Nissan Rogue Service Manual: Oil cooler

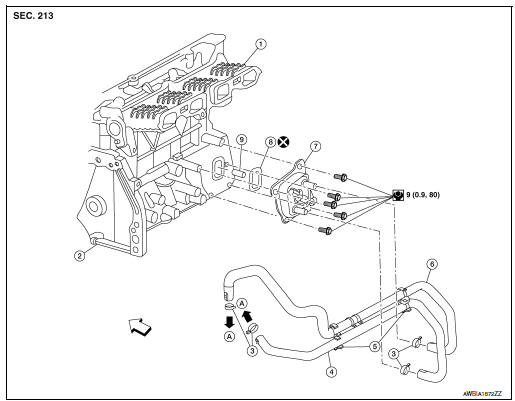

Exploded View

- Intake manifold

- Cylinder block

- Clamp

- Water hose

- Water hose clip

- Water hose

- Oil cooler

- Gasket

- Oil cooler relief valve

Front

Front

Removal and Installation

WARNING: Be careful not to burn yourself, as engine oil and engine coolant may be hot.

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Drain engine coolant. Refer to CO-8, "Draining".

- Remove front air spoiler (RH). Refer to EXT-16, "Exploded View"

- Remove fender protector (RH). Refer to EXT-28, "FENDER PROTECTOR : Exploded View".

- Disconnect water hoses from the oil cooler.

- Remove oil cooler bolts in reverse numerical order.

- Remove oil cooler.

CAUTION:

- Be careful not to get burned when engine and engine oil may be hot.

- When removing, prepare a shop cloth to absorb any engine oil leaks or spillage.

- Completely wipe off any engine oil that adheres to engine and vehicle.

- Remove relief valve and O-ring, (if necessary).

INSTALLATION

Installation is in the reverse order of removal.

- Tighten oil cooler to specification as shown.

CAUTION:

- Do not reuse O-ring.

- Ensure O-ring and oil cooler sealing surface is free from dust, flaws, or deformation.

- Ensure water hose assembly is installed without kinks or areas of collapse.

- Replace relief valve, if removed.

Inspection

INSPECTION AFTER REMOVAL

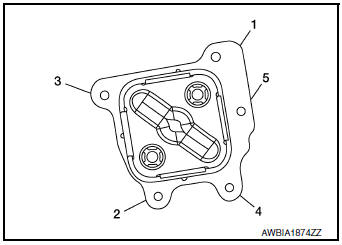

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary, replace oil cooler.

Relief valve

Inspect relief valve for movement, cracks, and breaks by pushing the ball. If replacement is necessary, remove the valve by prying it out using a suitable tool. Install a new valve by tapping it in place.

INSPECTION AFTER INSTALLATION

- Check the engine oil level and the engine coolant level and add engine oil and engine coolant. Refer to LU-7, "Inspection" and CO-8, "Inspection".

- Start the engine, and check that there are no leaks of engine oil or engine coolant.

- Stop the engine and wait for 5 minutes.

- Check the engine oil level and the engine coolant level again. Refer to LU-7, "Inspection" and CO-8, "Inspection".

Oil pump

Oil pump

Exploded View

Front cover (Oil pump body united)

Outer rotor

Inner rotor

Oil pump cover

Regulator valve

Regulator valve spring

Regulator valve plug

CAUTION ...

Other materials:

NISSAN Intelligent Key® (if so equipped)

Replace the battery in the Intelligent Key as follows:

Remove the mechanical key from the Intelligent

Key.

Insert a small screwdriver A into the slit B

of the corner and twist it to separate the

upper part from the lower part. Use a cloth to

protect the casing.

Replace th ...

U0141 lost communication (BCM A)

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

U0141

LOST COMM (BCM A)

(Lost Communication With Body Control Module

A)

When the ignition switch is turned ON, TCM continues no reception of

the ...

Throttle valve closed position learning

Description

Throttle Valve Closed Position Learning is a function of ECM to learn the

fully closed position of the throttle

valve by monitoring the throttle position sensor output signal. It must be

performed each time the harness connector

of the electric throttle control actuator or ECM is ...