Nissan Rogue Service Manual: Unit disassembly and assembly

ELECTRIC CONTROLLED COUPLING

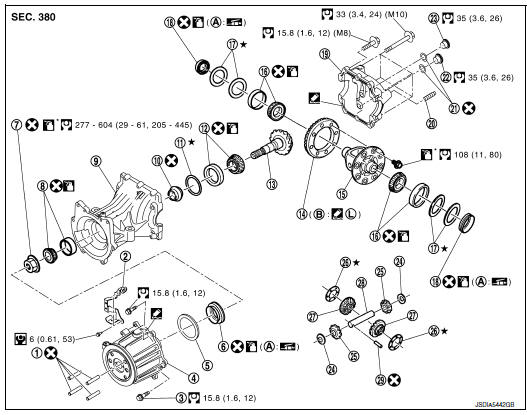

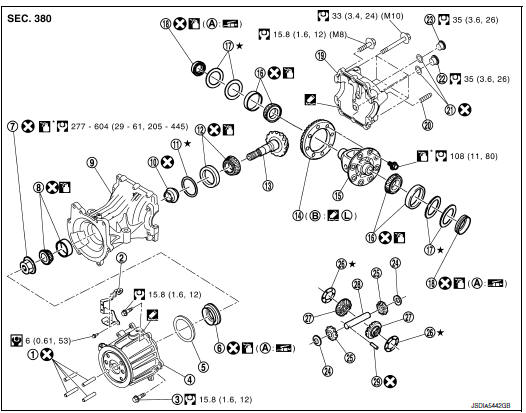

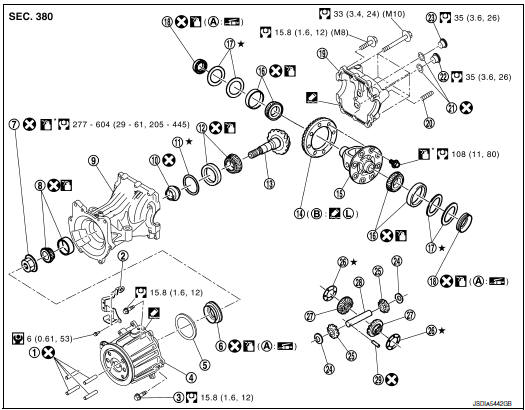

Exploded View

- Stud bolt

- Connector bracket

- Reamer bolt

- Electric controlled coupling assembly

- Wave spring

- Drive pinion oil seal

- Drive pinion lock nut

- Pinion front bearing

- Gear carrier

- Collapsible spacer

- Drive pinion adjusting shim

- Pinion rear bearing

- Drive pinion

- Drive gear

- Differential case

- Side bearing

- Side bearing adjusting shim

- Side oil seal

- Rear cover

- Stud bolt

- Gasket

- Drain plug

- Filler plug

- Pinion mate thrust washer

- Pinion mate gear

- Side gear thrust washer

- Side gear

- Pinion mate shaft

- Lock pin

- Oil seal lip

- Screw hole

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

: Always replace after every

disassembly.

: Select with proper thickness.

: Select with proper thickness.

: Apply gear oil.

: Apply gear oil.

*: Apply anti-corrosion oil.

*: Apply anti-corrosion oil.

: Apply multi purpose grease.

: Apply multi purpose grease.

: Apply Genuine Silicone RTV or

equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

: Apply Genuine Silicone RTV or

equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

: Apply Genuine High Strength

Thread Locking Sealant or equivalent. Refer to GI-22, "Recommended Chemical

Products

and Sealants".

: Apply Genuine High Strength

Thread Locking Sealant or equivalent. Refer to GI-22, "Recommended Chemical

Products

and Sealants".

Disassembly and Assembly

DISASSEMBLY

- Remove stud bolts .

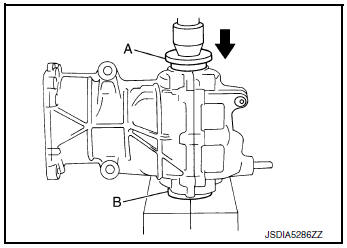

- Remove electric controlled coupling assembly from final drive assembly.

- Remove wave spring.

- Remove drive pinion oil seal from the inside of gear carrier.

Refer to DLN-136, "Disassembly and Assembly".

CAUTION: When removing electric controlled coupling, replace drive pinion oil seal.

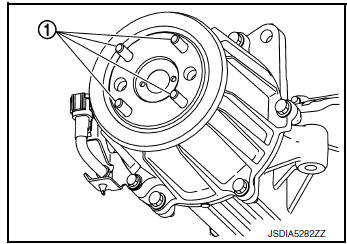

- Remove connector bracket 1 from electric controlled coupling.

- Separate band clip and connector clip from connector bracket.

ASSEMBLY

- Install connector bracket to electric controlled coupling.

- For tightening torque, refer to DLN-120, "Exploded View".

- Fix AWD solenoid harness with band clip and connector clip.

- Install drive pinion oil seal to the inside of gear carrier. Refer to DLN-136, "Disassembly and Assembly".

CAUTION: When removing electric controlled coupling, replace drive pinion oil seal.

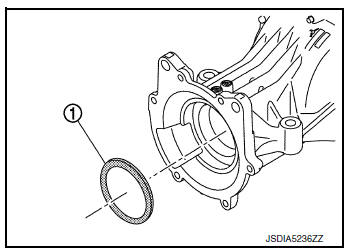

- Install wave spring 1 to the inside of gear carrier.

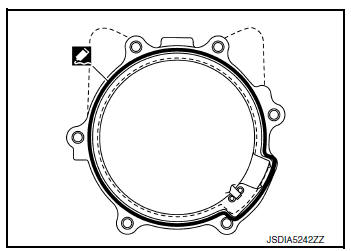

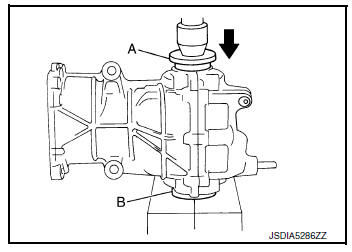

- Apply liquid gasket to mating surface of electric controlled coupling assembly.

CAUTION:

- Remove old gasket adhering to the mounting surfaces.

Also remove any moisture, oil, or foreign material adhering to the mounting surfaces.

- The width of sealant bead is approximately 3 mm (0.12 in).

Apply sealant evenly.

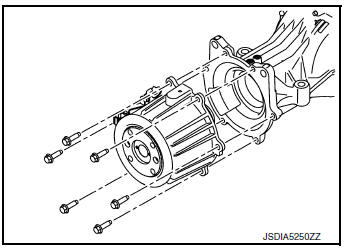

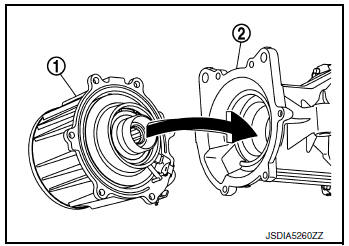

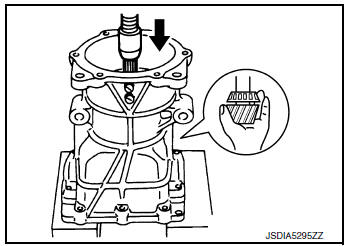

- Match electric controlled coupling assembly 1 to spline of drive

pinion, then install it to final drive assembly 2.

CAUTION: Be careful not to damage drive pinion oil seal.

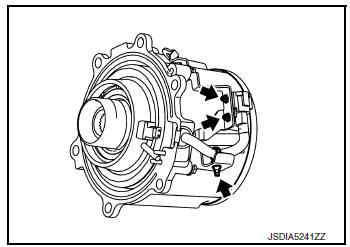

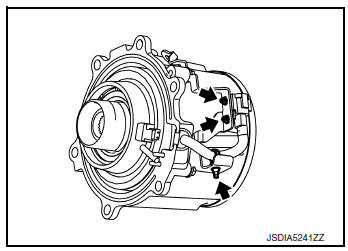

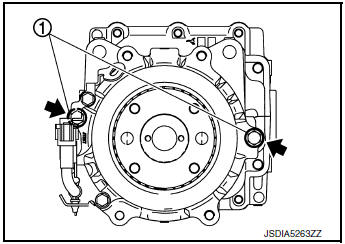

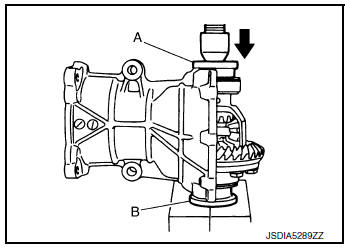

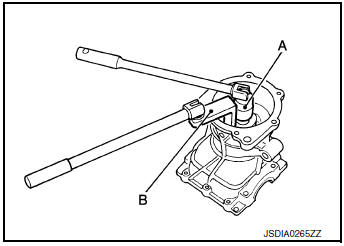

- Temporarily tighten reamer bolts 1 to the positions shown in the figure.

- Tighten reamer bolts and electric controlled coupling assembly mounting bolts to the specified torque.

- For tightening torque, refer to DLN-120, "Exploded View".

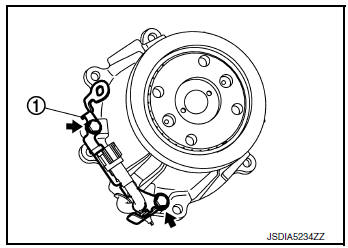

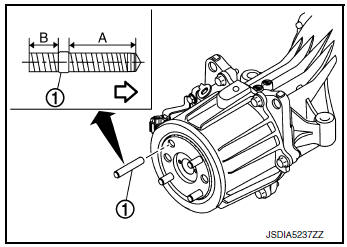

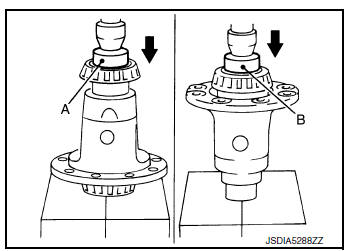

- Install stud bolts 1.

: Electric controlled

coupling side

: Electric controlled

coupling side

Thread length

A : Long

B : Short

CAUTION:

- Never reuse stud bolt.

- Screw long thread side of stud bolt to electric controlled coupling.

- Screw the stud bolt until the stop by applying a torque of 15 N·m (1.5 kg-m, 11 ft-lb) ±20%.

- After installing stud bolt, the length of the protrusion from electric controlled coupling must be 19.8 mm (0.780 in) ±1.4 mm (0.055 in).

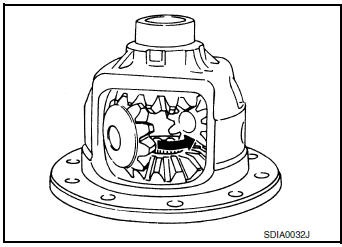

DIFFERENTIAL ASSEMBLY

Exploded View

- Stud bolt

- Connector bracket

- Reamer bolt

- Electric controlled coupling assembly

- Wave spring

- Drive pinion oil seal

- Drive pinion lock nut

- Pinion front bearing

- Gear carrier

- Collapsible spacer

- Drive pinion adjusting shim

- Pinion rear bearing

- Drive pinion

- Drive gear

- Differential case

- Side bearing

- Side bearing adjusting shim

- Side oil seal

- Rear cover

- Stud bolt

- Gasket

- Drain plug

- Filler plug

- Pinion mate thrust washer

- Pinion mate gear

- Side gear thrust washer

- Side gear

- Pinion mate shaft

- Lock pin

- Oil seal lip

- Screw hole

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

: Always replace after every

disassembly.

: Select with proper thickness.

: Select with proper thickness.

: Apply gear oil.

: Apply gear oil.

*: Apply anti-corrosion oil.

*: Apply anti-corrosion oil.

: Apply multi purpose grease.

: Apply multi purpose grease.

Apply Genuine Silicone RTV or

equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

Apply Genuine Silicone RTV or

equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

: Apply Genuine High Strength

Thread Locking Sealant or equivalent. Refer to GI-22, "Recommended Chemical

Products

: Apply Genuine High Strength

Thread Locking Sealant or equivalent. Refer to GI-22, "Recommended Chemical

Products

Disassembly and Assembly

DISASSEMBLY

- Remove drain plug, filler plug and gaskets.

- Remove the side oil seal, using oil seal remover (commercial

service tool).

CAUTION: Never damage gear carrier and rear cover.

- Remove rear cover mounting bolts.

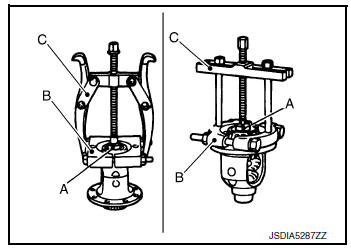

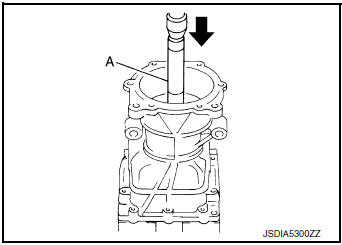

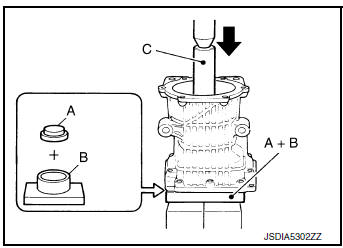

- Set drifts (A and B) to the right and left side bearing adjusting shims individually. Press differential assembly with side bearing to remove gear carrier assembly and rear cover assembly.

A : Drift [SST: KV40100610 (J-26089)]

B : Drift [SST: KV40100610 (J-26089)]

CAUTION: The pressure shall be as low as possible to remove gear carrier assembly and rear cover assembly. The maximum pressure shall be 10 kN (1 ton, 1.0 Imp ton).

NOTE: Differential assembly, side bearings, and adjusting washers are compressed and integrated in gear carrier and rear cover.

- Remove stud bolt from rear cover.

NOTE: It is not necessary to remove stud bolt except when it is replaced.

- Remove side bearing adjusting shims and side bearing outer races.

CAUTION: Mark the side bearing adjusting shims so that the original mounting positions (right/left) can be identified later.

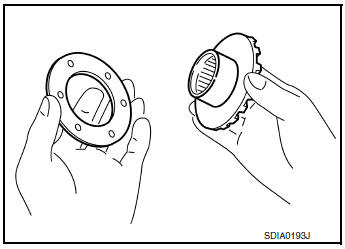

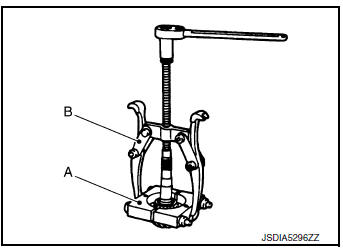

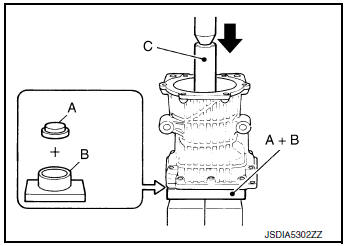

- Remove side bearing inner races, using adaptor (A), separator (B) and puller (C).

A : Adaptor [ST33052000 ( — )]

B : Separator (commercial service tool)

C : Puller (commercial service tool)

CAUTION:

- To prevent damage to the side bearing and drive gear, place copper plates between these parts and vise.

- It is not necessary to remove side bearing inner race except when it is replaced.

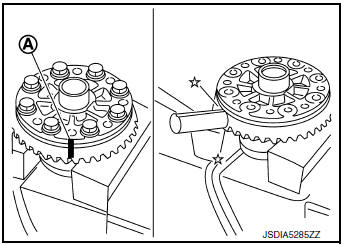

- For proper reinstallation, paint matching marks A on one differential

assembly and drive gear.

CAUTION: For matching marks, use paint. Never damage differential assembly and drive gear.

- Remove drive gear mounting bolts and then remove drive gear from differential assembly.

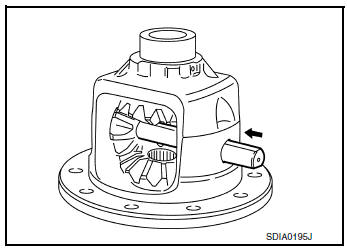

- Remove lock pin of pinion mate shaft, using the pin punch (commercial service tool).

- Remove pinion mate shaft.

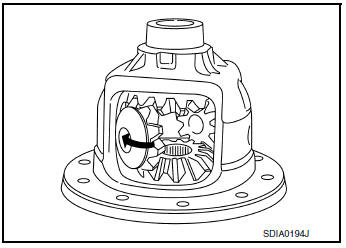

- Remove pinion mate gears, pinion mate thrust washers, side gears, side gear thrust washers from differential case.

- Perform inspection after disassembly. Refer to DLN-134, "Inspection".

ASSEMBLY

- Install side gear thrust washers with the same thickness as the ones installed prior to disassembly or reinstall the old ones on the side gears.

- Install side gears and side gear thrust washers into differential case.

- Align 2 pinion mate gears in diagonally opposite positions, then rotate and install them into differential case after installing thrust washer to pinion mate gear.

- Align the lock pin holes on differential case with pinion mate shaft, and install pinion mate shaft.

- Measure side gear end play. If necessary, select the appropriate side gear thrust washers.

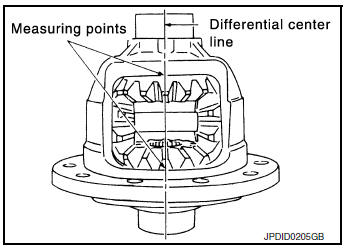

- Place differential assembly straight up so that side gear to be measured comes upward.

- Using feeler gauge, measure the clearance between side gear back and differential case at 3 different points, while rotating side gear. Average the 3 readings, and then measure the clearance of the other side as well.

Side gear back clearance : Refer to DLN-141, "Differential Side Gear Clearance".

CAUTION: To prevent side gear from tilting, insert feeler gauges with the same thickness from both sides.

- If the back clearance is outside the specification, use a thicker/ thinner side gear thrust washer to adjust. For selecting thrust washer, refer to the latest parts information.

When the back clearance

is large

: Use a thicker thrust washer.

When the back clearance

is small: Use a thinner thrust washer.

CAUTION: Select a side gear thrust washer for right and left individually.

- Drive a lock pin into pinion mate shaft, using the pin punch (commercial service tool).

CAUTION: Never reuse lock pin.

- Press side bearing inner races to differential assembly, using the drifts (A and B).

A : Drift [SST: KV40105020 ( — )]

B : Drift [SST: KV40105020 ( — )]

CAUTION:

- Never reuse side bearing inner race.

- Apply gear oil to side bearing.

- Apply thread locking sealant into the thread hole of drive gear.

CAUTION: Clean and degrees drive gear back and threaded holes sufficiently.

- Install the drive gear to differential assembly.

CAUTION: Align the matching mark of differential assembly and drive gear.

- Tighten the bolts in a crisscross fashion to the specified torque.

- For tightening torque, refer to DLN-124, "Exploded View".

CAUTION: Apply anti-corrosion oil to the thread and seat of mounting bolts.

- Assemble side bearing outer races to inner races.

CAUTION:

- Never reuse side bearing outer race.

- Apply gear oil to side bearing.

- Install new side bearing adjusting shims (2 pieces for one side) with the same thickness as the ones installed prior to disassembly or re-install the old ones, on side bearing outer race of differential assembly.

If side bearing adjusting shims have been already selected, use them.

- Set the drifts (A and B) to the right and left side bearing adjusting shims individually. Compress differential assembly and side bearing to gear carrier assembly to install differential assembly.

A : Drift [KV40100610 (J-26089)]

B : Drift [KV40100610 (J-26089)]

CAUTION:

- The drift shall be placed on the center of the adjusting shims.

- The pressure shall be as low as possible to install differential assembly into gear carrier assembly. The maximum pressure shall be 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).

- If the adjusting shims are installed by tapping, the gear carrier may be damaged. Avoid tapping.

- Install dummy cover set [SST: KV381086S1 ( — )], check and adjust drive gear runout, tooth contact, backlash, and total preload torque. Refer to DLN-130, "Adjustment".

- Remove dummy cover set.

- Install stud bolt to rear cover.

CAUTION: Screw the stud bolt until the thread becomes invisible by applying a torque of 20 N·m (2.0 kg-m, 15 ft-lb) or less.

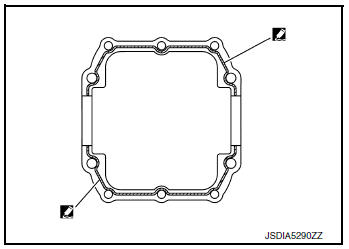

- Apply liquid gasket to mating surface of rear cover.

CAUTION:

- Remove old gasket adhering to the mounting surfaces.

Also remove any moisture, oil, or foreign material adhering to the mounting surfaces.

- The width of sealant bead is approximately 3 mm (0.12 in).

Apply sealant evenly.

- Set the drifts (A and B) to the right and left side bearing adjusting shims individually. Compress differential assembly and side bearing to install rear cover.

A : Drift [KV40100610 (J-26089)]

B : Drift [KV40100610 (J-26089)]

CAUTION:

- The drift shall be placed on the center of the adjusting shims.

- The pressure shall be as low as possible to install differential assembly into gear carrier assembly.

- he maximum pressure shall be 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).

• If the adjusting shims are installed by tapping, the gear carrier may be damaged. Avoid tapping.

- Tighten rear cover mounting bolts to the specified torque.

- For tightening torque, refer to DLN-124, "Exploded View".

- Using the drift (A) [SST: KV38100200 (J-26233)], drive side oil seals until it becomes flush with the gear carrier end.

CAUTION:

- Never reuse oil seals.

- When installing, do not incline oil seals.

- Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

- Check total preload torque. Refer to DLN-130, "Adjustment".

Adjustment

TOTAL PRELOAD TORQUE

- Remove electric controlled coupling assembly. Refer to DLN-121, "Disassembly and Assembly".

- Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

- Rotate drive pinion at least 20 times to check for smooth operation of the bearing.

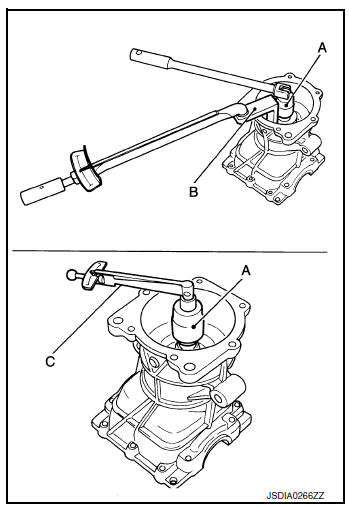

- Fit drive pinion socket onto drive pinion spline. Measure the total preload, using the preload gauge and drive pinion socket.

A : Preload gauge [SST: ST3127S000 (J-25765-A)]

B : Drive pinion socket [SST: KV38109500 ( — )]

Standard

Total preload torque : Refer to DLN-141, "Preload

Torque".

NOTE: Total preload torque = Pinion bearing torque + Side bearing torque

- If measured value is out of the specification, disassemble it to

check and adjust each part. Adjust the pinion

bearing preload and side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bearing preload.

When the preload torque is large

On pinion bearings: Replace the collapsible spacer.

On side bearings: Use thinner side bearing adjusting shims. For selecting

adjusting

shim, refer to the latest parts information.

When the preload is small

On pinion bearings: Tighten the drive pinion nut.

On side bearings: Use thicker side bearing adjusting shims. For selecting

adjusting

shim, refer to the latest parts information.

DRIVE GEAR RUNOUT

- Remove rear cover. Refer to DLN-125, "Disassembly and Assembly".

- Following the procedure below, install a dummy cover set [SST: KV381086S1 ( — )] to gear carrier.

- Set dummy cover shims [SST: KV38108630 ( — )] to the right and left side bearing adjusting shims.

- Temporarily tighten dummy cover [SST: KV38108610 ( — )] to gear carrier.

- Position dummy cover spacers [SST: KV38108621 ( — )] to dummy cover [SST: KV38108610 ( — )].

- Tighten rear cover mounting bolts to the specified torque. Refer to DLN-124, "Exploded View".

- Tighten dummy cover spacer mounting bolts evenly to the specified torque.

: 5.9 N·m (0.6 kg-m, 52

in-lb)

: 5.9 N·m (0.6 kg-m, 52

in-lb)

- Fit a dial indicator to the drive gear back face.

- Rotate the drive gear to measure runout.

Limit

Drive gear back face

runout

: Refer to DLN-141, "Drive

Gear Runout".

- If the runout is outside of the repair limit, check drive gear assembly condition; foreign material may be caught between drive gear and differential case, or differential case or drive gear may be deformed, etc.

CAUTION: Replace drive gear and drive pinion as a set.

TOOTH CONTACT

- Remove rear cover. Refer to DLN-125, "Disassembly and Assembly".

- Following the procedure below, install a dummy cover set [SST: KV381086S1 ( — )] to gear carrier.

- Set dummy cover shims [SST: KV38108630 ( — )] to the right and left side bearing adjusting shims.

- Temporarily tighten dummy cover [SST: KV38108610 ( — )] to gear carrier.

- Position dummy cover spacers [SST: KV38108621 ( — )] to dummy cover [SST: KV38108610 ( — )].

- Tighten rear cover mounting bolts to the specified torque. Refer to DLN-124, "Exploded View".

- Tighten dummy cover spacer mounting bolts evenly to the specified torque.

: 5.9 N·m (0.6 kg-m, 52

in-lb)

: 5.9 N·m (0.6 kg-m, 52

in-lb)

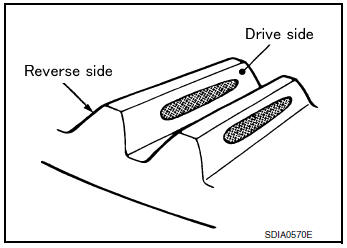

- Apply red lead to drive gear.

CAUTION: Apply red lead to both the faces of 3 to 4 gears at 4 locations evenly spaced on drive gear.

- Rotate drive gear back and forth several times, check drive pinion gear to drive gear tooth contact.

CAUTION: Check tooth contact on drive side and reverse side.

Tooth Contact Judgment Guide

- If tooth contact is improperly adjusted, follow the procedure below to adjust the pinion height (dimension X).

- If the tooth contact is near the face (face contact), or near the

heel (heel contact), thicken drive pinion gear adjusting shim to

move drive pinion closer to drive gear.

For selecting adjusting shim, refer to the latest parts information.

- If the tooth contact is near the flank (flank contact), or near the

toe (toe contact), thin drive pinion gear adjusting shim to move

drive pinion farther from drive gear.

For selecting adjusting shim, refer to the latest parts information.

BACKLASH

- Remove rear cover. Refer to DLN-125, "Disassembly and Assembly".

- Following the procedure below, install a dummy cover set [SST: KV381086S1 ( — )] to gear carrier.

- Set dummy cover shims [SST: KV38108630 ( — )] to the right and left side bearing adjusting shims.

- Temporarily tighten dummy cover [SST: KV38108610 ( — )] to gear carrier.

- Position dummy cover spacers [SST: KV38108621 ( — )] to dummy cover [SST: KV38108610 ( — )].

- Tighten rear cover mounting bolts to the specified torque. Refer to DLN-124, "Exploded View".

- Tighten dummy cover spacer mounting bolts evenly to the specified torque.

: 5.9 N·m (0.6 kg-m, 52

in-lb)

: 5.9 N·m (0.6 kg-m, 52

in-lb)

- Fit a dial indicator to the drive gear face to measure the backlash.

Standard

Backlash : Refer to DLN-141, "Backlash".

- If the backlash is outside of the specified value, change the thickness of side bearing adjusting shims.

When the backlash is large: Make drive gear back adjusting shims thicker, and drive gear front adjusting shims thinner. For selecting adjusting shim, refer to the latest parts information.

When the backlash is small: Make drive gear back adjusting shims thinner, and drive gear front adjusting shims thicker. For selecting adjusting shim, refer to the latest parts information.

Inspection

INSPECTION AFTER DISASSEMBLY

Drive Gear and Drive Pinion

- Clean up the disassembled parts.

- If the gear teeth never mesh or line-up correctly, determine the cause and adjust or replace as necessary.

- If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new drive gear and drive pinion as a set.

Bearing

- Clean up the disassembled parts.

- If any chipped (by friction), pitted, worn, rusted or scratched marks, or unusual noise from the bearing is observed, replace as a bearing assembly (as a new set).

Oil Seal

- Whenever disassembled, replace.

- If wear, deterioration of adherence (sealing force lips), or damage is detected on the lips, replace them.

Differential Assembly

DIFFERENTIAL CASE

- Clean up the disassembled parts.

- If any wear or crack on the contact sides of the differential case is found, replace.

SIDE GEAR AND PINION MATE GEAR

- Clean up the disassembled parts.

- If any cracks or damage on the surface of the tooth is found, replace.

- If any worn or chipped mark on the contact sides of the thrust washer is found, replace.

SIDE GEAR THRUST WASHER AND PINION MATE THRUST WASHER

- Clean up the disassembled parts.

- If it is chipped (by friction), damaged, or unusually worn, replace.

DRIVE PINION

Exploded View

- Stud bolt

- Connector bracket

- Reamer bolt

- Electric controlled coupling assembly

- Wave spring

- Drive pinion oil seal

- Drive pinion lock nut

- Pinion front bearing

- Gear carrier

- Collapsible spacer

- Drive pinion adjusting shim

- Pinion rear bearing

- Drive pinion

- Drive gear

- Differential case

- Side bearing

- Side bearing adjusting shim

- Side oil seal

- Rear cover

- Stud bolt

- Gasket

- Drain plug

- Filler plug

- Pinion mate thrust washer

- Pinion mate gear

- Side gear thrust washer

- Side gear

- Pinion mate shaft

- Lock pin

- Oil seal lip

- Screw hole

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

: Always replace after every

disassembly.

: Select with proper

thickness.

: Select with proper

thickness.

: Apply gear oil.

: Apply gear oil.

*: Apply anti-corrosion oil.

*: Apply anti-corrosion oil.

: Apply multi purpose grease.

: Apply multi purpose grease.

: Apply Genuine Silicone RTV or

equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

: Apply Genuine Silicone RTV or

equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

: Apply Genuine High Strength

Thread Locking Sealant or equivalent. Refer to GI-22, "Recommended Chemical

Products

: Apply Genuine High Strength

Thread Locking Sealant or equivalent. Refer to GI-22, "Recommended Chemical

Products

Disassembly and Assembly

DISASSEMBLY

- Remove electric controlled coupling assembly. Refer to DLN-121, "Disassembly and Assembly".

- Remove differential assembly. Refer to DLN-125, "Disassembly and Assembly".

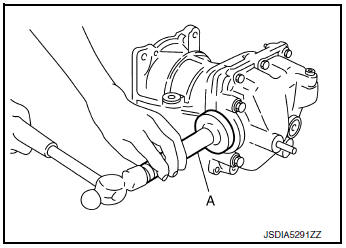

- Remove drive pinion oil seal, using oil seal remover (commercial service tool).

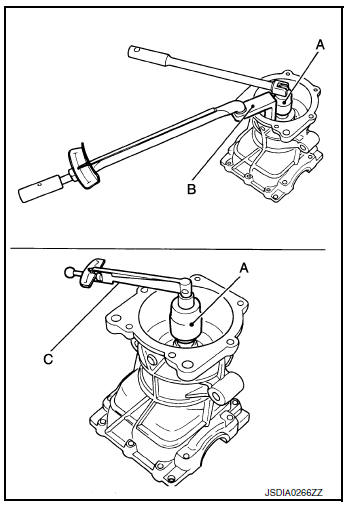

- Fit drive pinion socket (A) onto drive pinion spline. Remove drive pinion lock nut, using the pinion nut wrench (B).

A : Drive pinion socket [SST: KV38109500 ( — )]

B : Pinion nut wrench [SST: KV38109400 ( — )]

- Press drive pinion assembly out of gear carrier.

CAUTION: Never drop drive pinion assembly.

- Remove pinion front bearing inner race.

- Remove collapsible spacer.

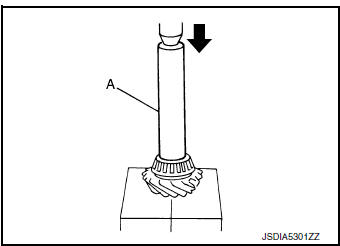

- Remove pinion rear bearing inner race from drive pinion, using the separator (A) and the puller (B).

A : Separator (commercial service tool)

B : Puller (commercial service tool)

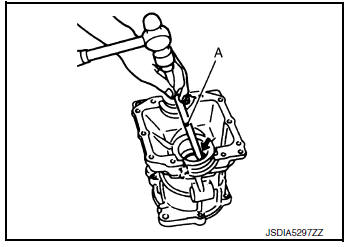

- Using a brass rod or equivalent (A), tap pinion front bearing outer race evenly from the 2 cutouts on gear carrier and remove pinion front bearing outer race.

CAUTION: Be careful not to damage gear carrier.

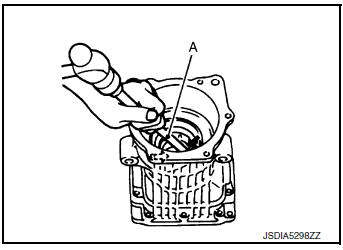

- Using a brass rod or equivalent (A), tap drive pinion adjusting

shim evenly from the 2 cutouts on gear carrier and remove drive

pinion adjusting shim and pinion rear bearing outer race.

CAUTION: Be careful not to damage gear carrier.

- Perform inspection after disassembly. Refer to DLN-140, "Inspection".

ASSEMBLY

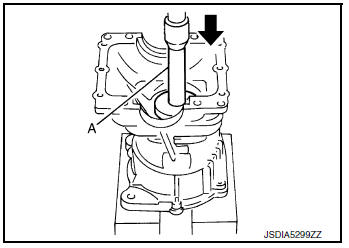

- Install a drive pinion adjusting shim of the same thickness as was installed prior to disassembly. Press pinion rear bearing outer race into gear carrier, using the drift (A) [SST: ST17130000 ( — )].

CAUTION:

- At first, using a hammer, tap bearing outer race until it becomes flush to gear carrier.

- Never reuse pinion rear bearing outer race.

- Press pinion front bearing outer race into gear carrier, using the drift (A) [SST: ST33230000 (J-25805-01)].

CAUTION:

- At first, using a hammer, tap bearing outer race until it becomes flush to gear carrier.

- Never reuse pinion front bearing outer race.

- Press pinion rear bearing inner race to drive pinion, using the drift (A) [SST: ST23860000 ( — )].

CAUTION: Never reuse pinion rear bearing inner race.

- Check and adjust the tooth contact and back lash of drive gear and drive pinion following the procedure below.

- Assemble drive pinion into gear carrier.

CAUTION:

- Never assemble collapsible spacer.

- Apply gear oil to pinion rear bearing.

- Assemble pinion front bearing inner race to drive pinion assembly.

CAUTION:

- Never reuse pinion front bearing inner race.

- Apply gear oil to pinion front bearing.

- Using the drifts (A and C) and press stand (B), press pinion front bearing inner race to drive pinion as far as drive pinion lock nut can be tightened.

A : Drift [SST: KV40100610 (J-26089)]

B : Press stand [SST: ST38220000 ( — )]

C : Drift [SST: ST23860000 ( — )]

- Temporarily tighten removed drive pinion lock nut to drive pinion.

NOTE: Use removed drive pinion lock nut only for the preload measurement.

- Rotate drive pinion more than 20 times to adjust bearing.

- Fit the drive pinion socket (A) onto the drive pinion. Using the pinion nut wrench (B), tighten drive pinion lock nut holding drive pinion, while adjusting pinion bearing preload torque using preload gauge (C).

A: Drive pinion socket [SST: KV38109500 ( — )]

B : Pinion nut wrench [SST: KV38109400 ( — )]

C : Preload gauge [SST: ST3127S000 (J-25765-A)]

Pinion bearing preload : Refer to DLN-141, "Preload Torque".

CAUTION: Drive pinion lock nut is tightened with no collapsible spacer. Be careful not to overtighten it. While measuring the preload, tighten it by 5° to 10°.

- Install new side bearing adjusting shims (2 pieces for one side) with

the same thickness or re-install the

old ones to the same mounting position they were in prior to disassembly.

Install differential assembly to

gear carrier. Refer to DLN-125, "Disassembly and Assembly".

CAUTION: Apply differential gear oil to the side bearings.

- Check and adjust tooth contact, drive gear to drive pinion backlash. Refer to DLN-130, "Adjustment".

- Remove differential assembly.

- Remove drive pinion assembly from gear carrier

- Remove drive pinion nut and press drive pinion assembly out of gear carrier.

- Remove pinion front bearing inner race.

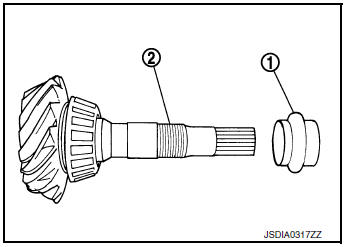

- Assemble collapsible spacer 1 to drive pinion 2.

CAUTION:

- Be careful of the mounting direction of collapsible spacer.

- Never reuse collapsible spacer.

- Assemble drive pinion into gear carrier.

CAUTION: Apply gear oil to pinion rear bearing.

- Assemble pinion front bearing inner race to drive pinion assembly.

CAUTION:

- Never reuse pinion front bearing inner race.

- Apply gear oil to pinion front bearing.

- Using the drifts (A and C) and press stand (B), press pinion front bearing inner race to drive pinion as far as drive pinion lock nut can be tightened.

A : Drift [SST: KV40100610 (J-26089)]

B : Press stand [SST: ST38220000 ( — )]

C : Drift [SST: ST23860000 ( — )]

- Apply anti-corrosion oil to the thread and seat of drive pinion

lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION: Never reuse drive pinion lock nut.

- Fit the drive pinion socket (A) onto the drive pinion. While holding drive pinion, tighten drive pinion lock nut within the limits of specified torque so as to keep the pinion bearing preload within a standard values, using the pinion nut wrench (B) and the preload gauge (C).

A : Drive pinion socket [SST: KV38109500 ( — )]

B : Pinion nut wrench [SST: KV38109400 ( — )]

C : Preload gauge [SST: ST3127S000 (J-25765-A)]

Drive pinion lock nut

tightening torque

: Refer to DLN-135, "Exploded

View".

Pinion bearing preload : Refer to DLN-141, "Preload

Torque".

CAUTION:

- Adjust the lower limit of the drive pinion lock nut tightening torque first.

- If the preload torque exceeds the specified value, replace collapsible spacer and tighten it again to adjust. Never loose n drive pinion lock nut to adjust the preload torque.

- After adjustment, rotate drive pinion back and forth 2 to 3 times to check for unusual noise, rotation malfunction, and other malfunctions.

- Install differential assembly. Refer to DLN-125, "Disassembly and Assembly".

CAUTION: Never install rear cover at this timing.

- Check and adjust drive gear runout, tooth contact, and drive gear to drive pinion backlash. Refer to DLN- 130, "Adjustment".

- Remove dummy cover set [SST: KV381086S1 ( — )], then install rear cover, and side oil seal. Refer to DLN-125, "Disassembly and Assembly".

- Check total preload torque. Refer to DLN-130, "Adjustment".

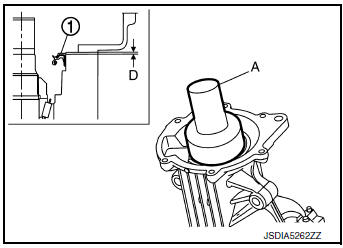

- Using the drift (A) [SST: ST35271000 (J-26091)], install drive pinion oil seal 1 within the dimension (D) shown as follows.

D : 0.8 – 1.2 mm (0.031 – 0.047 in)

CAUTION:

- Never reuse oil seal.

- When installing, never incline oil seal.

- Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

- Install electric controlled coupling assembly. Refer to DLN-121, "Disassembly and Assembly".

Inspection

INSPECTION AFTER DISASSEMBLY

Drive Gear and Drive Pinion

- Clean up the disassembled parts.

- If the gear teeth never mesh or line-up correctly, determine the cause and adjust or replace as necessary.

- If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new drive gear and drive pinion as a set.

Bearing

- Clean up the disassembled parts.

- If any chipped (by friction), pitted, worn, rusted or scratched marks, or unusual noise from the bearing is observed, replace as a bearing assembly (as a new set).

Oil Seal

- Whenever disassembled, replace.

- If wear, deterioration of adherence (sealing force lips), or damage is detected on the lips, replace them.

Unit removal and installation

Unit removal and installation

REAR FINAL DRIVE ASSEMBLY

Exploded View

Final drive mounting bracket

Mounting stopper

Rear final drive assembly

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Rem ...

Service data and specifications (SDS)

Service data and specifications (SDS)

General Specifications

Preload Torque

Drive Gear Runout

Backlash

Differential Side Gear Clearance

...

Other materials:

Component parts

CVT CONTROL SYSTEM

CVT CONTROL SYSTEM : Component Parts Location

Engine room, LH

Transaxle assembly

No.

Component

Function

1

Combination meter

Mainly transmits the following signal to TCM via CAN communication.

Overdrive control switch signal

...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

...

P0460 fuel level sensor

DTC Description

DTC DETECTION LOGIC

When the vehicle is parked, naturally the fuel level in the fuel tank is

stable. It means that output signal of the

fuel level sensor does not change. If ECM senses sloshing signal from the

sensor, fuel level sensor malfunction

is detected.

DTC No. ...