Nissan Rogue Service Manual: Oil pump

Exploded View

- Front cover (Oil pump body united)

- Outer rotor

- Inner rotor

- Oil pump cover

- Regulator valve

- Regulator valve spring

- Regulator valve plug

CAUTION: Before assembly, apply new engine oil to the parts as shown above.

Removal and Installation

REMOVAL

Remove front cover. Refer to EM-44, "Exploded View".

NOTE: Oil pump is built into front cover.

INSTALLATION

Installation is in the reverse order of removal.

- When installing, align crankshaft flat faces with inner rotor flat faces.

Disassembly and Assembly

DISASSEMBLY

- Remove bolts and oil pump cover.

- Remove inner rotor and outer rotor from front cover.

- After removing regulator valve plug, remove regulator valve spring and regulator valve.

ASSEMBLY

Assembly is in the reverse order of disassembly.

- Install the inner rotor and outer rotor with the punched marks on the oil pump cover side.

CAUTION: Before assembly apply new engine oil to the parts specified.

Inspection

INSPECTION AFTER DISASSEMBLY

OIL PUMP CLEARANCE

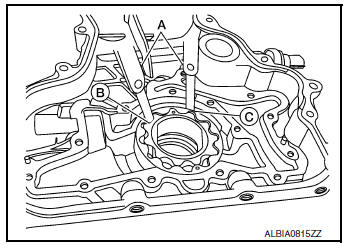

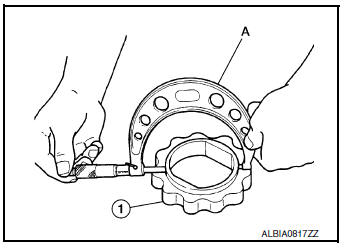

- Measure the clearance using a suitable tool (A).

- Clearance between outer rotor (B) and front cover (C)

Standard : Refer to LU-17, "Oil Pump".

- Tip clearance between inner rotor and outer rotor (B)

Standard : Refer to LU-17, "Oil Pump".

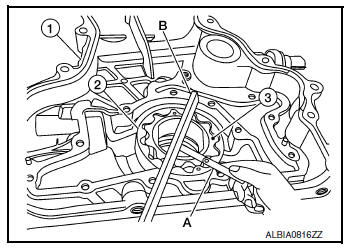

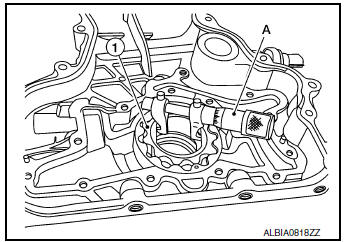

- Measure the clearance using suitable tools (A/B).

- Side clearance between inner rotor (3) and front cover (1)

Standard : Refer to LU-17, "Oil Pump".

- Side clearance between outer rotor (2) and front cover (1)

Standard : Refer to LU-17, "Oil Pump".

- Calculate the clearance between oil pump inner rotor and oil pump body as follows:

- Measure the outer diameter of protruded portion of inner rotor (1) using a suitable tool (A).

- Measure the inner diameter of inner rotor (1) using a suitable tool (A).

- (Clearance) = (Inner rotor inner diameter) – (Oil pump inner rotor outer diameter)

Standard : Refer to LU-17, "Oil Pump".

- If measured/calculated values are out of the standard, replace front cover and oil pump assembly.

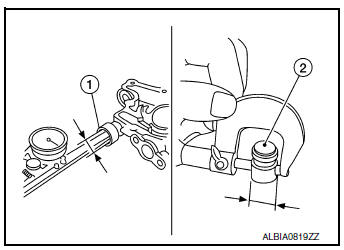

REGULATOR VALVE TO OIL PUMP COVER CLEARANCE

- (Clearance) = (Regulator valve hole (1) diameter) – (Regulator valve (2) outer diameter)

Standard : Refer to LU-17, "Oil Pump".

- If the calculated value is out of the standard, replace front cover and oil pump assembly.

CAUTION:

- Coat regulator valve with engine oil.

- Make sure that it falls smoothly into valve hole by its own weight.

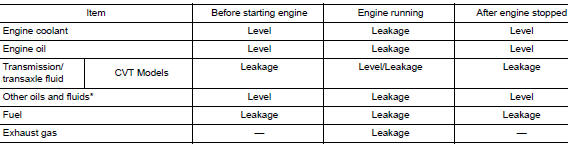

INSPECTION AFTER INSTALLATION

- Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required quantity, fill to the specified level. Refer to MA-11, "Fluids and Lubricants".

- Use procedure below to check for fuel leaks.

- Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks at connection points.

- Start engine. With engine speed increased, check again for fuel leaks at connection points.

- Run engine to check for unusual noise and vibration.

NOTE: If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after hydraulic pressure rises.

- Warm up engine thoroughly to make sure there are no leaks of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

- Bleed air from passages in lines and hoses, such as in cooling system.

- After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to specified level, if necessary.

- Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Oil cooler

Oil cooler

Exploded View

Intake manifold

Cylinder block

Clamp

Water hose

Water hose clip

Water hose

Oil cooler

Gasket

Oil cooler relief val ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Oil Pressure

*: Engine oil temperature at 80°C (176°F)

Oil Pump

Relief Valve

Oil Capacity

...

Other materials:

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2. CONFIRM THE SYMPTOM

Check the malfunction on the ...

CVT oil warmer

Exploded View

Transaxle assembly

CVT oil warmer

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur

from high pressure

engine coolant escaping from the radiator. Wrap a thick cloth around ...

Corrosion protection

Description

To provide improved corrosion prevention, the following anti-corrosive

measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is

necessary to use the same anti-corrosive

measures.

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL) ...