Nissan Rogue Service Manual: Meter control switch signal circuit

Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-32, "Wiring Diagram".

1.CHECK METER CONTROL SWITCH SIGNAL

- Turn ignition switch ON.

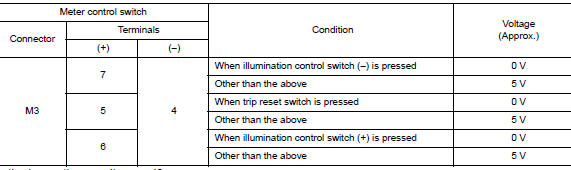

- Check voltage between the following terminals of the meter control switch harness connector M3.

Is the inspection result normal? YES >> Inspection End.

NO >> GO TO 2.

2.CHECK METER CONTROL SWITCH HARNESS

- Turn ignition switch OFF.

- Disconnect combination meter harness connector M77 and meter control switch harness connector M3.

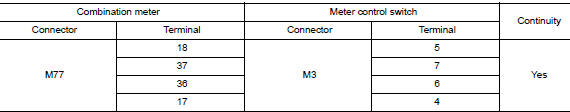

- Check continuity between combination meter harness connector M77 and meter control switch harness connector M3.

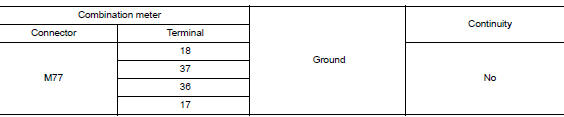

- Check continuity between combination meter harness connector and ground.

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace harness or connectors.

Component Inspection

1.CHECK METER CONTROL SWITCH

- Turn ignition switch OFF.

- Disconnect meter control switch connector.

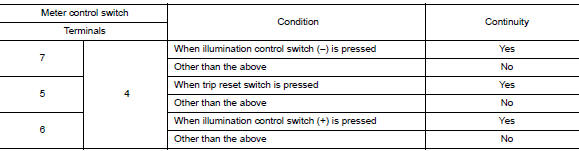

- Check meter control switch.

Is the inspection result normal? YES >> Inspection End.

NO >> Replace meter control switch. Refer to MWI-83, "Removal and Installation".

Ambient sensor signal circuit

Ambient sensor signal circuit

Description

It detects outside air temperature and converts it into a resistance value

which is then input into the combination

meter.

Diagnosis Procedure

Regarding Wiring Diagram information, r ...

Steering switch

Steering switch

Description

When one of the steering switches is pushed, the resistance in the steering

switch changes the signal to

identify which button is controlling the information display.

Diagnosis Proced ...

Other materials:

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

...

Wiring diagram

REAR WINDOW DEFOGGER SYSTEM

Wiring Diagram

...

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

Description

—

(J-39570)

Chassis Ear

Locating the noise

—

(J-50397)

NISSAN Squeak and Rattle

Kit

...