Nissan Rogue Owners Manual: Changing engine oil filter

>

Changing engine oil filter

>

Changing engine oil filter

- Park the vehicle on a level surface and apply the parking brake.

- Turn the engine off.

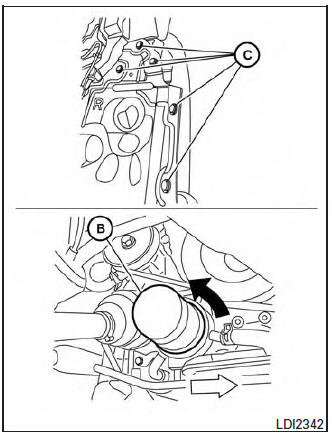

- Place a large drain pan under the oil filter B .

- Remove pins C from the right engine protector

located inside right wheel well, remove

protector. Remove oil filter B with an

oil filter wrench by turning it counterclockwise.

Then remove the oil filter by turning it by hand.

| CAUTION Be careful not to burn yourself. The engine oil may be hot. |

- Wipe the engine oil filter sealing surface with a clean rag.

CAUTION

|

- Coat the gasket on the new filter with clean engine oil.

- Screw on the oil filter until a slight resistance is felt, then tighten an additional 2/3 turn.

- Start the engine and check for leakage around the oil filter. Correct as required.

- Turn the engine off and wait more than 10 minutes. Check the oil level. Add engine oil if necessary.

Changing engine oil

Changing engine oil

Changing engine oil

Park the vehicle on a level surface and apply

the parking brake.

Start the engine and let it idle until it reaches

operating temperature, then turn it off.

& ...

Continuously Variable Transmission (CVT) fluid

Continuously Variable Transmission (CVT) fluid

CAUTION

NISSAN recommends using Genuine

NISSAN CVT Fluid NS-3 ONLY in

NISSAN CVTs. Do not mix with other

fluids.

Do not use Automatic transmission

fluid (ATF ...

Other materials:

Battery terminal with fusible link

Exploded View

Cover

Fusible link box (battery)

Positive cable

Battery

Harness connector

Front

Removal and Installation

REMOVAL

Loosen battery terminal nuts and disconnect both negative and

positive terminals from the battery.

CAUTION:

To prevent ...

System description

STRUCTURE AND OPERATION

Sectional View

Drive gear

Side bearing

Differential case

Pinion mate shaft

Side gear

Pinion mate gear

Drive pinion

Collapsible spacer

AWD solenoid

Stud bolt

Electric controlled coupling

Pinion front bearing

Pinion rear bearing

Elect ...

The low washer fluid warning continues displaying, or

does not display

Description

The warning is still displayed even after washer fluid is added.

The warning is not displayed even though the washer tank is empty.

Diagnosis Procedure

1.CHECK WASHER FLUID LEVEL SWITCH SIGNAL CIRCUIT

Check the washer fluid level switch signal circuit. Refer to MWI-71,

" ...