the engine oil level again. Refer to Inspection.

Other materials:

Mixture Ratio Self-Learning Value Clear

Description

This describes how to erase the mixture ratio self-learning value.

For the actual procedure, follow the instructions in “Diagnosis

Procedure”. (For details, refer to Work Procedure.)

Work Procedure

START

With CONSULT

Start engine and warm it up to normal operating tempe ...

NissanConnect Owner's Manual

For models equipped with the advanced NissanConnect System found in the Nissan Rogue, you can access the full digital NissanConnect Owner's Manual using the QR code on this page (US only) or refer to the printed version if supplied. This dedicated manual provides detailed guidance for operating th ...

Dtc/circuit Diagnosis. U0073-00 Control Module Comm Bus a Off

DTC Description

DESCRIPTIONCAN (Controller Area Network) is a serial

communication line for real time applications. It is an on-Nissan Ariya

vehicle multiplex communication line with high data communication speed

and excellent error detection ability. Modern Nissan Ariya vehicle is

equipped ...