Nissan Rogue (T33) 2021-Present Service Manual: How to Use This Manual :: Tightening Torque of Standard Bolts

Description

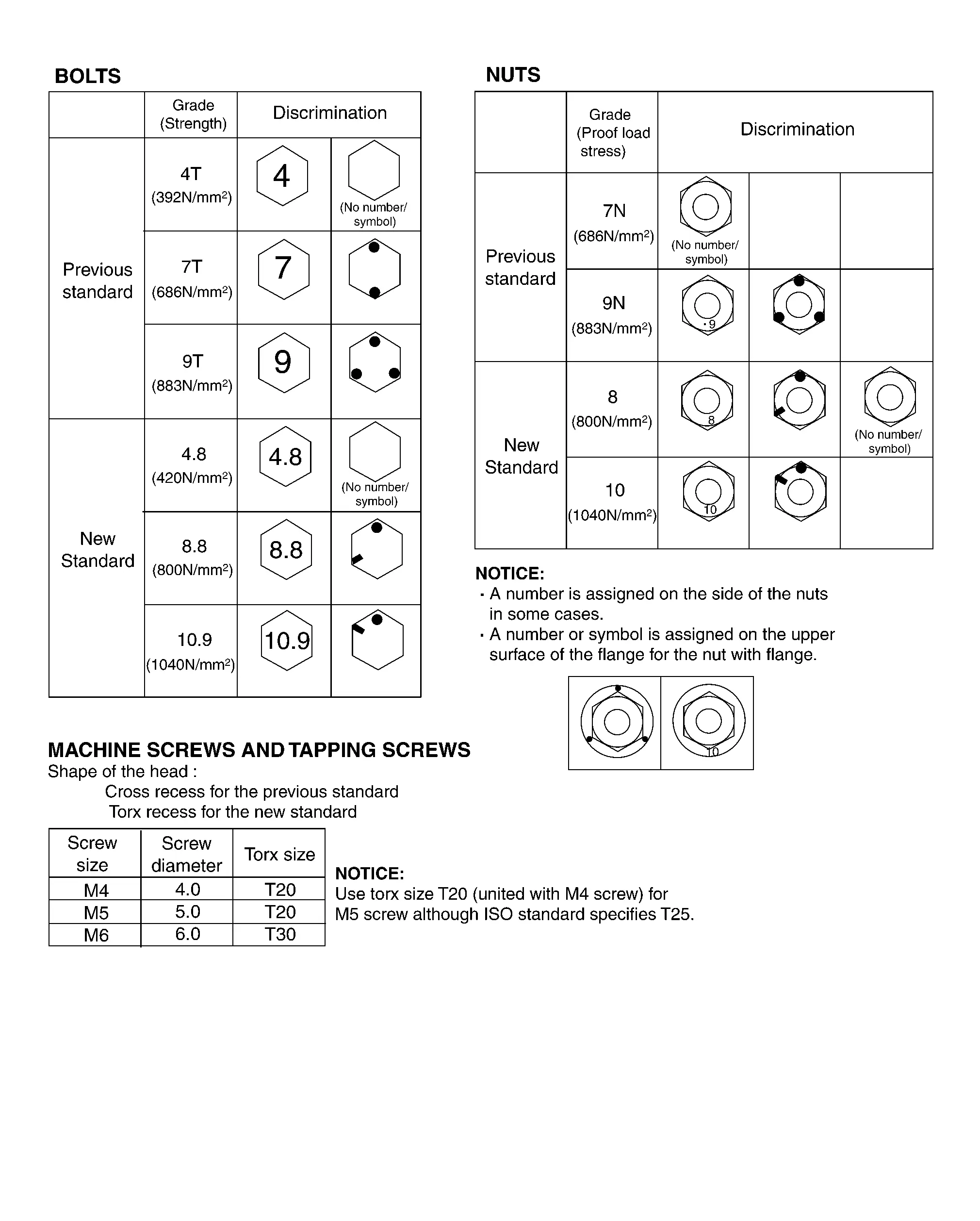

This vehicle has both new standard based on ISO* and previous standard bolts/nuts. There are some differences between these two types of bolts/ nuts; shape of the head, grade of strength, hexagonal width across flats and the standard tightening torque.

-

For guidance in discriminating, refer to Tightening Torque Table (New Standard Included).

-

The new standard machine screws and tapping screws have a head of ISO standard torx recess.

-

If the tightening torque is not described in the description or figure, refer to Tightening Torque Table (New Standard Included).

*ISO: International Organization for Standardization

Tightening Torque Table (New Standard Included)

CAUTION:

-

The special parts are excluded.

-

The bolts/nuts in these tables have a strength (discrimination) number/symbol assigned to the head or the like. As to the relation between the strength grade in these tables and the strength (discrimination) number/symbol, refer to ŌĆ£DISCRIMINATION OF BOLTS AND NUTSŌĆØ.

PREVIOUS STANDARD

| Grade (Strength grade) | Bolt size |

Bolt diameter mm |

Hexagonal width across flats mm |

Pitch mm | Tightening torque (Without lubricant) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hexagon head bolt | Hexagon flange bolt | |||||||||||

| N┬Ęm | kg-m | ft-lb | in-lb | N┬Ęm | kg-m | ft-lb | in-lb | |||||

| 4T | M6 | 6.0 | 10 | 1.0 | 5.5 | 0.56 | 4 | 49 | 7 | 0.71 | 5 | 62 |

| M8 | 8.0 | 12 | 1.25 | 13.5 | 1.4 | 10 | ŌĆö | 17 | 1.7 | 13 | ŌĆö | |

| 1.0 | 13.5 | 1.4 | 10 | ŌĆö | 17 | 1.7 | 13 | ŌĆö | ||||

| M10 | 10.0 | 14 | 1.5 | 28 | 2.9 | 21 | ŌĆö | 35 | 3.6 | 26 | ŌĆö | |

| 1.25 | 28 | 2.9 | 21 | ŌĆö | 35 | 3.6 | 26 | ŌĆö | ||||

| M12 | 12.0 | 17 | 1.75 | 45 | 4.6 | 33 | ŌĆö | 55 | 5.6 | 41 | ŌĆö | |

| 1.25 | 45 | 4.6 | 33 | ŌĆö | 65 | 6.6 | 48 | ŌĆö | ||||

| M14 | 14.0 | 19 | 1.5 | 80 | 8.2 | 59 | ŌĆö | 100 | 10 | 74 | ŌĆö | |

| 7T | M6 | 6.0 | 10 | 1.0 | 9 | 0.92 | 7 | 80 | 11 | 1.1 | 8 | 97 |

| M8 | 8.0 | 12 | 1.25 | 22 | 2.2 | 16 | ŌĆö | 28 | 2.9 | 21 | ŌĆö | |

| 1.0 | 22 | 2.2 | 16 | ŌĆö | 28 | 2.9 | 21 | ŌĆö | ||||

| M10 | 10.0 | 14 | 1.5 | 45 | 4.6 | 33 | ŌĆö | 55 | 5.6 | 41 | ŌĆö | |

| 1.25 | 45 | 4.6 | 33 | ŌĆö | 55 | 5.6 | 41 | ŌĆö | ||||

| M12 | 12.0 | 17 | 1.75 | 80 | 8.2 | 59 | ŌĆö | 100 | 10 | 74 | ŌĆö | |

| 1.25 | 80 | 8.2 | 59 | ŌĆö | 100 | 10 | 74 | ŌĆö | ||||

| M14 | 14.0 | 19 | 1.5 | 130 | 13 | 96 | ŌĆö | 170 | 17 | 125 | ŌĆö | |

| 9T | M6 | 6.0 | 10 | 1.0 | 11 | 1.1 | 8 | ŌĆö | 13.5 | 1.4 | 10 | ŌĆö |

| M8 | 8.0 | 12 | 1.25 | 28 | 2.9 | 21 | ŌĆö | 35 | 3.6 | 26 | ŌĆö | |

| 1.0 | 28 | 2.9 | 21 | ŌĆö | 35 | 3.6 | 26 | ŌĆö | ||||

| M10 | 10.0 | 14 | 1.5 | 55 | 5.6 | 41 | ŌĆö | 80 | 8.2 | 59 | ŌĆö | |

| 1.25 | 55 | 5.6 | 41 | ŌĆö | 80 | 8.2 | 59 | ŌĆö | ||||

| M12 | 12.0 | 17 | 1.75 | 100 | 10 | 74 | ŌĆö | 130 | 13 | 96 | ŌĆö | |

| 1.25 | 100 | 10 | 74 | ŌĆö | 130 | 13 | 96 | ŌĆö | ||||

| M14 | 14.0 | 19 | 1.5 | 170 | 17 | 125 | ŌĆö | 210 | 21 | 155 | ŌĆö | |

CAUTION:

The parts with aluminum or the cast iron washer surface/thread surface are excluded.

NEW STANDARD BASED ON ISO

| Grade (Strength grade) | Bolt size |

Bolt diameter mm |

Hexagonal width across flats mm |

Pitch mm | Tightening torque | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hexagon head bolt | Hexagon flange bolt | |||||||||||

| N┬Ęm | kg-m | ft-lb | in-lb | N┬Ęm | kg-m | ft-lb | in-lb | |||||

|

4.8 (Without lubricant) |

M6 | 6.0 | 10 | 1.0 | 5.5 | 0.56 | 4 | 49 | 7 | 0.71 | 5 | 62 |

| M8 | 8.0 | 13 | 1.25 | 13.5 | 1.4 | 10 | ŌĆö | 17 | 1.7 | 13 | ŌĆö | |

| 1.0 | 13.5 | 1.4 | 10 | ŌĆö | 17 | 1.7 | 13 | ŌĆö | ||||

| M10 | 10.0 | 16 | 1.5 | 28 | 2.9 | 21 | ŌĆö | 35 | 3.6 | 26 | ŌĆö | |

| 1.25 | 28 | 2.9 | 21 | ŌĆö | 35 | 3.6 | 26 | ŌĆö | ||||

| M12 | 12.0 | 18 | 1.75 | 45 | 4.6 | 33 | ŌĆö | 55 | 5.6 | 41 | ŌĆö | |

| 1.25 | 45 | 4.6 | 33 | ŌĆö | 65 | 6.6 | 48 | ŌĆö | ||||

| M14 | 14.0 | 21 | 1.5 | 80 | 8.2 | 59 | ŌĆö | 100 | 10 | 74 | ŌĆö | |

|

4.8 (With lubricant) |

M6 | 6.0 | 10 | 1.0 | 4 | 0.41 | 3 | 35 | 5.5 | 0.56 | 4 | 49 |

| M8 | 8.0 | 13 | 1.25 | 11 | 1.1 | 8 | ŌĆö | 13.5 | 1.4 | 10 | ŌĆö | |

| 1.0 | 11 | 1.1 | 8 | ŌĆö | 13.5 | 1.4 | 10 | ŌĆö | ||||

| M10 | 10.0 | 16 | 1.5 | 22 | 2.2 | 16 | ŌĆö | 28 | 2.9 | 21 | ŌĆö | |

| 1.25 | 22 | 2.2 | 16 | ŌĆö | 28 | 2.9 | 21 | ŌĆö | ||||

| M12 | 12.0 | 18 | 1.75 | 35 | 3.6 | 26 | ŌĆö | 45 | 4.6 | 33 | ŌĆö | |

| 1.25 | 35 | 3.6 | 26 | ŌĆö | 45 | 4.6 | 33 | ŌĆö | ||||

| M14 | 14.0 | 21 | 1.5 | 65 | 6.6 | 48 | ŌĆö | 80 | 8.2 | 59 | ŌĆö | |

|

8.8 (With lubricant) |

M6 | 6.0 | 10 | 1.0 | 8 | 0.82 | 6 | 71 | 10 | 1.0 | 7 | 89 |

| M8 | 8.0 | 13 | 1.25 | 21 | 2.1 | 15 | ŌĆö | 25 | 2.6 | 18 | ŌĆö | |

| 1.0 | 21 | 2.1 | 15 | ŌĆö | 25 | 2.6 | 18 | ŌĆö | ||||

| M10 | 10.0 | 16 | 1.5 | 40 | 4.1 | 30 | ŌĆö | 50 | 5.1 | 37 | ŌĆö | |

| 1.25 | 40 | 4.1 | 30 | ŌĆö | 50 | 5.1 | 37 | ŌĆö | ||||

| M12 | 12.0 | 18 | 1.75 | 70 | 7.1 | 52 | ŌĆö | 85 | 8.7 | 63 | ŌĆö | |

| 1.25 | 70 | 7.1 | 52 | ŌĆö | 85 | 8.7 | 63 | ŌĆö | ||||

| M14 | 14.0 | 21 | 1.5 | 120 | 12 | 89 | ŌĆö | 140 | 14 | 103 | ŌĆö | |

|

10.9 (With lubricant) |

M6 | 6.0 | 10 | 1.0 | 10 | 1.0 | 7 | 89 | 12 | 1.2 | 9 | 106 |

| M8 | 8.0 | 13 | 1.25 | 27 | 2.8 | 20 | ŌĆö | 32 | 3.3 | 24 | ŌĆö | |

| 1.0 | 27 | 2.8 | 20 | ŌĆö | 32 | 3.3 | 24 | ŌĆö | ||||

| M10 | 10.0 | 16 | 1.5 | 55 | 5.6 | 41 | ŌĆö | 65 | 6.6 | 48 | ŌĆö | |

| 1.25 | 55 | 5.6 | 41 | ŌĆö | 65 | 6.6 | 48 | ŌĆö | ||||

| M12 | 12.0 | 18 | 1.75 | 95 | 9.7 | 70 | ŌĆö | 110 | 11 | 81 | ŌĆö | |

| 1.25 | 95 | 9.7 | 70 | ŌĆö | 110 | 11 | 81 | ŌĆö | ||||

| M14 | 14.0 | 21 | 1.5 | 160 | 16 | 118 | ŌĆö | 180 | 18 | 133 | ŌĆö | |

CAUTION:

-

Use tightening torque with lubricant for the new standard bolts/nuts in principle. Friction coefficient stabilizer is applied to the new standard bolts/nuts.

-

However, use tightening torque without lubricant for the following cases. Friction coefficient stabilizer is not applied to the following bolts/nuts.

-

Grade 4.8, M6 size bolt, Conical spring washer installed

-

Paint removing nut (Size M6 and M8) for fixing with weld bolt

-

DISCRIMINATION OF BOLTS AND NUTS

Other materials:

Usb Charge Port. System Description. Component Parts

Component Parts

Usb Charge Port

Component Parts Location

A -1

TYPE 1

A -2

TYPE 2

A -3

TYPE 3

No.Component

1.

Rear USB charge port

USB Charge Port

USB Charge PortSupply DC 5V from the (USB) port.Specification Rated voltage

’╝łV’╝ē

5

Maximum electric capacity

’╝łW’╝ē ...

Dtc/circuit Diagnosis. B2921-A2 Driver Seat Control Unit

DTC Description

DTC DETECTION LOGIC DTC No.

CONSULT screen items

(Trouble diagnosis content) DTC detection condition

B2921-A2

Driver seat control unit

(Driver seat control unit)

Diagnosis condition

The power consumption control of driver seat control unit is in wake-up state

...

U1327-52 Mac Key

DTC Description

DTC DETECTION LOGIC DTC No. CONSULT screen terms DTC detection condition

U1327

52

MAC key update

Diagnosis condition

ŌĆö

Signal (terminal)

ŌĆö

Threshold

MAC key writing is incomplete.

Diagnosis delay time

ŌĆö

POSSIBLE CAUSE

Network com ...