Nissan Rogue Service Manual: Component parts

Component Parts Location

ENGINE ROOM COMPARTMENT

| No. | Component | Function |

| 1 | IPDM E/R |

|

| 2 | Mass air flow sensor (with intake air temperature sensor) | EC-21, "Mass Air Flow Sensor (With Intake Air Temperature Sensor)" |

| 3 | Electric throttle control actuator (with built in throttle position sensor and throttle control motor) | EC-19, "Electric Throttle Control Actuator" |

| 4 | EVAP canister purge volume control solenoid valve | EC-27, "EVAP Canister Purge Volume Control Solenoid Valve" |

| 5 | Intake manifold runner control valve actuator | EC-24, "Intake Manifold Runner Control Valve" |

| 6 | Refrigerant pressure sensor | EC-28, "Refrigerant Pressure Sensor" |

| 7 | EVAP service port | When perform the EVAP leak check, positive pressure is

delivered to the EVAP system through the EVAP service

port.

Refer to EC-496, "Inspection". |

| 8 | Transmission range switch |

|

| 9 | ECM | EC-18, "ECM" |

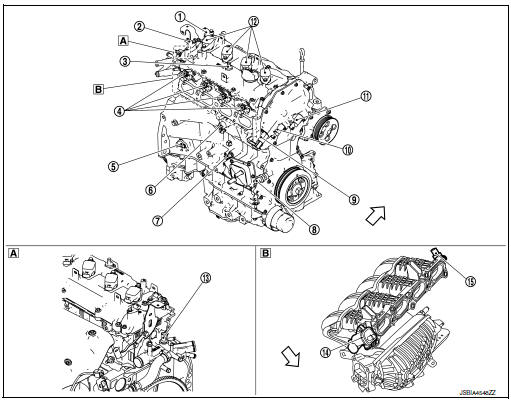

ENGINE COMPARTMENT

A Engine rear side

B Intake side

: Vehicle front

: Vehicle front

| No. | Component | Function |

| 1 | Exhaust valve timing control position sensor | EC-23, "Exhaust Valve Timing Control Position Sensor" |

| 2 | Camshaft position sensor (PHASE) | EC-22, "Camshaft Position Sensor (PHASE)" |

| 3 | PCV valve | The positive crankcase ventilation (PCV) valve is provided to conduct crankcase blow-by gas to the intake manifold. |

| 4 | Fuel injector | EC-20, "Fuel Injector" |

| 5 | Crankshaft position sensor (POS) | EC-22, "Crankshaft Position Sensor (POS)" |

| 6 | Knock sensor | EC-25, "Knock Sensor" |

| 7 | Engine oil temperature sensor | EC-26, "Engine Oil Temperature Sensor" |

| 8 | Engine oil pressure sensor | EC-26, "Engine Oil Pressure Sensor" |

| 9 | Intake valve timing intermediate lock control solenoid valve | EC-23, "Intake Valve Timing Intermediate Lock Control Solenoid Valve" |

| 10 | Intake valve timing control solenoid valve | EC-23, "Intake Valve Timing Control Solenoid Valve" |

| 11 | Exhaust valve timing control solenoid valve | EC-24, "Exhaust Valve Timing Control Solenoid Valve" |

| 12 | Ignition coil (with power transistor) | EC-19, "Ignition Coil With Power Transistor" |

| 13 | Engine coolant temperature sensor | EC-21, "Engine Coolant Temperature Sensor" |

| 14 | Intake manifold runner control valve position sensor | EC-24, "Intake Manifold Runner Control Valve" |

| 15 | Intake manifold runner control valve actuator |

EXHAUST COMPARTMENT

A To engine assembly

| No. | Component | Function |

| 1 | Air fuel ratio (A/F) sensor 1 | EC-24, "Air Fuel Ratio (A/F) Sensor 1" |

| 2 | Heated oxygen sensor 2 | EC-25, "Heated Oxygen Sensor 2" |

BODY COMPARTMENT

A Instrument panel area

B Periphery of pedals

C Inside fuel tank area

D Behind fuel tank

: Vehicle front

: Vehicle front

| No. | Component | Function | |

| 1 | Combination meter | Malfunction indicator lamp (MIL) | EC-49, "WARNING/INDICATOR/CHIME LIST : Malfunction Indicator Lamp (MIL)" |

| Information display | EC-28, "Information Display" | ||

| 2 | ASCD steering switch | EC-28, "ASCD Steering Switch" | |

| 3 | Stop lamp switch | EC-28, "Stop Lamp Switch & Brake Pedal Position Switch" | |

| 4 | Brake pedal position switch | ||

| 5 | Accelerator pedal position sensor | EC-18, "Accelerator Pedal Position Sensor" | |

| 6 | Fuel level sensor unit and fuel pump | EC-20, "Fuel Level Sensor Unit and Fuel Pump" | |

| 7 | Fuel tank temperature sensor | EC-20, "Fuel Tank Temperature Sensor" | |

| 8 | EVAP control system pressure sensor | EC-27, "EVAP Control System Pressure Sensor" | |

| 9 | EVAP canister vent control valve | EC-27, "EVAP Canister Vent Control Valve" | |

| 10 | EVAP canister | EC-27, "EVAP Canister" | |

ECM

The ECM consists of a microcomputer and connectors for signal input and output and for power supply. The ECM controls the engine.

Accelerator Pedal Position Sensor

The accelerator pedal position sensor is installed on the upper end of the accelerator pedal assembly. The sensor detects the accelerator position and sends a signal to the ECM.

Accelerator pedal position sensor has two sensors. These sensors are a kind of potentiometers which transform the accelerator pedal position into output voltage, and emit the voltage signal to the ECM.

In addition, these sensors detect the opening and closing speed of the accelerator pedal and feed the voltage signals to the ECM. The ECM judges the current opening angle of the accelerator pedal from these signals and controls the throttle control motor based on these signals.

Idle position of the accelerator pedal is determined by the ECM receiving the signal from the accelerator pedal position sensor. The ECM uses this signal for the engine operation such as fuel cut.

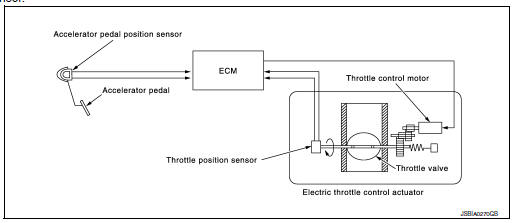

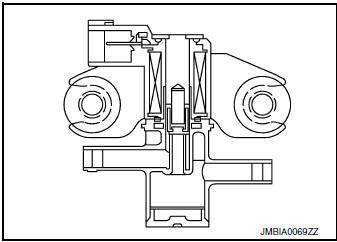

Electric Throttle Control Actuator

Electric throttle control actuator consists of throttle body, throttle valve, throttle control motor and throttle position sensor.

THROTTLE CONTROL MOTOR RELAY

Power supply for the throttle control motor is provided to the ECM via throttle control motor relay. The throttle control motor relay is ON/OFF controlled by the ECM. When the ignition switch is turned ON, the ECM sends an ON signal to throttle control motor relay and battery voltage is provided to the ECM. When the ignition switch is turned OFF, the ECM sends an OFF signal to throttle control motor relay and battery voltage is not provided to the ECM.

THROTTLE CONTROL MOTOR

The throttle control motor is operated by the ECM and it opens and closes the throttle valve.

The current opening angle of the throttle valve is detected by the throttle position sensor and it provides feedback to the ECM to control the throttle control motor to make the throttle valve opening angle properly in response to driving condition.

THROTTLE POSITION SENSOR

The throttle position sensor responds to the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a kind of potentiometers which transform the throttle valve position into output voltage, and emit the voltage signal to the ECM. In addition, these sensors detect the opening and closing speed of the throttle valve and feed the voltage signals to the ECM. The ECM judges the current opening angle of the throttle valve from these signals and the ECM controls the throttle control motor to make the throttle valve opening angle properly in response to driving condition.

Ignition Coil With Power Transistor

The ignition signal from the ECM is sent to and amplified by the power transistor. The power transistor turns ON and OFF the ignition coil primary circuit. This ON/OFF operation induces the proper high voltage in the coil secondary circuit.

Fuel Injector

The fuel injector is a small, precise solenoid valve. When the ECM supplies a ground to the fuel injector circuit, the coil in the fuel injector is energized. The energized coil pulls the ball valve back and allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the fuel injector remains open. The ECM controls the injection pulse duration based on engine fuel needs.

Fuel Level Sensor Unit and Fuel Pump

FUEL PUMP

The ECM activates the fuel pump for 1 second after the ignition switch is turned ON to improve engine start ability. If the ECM receives a engine speed signal from the camshaft position sensor (PHASE), it knows that the engine is rotating, and causes the pump to operate. If the engine speed signal is not received when the ignition switch is ON, the engine stalls. The ECM stops pump operation and prevents battery discharging, thereby improving safety. The ECM does not directly drive the fuel pump. It sends the control signal to the fuel pump control module, which in turn controls the fuel pump.

| Condition | Fuel pump opera |

| Ignition switch is turned to ON. | Operates for 1 second. |

| Engine running and cranking | Operates. |

| When engine is stopped | Stops in 1.5 seconds. |

| Except as shown above | Stops |

FUEL LEVEL SENSOR

The fuel level sensor is mounted in the fuel level sensor unit.

The sensor detects a fuel level in the fuel tank and transmits a signal to the combination meter. The combination meter sends the fuel level sensor signal to the ECM via the CAN communication line.

It consists of two parts, one is mechanical float and the other is variable resistor. Fuel level sensor output voltage changes depending on the movement of the fuel mechanical float.

Fuel Tank Temperature Sensor

The fuel tank temperature sensor is used to detect the fuel temperature inside the fuel tank. The sensor modifies a voltage signal from the ECM. The modified signal returns to the ECM as the fuel temperature input. The sensor uses a thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor decreases as temperature increases.

*: These data are reference values and are measured between ECM terminals.

Mass Air Flow Sensor (With Intake Air Temperature Sensor)

MASS AIR FLOW SENSOR

The mass air flow sensor 1 is placed in the stream of intake air. It measures the intake flow rate by measuring a part of the entire intake flow. The MAF sensor controls the temperature of the heater in sensing element to a certain amount. The temperature distribution around the heater changes according to the increase in intake air volume. The change is detected by a thermistor and the air volume data is sent to ECM by the MAF sensor.

INTAKE AIR TEMPERATURE SENSOR

The intake air temperature sensor is built-into mass air flow sensor. The sensor detects intake air temperature and transmits a signal to the ECM.

The temperature sensing unit uses a thermistor which is sensitive to the change in temperature.

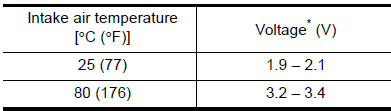

<Reference data>

*: These data are reference values on the diagnosis tool.

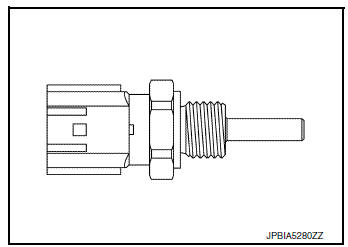

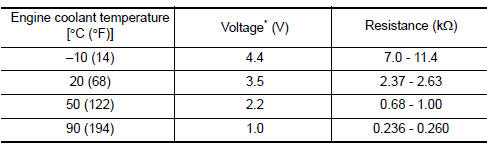

Engine Coolant Temperature Sensor

The engine coolant temperature sensor is used to detect the engine coolant temperature. The sensor modifies a voltage signal from the ECM. The modified signal returns to the ECM as the engine coolant temperature input. The sensor uses a thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor decreases as temperature increases.

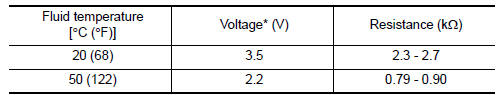

<Reference data>

*: These data are reference values and are measured between ECM terminals.

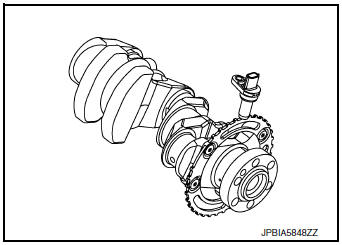

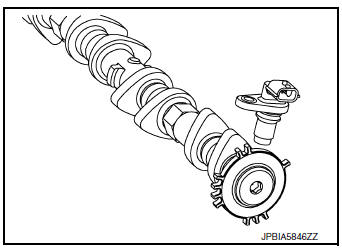

Crankshaft Position Sensor (POS)

The crankshaft position sensor (POS) is located on the oil pan facing the gear teeth (cogs) of the signal plate. It detects the fluctuation of the engine revolution.

The sensor consists of a permanent magnet and Hall IC.

When the engine is running, the high and low parts of the teeth cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to change.

Due to the changing magnetic field, the voltage from the sensor changes.

The ECM receives the voltage signal and detects the fluctuation of the engine revolution.

ECM receives the signals as shown in the figure.

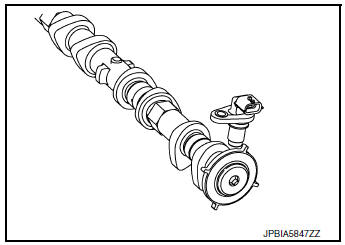

Camshaft Position Sensor (PHASE)

The camshaft position sensor (PHASE) senses the retraction of intake camshaft to identify a particular cylinder. The camshaft position sensor (PHASE) senses the piston position.

When the crankshaft position sensor (POS) system becomes inoperative, the camshaft position sensor (PHASE) provides various controls of engine parts instead, utilizing timing of cylinder identification signals.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to change.

Due to the changing magnetic field, the voltage from the sensor changes.

ECM receives the signals as shown in the figure.

Intake Valve Timing Control Solenoid Valve

Intake valve timing control solenoid valve is activated by ON/OFF pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil amount and direction of flow through intake valve timing control unit or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve stops oil pressure flow to fix the intake valve angle at the control position.

Intake Valve Timing Intermediate Lock Control Solenoid Valve

Intake valve timing intermediate lock control solenoid valve is activated by ON/OFF signals from the ECM.

The intake valve timing intermediate lock control solenoid valve opens/closes the path of oil pressure acting on the lock key in the camshaft sprocket (INT).

- When the solenoid valve becomes ON, oil pressure to the lock key is trained to perform intermediate lock.

- When the solenoid valve becomes OFF, oil pressure is acted on the lock key to release the intermediate lock.

Exhaust Valve Timing Control Position Sensor

Exhaust valve timing control position sensor detects the protrusion of the signal plate installed to the exhaust camshaft front end.

This sensor signal is used for sensing a position of the exhaust camshaft.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to change.

Due to the changing magnetic field, the voltage from the sensor changes.

Exhaust Valve Timing Control Solenoid Valve

Exhaust valve timing control solenoid valve is activated by ON/OFF pulse duty (ratio) signals from the ECM.

The exhaust valve timing control solenoid valve changes the oil amount and direction of flow through exhaust valve timing control unit or stops oil flow.

The longer pulse width retards valve angle.

The shorter pulse width advances valve angle.

When ON and OFF pulse widths become equal, the solenoid valve stops oil pressure flow to fix the exhaust valve angle at the control position.

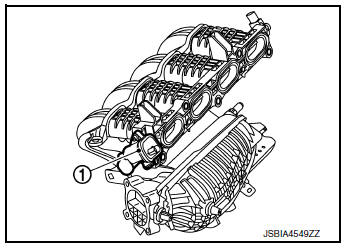

Intake Manifold Runner Control Valve

Intake manifold runner control valve 1 is integrated to intake manifold.

Intake manifold runner control valve is mounted each port of the intake manifold and opened/closed by the intake manifold runner control valve motor.

ECM controls the intake manifold runner control valve motor, according to signals of engine speed, water temperature, etc. and stabilizes combustion by generating a strong tunmble flow.

INTAKE MANIFOLD RUNNER CONTROL VALVE MOTOR

Intake manifold runner control valve motor is connected to the rear end of the valve shaft.

The motor opens or closes the valve by the output signal of the ECM.

INTAKE MANIFOLD RUNNER CONTROL VALVE POSITION SENSOR

Intake manifold runner control valve position sensor is connected to the front end of the valve shaft.

The sensor consists of valiable resister. It senses the valve shaft movement and feeds the voltage signals to the ECM.

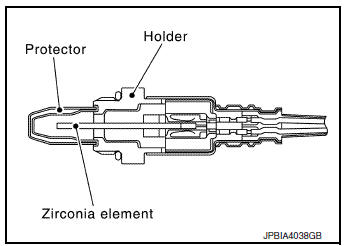

Air Fuel Ratio (A/F) Sensor 1

The sensor element of the A/F sensor 1 is composed an electrode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement λ = 1, but also in the lean and rich range. Together with its control electronics, the sensor outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at the sensor cell. An electrode layer is applied voltage, and this current relative oxygen density in lean. Also this current relative hydrocarbon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this electrode layer of current. In addition, a heater is integrated in the sensor to ensure the required operating temperature of approximately 760°C (1,400°F).

A/F SENSOR 1 HEATER

A/F sensor 1 heater is integrated in the sensor.

The ECM performs ON/OFF duty control of the A/F sensor 1 heater corresponding to the engine operating condition to keep the temperature of A/F sensor 1 element within the specified range.

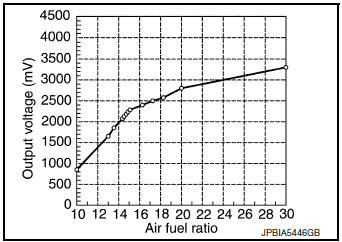

Heated Oxygen Sensor 2

The heated oxygen sensor 2, after three way catalyst (manifold), monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1 are shifted, the air fuel ratio is controlled to stoichiometric, by the signal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates voltage from approximately 1 V in richer conditions to 0 V in leaner conditions.

Under normal conditions the heated oxygen sensor 2 is not used for engine control operation.

HEATED OXYGEN SENSOR 2 HEATER

Heated oxygen sensor 2 heater is integrated in the sensor.

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater corresponding to the engine speed, amount of intake air and engine coolant temperature.

| Engine speed | Heated oxygen sensor 2 heater |

| Above 3,600 rpm | OFF |

Below 3,600 rpm after the following conditions are met.

|

ON |

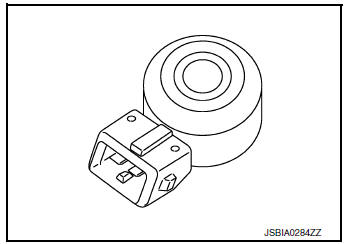

Knock Sensor

The knock sensor is attached to the cylinder block. It senses engine knocking using a piezoelectric element. A knocking vibration from the cylinder block is sensed as vibrational pressure. This pressure is converted into a voltage signal and sent to the ECM.

Engine Oil Pressure Sensor

The engine oil pressure (EOP) sensor is detects engine oil pressure and transmits a voltage signal to the ECM.

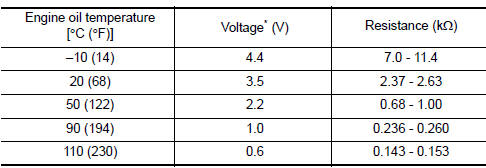

Engine Oil Temperature Sensor

The engine oil temperature sensor is used to detect the engine oil temperature. The sensor modifies a voltage signal from the ECM.

The modified signal returns to the ECM as the engine oil temperature input. The sensor uses a thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor decreases as temperature increases.

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Cooling Fan

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant pressure, and air conditioner ON signal. The control system has 4-step control [HIGH/MIDDLE/LOW/OFF].

Cooling fan operates at each speed when the current flows in the cooling fan motor.

Refer to EC-46, "COOLING FAN CONTROL : System Description" for cooling fan operation.

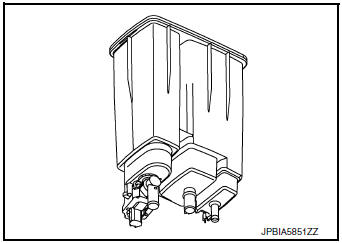

EVAP Canister

EVAP canister stores the generated fuel vapors in the sealed fuel tank to activated charcoals of EVAP canister when the engine is not operating or when refueling to the fuel tank.

EVAP Canister Purge Volume Control Solenoid Valve

The EVAP canister purge volume control solenoid valve uses a ON/ OFF duty to control the flow rate of fuel vapor from the EVAP canister.

The EVAP canister purge volume control solenoid valve is moved by ON/OFF pulses from the ECM. The longer the ON pulse, the greater the amount of fuel vapor that will flow through the valve.

EVAP Canister Vent Control Valve

The EVAP canister vent control valve is located on the EVAP canister and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal the vent is necessary for the on board diagnosis of other evaporative emission control system components.

This solenoid valve is used only for diagnosis, and usually remains opened.

When the vent is closed, under normal purge conditions, the evaporative emission control system is depressurized and allows “EVAP Control System” diagnosis.

EVAP Control System Pressure Sensor

The EVAP control system pressure sensor detects pressure in the purge line. The sensor output voltage to the ECM increases as pressure increases.

Refrigerant Pressure Sensor

The refrigerant pressure sensor is installed at the condenser of the air conditioner system. The sensor uses an electrostatic volume pressure transducer to convert refrigerant pressure to voltage. The voltage signal is sent to ECM, and ECM controls cooling fan system.

Stop Lamp Switch & Brake Pedal Position Switch

Stop lamp switch and brake pedal position switch are installed to brake pedal bracket.

ECM detects the state of the brake pedal by those two types of input (ON/OFF signal).

| Brake pedal | Brake pedal position switch | Stop lamp switch |

| Released | ON | OFF |

| Depressed | OFF | ON |

ASCD Steering Switch

ASCD steering switch has variant values of electrical resistance for each button. ECM reads voltage variation of switch, and determines which button is operated.

Information Display

The operation mode of the ASCD is indicated on the information display in the combination meter.

ECM transmits the status signal to the combination meter via CAN communication according to ASCD operation.

Structure and operation

Structure and operation

Positive Crankcase Ventilation

This system returns blow-by gas to the intake manifold.

The positive crankcase ventilation (PCV) valve is provided to conduct crankcase

blow-by gas to the inta ...

Other materials:

Symptom diagnosis

HEATER AND AIR CONDITIONING SYSTEM CONTROL SYMPTOMS

Diagnosis Chart By Symptom

NOTE:

Perform the self-diagnoses with CONSULT before performing the symptom diagnosis.

If DTC is detected, perform

the corresponding diagnosis.

Symptom

Corresponding malfunction part

Refere ...

Symptom diagnosi

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH troubleshooting - engine noise

Valve mechanism

Intake and exhaust valve

Water pump

Timing chain

Drive belt

Rotation mechanism

Tappet noise

Camshaft bearing noise

&nb ...

VDC off switch

Component Function Check

1.CHECK VDC OFF SWITCH OPERATION

Check that VDC OFF indicator lamp in combination meter turns ON/OFF when VDC

OFF switch is operated.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to BRC-117, "Diagnosis Procedure".

Diagn ...