Nissan Rogue (T33) 2021-Present Service Manual: With Idle Start/stop :: Removal and Installation. Sub Starter & Generator

Sub Starter & Generator

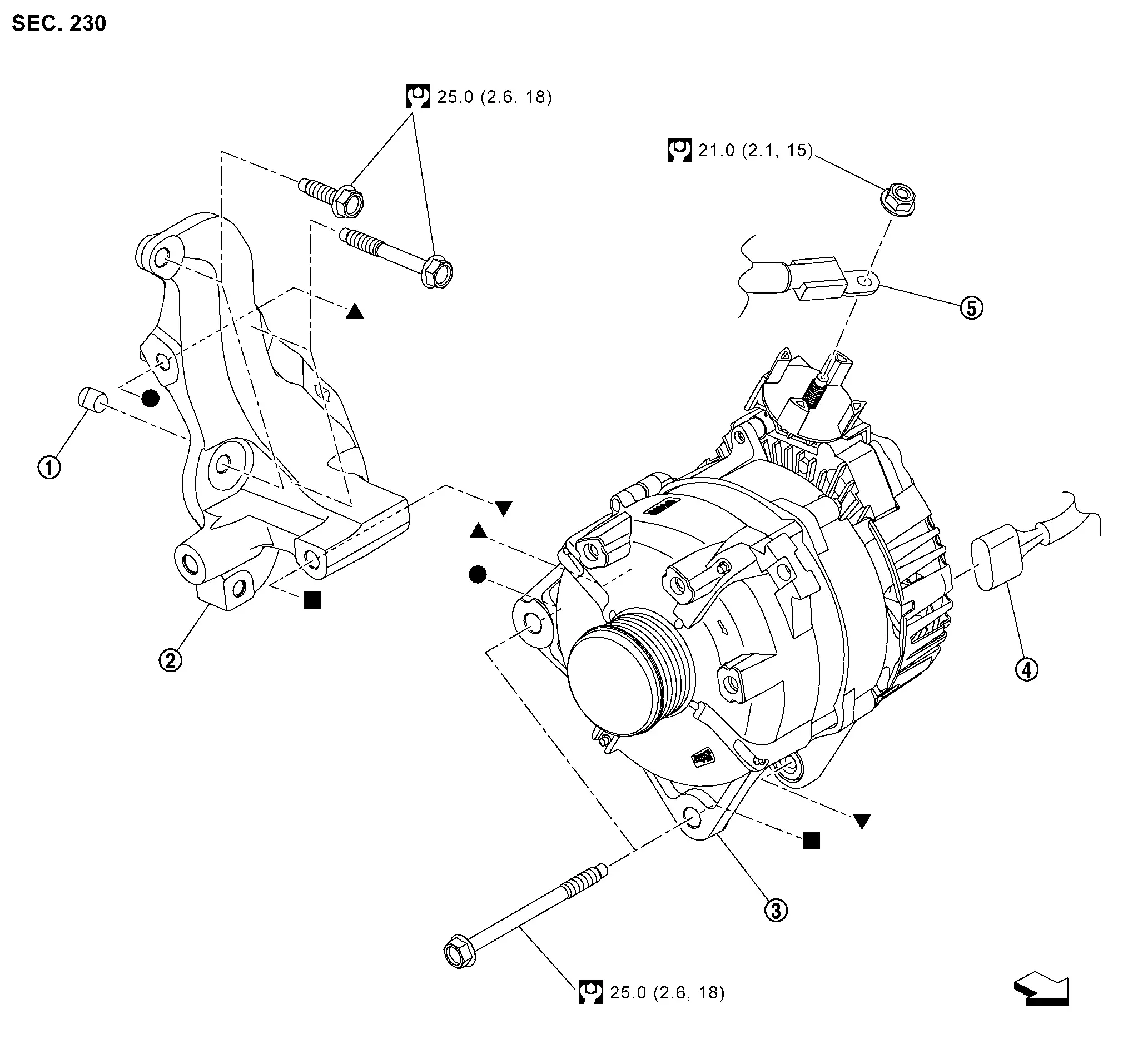

Exploded View

REMOVAL

| 1. | Collar | 2. | Sub starter, generator and compressor bracket | 3. | Sub starter & generator |

| 4. | Sub starter & generator harness connector | 5. | ŌĆ£BŌĆØ terminal | - | - |

|

: Nissan Ariya Vehicle front | ||||

, ,  , ,  , ,  : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. : Indicates that the part is connected at points with same symbol in actual Nissan Ariya vehicle. |

|||||

Removal and Installation

REMOVAL

Disconnect battery cable from negative terminal. Refer to Precautions for Removing Battery Terminal.

Remove drive belt auto-tensioner. Refer to Removal and Installation.

Remove internal heat exchanger pipe. Refer to Removal and Installation.

Remove front grille cover. Refer to Exploded View.

Remove washer tank inlet. Refer to Exploded View.

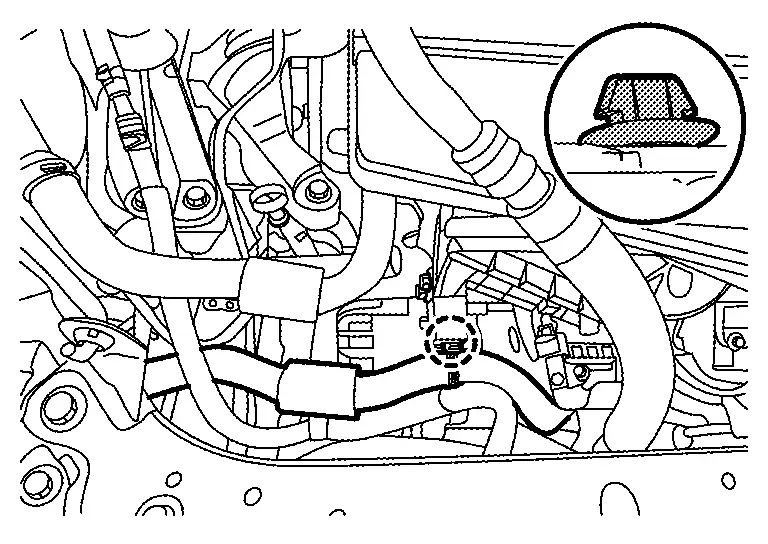

Release reservoir tank hose clip.

|

: Clip |

Remove sub radiator reservoir tank mounting bolts, and then move sub radiator reservoir tank to create work space. Refer to Exploded View.

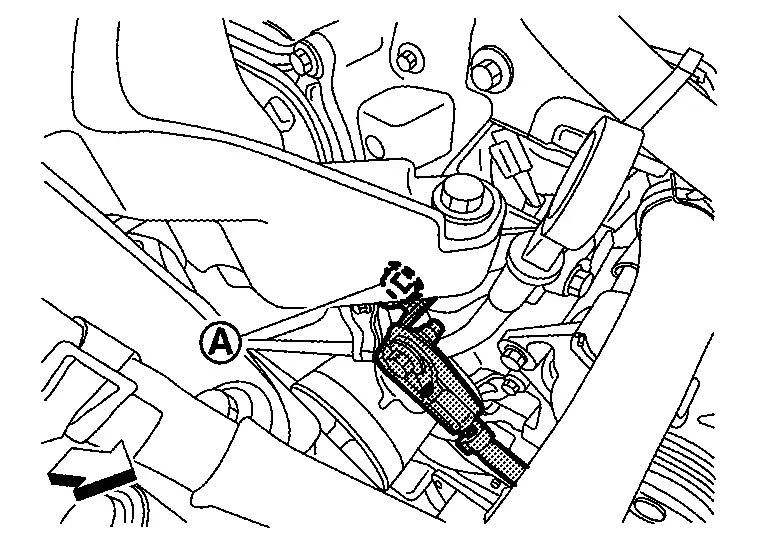

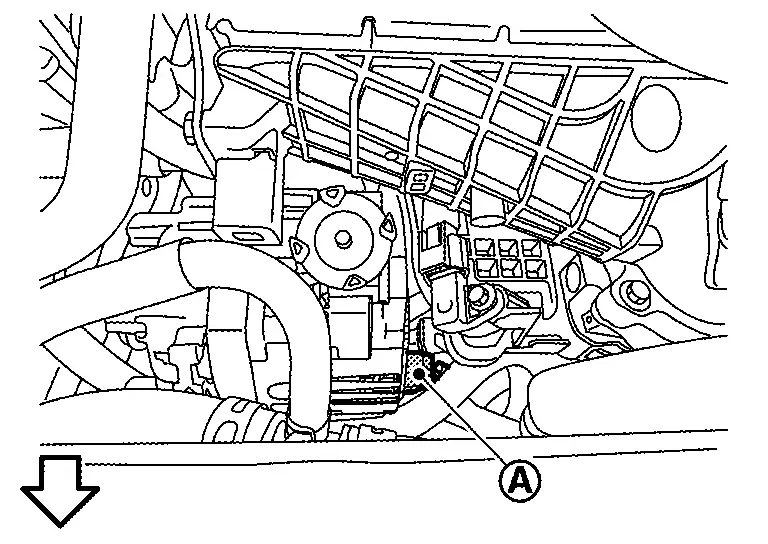

Remove ground harness mounting bolt (A), and then disconnect ground harness.

|

:Front |

Remove oil level gauge.

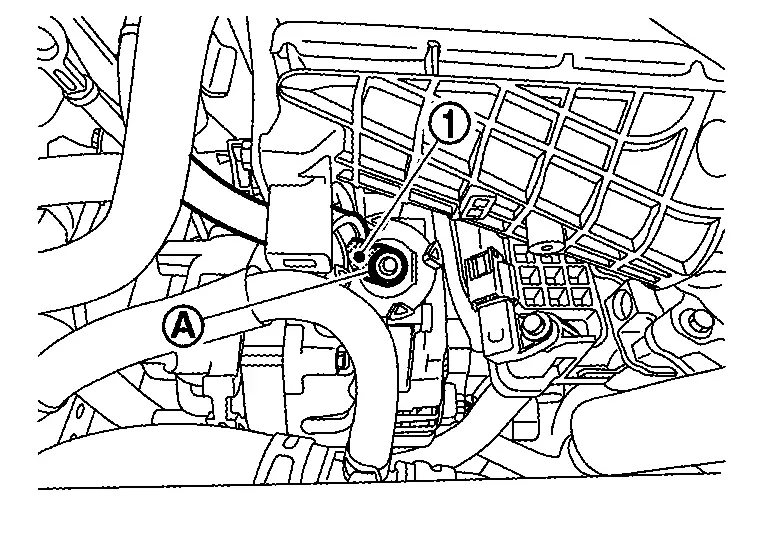

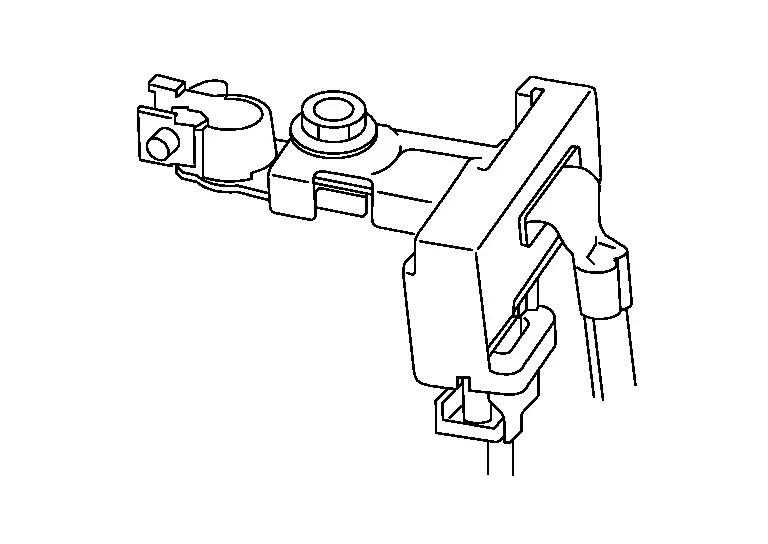

Remove ŌĆ£BŌĆØ terminal mounting nut (A), and then disconnect ŌĆ£BŌĆØ terminal (1).

Disconnect sub starter and generator harness connector (A).

|

:Front |

Remove sub starter and generator bolts, and then remove generator.

CAUTION:

-

Be cafreful not to damage surrounding components.

-

Do not erase the sub starter & generator operation counter except when replacing sub starter & generator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

-

Temporarily tighten sub starter & generator bolts in order from the lower side to the upper side, and then tighten them in order from the upper side to the lower side.

For sub starter & generator, the front side (pulley side) surface is the reference surface. Fit the reference surface to sub starter & generator mounting part, and then tighten bolts.

-

Be careful to tighten ŌĆ£BŌĆØ terminal nut to the specified torque.

-

Install sub starter & generator, and check tension of belt. Refer to Inspection.

-

For this model (with 12V battery current sensor models), energy management system that controls power generation voltage of sub starter & generator has been adopted. Therefore, energy management system operation inspection should be performed after replacing sub starter & generator, and then make sure that the system operates normally. Refer to Work Flow (With EXP-800 NI or GR8-1200 NI) or Work Flow (Without EXP-800 NI or GR8-1200 NI).

12V Battery current sensor is installed to 12V battery cable at negative terminal.

-

Perform "ADDITIONAL SERVICE WHEN REPLACING SUB STARTER & GENERATOR" when replacing sub starter & generator. Not doing so will cause sub starter & generator control function to not operate normally. Refer to Description

Inspection

Perform the following.

Make sure that generator pulley does not rattle.

Make sure that generator pulley nut is tight.

NOTE:

NOTE:

Replace the generator as an assembly if necessary.

Other materials:

Symptom Diagnosis. Automatic Back Door Functions Do Not Cancel

Diagnosis Procedure

CHECK ŌĆ£POWER BACK DOOR SETTINGŌĆØ IN COMBINATION METER

Check ŌĆ£Power back door settingŌĆØ is in the OFF.

Is the inspection result normal?

YES>>

GO TO 2.

NO>>

Set ŌĆ£Power back door settingŌĆØ to ŌĆ£OFFŌĆØ.

REPLACE AUTOMATIC BACK DOOR CONTROL UNIT

Rep ...

Informations de base

S├®lecteur mode de conduite : Mod├©les 4x2

S├®lecteur mode de conduite : Mod├©les avec transmission

int├®grale

├ēcran d'informations du v├®hicule : Mod├©les 4x2

├ēcran d'informations du v├®hicule : Mod├©les avec

transmission int├®grale

Le Nissan Rogue propose plusieurs ...

Rehausseurs

Informations de base

Pour plus d'informations concernant

l'installation d'un si├©ge rehausseur dans

votre v├®hicule, suivez attentivement les instructions indiqu├®es

dans cette section. Le choix et lŌĆÖinstallation corrects dŌĆÖun rehausseur dans un Nissan Rogue contribuent ├Ā un positionnem ...