Nissan Rogue Service Manual: Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

With CONSULT

With CONSULT

- Turn ignition switch ON.

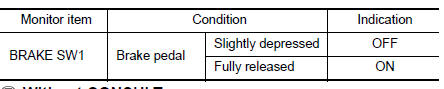

- Select “BRAKE SW1” in “DATA MONITOR” mode with CONSULT.

- Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT

Without CONSULT

- Turn ignition switch ON.

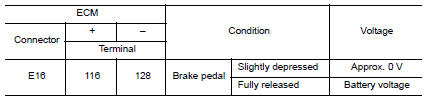

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-455, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect brake pedal position switch harness connector.

- Turn ignition switch ON.

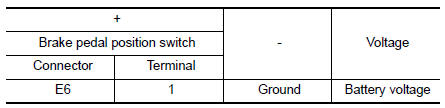

- Check the voltage between brake pedal position switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect fuse block (J/B) harness connector.

- Check the continuity between brake pedal position switch harness connector and fuse block (J/B) harness connector.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

3.CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

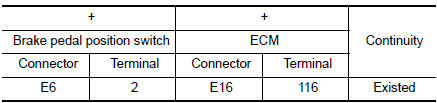

- Check the continuity between brake pedal position switch harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK BRAKE PEDAL POSITION SWITCH

Check brake pedal position switch. Refer to EC-456, "Component Inspection (Brake Pedal Position Switch)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-41, "Intermittent Incident".

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View".

Component Inspection (Brake Pedal Position Switch)

1.CHECK BRAKE PEDAL POSITION SWITCH-1

- Turn ignition switch OFF.

- Disconnect brake pedal position harness connector.

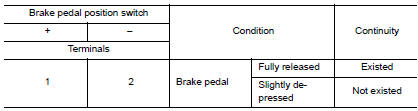

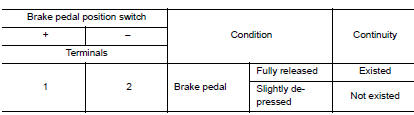

- Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH-2

- Adjust brake pedal position switch installation. Refer to BR-15, "Adjustment".

- Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View".

P2610 ECM internal timer

P2610 ECM internal timer

Description

This ECM contains a timer and measures time between an ignition switch OFF

and the next ignition switch

ON. This enables the judging of the state of engine cooling at an engine start.

...

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

Turn ignition switch ON.

Perform “COOLING FAN (DUAL)” in “ACTIVE TEST” mode of “IPDM E/R”

using CO ...

Other materials:

P0456 EVAP control system

DTC Description

DTC DETECTION LOGIC

This diagnosis detects leaks in the EVAP line between fuel tank and EVAP

canister purge volume control solenoid

valve, using the negative pressure caused by decrease of fuel temperature in the

fuel tank after turning

ignition switch OFF.

If ECM judges t ...

P0606 ECM

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0606

CONTROL MODULE

(Control module processor)

Malfunction in ECM processor

POSSIBLE CAUSE

ECM

FAIL-SAFE

Not applicable

DTC CONFIRMATION ...

U0101 CAN comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...