Nissan Rogue (T33) 2021-Present Service Manual: Corrosion Protection

Description

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-corrosive measures.

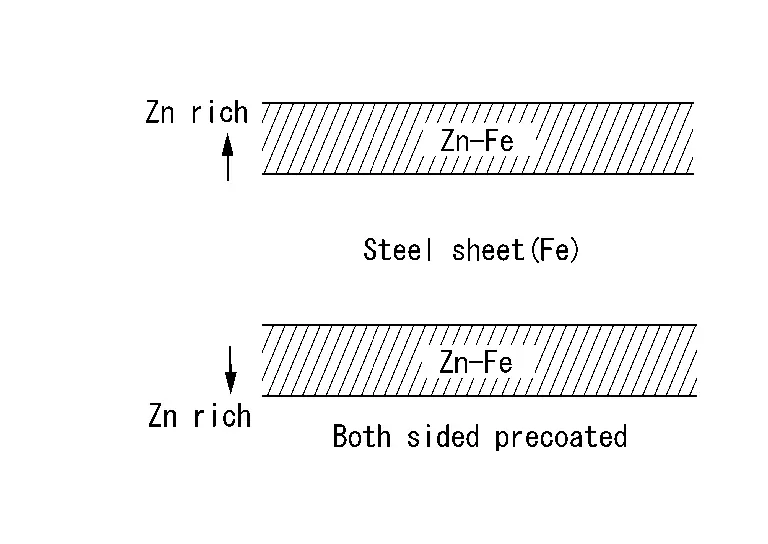

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL)

To improve repairability and corrosion resistance, a new type of anti-corrosive precoated steel sheet is adopted replacing conventional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron alloy, which provides excellent and long term corrosion resistance with cationic electrodeposition primer.

NISSAN genuine parts are fabricated from galvannealed steel. Therefore, it is recommended that NISSAN genuine parts or an equivalent be used for panel replacement to maintain the anti-corrosive performance built into the Nissan Ariya vehicle at the factory.

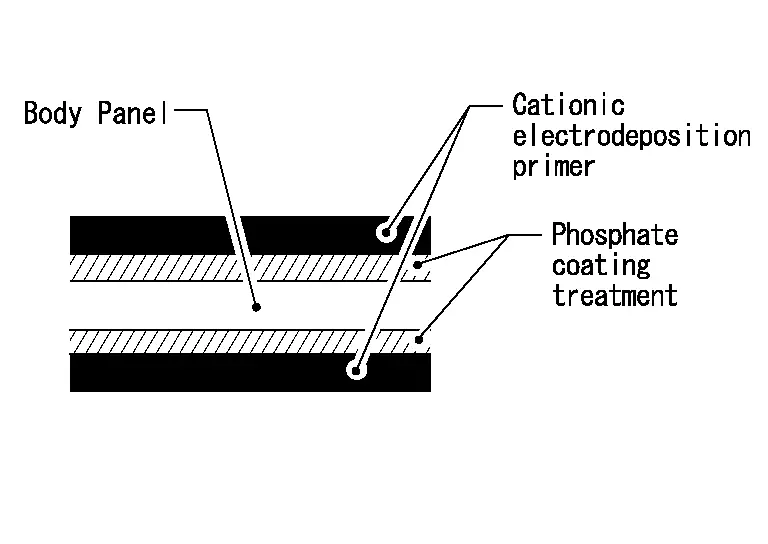

PHOSPHATE COATING TREATMENT AND CATIONIC ELECTRODEPOSITION PRIMER

A phosphate coating treatment and a cationic electrodeposition primer, which provide excellent corrosion protection, are applied to all body components.

CAUTION:

Confine paint removal during welding operation to an absolute minimum.

NISSAN genuine parts are also treated in the same manner. Therefore, it is recommended that NISSAN genuine parts or an equivalent be used for panel replacement to maintain anti-corrosive performance built into the Nissan Ariya vehicle at the factory.

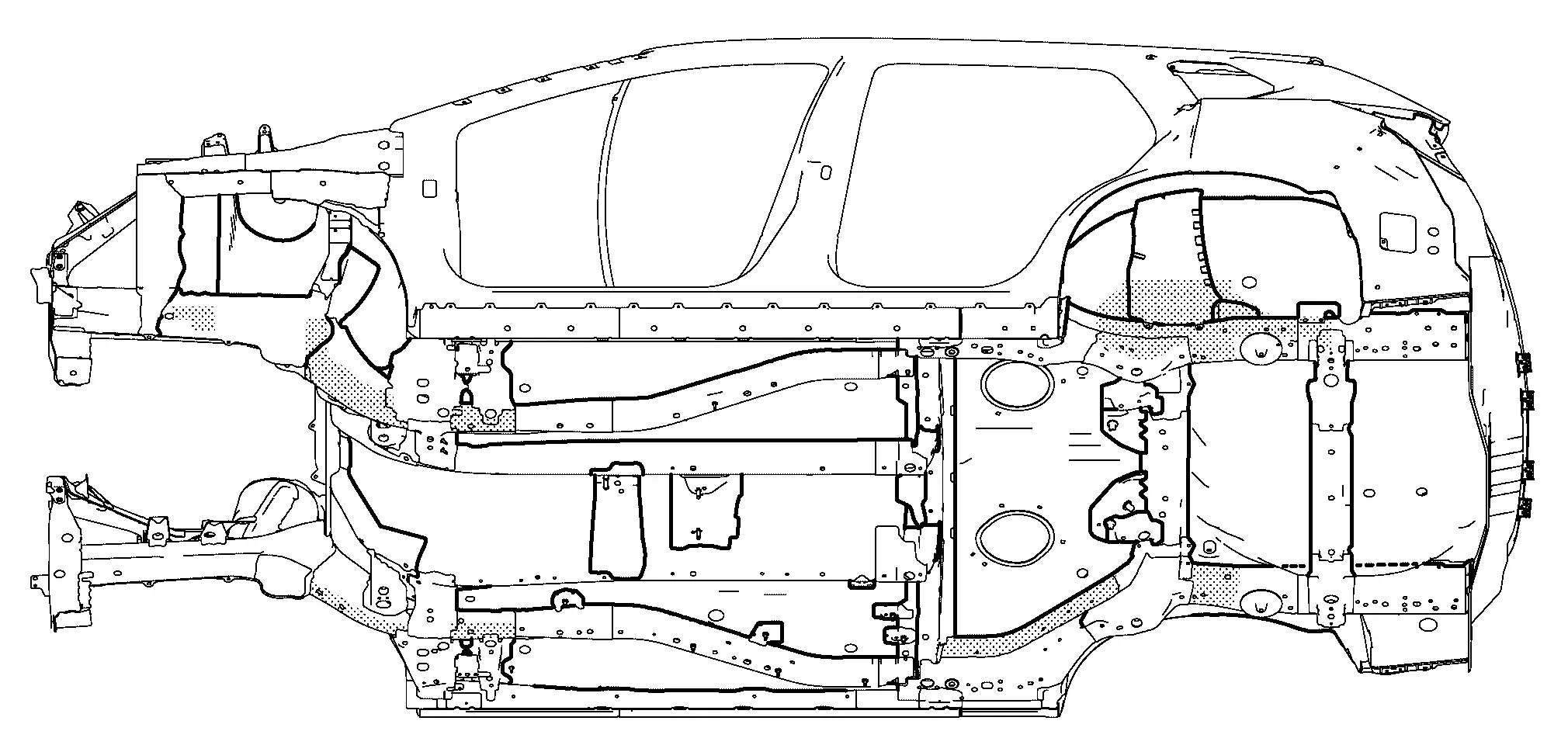

Undercoating

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chipping. Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoating which is rust resistant, soundproof, vibration-proof, shock-resistant, adhesive, and durable.

PRECAUTIONS IN UNDERCOATING

-

Never apply undercoating to any place unless specified (such as the areas above the muffler and three way catalyst that are subjected to heat).

-

Never undercoat the exhaust pipe or other parts that become hot.

-

Never undercoat rotating parts.

-

Apply cavity wax after applying undercoating.

-

After putting seal on the Nissan Ariya vehicle, put undercoating on it.

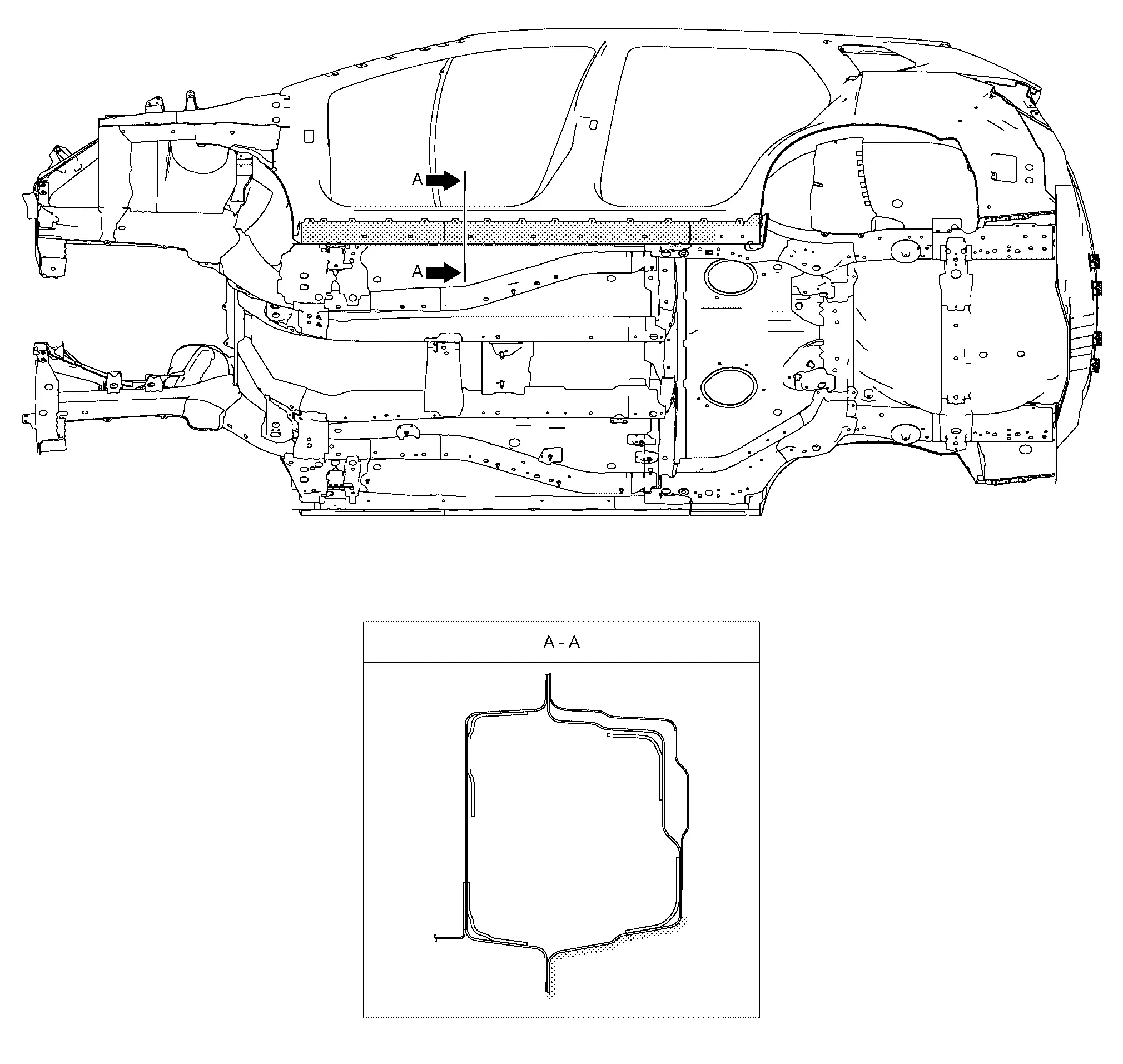

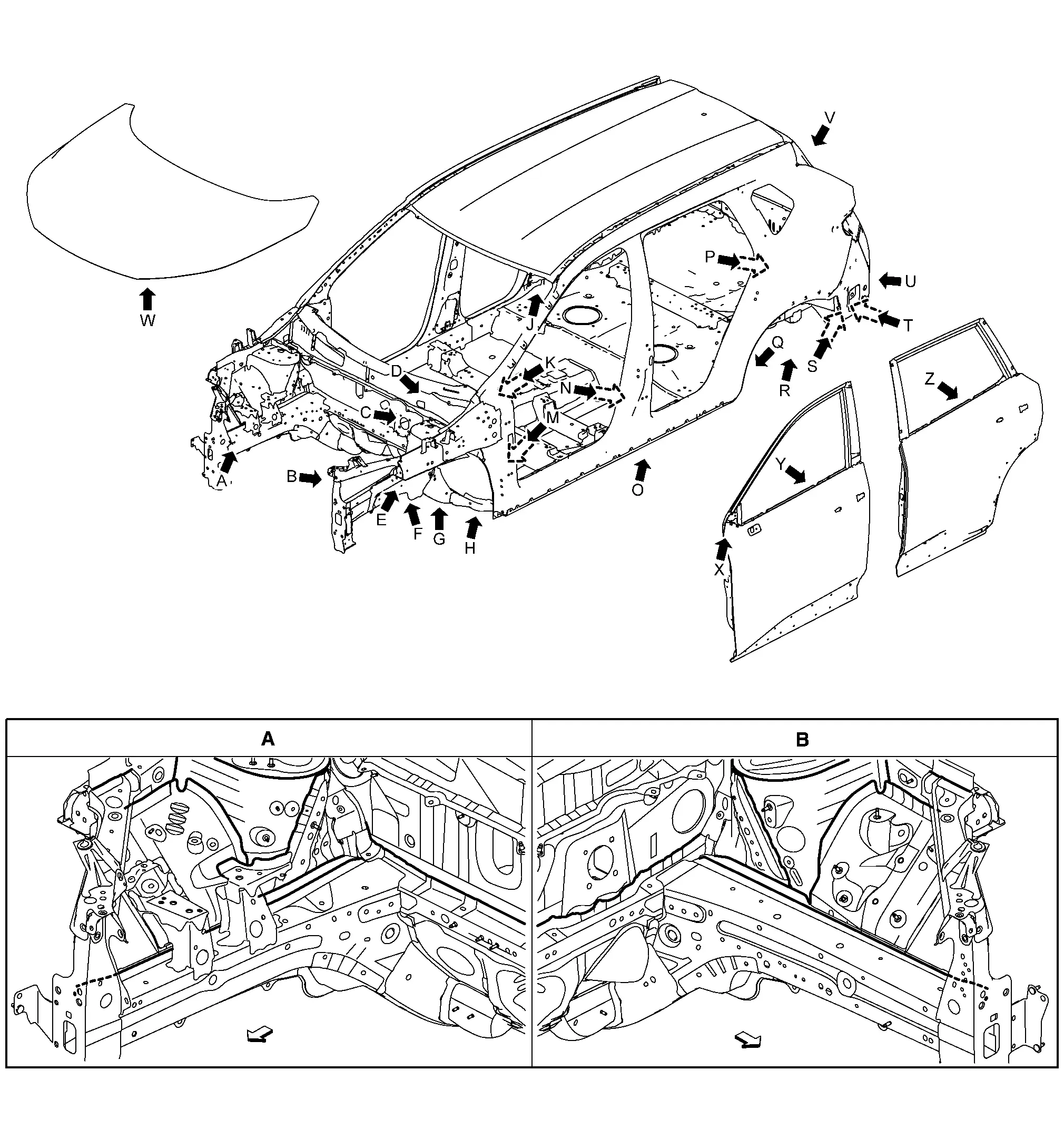

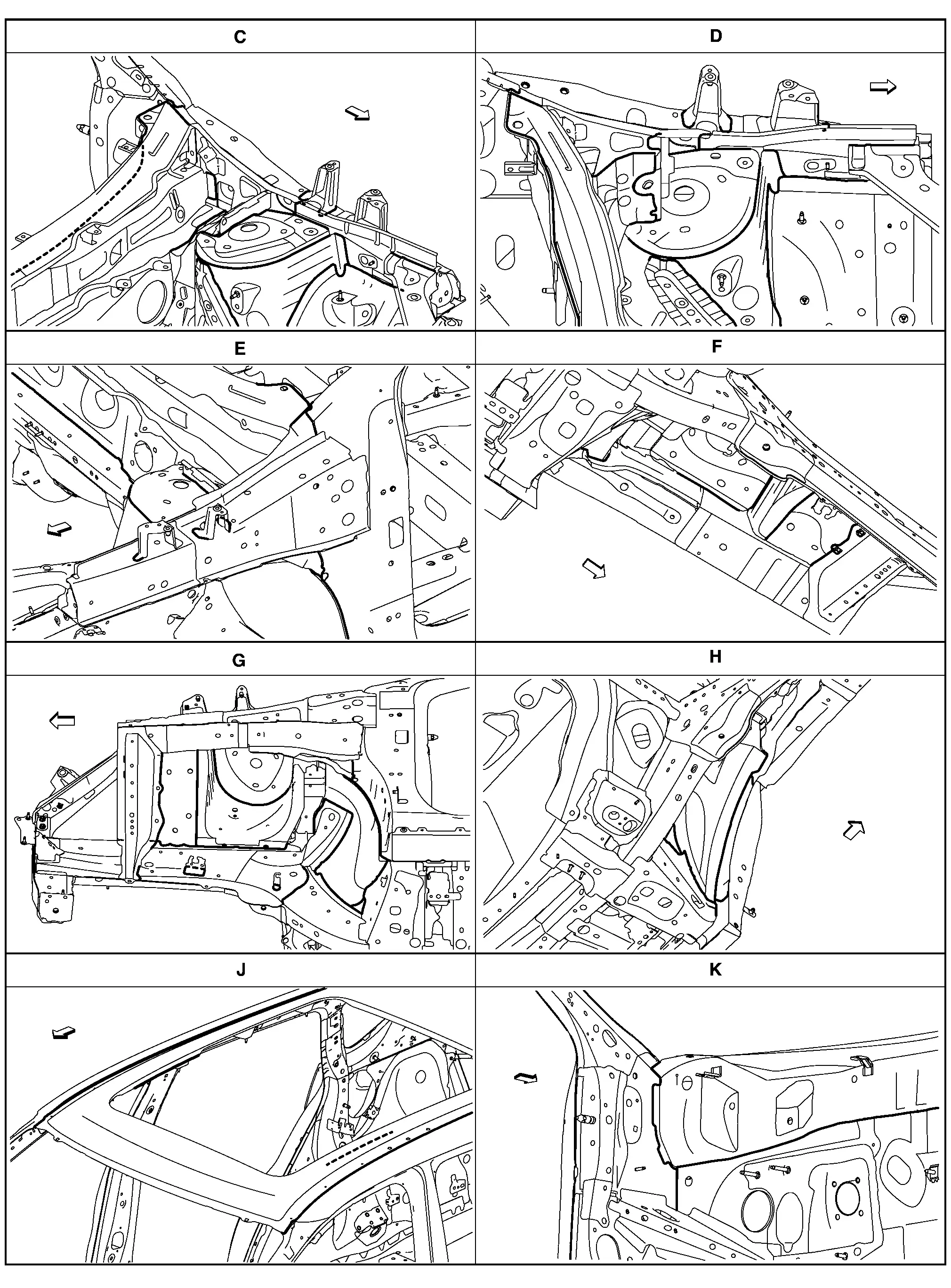

UNDERCOATED AREAS

|

: Sealed portions : Sealed portions |

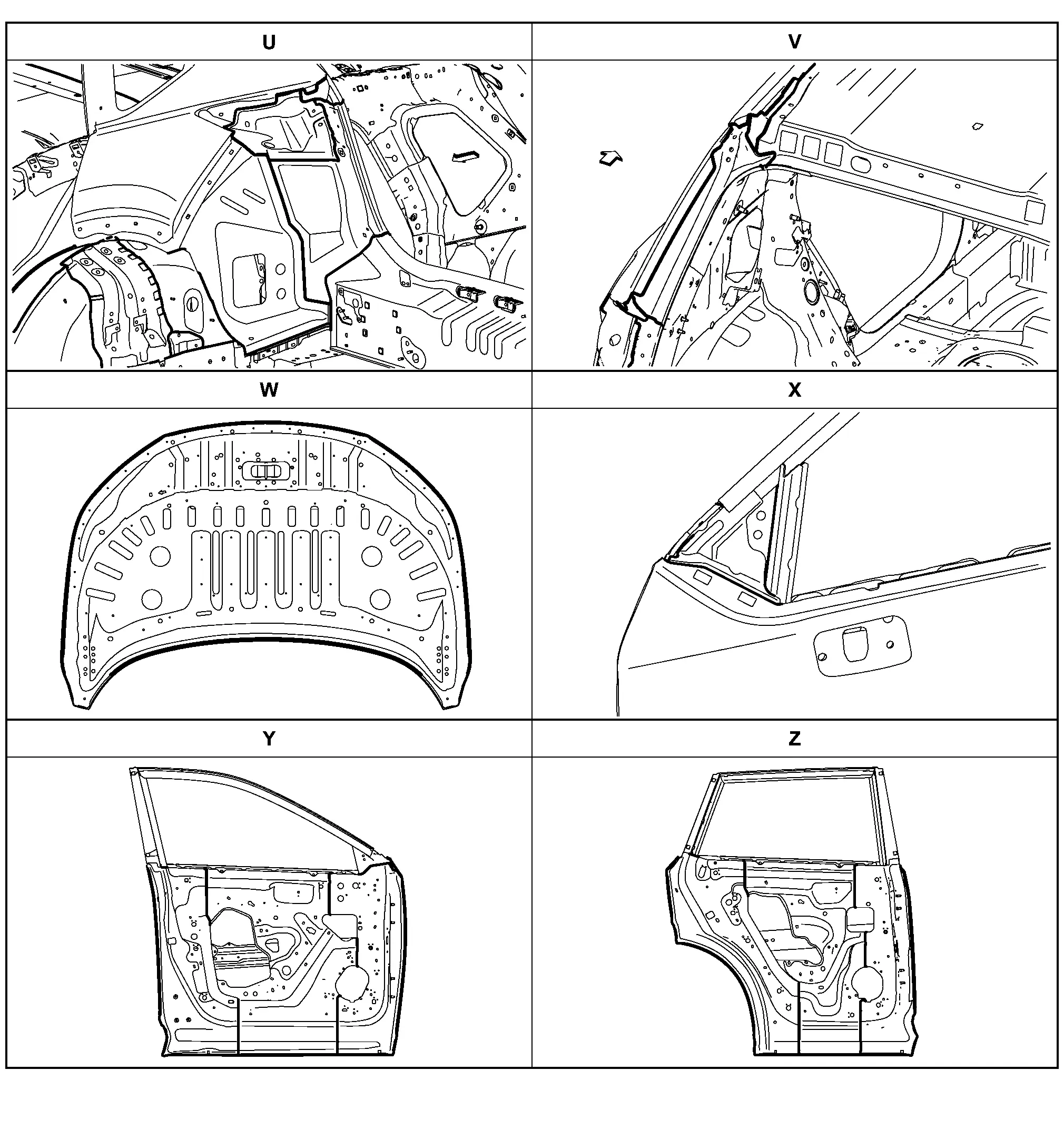

Stone Guard Coat

To prevent damage caused by stones, the lower outer body panel (fender, door, etc.) have an additional layer of Stone Guard Coating over the ED primer coating. When replacing or repairing these panels, apply Stone Guard coating to the same portions as before. Use a coating which is rust preventive, durable, shock-resistant and has a long shelf life.

: Stone guard coated portions : Stone guard coated portions |

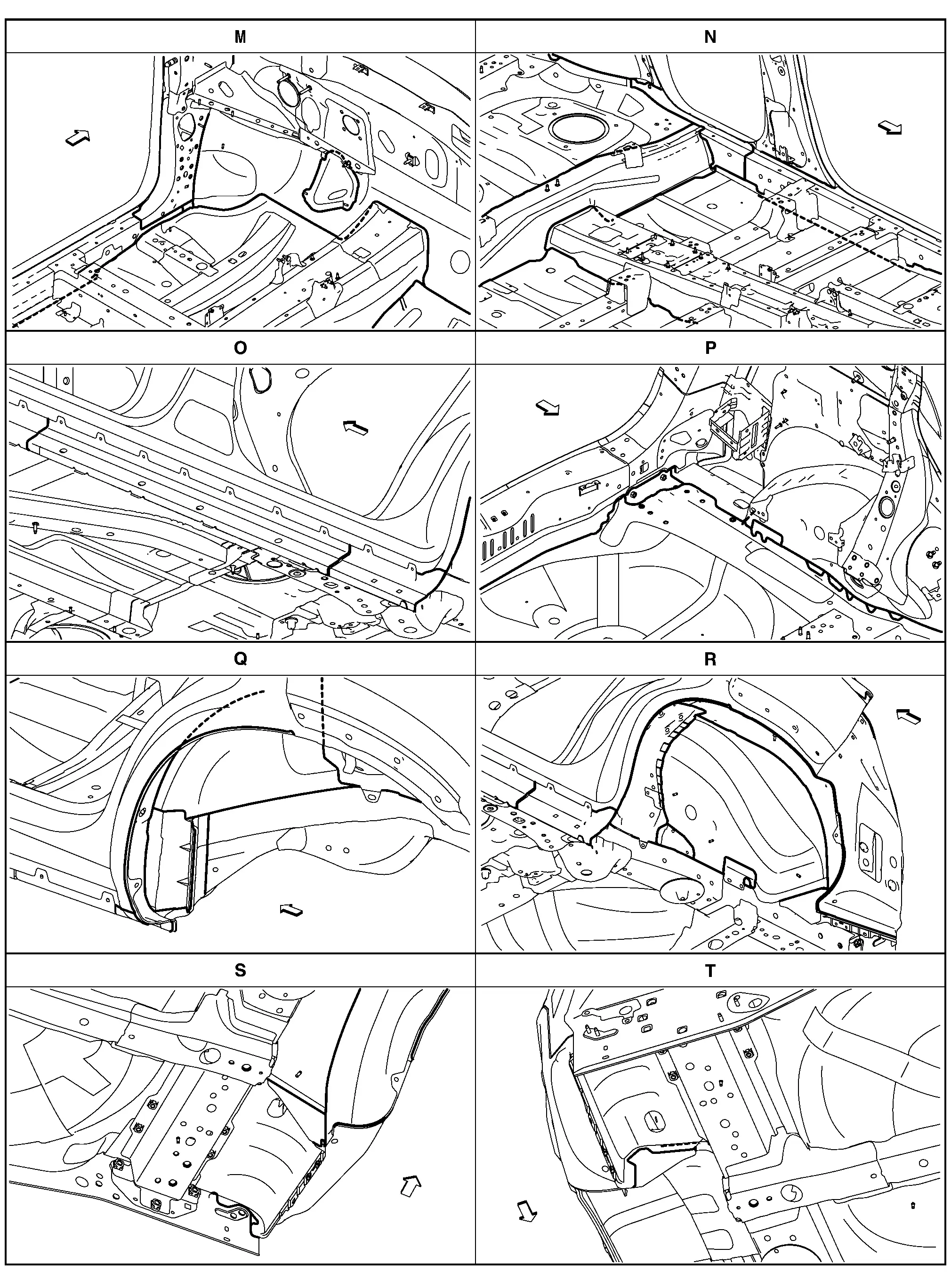

Body Sealing

The following figure shows the areas that are sealed at the factory. Sealant that is applied to these areas should be smooth and free from cuts or gaps. Care should be taken not to apply an excess amount of sealant and not to allow other unaffected parts to come into contact with the sealant.

|

: Sealed portions : Sealed portions |

|

: Sealed portions : Sealed portions |

|

: Sealed portions : Sealed portions |

|

: Sealed portions : Sealed portions |

Other materials:

ContrÃīle dynamique

Informations de base

Le contrÃīle dynamique du Nissan Rogue est un module ÃĐlectronique avancÃĐ regroupant plusieurs fonctions destinÃĐes à amÃĐliorer la stabilitÃĐ, le confort et la tenue de route.

SystÃĻme de contrÃīle en virage intelligent

ContrÃīle actif de suspension (selon lâÃĐquipem ...

Removal and Installation. Sonar Control Unit

Removal and Installation

REMOVALCAUTION:

When replacing the sonar control unit, perform âADDITIONAL SERVICE WHEN REPLACING SONAR CONTROL UNITâ. Refer to Description.

Remove the luggage rear plate. Refer to Removal and Installation.

Disconnect the harness connector.

Press the mounting pawls ...

Ecu Diagnosis Information. Automatic Back Door Control Unit

Reference Value

VALUES ON THE DIAGNOSIS TOOLNOTE:

The following table includes information (items)

inapplicable to this Nissan Ariya vehicle. For information (items)

applicable to this vehicle, refer to CONSULT display items.

CONSULT MONITOR ITEM Monitor Item Condition Value/Status

Autom ...

: Nissan Ariya Vehicle front

: Nissan Ariya Vehicle front