Nissan Rogue Service Manual: Unit removal and installation

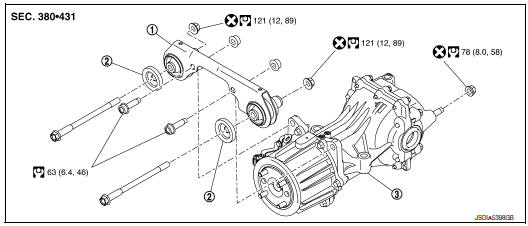

REAR FINAL DRIVE ASSEMBLY

Exploded View

- Final drive mounting bracket

- Mounting stopper

- Rear final drive assembly

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

- Remove rear propeller shaft. Refer to DLN-99, "Exploded View".

- Remove rear drive shafts. Refer to RAX-19, "Exploded View".

- Disconnect AWD solenoid harness connector.

- Remove rear final drive breather hose and electric controlled coupling breather hose.

- Support final drive assembly with a suitable jack.

- Remove final drive nuts and final drive bolts with power tool.

If necessary, remove final drive bracket and washer with power tool.

CAUTION: Secure final drive assembly to a suitable jack while removing it.

INSTALLATION Installation is in the reverse order of removal.

- When oil leaks while removing final drive assembly, check oil level after the installation. Refer to DLN-111, "Inspection".

- When replacing rear final drive assembly, perform writing unit characteristics. Refer to DLN-35, "Work Procedure".

Removal and installation

Removal and installation

DRIVE PINION OIL SEAL

Exploded View

Rear final drive assembly

Drive pinion oil seal

Electric controlled coupling assembly

Oil seal lip

Always replace after every

disassembly.

: ...

Unit disassembly and assembly

Unit disassembly and assembly

ELECTRIC CONTROLLED COUPLING

Exploded View

Stud bolt

Connector bracket

Reamer bolt

Electric controlled coupling assembly

Wave spring

Drive pinion oil seal

Drive pinion lock nut ...

Other materials:

B1431 seat belt pre-tensioner

DTC Logic

DTC DETECTION LOGIC

CONSULT name

DTC

DTC detecting condition

Repair order

FRONT PRE-TEN RH CIRCUIT

[OPEN]

B1431

RH seat belt pre-tensioner circuit is open.

Refer to SRC-61, "Diagnosis Procedure"

FRONT PRE-TEN RH CIRC ...

P0112, P0113 IAT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0112

IAT SEN/CIRCUIT- B1

(Intake air temperature sensor 1 circuit low

bank 1)

An excessively low voltage from the intake air temperature sensor ...

P0128 thermostat function

DTC Description

DTC DETECTION LOGIC

Engine coolant temperature has not risen enough to open the thermostat even

though the engine has run long

enough.

This is due to a leak in the seal or the thermostat being stuck open.

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

...