Nissan Rogue Service Manual: Differential side oil seal

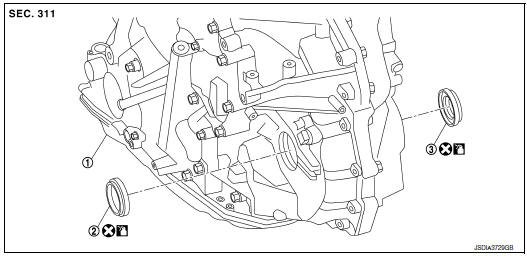

Exploded View

- Transaxle assembly

- Differential side oil seal (left side)

- Differential side oil seal (right side) (FWD models only)

: Always replace after every

disassembly.

: Always replace after every

disassembly.

: Apply CVT fluid

: Apply CVT fluid

Removal and Installation

REMOVAL

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

- Remove front drive shaft. Refer to FAX-18, "Removal and Installation (LH)" (FWD) or FAX-50, "Removal and Installation (LH)" [LH (AWD)]or FAX-52, "Removal and Installation (RH)" [RH(AWD)].

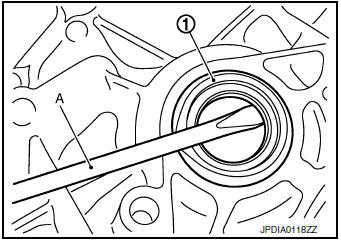

- Remove differential side oil seal (1) using suitable tool (A).

CAUTION: Be careful not to scratch transaxle case and converter housing.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse differential side oil seal.

- Apply CVT fluid to differential side oil seals.

- When inserting the drive shaft, be sure to use Tool.

Tool number: KV38107900

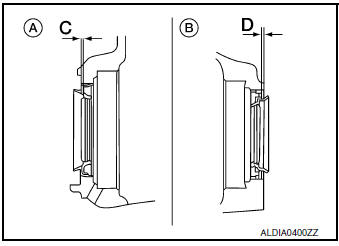

Install each differential side oil seal evenly using suitable tool so that differential side oil seal protrudes by the dimension (C) and (D) respectfully.

(A) : Differential side oil seal (LH)

(B) : Differential side oil seal (RH) (FWD models only)

Dimension (C) :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ± 0.020 in).

Dimension (D) :Height difference from case end surface is within 2.2 ± 0.5 mm (0.087 ± 0.020 in).

NOTE: The reference is the installation direction of the differential side oil seal.

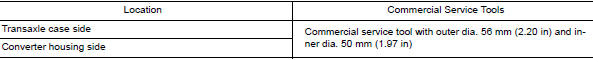

Drift to be used:

Inspection and Adjustment

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-190, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-192, "Adjustment".

Output speed sensor

Output speed sensor

Exploded View

Transaxle assembly

Output speed sensor

O-ring

Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

Removal and Installation

REMOVAL

...

Water hose

Water hose

Exploded View

Water outlet

Hose clamp

Water hose A

Clip

CVT oil warmer

Transaxle assembly

Water hose B

Heater thermostat

Water hose C

: Always replace after every

di ...

Other materials:

Symptom diagnosis

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any

custome ...

Changing engine oil filter

>

Changing engine oil filter

Park the vehicle on a level surface and apply

the parking brake.

Turn the engine off.

Place a large drain pan under the oil filter B .

Remove pins C from the right engine protector

located inside right wheel well, remove

protector. Remove oil ...

System description

COMPONENT PARTS

Component Part Location

RH side of engine compartment

RH front of vehicle (view with front

bumper fascia removed)

No.

Component

Description

1

IPDM E/R

Refer to PCS-5, "RELAY CONTROL SYSTEM : System Description".

...