Nissan Rogue Service Manual: Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger switch signal, etc.) is transferred via the CAN communication.

Component Function Check

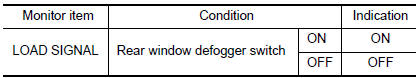

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

- Turn ignition switch ON.

- Connect CONSULT and select ÔÇťDATA MONITORÔÇŁ mode.

- Select ÔÇťLOAD SIGNALÔÇŁ and check indication under the following conditions.

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to EC-462, "Diagnosis Procedure".

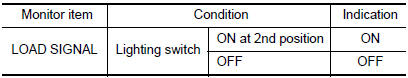

2.CHECK LIGHTING SWITCH FUNCTION

Check ÔÇťLOAD SIGNALÔÇŁ indication under the following conditions.

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to EC-462, "Diagnosis Procedure".

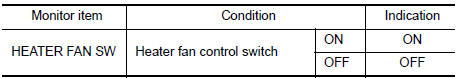

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

Select ÔÇťHEATER FAN SWÔÇŁ and check indication under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-462, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-462, "Component Function Check".

Which circuit is related to the incident? Rear window defogger>>GO TO 2.

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Check rear window defogger system. Refer to DEF-19, "Work Flow".

>> INSPECTION END

3.CHECK HEADLAMP SYSTEM

Check headlamp system. Refer to EXL-82, "Work Flow" (with halogen headlamp) or EXL-219, "Work Flow" (with LED headlamp).

>> INSPECTION END

4.CHECK HEATER FAN CONTROL SYSTEM

Check heater fan control system. Refer to HAC-46, "Work Flow" (with automatic air conditioner) or HAC-146, "Work Flow" (with manual air conditioner).

>> INSPECTION END

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

Turn ignition switch ON.

Perform ÔÇťCOOLING FAN (DUAL)ÔÇŁ in ÔÇťACTIVE TESTÔÇŁ mode of ÔÇťIPDM E/RÔÇŁ

using CO ...

Fuel injector

Fuel injector

Component Function Check

1.INSPECTION START

Turn ignition switch to START.

Are any cylinders ignited?

YES >> GO TO 2.

NO >> Proceed to EC-464, "Diagnosis Procedure".

2. ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as ÔÇťAIR BAGÔÇŁ and ÔÇťSEAT BELT

PRE-TENSIONERÔÇŁ, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

P1226 TP sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P1226

CTP LEARNING-B1

(CTP LEARNING-B1)

Closed throttle position learning is not performed successfully,

repeatedly

POSSIBLE CAUSE

Elect ...

Diagnosis system (BCM) (with intelligent key system)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

Ecu Identification

The BCM part number is displayed.

Self Diagnostic ...