Nissan Rogue Service Manual: Charging system preliminary inspection

Diagnosis Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair battery terminal connection. Confirm repair by performing complete Charging system test using EXP-800 NI or GR8-1200 NI (if available). Refer to the applicable Instruction Manual for proper testing procedures.

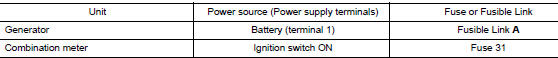

2.CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the blown fuse or fusible link after repairing the affected circuit.

3.CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to MA-13, "DRIVE BELTS : Tension Adjustment".

Is the inspection result normal? YES >> Inspection End.

NO >> Repair as needed.

Power generation voltage variable control system operation

inspection

Power generation voltage variable control system operation

inspection

Diagnosis Procedure

Regarding Wiring Diagram information. Refer to CHG-7, "Wiring Diagram".

CAUTION:

When performing this inspection, always use a charged battery that has completed

the ...

Other materials:

Preparation

Special Service Tool

The actual shape of the tool may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

KV991J0080

(J-45741)

ABS active wheel sensor tester

Checking operation of ABS active wheel sensors

Comm ...

How to erase permanent DTC

Description

OUTLINE

When a DTC is stored in ECM

When a DTC is stored in ECM and MIL is ON, a permanent DTC is erased with MIL

shutoff if the same malfunction

is not detected after performing the driving pattern for MIL shutoff three times

in a raw.

*1: When the same malfunction is detecte ...

Interior room lamp power supply circuit

Description

Provides the interior room lamp power supply. Also cuts the power supply when

the interior room lamp battery

saver is activating.

Component Function Check

1.CHECK INTERIOR ROOM LAMP POWER SUPPLY FUNCTION

CONSULT ACTIVE TEST

Turn power switch ON.

Turn each interio ...