Nissan Rogue Service Manual: Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

- Turn ignition switch ON.

- Perform “COOLING FAN (DUAL)” in “ACTIVE TEST” mode of “IPDM E/R” using CONSULT.

- Touch “LOW”, “HI” on the CONSULT screen.

- Check that cooling fan operates.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-458, "Diagnosis Procedure".

Diagnosis Procedure

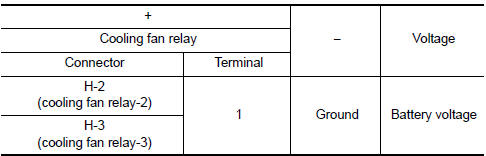

1.CHECK COOLING FAN RELAY POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect cooling fan relays-2, -3.

- Turn ignition switch ON.

- Check the voltage between cooling fan relays-2, -3 harness connectors and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Perform trouble diagnosis for power supply circuit.

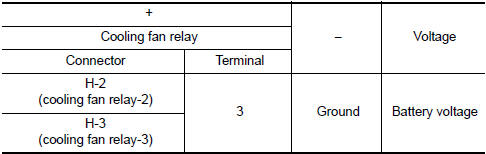

2.CHECK COOLING FAN MOTOR CIRCUIT-1

Check the voltage between cooling fan relays-2, -3 harness connectors and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 4.

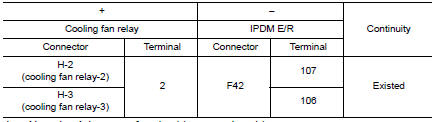

3.CHECK COOLING FAN RELAY OUTPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connectors.

- Check the continuity between cooling fan relay-2, -3 harness connectors and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

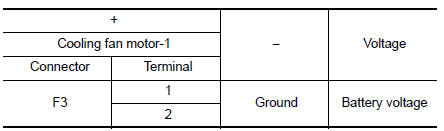

4.CHECK COOLING FAN MOTOR POWER SUPPLY CIRCUIT

- Disconnect cooling fan motor-1 harness connector.

- Check the voltage between cooling fan motor-1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Perform trouble diagnosis for power supply circuit.

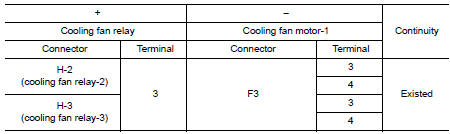

5.CHECK COOLING FAN MOTOR CIRCUIT-2

- Check the continuity between cooling fan relay-2, -3 harness connectors and cooling fan motor-1, -2 harness connectors.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 11.

NO >> Repair or replace error-detected parts.

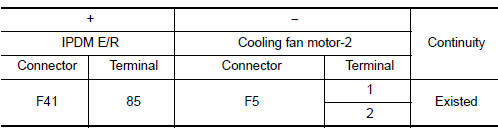

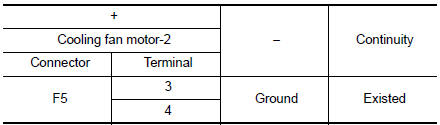

6.CHECK COOLING FAN MOTOR CIRCUIT-3

- Check the continuity between IPDM E/R harness connector and cooling fan motor-2 harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

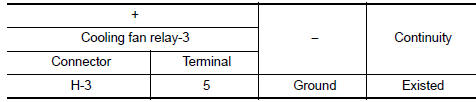

7.CHECK COOLING FAN MOTOR CIRCUIT-4

- Check the continuity between cooling fan relay-3 harness connectors and ground.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

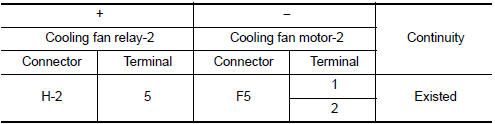

8.CHECK COOLING FAN MOTOR CIRCUIT-5

- Check the continuity between cooling fan relay--3 harness connectors and cooling fan motor-2 harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts.

9.CHECK COOLING FAN MOTOR CIRCUIT-4

- Check the continuity between cooling fan motor-2 harness connector and ground.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair or replace error-detected parts.

10.CHECK COOLING FAN RELAY-2 AND -3

Refer to EC-461, "Component Inspection (Cooling Fan Relay)".

Is the inspection result normal? YES >> GO TO 11.

NO >> Replace malfunctioning cooling fan relay.

11.CHECK COOLING FAN MOTORS-1 AND -2

Refer to EC-461, "Component Inspection (Cooling Fan Motor)".

Is the inspection result normal? YES >> GO TO 12.

NO >> Replace malfunctioning cooling fan motor. Refer to CO-17, "Removal and Installation".

12.CHECK INTERMITTENT INCIDENT

Perform GI-41, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

NO >> Repair or replace error-detected parts.

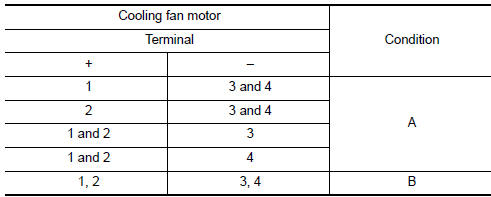

Component Inspection (Cooling Fan Motor)

1.CHECK COOLING FAN MOTOR

- Turn ignition switch OFF.

- Disconnect cooling fan motor harness connector.

- Supply cooling fan motor terminals with battery voltage and check operation.

Check that cooling fan speed of condition B is higher than that of A.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace cooling fan motor. Refer to CO-17, "Removal and Installation".

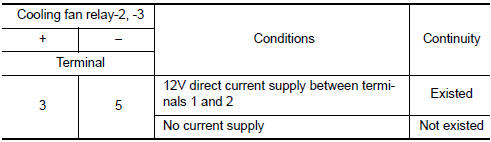

Component Inspection (Cooling Fan Relay)

1.CHECK COOLING FAN RELAYS

- Turn ignition switch OFF.

- Remove cooling fan relay-2, -3.

- Check the continuity between cooling fan relay-2, -3 terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace cooling fan relay.

Brake pedal position switch

Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

With CONSULT

Turn ignition switch ON.

Select “BRAKE SW1” in “DATA MONITOR” mode with CONSULT.

...

Electrical load signal

Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger

switch signal, etc.) is transferred via

the CAN communication.

Component Function Check

1.CHECK REAR WINDOW D ...

Other materials:

Harness connector

Description

HARNESS CONNECTOR (TAB-LOCKING TYPE)

The tab-locking type connectors help prevent accidental looseness

or disconnection.

The tab-locking type connectors are disconnected by pushing or

lifting the locking tab(s). Refer to the figure

below.

Refer to the next p ...

Driving safety precautions

Your NISSAN is designed for both normal and

off-road use. However, avoid driving in deep water

or mud as your NISSAN is mainly designed for

leisure use, unlike a conventional off-road vehicle.

Remember that two-wheel drive models are less

capable than all-wheel drive models for rough

road dr ...

Diagnosis system (BCM) (without intelligent key system)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

Ecu Identification

The BCM part number is displayed.

Self Diagnostic ...