Nissan Rogue Service Manual: Removal and installation

DRIVE PINION OIL SEAL

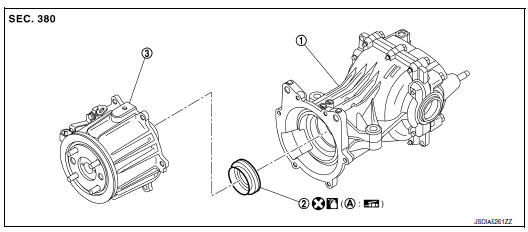

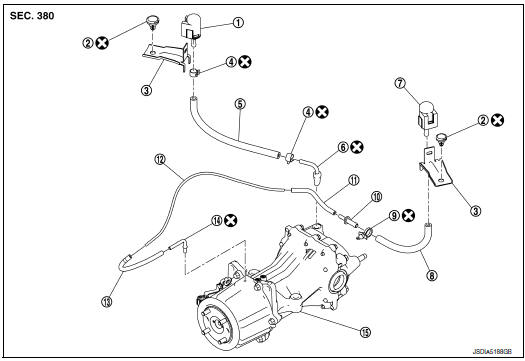

Exploded View

- Rear final drive assembly

- Drive pinion oil seal

- Electric controlled coupling assembly

- Oil seal lip

Always replace after every

disassembly.

Always replace after every

disassembly.

: Apply gear oil.

: Apply gear oil.

: Apply multi-purpose grease.

: Apply multi-purpose grease.

Removal and Installation

REMOVAL

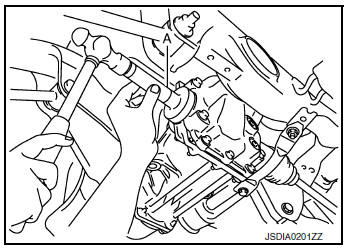

- Remove electric controlled coupling. Refer to DLN-114, "Removal and Installation".

- Using a suitable tool remove drive pinion oil seal.

CAUTION: Do not damage rear final drive assembly.

INSTALLATION

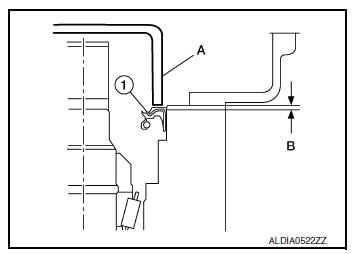

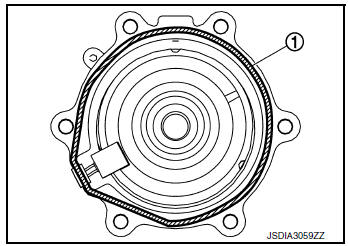

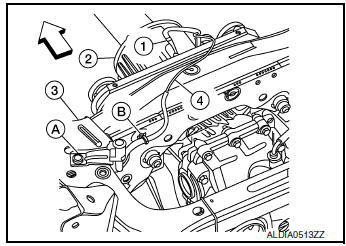

- Install drive pinon oil seal (1) using Tool (A).

Oil seal installation

length (B)

: 0.8 - 1.2 mm (0.031 - 0.047 in)

Tool number : KV38100200 (J-26233)

: ST27861000 ( — )

CAUTION:

- Do not reuse oil seal.

- When installing, do not incline oil seal.

- Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

- Install rear propeller shaft. Refer to DLN-99, "Exploded View".

- When oil leaks while removing, check oil level after the installation. Refer to DLN-111, "Inspection".

SIDE OIL SEAL

Exploded View

- Rear final drive assembly

- Side oil seal

- Oil seal lip

: Always replace after every

disassembly.

: Always replace after every

disassembly.

: Apply gear oil.

: Apply gear oil.

: Apply multi-purpose grease.

: Apply multi-purpose grease.

Removal and Installation

REMOVAL

- Remove rear drive shaft (LH/RH) with power tool. Refer to RAX-19, "Exploded View".

- Remove side oil seal (LH/RH), using a suitable tool.

CAUTION: Do not damage gear carrier and rear cover.

INSTALLATION

- Install side oil seals until it becomes flush with the carrier end, using Tool (A).

Tool number : KV38100200 (J-26233)

CAUTION:

- Do not reuse oil seals.

- When installing, do not incline oil seals.

- Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

- Install rear drive shafts. Refer to RAX-19, "Exploded View".

- When oil leaks while removing, check oil level after the

installation.

Refer to DLN-111, "Inspection".

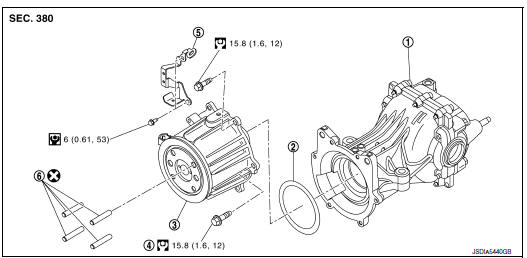

ELECTRIC CONTROLLED COUPLING

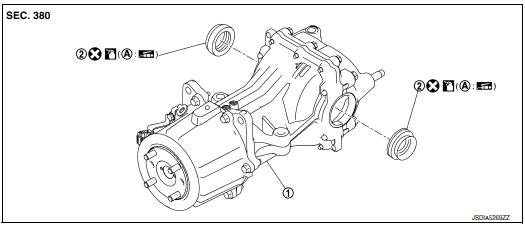

Exploded View

- Rear final drive assembly

- Wave spring

- Electric controlled coupling assembly

- Reamer bolt

- Connector bracket Stud bolt

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

: Always replace after every

disassembly.

Removal and Installation

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Remove rear propeller shaft from the torsional damper, and support the end of the propeller shaft. Refer to DLN-99, "Exploded View".

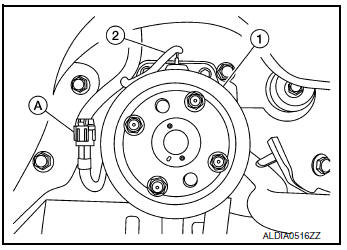

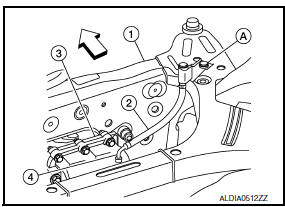

- Remove electric controlled coupling breather hose (2) from electric controlled coupling (1).

- Disconnect the electric controlled coupling harness connector (A).

- Remove harness connector bracket.

- Remove bolts from electric controlled coupling.

- Remove the electric controlled coupling.

CAUTION: Be careful that the wave washer does not fall out or get damaged when removing the electric controlled coupling.

- Remove wave washer (1).

(2) : Rear final drive assembly

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse hose clamp and breather connector.

- Make sure there are no pinched or restricted areas on the breather hose caused by bending or winding when installing it.

- Install the hose clamp at the final drive side, with the tab facing to the vehicle front.

- Install the hose clamp at the suspension member side, with the tab facing downward.

- Use Genuine Silicone RTV or an equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

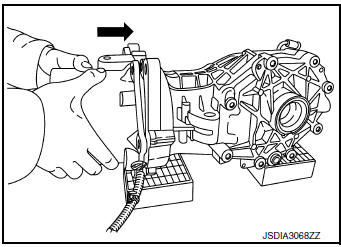

- Remove the old sealant from mating surfaces using a suitable tool before installing.

- Apply liquid gasket (1) to mating surface of coupling cover.

Use Genuine Silicone RTV or equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

CAUTION:

- The width of sealant bend is approximately 3 mm (0.012 in).

- Installation should be done within 5 minutes after applying liquid gasket.

- Do not fill the engine within engine oil for at least 30 minutes after the components are installed to allow the sealant to cure.

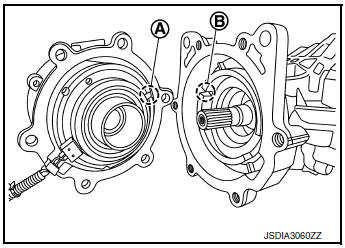

- Install electric controlled coupling to spline of drive pinion inside final drive assembly.

CAUTION:

- Align the pin (A) on electric controlled coupling with the groove (B) of final drive assembly.

- Be careful not to damage center oil seal.

- Press the electric controlled coupling pin to check that it is

positioned

in the groove of the final drive assembly as shown.

NOTE: If the pin is properly positioned in the groove, then the electric controlled coupling can be pressed into position by the same amount of flection of the wave washer.

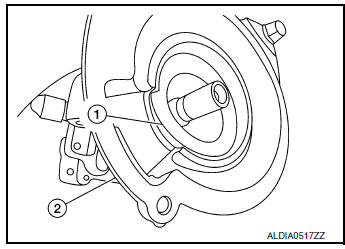

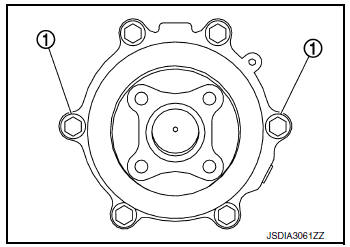

- Temporarily tighten reamer bolts (1) to the positions shown.

CAUTION:

- • Do not use tools. Always tighten by hand.

- • If reamer bolts cannot be tightened all the way by hand, the electric controlled coupling pin may not be positioned in the groove of the final drive assembly. In this case, remove electric controlled coupling and reinstall it.

- When oil leaks while removing, check oil level after the installation. Refer to DLN-111, "Inspection".

AIR BREATHER

Exploded View

- Breather connector (resin)

- Trim clip

- Bracket

- Hose clamp

- Air breather hose

- Breather connector (metal)

- Breather connector (resin)

- Air breather hose

- Clip

- Hose connector

- Air breather hose*

- Air breather tube*

- Air breather hose*

- Breather connector (metal)

- Rear final drive assembly

: Always replace after every

disassembly.

: Always replace after every

disassembly.

*: These parts are adhered to each other. Therefore they are assembled parts.

Removal and Installation

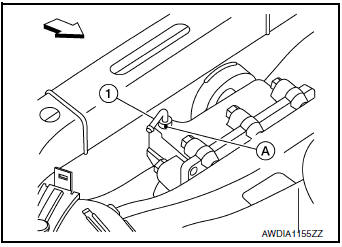

- REMOVAL Remove clip (A) from rear suspension member (1).

(3) : Rear final drive assembly

: Front

: Front

- Remove air breather hose (2) and breather tube (4) together.

- Loosen hose clamp and remove breather tube from air breather hose.

- Remove clips (A) from rear suspension member (3).

(2) : Rear final drive assembly

: Front

: Front

INSTALLATION

Installation is in the reverse order of removal.

- For non-reusable parts, refer to DLN-117, "Exploded View".

- Set breather connector (1) to rear final drive with the paint mark (A) facing front as shown.

: Front

: Front

- When installing air breather hose, make sure there are no pinched or restricted areas on air breather hose caused by bending or winding.

Periodic maintenance

Periodic maintenance

REAR DIFFERENTIAL GEAR OIL

Inspection

OIL LEAKS

Make sure that oil is not leaking from final drive assembly or around it.

OIL LEVEL

Remove filler plug (1) and check oil level from filler ...

Unit removal and installation

Unit removal and installation

REAR FINAL DRIVE ASSEMBLY

Exploded View

Final drive mounting bracket

Mounting stopper

Rear final drive assembly

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Rem ...

Other materials:

C1113, C1145, C1146 yaw rate/side/decel G sensor

DTC

Display Item

Malfunction detected condition

Possible causes

C1113

G SENSOR

When a malfunction is detected in longitudinal G sensor

signal.

Harness or connector

Yaw rate/side/decel G sensor

• ABS actuator and electric unit

(control ...

P0117, P0118 ECT sensor

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0117

ECT SEN/CIRC

(Engine coolant temperature sensor 1 circuit

low)

An excessively low voltage from the engine coolant temperature

sensor i ...

NISSAN Intelligent Key® Operation

NISSAN Intelligent Key® Operation

You can lock or unlock the doors without taking

the Intelligent Key out of your pocket or bag.

When you carry the Intelligent Key with you, you

can lock or unlock all doors by pushing the door

handle request switch within the range of operation.

Loc ...