Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

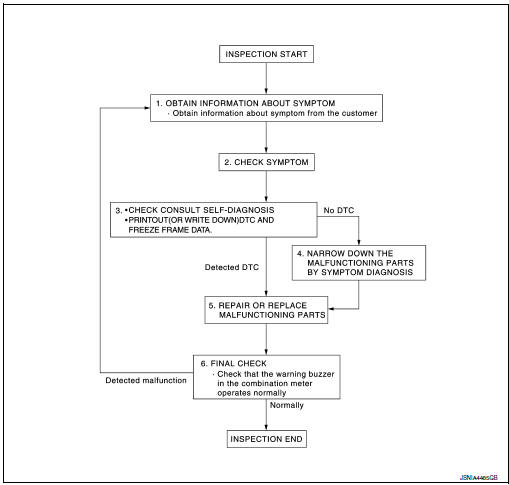

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

> GO TO 3.

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

- Connect CONSULT and perform "self-diagnosis". Refer to WCS-27, "DTC Index".

- When DTC is detected, follow the instructions below:

- Record DTC and Freeze Frame Data.

Are self-diagnosis results normal? YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE: If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 1.

Wiring diagram

Wiring diagram

Wiring Diagram

...

Other materials:

Removal and installation

NATS ANTENNA AMP.

Removal and Installation

REMOVAL

Remove the steering column covers. Refer to IP-17, "Removal and

Installation".

Disconnect the harness connector from the NATS antenna amp.

Release pawls and remove NATS antenna amp. (1) from the

ignition sw ...

DTC/circuit diagnosis

U0428 STEERING ANGLE SENSOR

DTC Logic

DTC DETECTION LOGIC

CONSULT Display

DTC Detection Condition

Possible Cause

ST ANG SEN CALIB

[U0428]

Predictive course line center position adjustment

of steering angle sensor is incomplete.

Adjust predictive cours ...

Oil cooler

Exploded View

Intake manifold

Cylinder block

Clamp

Water hose

Water hose clip

Water hose

Oil cooler

Gasket

Oil cooler relief valve

Front

Removal and Installation

WARNING:

Be careful not to burn yourself, as engine oil and ...