Nissan Rogue (T33) 2021-Present Service Manual: Kr15ddt :: Basic Inspection

Camshaft Valve Clearance

Inspection and Adjustment

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if there is unusual engine conditions regarding valve clearance.

-

Remove rocker cover. Refer to Removal and Installation.

-

Measure the valve clearance with the following procedure:

-

Set No. 1 cylinder at TDC of its compression stroke.

-

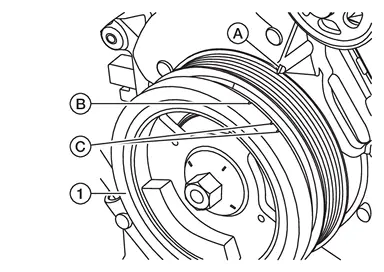

Rotate crankshaft pulley

clockwise and align TDC mark (no paint)

clockwise and align TDC mark (no paint)  to timing indicator

to timing indicator  on front cover.

on front cover.

(C) : Paint marks (Not used for service) -

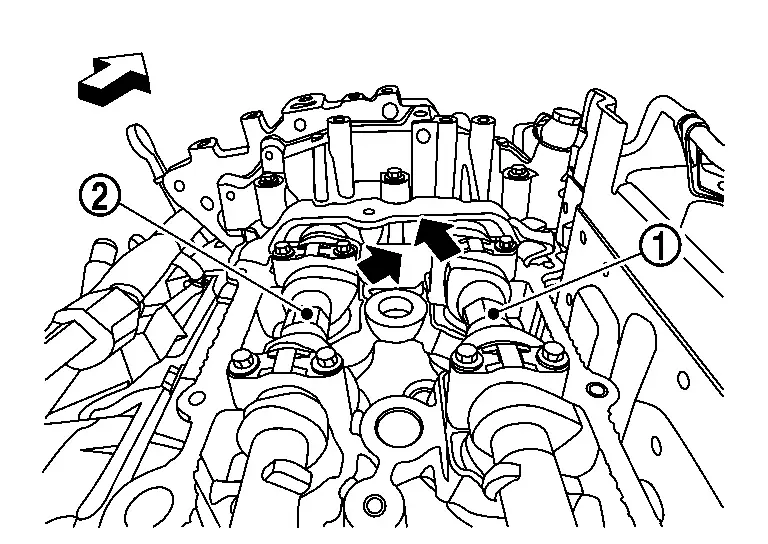

At the same time, check that both intake and exhaust cam noses of No. 1 cylinder face inside (

) as shown in the figure.

) as shown in the figure.

: Camshaft (EXH)

: Camshaft (INT)

: Engine front -

If they do not face inside, rotate crankshaft pulley once more (360 degrees) and align as shown in the figure.

-

-

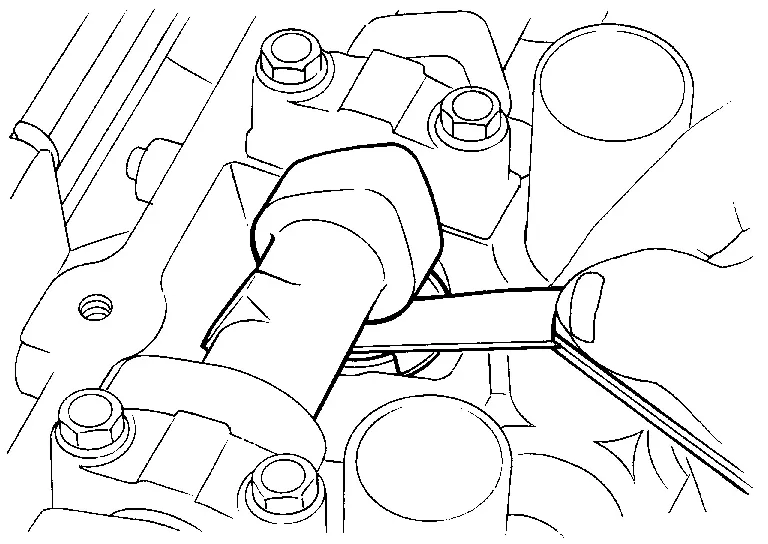

Use a feeler gauge, measure the clearance between valve lifter and camshaft.

Valve clearance : Refer to Camshaft. -

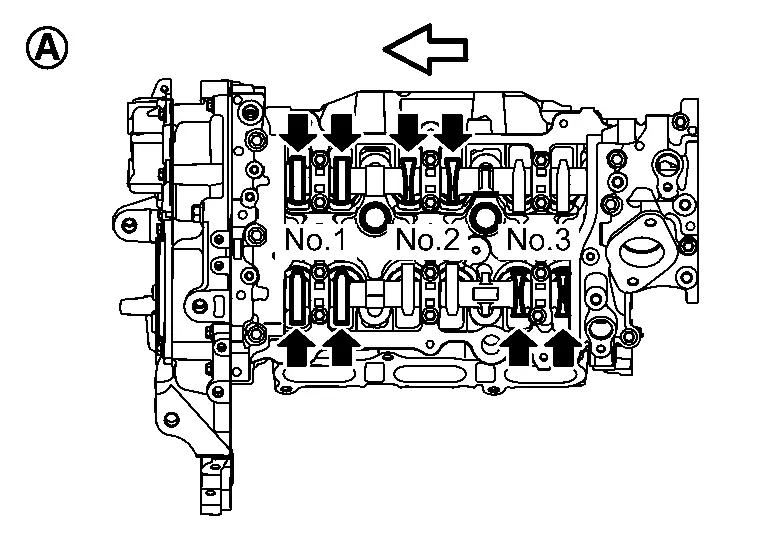

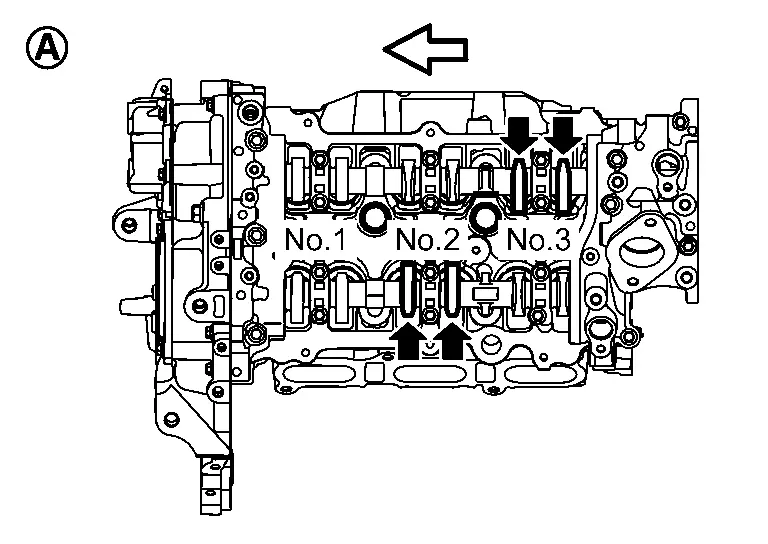

By referring to the figure, measure the valve clearances at locations marked âÃâ as shown in the table below [locations indicated with black arrow (

) in the figure] with a feeler gauge.

) in the figure] with a feeler gauge.

: No. 1 cylinder at compression TDC

: Engine front Measuring position No. 1 CYL. No. 2 CYL. No. 3 CYL. No. 1 cylinder at compression TDC EXH Ã Ã INT Ã Ã

-

-

Set No. 3 cylinder at TDC of its compression stroke.

-

Rotate crankshaft pulley (480 degrees).

CAUTION:

Do not rotate crankshaft pulley counterclockwise. In case of excess rotate, set the No.1 cylinder at TDC of its compression stroke, and turn it 480 degrees clockwise.

-

By referring to the figure, measure the valve clearance at locations marked âÃâ as shown in the table below [locations indicated with black arrow (

) in the figure] with a feeler gauge.

) in the figure] with a feeler gauge.

: No. 3 cylinder at compression TDC

: Engine front Measuring position No. 1 CYL. No. 2 CYL. No. 3 CYL. No. 3 cylinder at compression TDC EXH Ã INT Ã

-

-

-

If out of standard, perform adjustment.

ADJUSTMENT

-

Perform adjustment depending on selected head thickness of valve lifter.

-

Remove camshaft. Refer to Removal and Installation.

-

Remove valve lifters at the locations that are out of the standard.

-

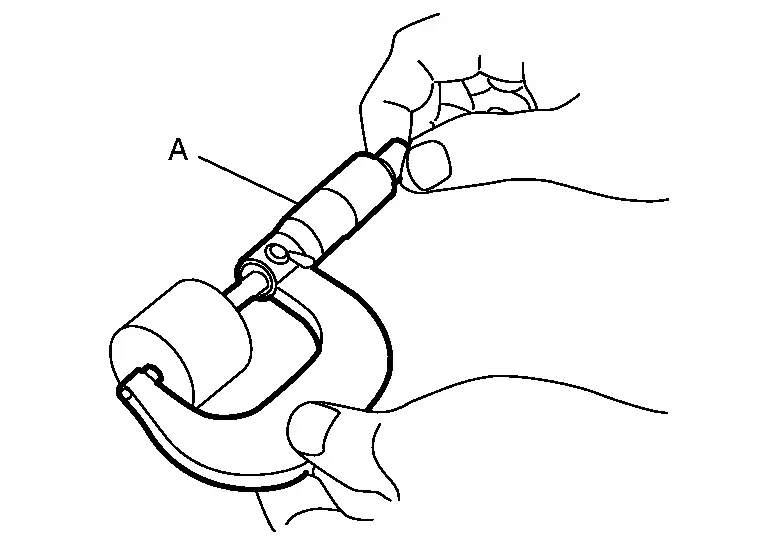

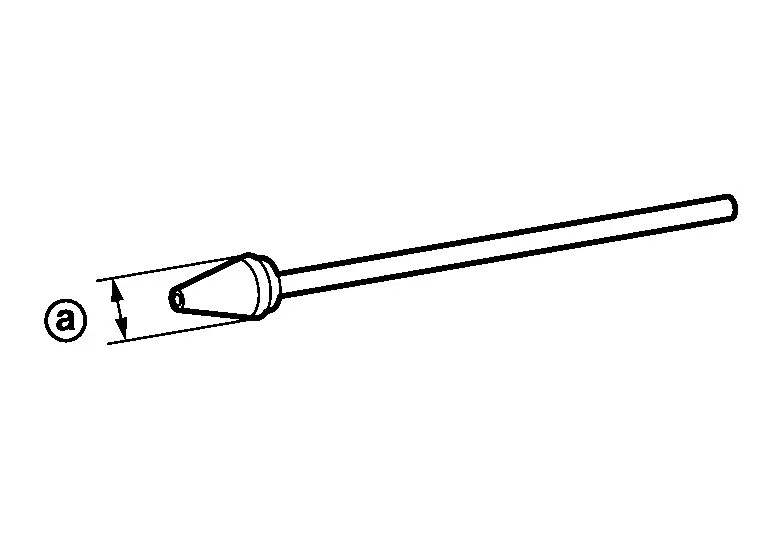

Measure the center thickness of the removed valve lifters with a suitable tool (A).

-

Use the equation below to calculate valve lifter thickness for replacement.

Valve lifter thickness calculation: t = t1 + (C1 â C2) t = Valve lifter thickness to be replaced t1 = Removed valve lifter thickness C1 = Measured valve clearance C2 = Standard valve clearance: Intake : 0.32 mm (0.0126 in) Exhaust : 0.31 mm (0.0122 in) -

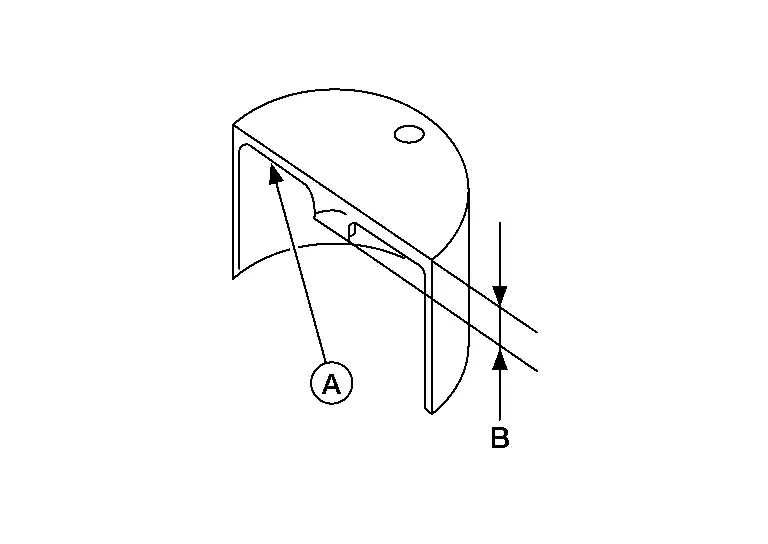

Thickness of new valve lifter (B) can be identified by stamp mark

on the reverse side (inside the cylinder).

on the reverse side (inside the cylinder).

-

Stamp mark â302â indicates 3.02 mm (0.1189 in) in thickness.

NOTE:

NOTE:

Available thickness of valve lifter: 26 sizes range 3.00 to 3.50 mm (0.1181 to 0.1378 in) in steps of 0.02 mm (0.0008 in) (when manufactured at factory). Refer to Camshaft.

-

-

Install the selected valve lifter.

-

Install camshaft. Refer to Removal and Installation.

-

Install timing chain and related parts. Refer to Removal and Installation.

-

Manually rotate crankshaft pulley a few rotations.

-

Check that the valve clearance is within the standard. Refer to Inspection.

-

Installation of the remaining parts is in the reverse order of removal.

-

Warm up the engine, and check for unusual noise and vibration.

Compression Pressure

Inspection

-

Warm up engine thoroughly. Then, stop it.

-

Release fuel pressure. Refer to Work Procedure.

-

Disconnect fuel pump fuse to avoid fuel injection during measurement. Refer to How To Check.

-

Remove ignition coil and spark plug from each cylinder. Refer to Removal and Installation.

-

Connect engine tachometer (not required in use of CONSULT).

-

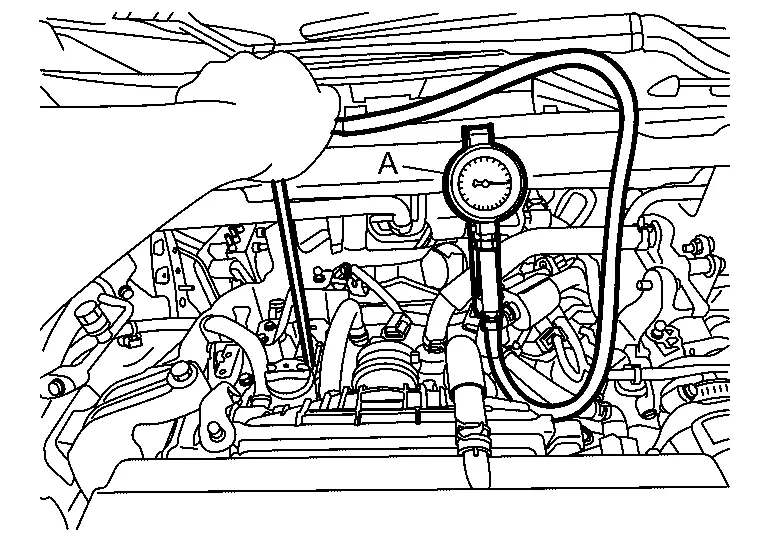

Install compression tester (A) with adapter onto spark plug hole.

-

Use compression tester whose end

(rubber portion) is smaller than 20 mm (0.79 in) in diameter.

(rubber portion) is smaller than 20 mm (0.79 in) in diameter.

-

-

With accelerator pedal fully depressed, turn ignition switch to âSTARTâ for cranking. When the gauge pointer stabilizes, read the compression pressure and engine rpm. Perform these steps to check each cylinder.

Compression pressure : Refer to General Specification. CAUTION:

Always use a fully charged battery to obtain specified engine speed.

-

If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine speed again with normal battery gravity.

-

If compression pressure is below minimum value, check valve clearances and parts associated with combustion chamber (Valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head gasket). After the checking, measure the compression pressure again.

If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole of the cylinder to re-check it for compression.

-

If the added engine oil improves the compression, piston rings may be worn out or damaged. Check piston rings and replace if necessary.

-

If the compression pressure remains at low level despite the addition of engine oil, valves may be malfunctioning. Check valves for damage. Replace valve or valve seat accordingly.

-

-

If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, gaskets are leaking. In such a case, replace cylinder head gaskets.

-

-

After inspection is completed, install removed parts.

-

Start engine, and confirm that engine runs smoothly.

-

Perform trouble diagnosis. If DTC appears, erase it. Refer to Description.

Other materials:

Fonctionnement du systÃĻme RAB

Exemple

TÃĐmoin d'avertissement du systÃĻme RAB (sur l'ÃĐcran d'informations du vÃĐhicule)

TÃĐmoin d'avertissement de dÃĐsactivation du systÃĻme RAB (sur le tableau de bord)

Commandes au volant (cÃītÃĐ gauche)

Ãcran d'informations du vÃĐhicule

Centre d'affichage (si le vÃĐhicule e ...

Commande de dÃĐgivrage de lunette arriÃĻre et de rÃĐtroviseurs extÃĐrieurs du Nissan Rogue

Commandes de confort thermique

Pour ÃĐliminer rapidement le givre ou la buÃĐe sur la lunette arriÃĻre et les miroirs des rÃĐtroviseurs extÃĐrieurs chauffants de votre Nissan Rogue, dÃĐmarrez le moteur et appuyez sur l'interrupteur de dÃĐgivrage. Le tÃĐmoin lumineux (A) confirmera le fonctionn ...

Symptom Diagnosis. Low Tire Pressure Warning Lamp Blinks

Description

When the ignition switch is placed ON, the low tire pressure warning

lamp blinks. And then 1 minute later, low tire pressure warning lamp

turns ON.

Diagnosis Procedure

CHECK TIRE PRESSURE SENSOR INSTALLATION

Check visually that tire pressure sensors are installed to each wheels c ...