Nissan Rogue Service Manual: Output speed sensor

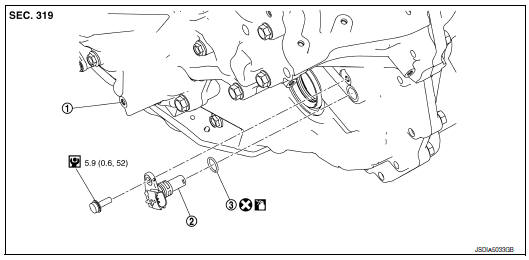

Exploded View

- Transaxle assembly

- Output speed sensor

- O-ring

Always replace after every

disassembly.

Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Apply CVT fluid

: Apply CVT fluid

Removal and Installation

REMOVAL

- Remove engine undercover. Refer to TM-209, "Removal and Installation".

- Disconnect the output speed sensor harness connector.

- Remove the output speed sensor bolt and remove the output speed sensor.

- Remove the O-ring from the output speed sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse O-ring.

- Apply CVT fluid to the O-ring.

Inspection and Adjustment

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-190, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-192, "Adjustment".

Primary speed sensor

Primary speed sensor

Exploded View

Transaxle assembly

O-ring

Primary speed sensor

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

Removal and Installation

REMOVAL

...

Differential side oil seal

Differential side oil seal

Exploded View

Transaxle assembly

Differential side oil seal (left side)

Differential side oil seal (right side)

(FWD models only)

: Always replace after every

disassembly.

: Appl ...

Other materials:

DTC/circuit diagnosis

U1000 CAN COMM CIRCUIT

Description

Refer to LAN-8, "System Description".

DTC Logic

DTC DETECTION LOGIC

CONSULT Display

DTC Detection Condition

Possible Cause

CAN COMM CIRCUIT

[U1000]

When IPDM E/R cannot communicate with CAN communication

sig ...

Removal and installation

FRONT COIL SPRING AND STRUT

Exploded View

Strut mount insulator

Rotary stop

Front spring upper rubber seat

Front suspension bound bumper

Front spring

Front spring lower rubber seat

Stabilizer connecting rod

Strut

Steering knuckle

Removal and Installation

REMO ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition

and the environment when the

incident/malfunction occurred).

>> GO TO 2.

2.CONFIRM THE SYMPTOM

Try t ...